Production technology of amidated pectin

A technology of amidated pectin and high-ester pectin, which is applied in the field of food additives, can solve the problems of not considering the avoidance of β-elimination reaction, not considering the β-elimination reaction, and difficult to guarantee product quality, etc., to break the international monopoly, The effect of reducing the degree of degradation and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The preparation of pectin of the present invention

[0023] The preparation method of amidated pectin of the present invention is as follows

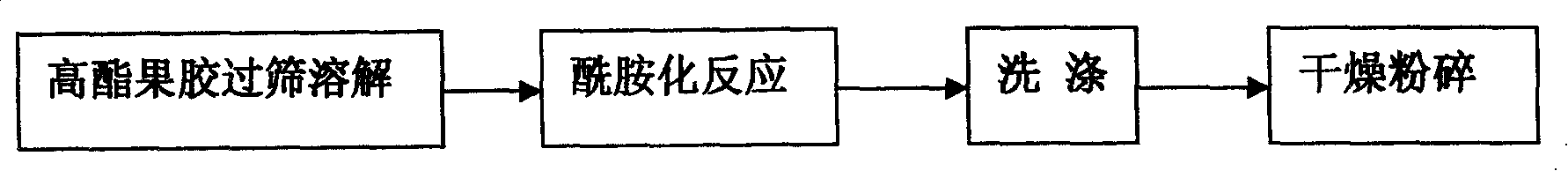

[0024] The first step is to prepare the solution: if figure 2 As shown, first measure the dry high-ester pectin that passed through the 60-mesh sieve, and weigh it according to the ratio of high-ester pectin weight: pure water weight = 6: 100, and use the high-ester pectin that has been weighed first Soak the high-ester pectin in a part of pure water for 10 hours. After the high-ester pectin is fully dissolved, add the remaining pure water into the container soaked in the high-ester pectin to prepare a high-ester pectin solution, and store it at 5°C for later use. Next, the alcoholic ammonia solution was prepared by mixing concentrated ammonia water and 60% isopropanol at a ratio of 1:3 to obtain an alcoholic ammonia solution, and stored it at 5° C. for future use.

[0025] The second step is amidation reaction: t...

Embodiment 2

[0028] The preparation of embodiment 2 pectin

[0029] The preparation method is the same as in Example 1, except that the reaction temperature is 25°C.

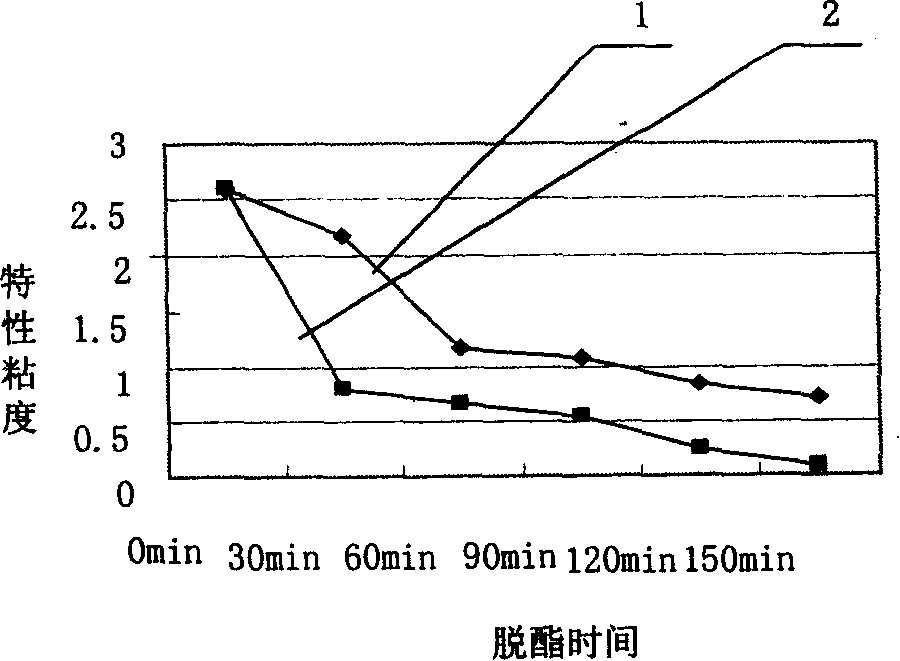

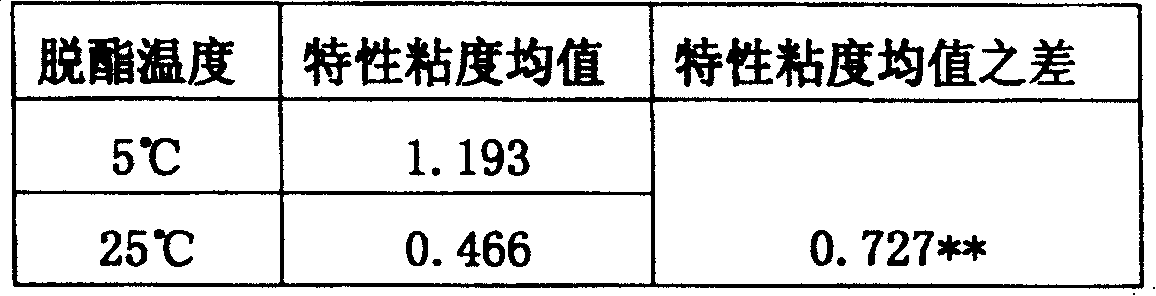

[0030] When the pectin prepared by embodiment 1 and embodiment 2 is deesterified, the intrinsic viscosity curve is shown in figure 1 .

[0031] figure 1 It reflects the change trend of intrinsic viscosity of pectin in the process of amidation deesterification, by figure 1 It can be seen that the intrinsic viscosity of pectin decreases with the progress of deesterification. The intrinsic viscosity of pectin decreases greatly in the first 60 minutes of deesterification, and then decreases slowly; Conducive to the maintenance of pectin viscosity.

[0032] Since the molecular weight of pectin and the gel strength are directly related to the viscosity of the pectin solution, the viscosity of the pectin solution can indirectly but conveniently and quickly reflect the degradation of pectin during deesterification (β-elimination...

Embodiment 3

[0040] Embodiment 3 The preparation of pectin of the present invention

[0041] The preparation method is the same as in Example 1, except that ethanol is used instead of isopropanol, and it is found that the filtration of flocs is difficult, and the yield of finished amidated pectin is greatly reduced, and the effect is not as good as using isopropanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com