Rear wheel suspension for automobile

A suspension device, rear wheel technology, applied in the direction of suspension, wheel, elastic suspension, etc., can solve the problems of increased load noise, inability to ensure the practicability of the car, etc., to eliminate unnatural movements and achieve excellent handling stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

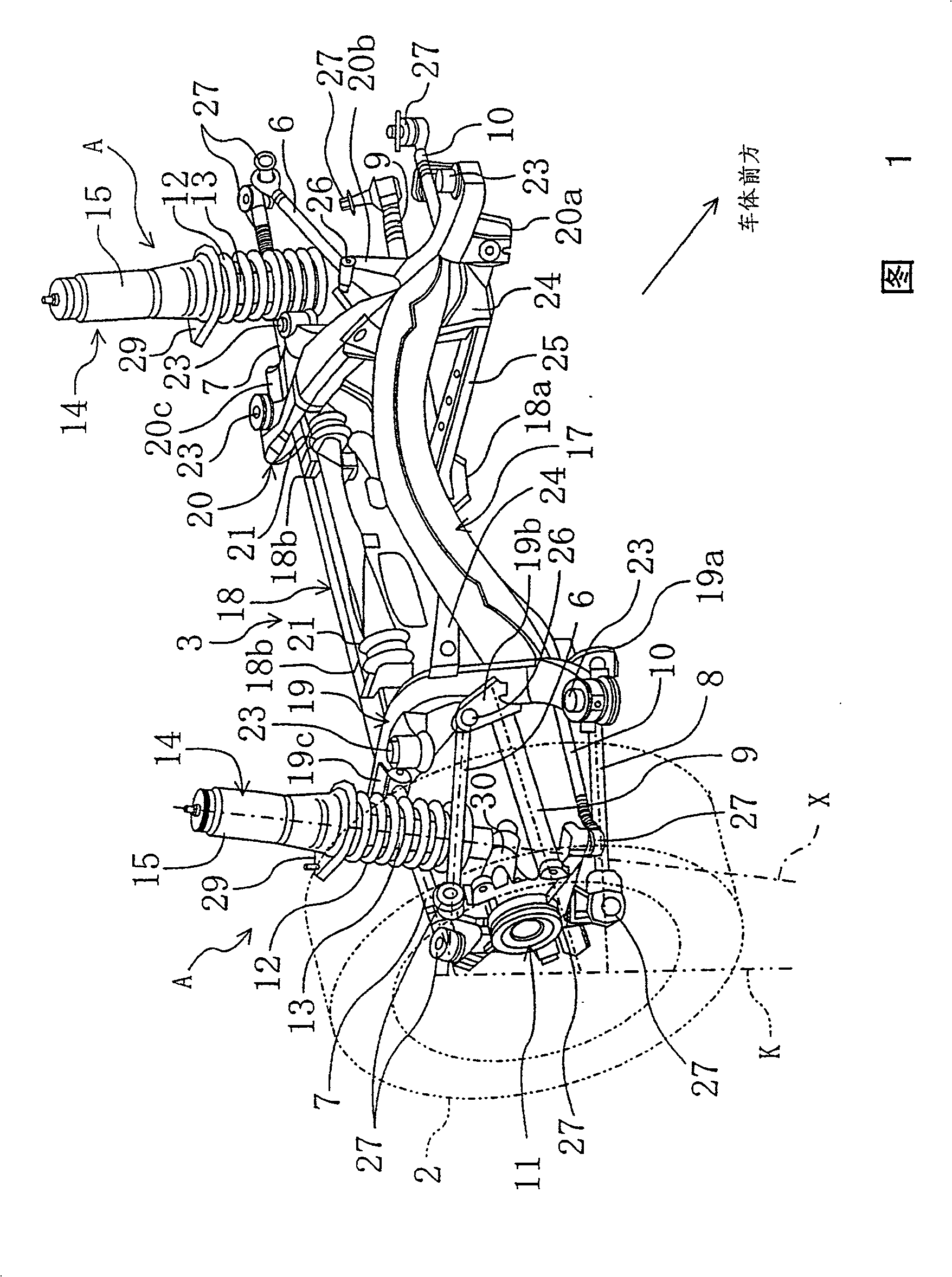

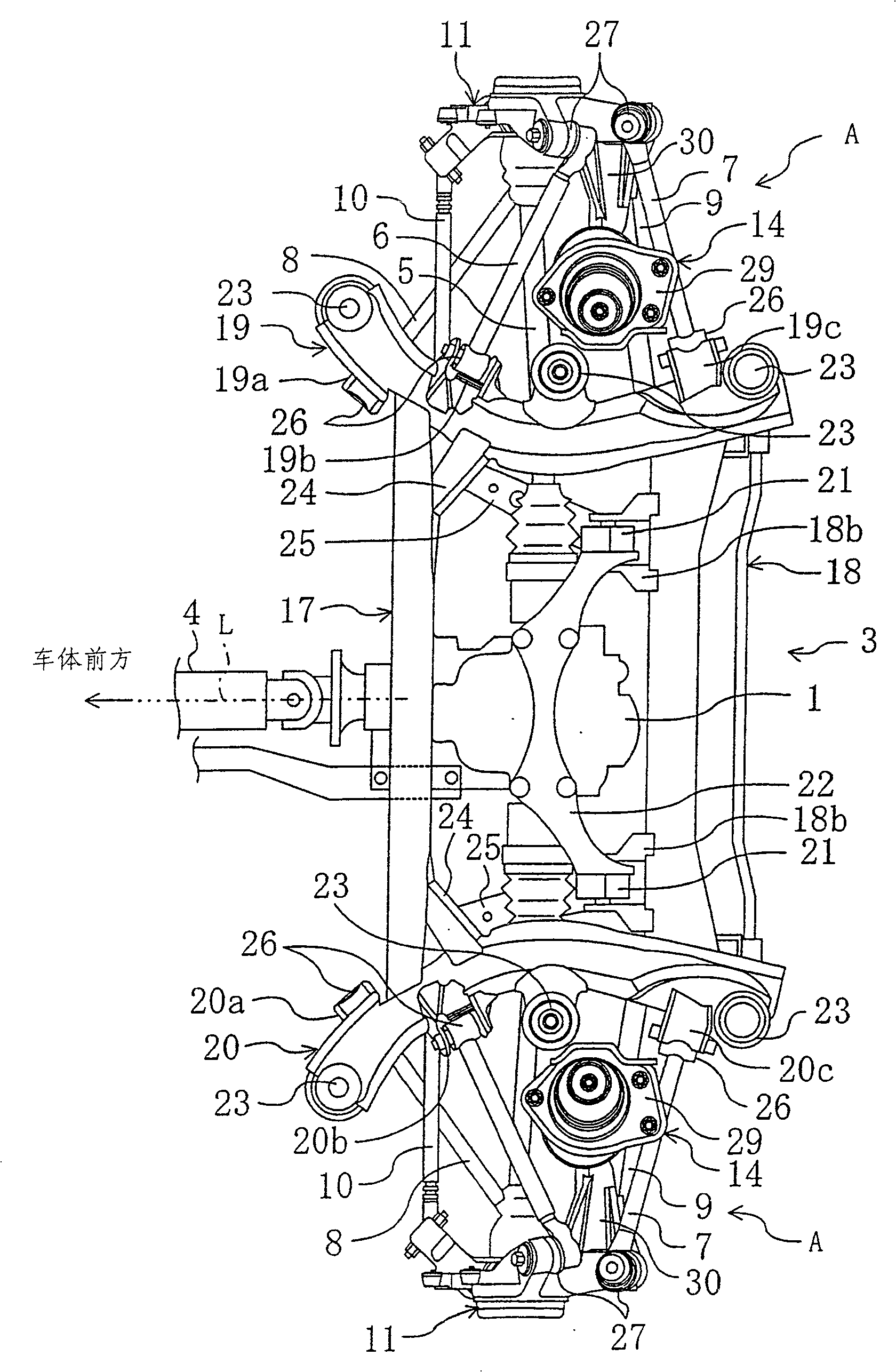

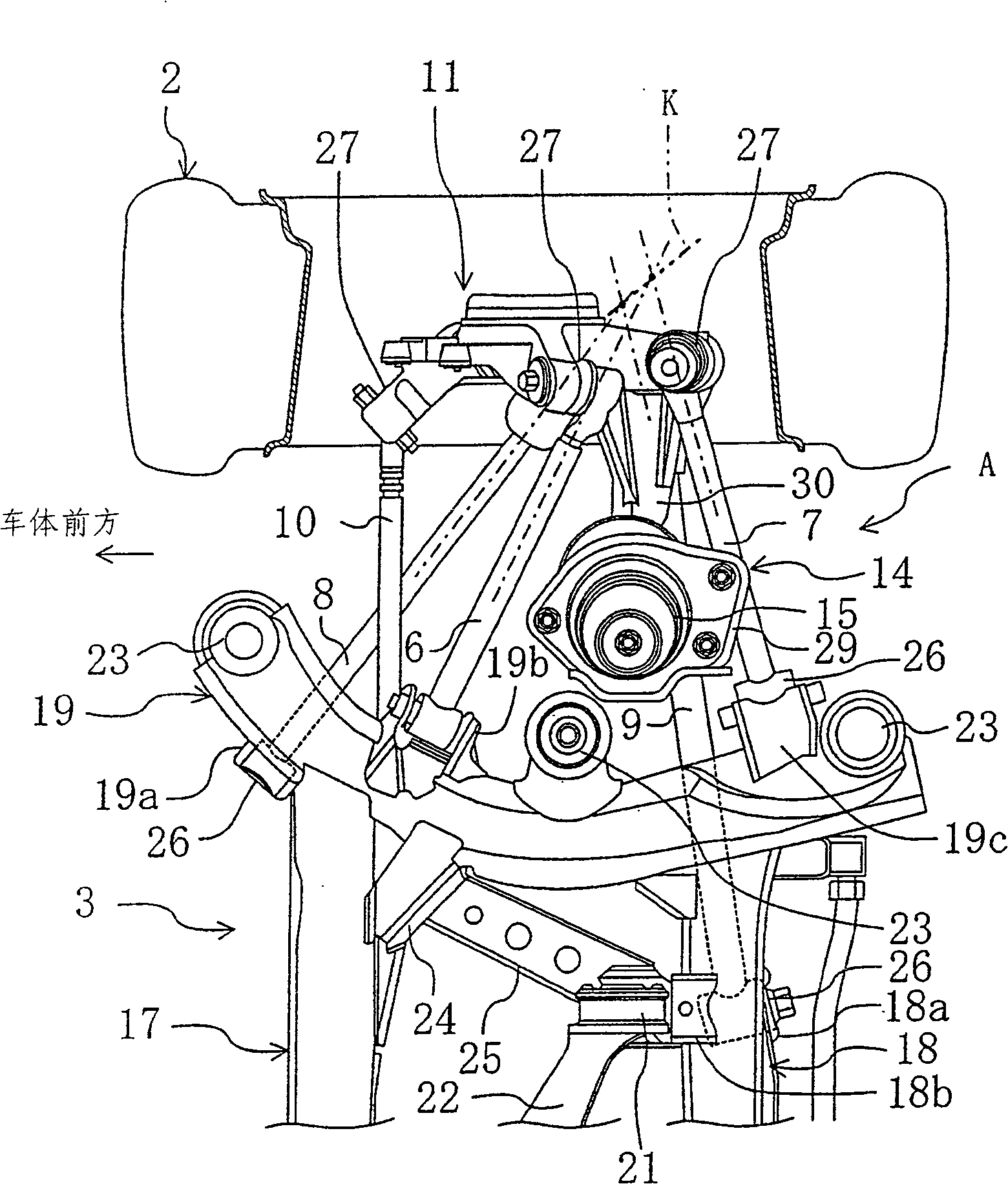

Image

Examples

Embodiment -

[0134] The structure of the present invention is not limited to the above-described embodiments, and various other structures may be included. That is, in the above-mentioned embodiment, the left and right rear suspensions A, A are attached to the vehicle body through the subframe 3, but the present invention is not limited thereto, and the rear suspensions A, A may be directly attached to the vehicle body.

[0135] In addition, in the rear suspension A of the above-mentioned embodiment, rubber bushings 26 are arranged at the connecting parts of the five links 6 to 10 on the vehicle body side, and the end parts on the wheel side are mounted by ball joints 27. On the wheel stay 11, but not limited thereto, rubber bushes may be provided on both ends of any one link. Also, the elastic bush is not limited to the rubber bush 26, and may be a resin product having desired elasticity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com