Viscose filament with abnormal section, preparation method thereof and spinneret assembly

A technology of viscose filaments and special-shaped cross-sections, which is applied in filament/thread forming, wet spinning, textiles and papermaking, etc. It can solve the problem of fewer varieties and achieve large air volume, soft luster, and good two-way adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Equipment: Alkali cellulose manufacturing: dipping, pressing and powdering combined machine;

[0032] Viscose manufacturing: yellowing kneading and dissolving machine, post-dissolving machine, plate and frame filter press, defoaming barrel;

[0033] Spinning: semi-continuous centrifugal spinning machine;

[0034] Post-processing: washing machine, dehydrator, dryer, winding machine;

[0035] Process conditions:

[0036] Spinning glue conditions: α-cell: 8.25%, NaOH: 5.8%, S: 2.25%, viscosity: 30-40S (20°C, falling ball), maturity: 8.4ml (10% NH 4 CL); coagulation bath condition: H 2 SO 4 : 132g / l, Na 2 SO 4 : 265g / l, ZnSO 4 : 10g / l, Tep: 51℃;

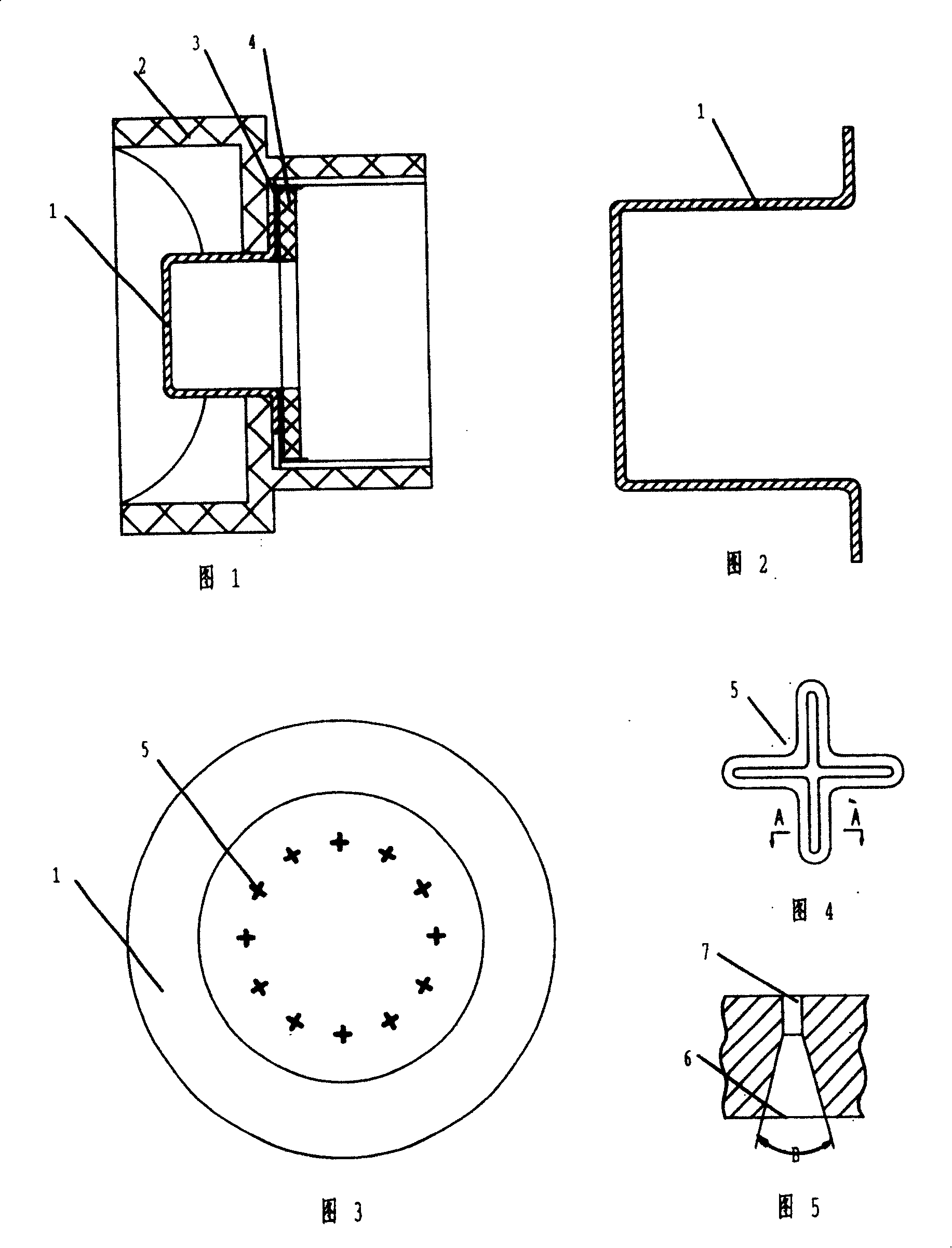

[0037] Spinning conditions: spinneret specifications: cross-hole shape, the width and length of each leaf size is 1:3.5, spinning speed: 83.7m / min; spinneret draw: 82.9%, draft: 25%, tight draft: 2.67%;

[0038] Silk cake washing conditions:

[0039] Desulfurization: concentration NaOH 5.6g / l, temperature: 65°C, time: 1...

Embodiment 2

[0043] Equipment: Alkali cellulose manufacturing: classical impregnation press, coarse and fine grinder;

[0044] Viscose manufacturing: yellowing kneading and dissolving machine, post-dissolving machine, plate and frame filter press, defoaming barrel;

[0045] Spinning: semi-continuous centrifugal spinning machine;

[0046] Post-processing: washing machine, dehydrator, dryer, winding machine;

[0047] Process conditions:

[0048] Spinning glue conditions: α-cell: 8.3%, NaOH: 5.8%, S: 2.35%, viscosity: 30-40S (20°C, falling ball), maturity: 8.0ml (10% NH 4 CL);

[0049] Coagulation bath condition: H 2 SO 4 : 130g / l, Na 2 SO 4 : 265g / l, ZnSO 4 : 10.5g / l, Tep: 52°C;

[0050] Spinning conditions: Spinneret specifications: cross-hole shape, the width and length of each blade are 1:5;

[0051] Spinning speed: 81.7m / min, spinneret draw: 78.4%, draft: 25%, tight draft: 4.12%;

[0052] Silk cake washing conditions:

[0053] Desulfurization: concentration NaOH 5g / l; tempera...

Embodiment 3

[0057] Equipment: Alkali cellulose manufacturing: classical impregnation press, coarse and fine grinder;

[0058] Viscose manufacturing: yellowing kneading and dissolving machine, post-dissolving machine, plate and frame filter press, defoaming barrel;

[0059] Spinning: semi-continuous centrifugal spinning machine;

[0060] Post-processing: washing machine, dehydrator, dryer, winding machine;

[0061] Process conditions:

[0062] Spinning glue conditions: α-cell: 8.3%, NaOH: 5.8%, S: 2.35%, viscosity: 30-40S (20°C, falling ball), maturity: 9.0ml (10% NH 4 CL);

[0063] Coagulation bath condition: H 2 SO 4 : 138g / l, Na 2 SO 4 : 265g / l, ZnSO 4 : 11g / l, Tep: 54°C;

[0064] Spinning conditions: Spinneret specifications: cross-hole shape, the width and length of each blade are 1:8;

[0065] Spinning speed: 77m / min, spinneret draw: 90%, draft: 20%, tight draft: 4.12%;

[0066] Silk cake washing conditions:

[0067] Desulfurization: concentration NaOH 5.6g / l, temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com