Clamping device

A technology of clamping mechanism and connecting piece, applied in the direction of clamping, metal processing mechanical parts, support, etc., can solve problems such as poor positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

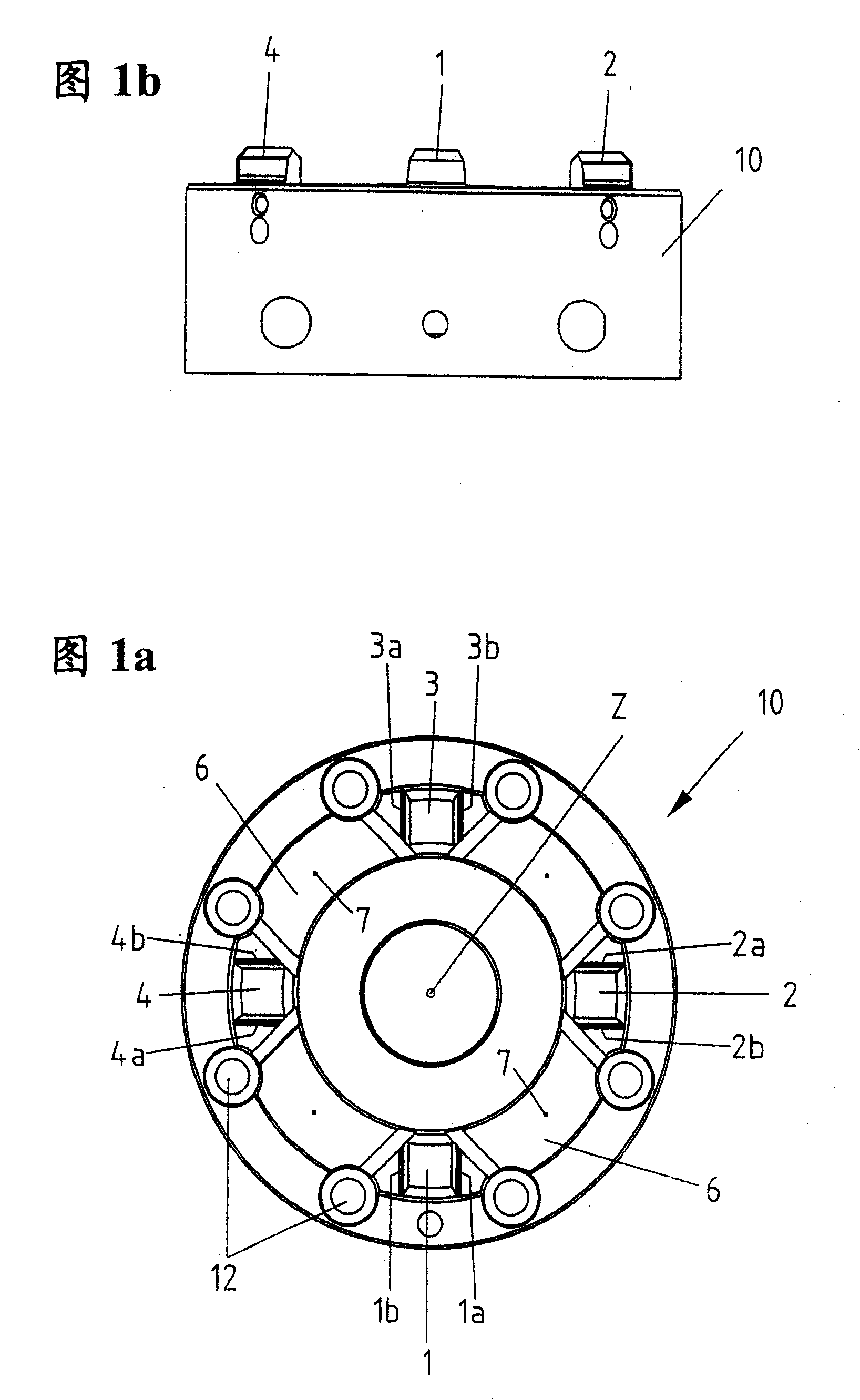

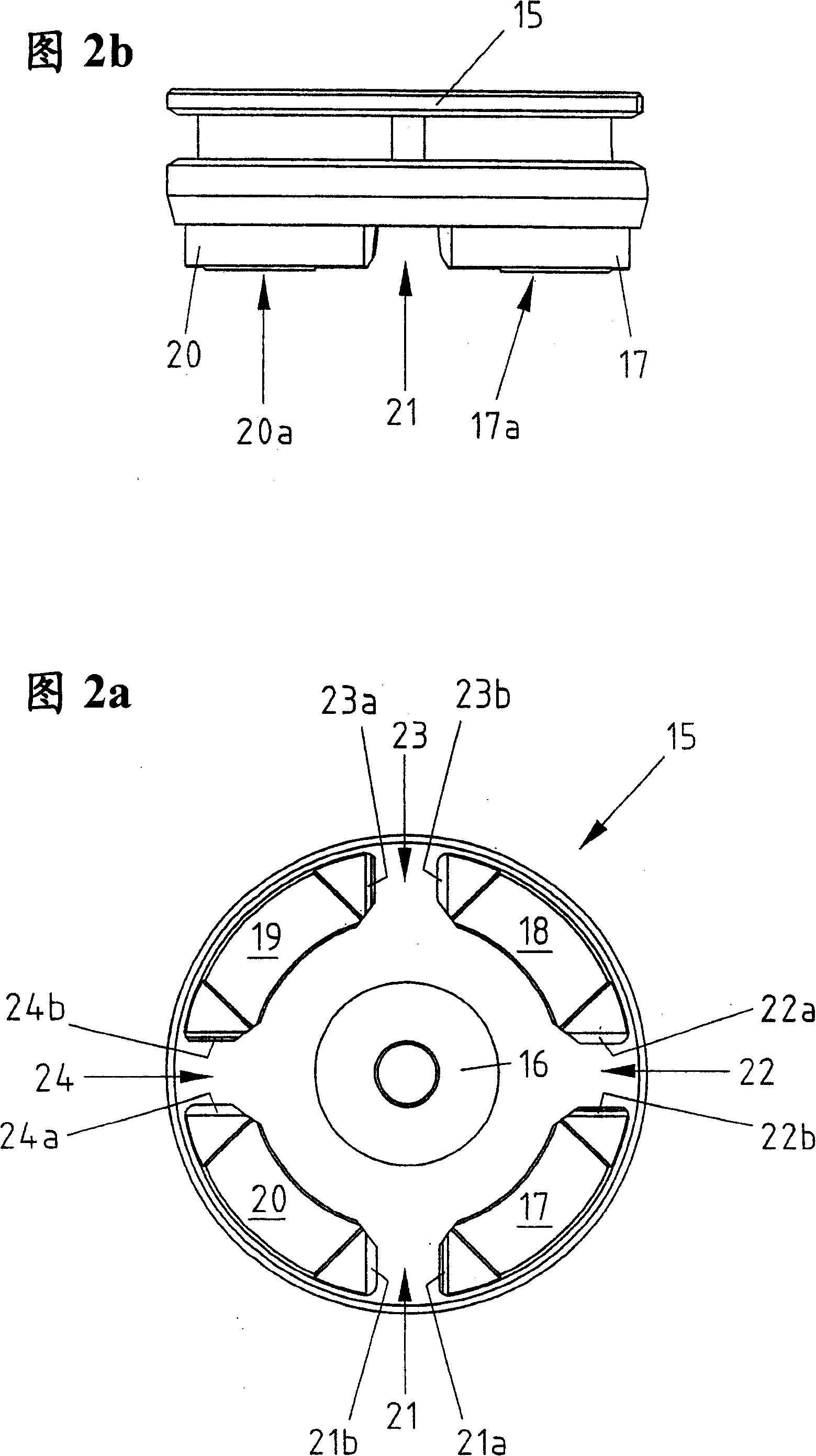

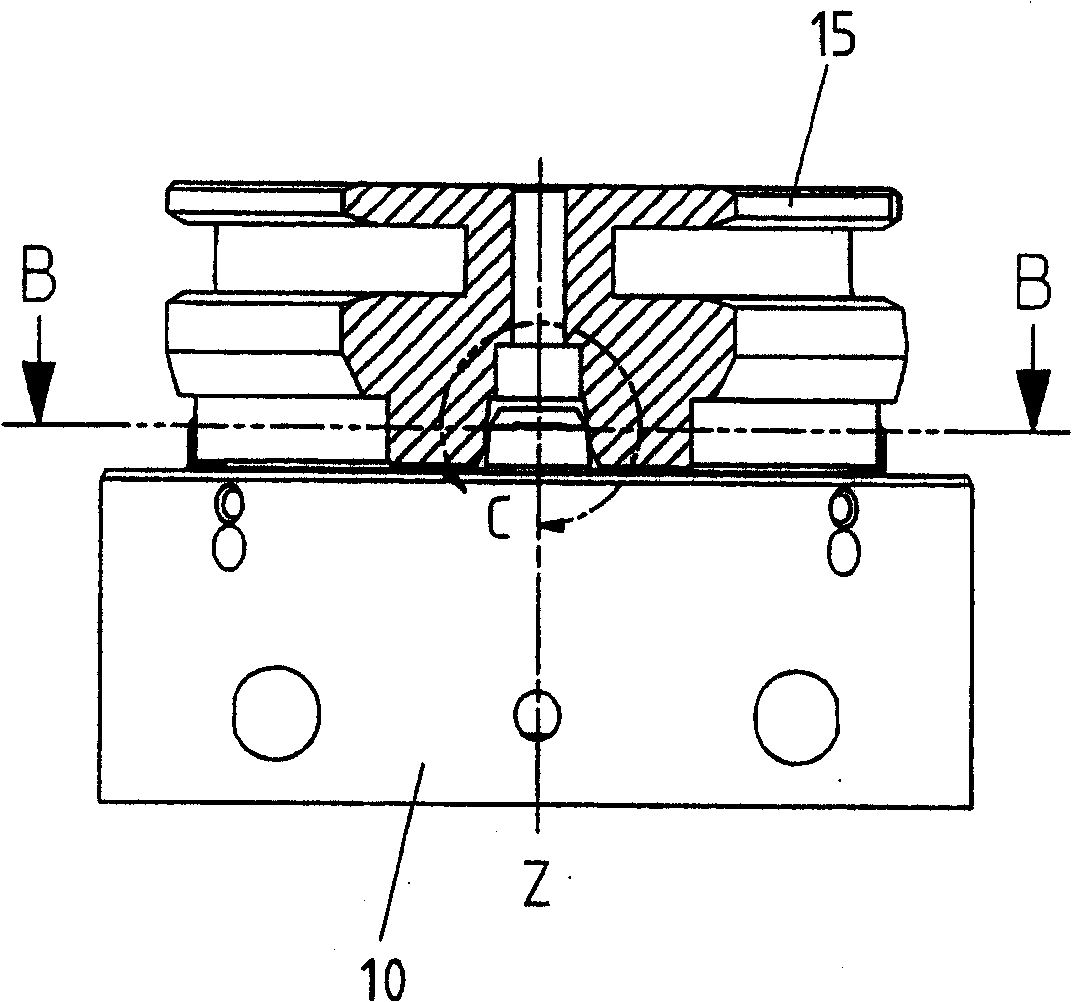

[0022] Figure 1a shows a top view of a first substantially cylindrical connecting element 10. Figure 1 b shows a side view of the first substantially cylindrical connecting element 10 . Typically, this first attachment 10 is connected to the machine tool and serves as a clamping member for a second attachment 15 as shown in Figures 2a and 2b, which can receive a workpiece, tool or similar.

[0023] On the top of the first connecting piece 10, four center pins 1, 2, 3, 4 protrude. These center pins are offset from each other by 90° with respect to the center line Z. Each central pin 1, 2, 3, 4 comprises two tapered sides 1a, 1b, 2a, 2b, 3a, 3b, 4a, 4b.

[0024] Between the two central pins 1, 2; 2, 3; 3, 4; 4, 1 there is an intermediate surface 6 which serves as a reference in the Z direction. In the middle of the surface 6, an outlet 7 is provided to allow the air to escape. For fixing, the first connecting piece 10 is provided with a plurality of fixing holes 12 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com