Method for manufacturing color double-face symmetrical pattern jacquard

A technology for a jacquard fabric and a production method, which is applied in the directions of textiles and papermaking, textiles, pattern design devices, etc., can solve the problems of poor pattern symmetry, thick thickness and difficulty in mass production of color double-sided symmetrical pattern jacquard fabrics. , to achieve the effect of ensuring firmness, enhancing three-dimensional sense, and not easy to reveal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

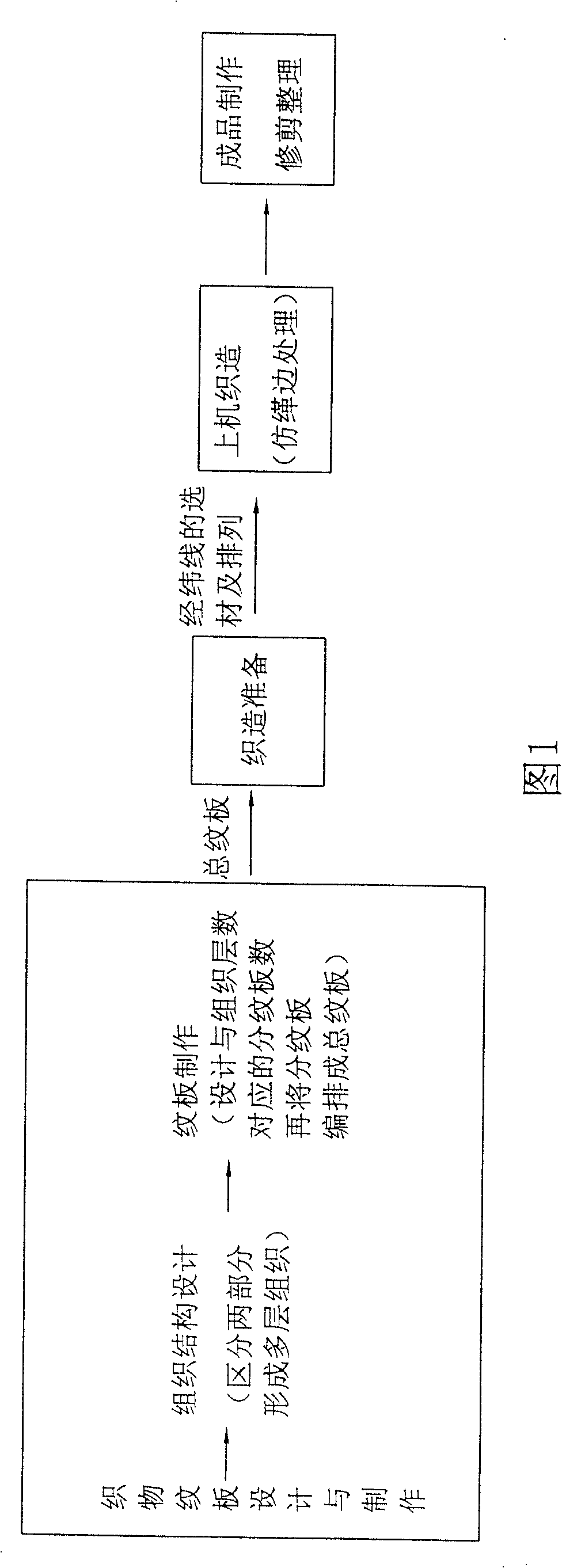

[0027] Embodiment 1: as shown in Figure 1, a kind of preparation method of weavable color double-sided symmetrical pattern jacquard fabric, its steps are: (one) fabric pattern design and manufacture; (two) weaving preparation; (three) on the machine Weaving; (4) finished product production, which is characterized in that the steps of fabric pattern design and production are:

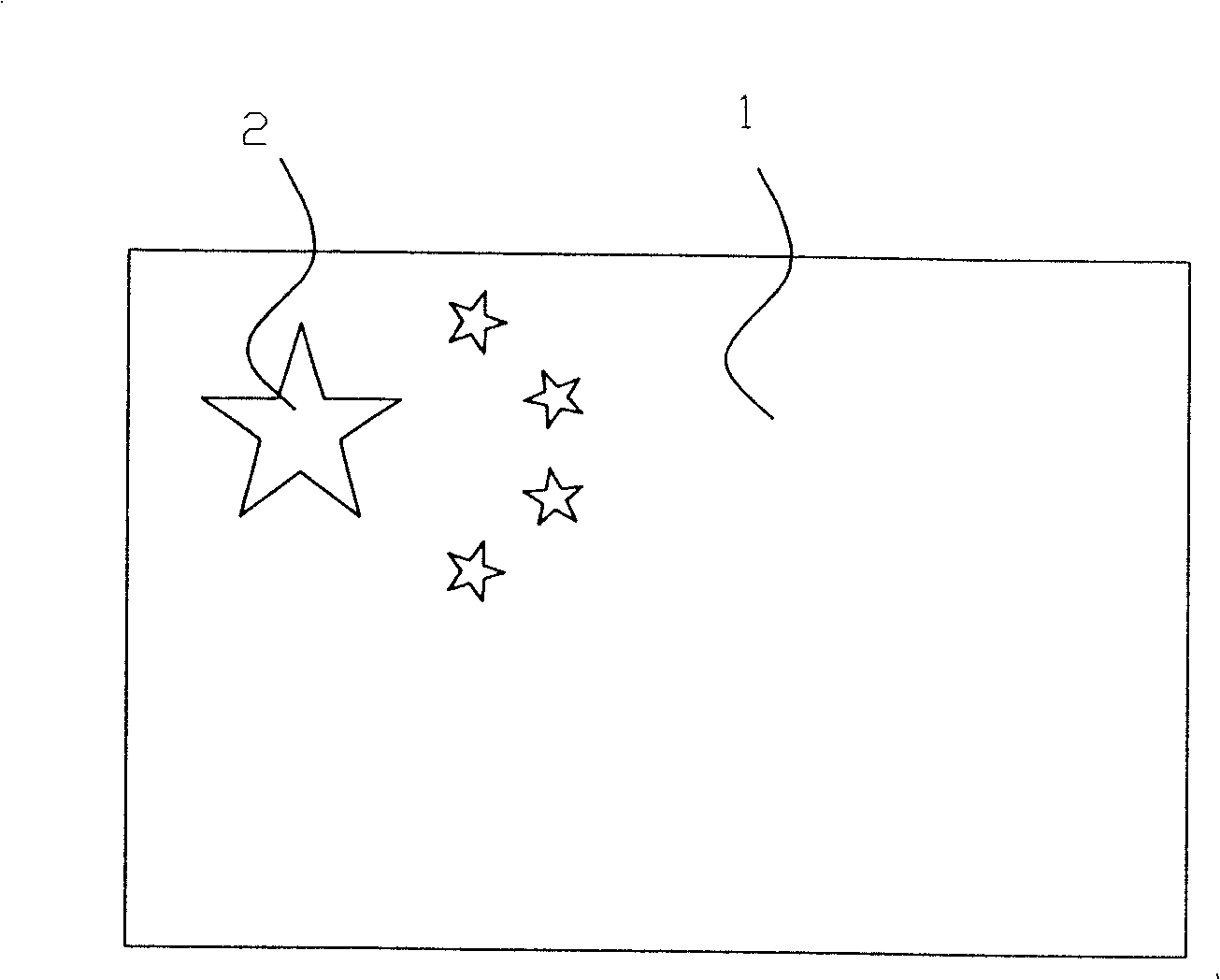

[0028] (1) Read the target image of the jacquard fabric to be made into the computer. The target image is an image that needs to be displayed symmetrically on both sides, similar to the image of a landscape painting or a national flag. For example, put a picture of a five-star red flag into a scanner connected to a computer. read into the computer;

[0029] (2) preview and adjust the read-in image, and set parameters according to the design and production needs, adjust the warp (longitudinal) pixel number of the image file to be the same as the warp number of the pre-woven fabric, and adjust the weft (ho...

Embodiment 2

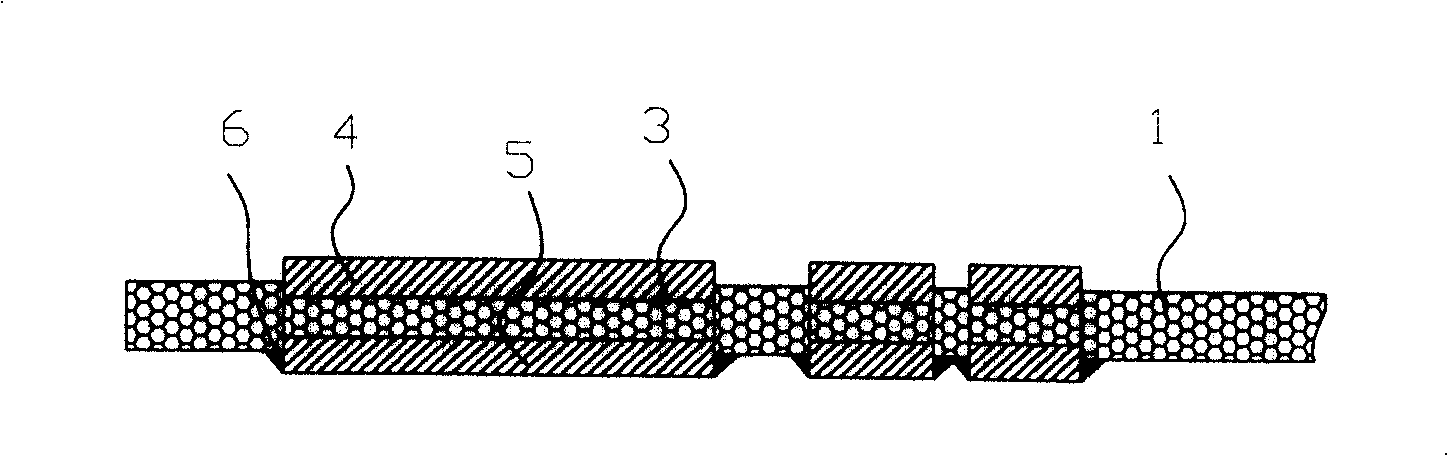

[0043] Embodiment 2: the weaving preparation includes selecting a silk thread with dyeing performance as the warp and weft of the middle support layer tissue of the basic part 1 and pattern part 2, and selecting another silk thread with dyeing performance as the pattern part 2 The warp and weft threads of the front surface layer 4 and the front surface layer 5 organization. All the other are with embodiment 1. Utilizing the dyeing and color-absorbing properties of different silk threads, the woven product can be dyed in one bath to display a colorful five-star red flag composed of red and yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com