Process for preparing graft gelatine glue

A production method and technology of animal glue, applied in the field of modified animal glue production method, can solve the problems of differences between actual dosage and formula dosage, product quality fluctuation, long production cycle, etc., achieve good moisture absorption and release performance, and improve product quality , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

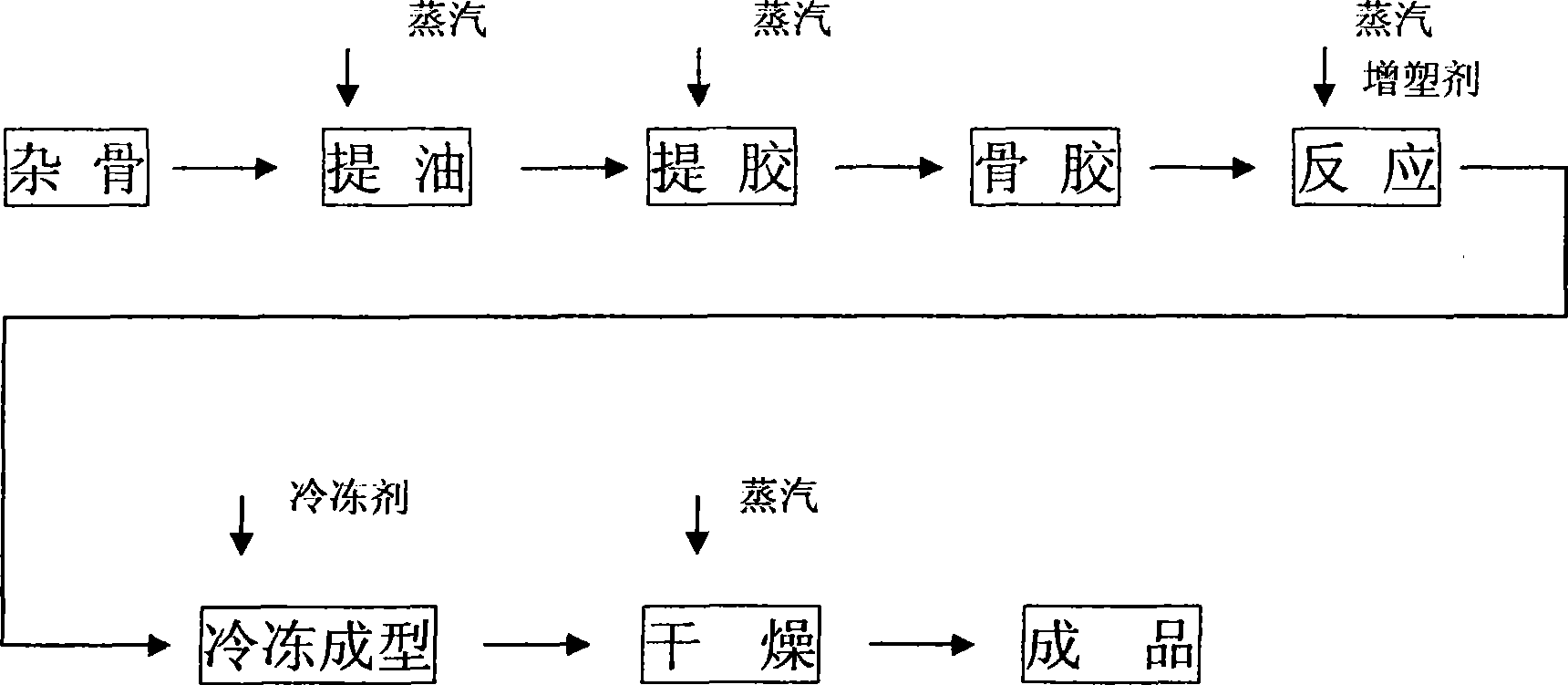

[0009] Embodiment 1: with reference to attached figure 1 . The production method of grafted animal glue is characterized in that: bone glue extracted from pig and bovine bones is used as raw material, or the commercial bone glue is swelled in cold water for 2 to 3 hours, heated to dissolve completely after swelling, and then 20 to 20% of the weight of the bone glue is used. 30%, 0.5-1.5%, and 0.05-0.15% are added as auxiliary materials such as glycerin, zinc sulfate, and sodium dithionite respectively, the temperature is kept at 65-70°C, the reaction is stirred for 0.5-1.5 hours, and then freeze-dried.

Embodiment 2

[0010] Embodiment 2: with reference to attached figure 1 . The production method of grafted animal glue is characterized in that: the bone glue extracted from pig and bovine bones is used as raw material, or the commercial bone glue is swelled in cold water for 2 hours, heated to completely dissolve after being completely swollen, and then 20% or 0.5% of the weight of the bone glue is used. % and 0.05% by adding glycerin, zinc sulfate, and sodium dithionite as auxiliary materials respectively, keeping the temperature at 65° C., stirring and reacting for 0.5 hours, and then freeze-drying.

Embodiment 3

[0011] Embodiment 3: with reference to attached figure 1 . The production method of grafted animal glue is characterized in that: bone glue extracted from pig and bovine bones is used as raw material, or commercial bone glue is swelled in cold water for 2 to 3 hours, heated until completely dissolved after fully swelling, and then weighed by 30% of the weight of the bone glue , 1.5%, 0.15% by adding glycerin, zinc sulfate, and sodium dithionite auxiliary materials respectively, keeping the temperature at 70° C., stirring and reacting for 1.5 hours, and then freeze-drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com