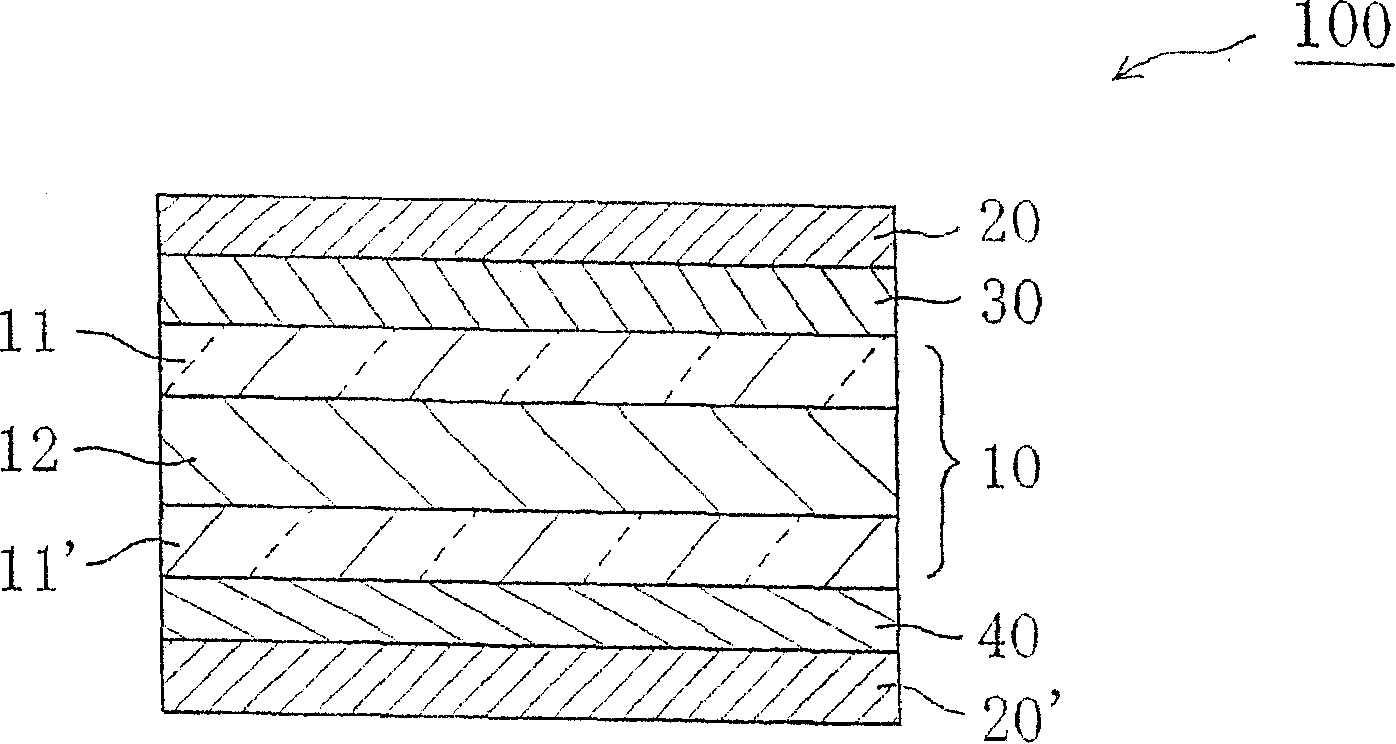

Lc panel and LCD device

A liquid crystal panel, liquid crystal cell technology, applied in nonlinear optics, instruments, optics, etc., to achieve the effects of good display performance, increased contrast, and small photoelastic coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0222] Using phosgene as the carbonate precursor, while (A) 2,2-bis-(4-hydroxyphenyl)propane and (B) 1,1-bis(4-hydroxypropyl)-3,3,5- Trimethylcyclohexane is used as an aromatic dihydric phenol component to obtain a weight-average molecular weight (Mw) of 60,000 and a polycarbonate resin (number The average molecular weight (Mn) was 33,000, Mw / Mn was 1.78, and the weight ratio (A):(B) was 4:6). 70 parts by weight of polycarbonate-based resin and 30 parts by weight of styrene-based resin (HIMER SB75, Sanyo Chemical Industries, Inc. , Ltd. (manufactured by Sanyo Chemical Industry Co., Ltd.)) was added to 300 parts by weight of dichloromethane. The whole was mixed with stirring at room temperature for 4 hours, thereby preparing a clear solution. The solution was cast on a glass plate and allowed to stand at room temperature for 15 minutes. Next, the solution was peeled off from the glass plate and dried in an oven at 80°C for 10 minutes and then at 120°C for 20 minutes to obtai...

preparation Embodiment 2

[0232] A retardation film B was prepared in the same manner as in Preparation Example 1, except that the stretch ratio was changed from 1.27 times to 1.30 times. Table 2 shows the stretching conditions and properties of the retardation film B obtained.

preparation Embodiment 3

[0234] A retardation film C was prepared in the same manner as in Preparation Example 1, except that the stretching temperature was changed from 147°C to 146°C and the stretching ratio was changed from 1.27 times to 1.25 times. Table 2 shows the stretching conditions and properties of the retardation film C obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| photoelasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com