Processing method of puffed vegetable fruit crisp slice

A processing method and technology for puffing fruits and vegetables, applied in the field of food processing, can solve the problems of prolonged frying time, reduced product quality, long puffing time, etc., and achieve the effects of improving production capacity, shortening drying time, and excellent color and aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

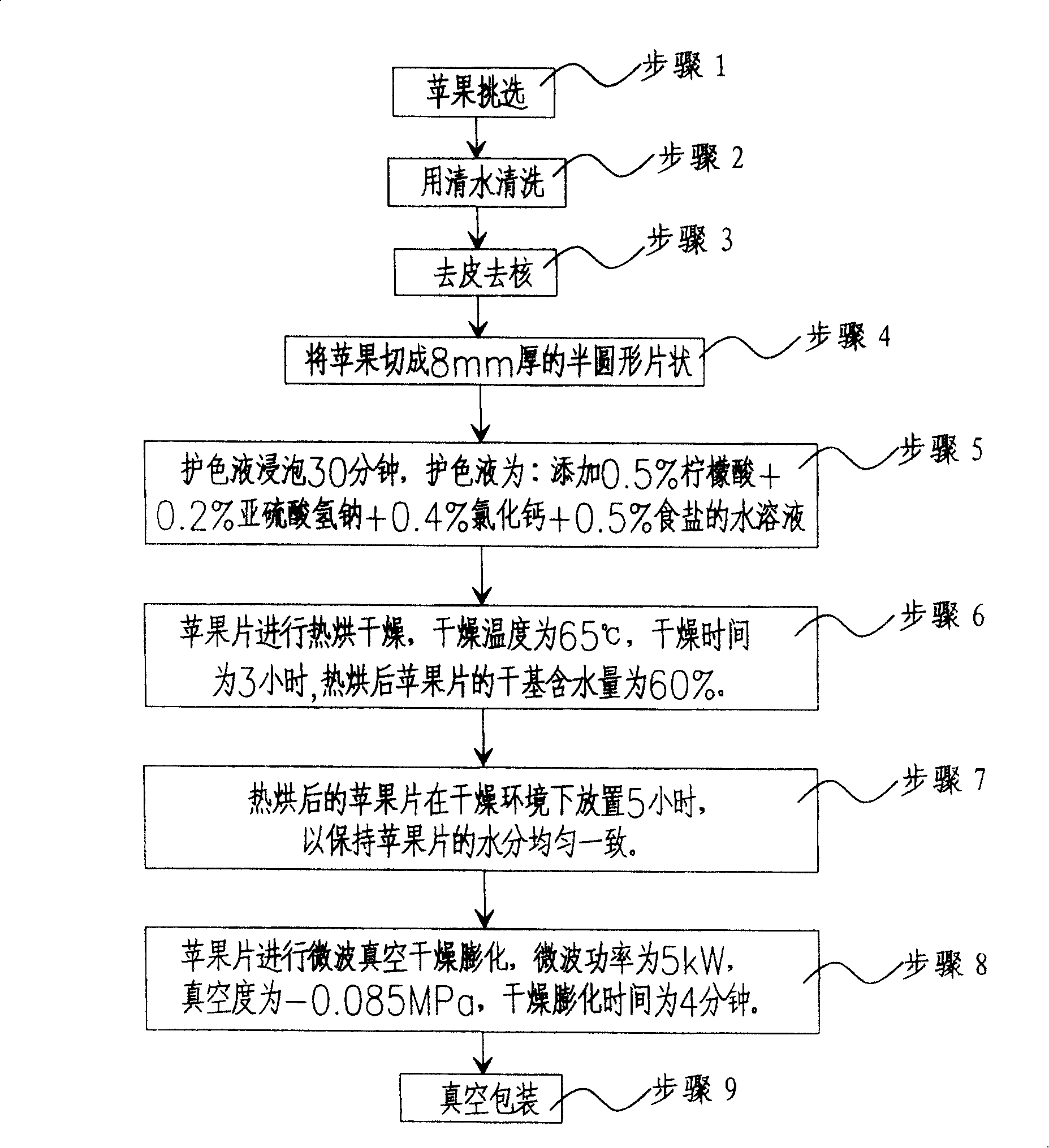

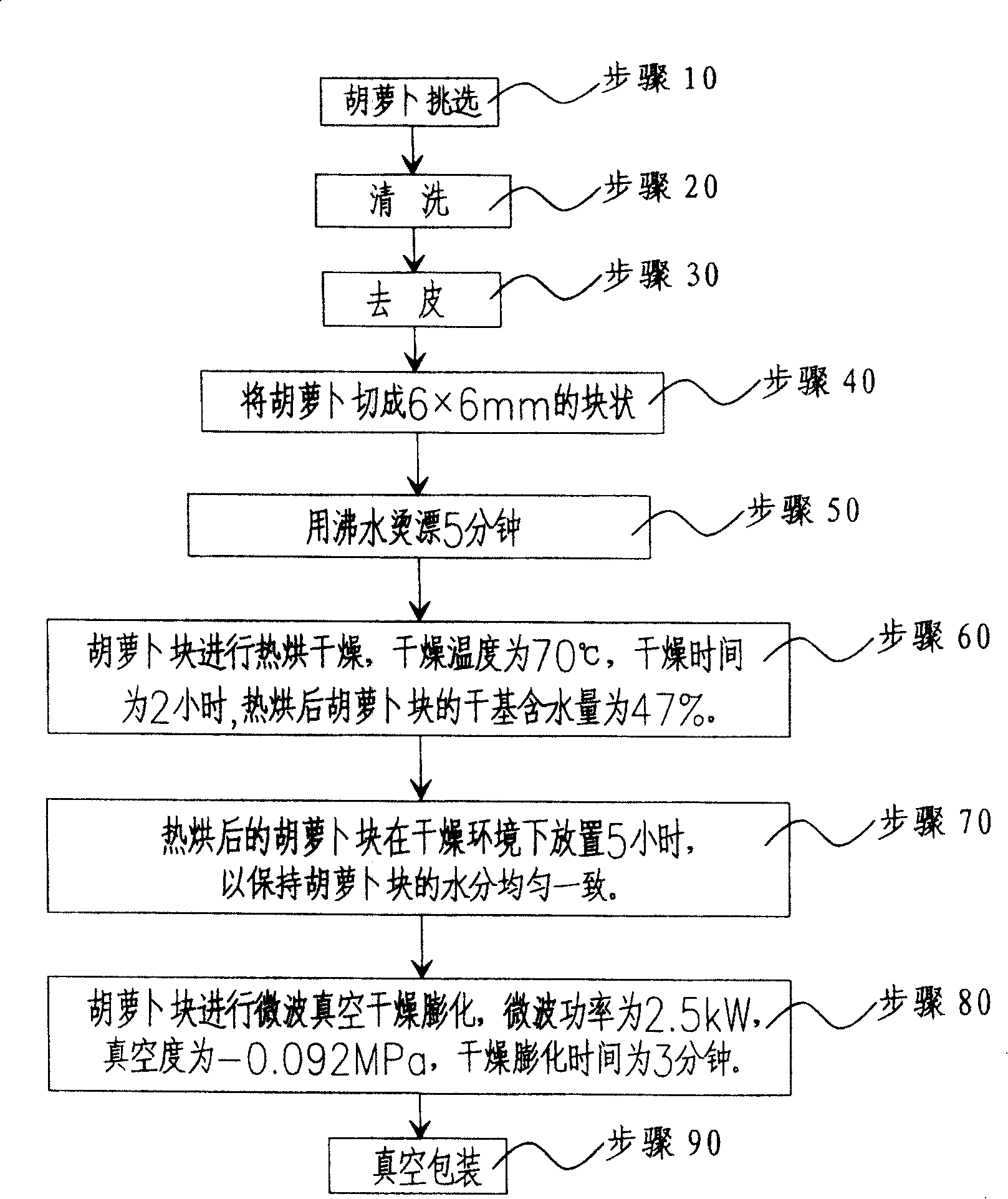

[0012] In order to better understand the essence of the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] The method of the invention is suitable for processing different fruit and vegetable products. After the raw materials are selected, cleaned, peeled and cored, they are sliced, and then treated with color protection and heat drying, and finally processed into crisp vegetable chips by microwave vacuum drying and puffing. The following description mainly refers to apples, but "apple" can be construed to mean any other fruit and vegetable product which can be treated according to the present invention. Of course, according to different types of raw materials, it is necessary to adjust the appropriate operating process parameters in order to give full play to the technical advantages of microwave vacuum drying and puffing. aroma and other characteristics.

[0014] fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com