Process of nickel oxide optical film dispersed nanometer silver grains

A technology of nano-silver particles and optical thin films, applied in optics, optical components, instruments, etc., to achieve the effects of excellent nonlinear optical properties, low price, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

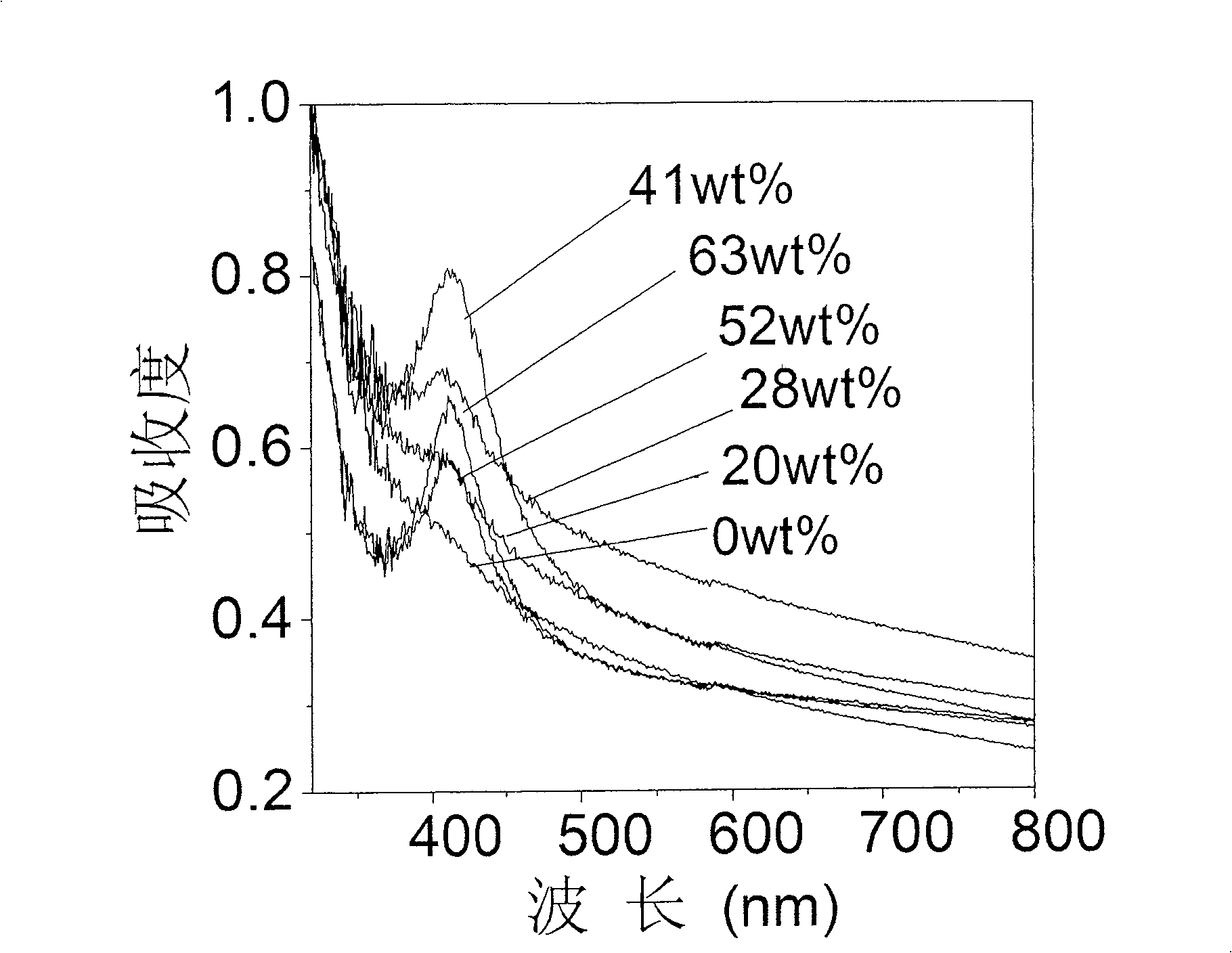

Image

Examples

Embodiment 1

[0015] Dissolve 0.5935g nickel nitrate in 10ml CH 3 OCH 2 CH 2 OH solvent, stirring for 1 hour to dissolve, adding 0.0024g AgNO 3 , stirred again for 05 hours to prepare the Ag / NiO precursor solution; before the glue was thrown, the substrate was immersed in acetone for ultrasonic vibration cleaning for 15 minutes, then the solution was dripped onto the substrate, and the solution was first run at 200rpm for 5 seconds, and then Run at 1000rpm for 10 seconds. Every time the glue is uniformed, the film is thermally decomposed at 100°C for 50 seconds. After the glue is glued once, the sample is placed in a rapid heat treatment furnace for annealing treatment for 10 minutes. The annealing temperature is 600°C, and the Ag content is 1wt% Ag. / NiO composite film.

Embodiment 2

[0017] Dissolve 0.8902g of nickel nitrate in 10ml of CH 3 OCH 2 CH 2 OH solvent, stir for 3 hours to dissolve, add 00392g AgNO 3 , and stirred again for 1 hour to prepare the Ag / NiO precursor solution; before the glue was thrown, the substrate was immersed in acetone for ultrasonic vibration cleaning for 15 minutes, and then the solution was dripped onto the substrate, first at 400rpm for 6 seconds, then at 1500rpm Run for 12 seconds. Every time the glue is glued, the film is thermally decomposed at 200°C for 100 seconds. After the glue is glued once, the sample is placed in a rapid heat treatment furnace for annealing treatment for 20 minutes. The annealing temperature is 500°C, and the Ag content is 10wt% Ag. / NiO composite film.

Embodiment 3

[0019] Dissolve 1.1869g of nickel nitrate in 10ml of CH 3 OCH 2 CH 2 OH solvent, stirring for 5 hours to dissolve, adding 01567g AgNO 3 , and stirred again for 15 hours to obtain the Ag / NiO precursor solution; before the glue was thrown, the substrate was immersed in acetone for ultrasonic vibration cleaning for 15 minutes, and then the solution was dripped onto the substrate, firstly at 500rpm for 9 seconds, then at 2600rpm Run for 30 seconds. Every time the glue is uniformed, the film is thermally decomposed at 300°C for 150 seconds. After the glue is glued once, the sample is placed in a rapid heat treatment furnace for annealing treatment for 30 minutes. The annealing temperature is 900°C, and the Ag content is 25wt% Ag. / NiO composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com