Vertical shaft high power wind-driven generator

A wind turbine and high-power technology, which is applied to wind turbine components, wind turbines, wind turbine combinations, etc., can solve the problems of high cost and low utilization rate of wind energy, and achieve low friction loss, high utilization rate of wind energy, and convenience. maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention will be described below by taking a megawatt generator as an example, but the present invention is not limited thereto.

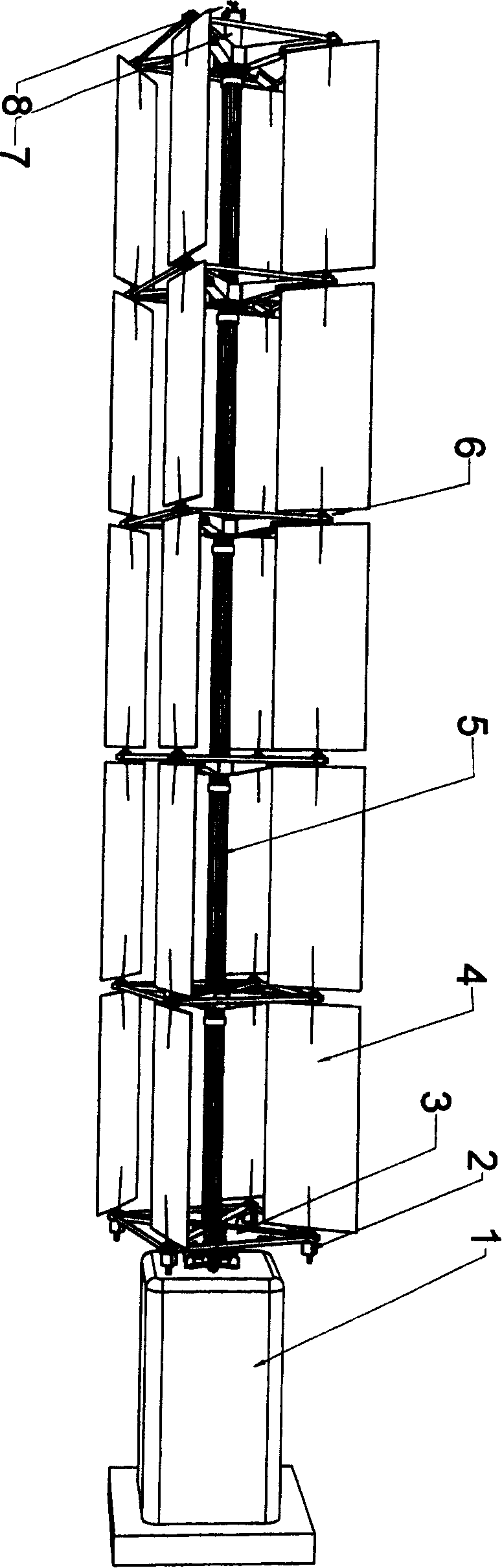

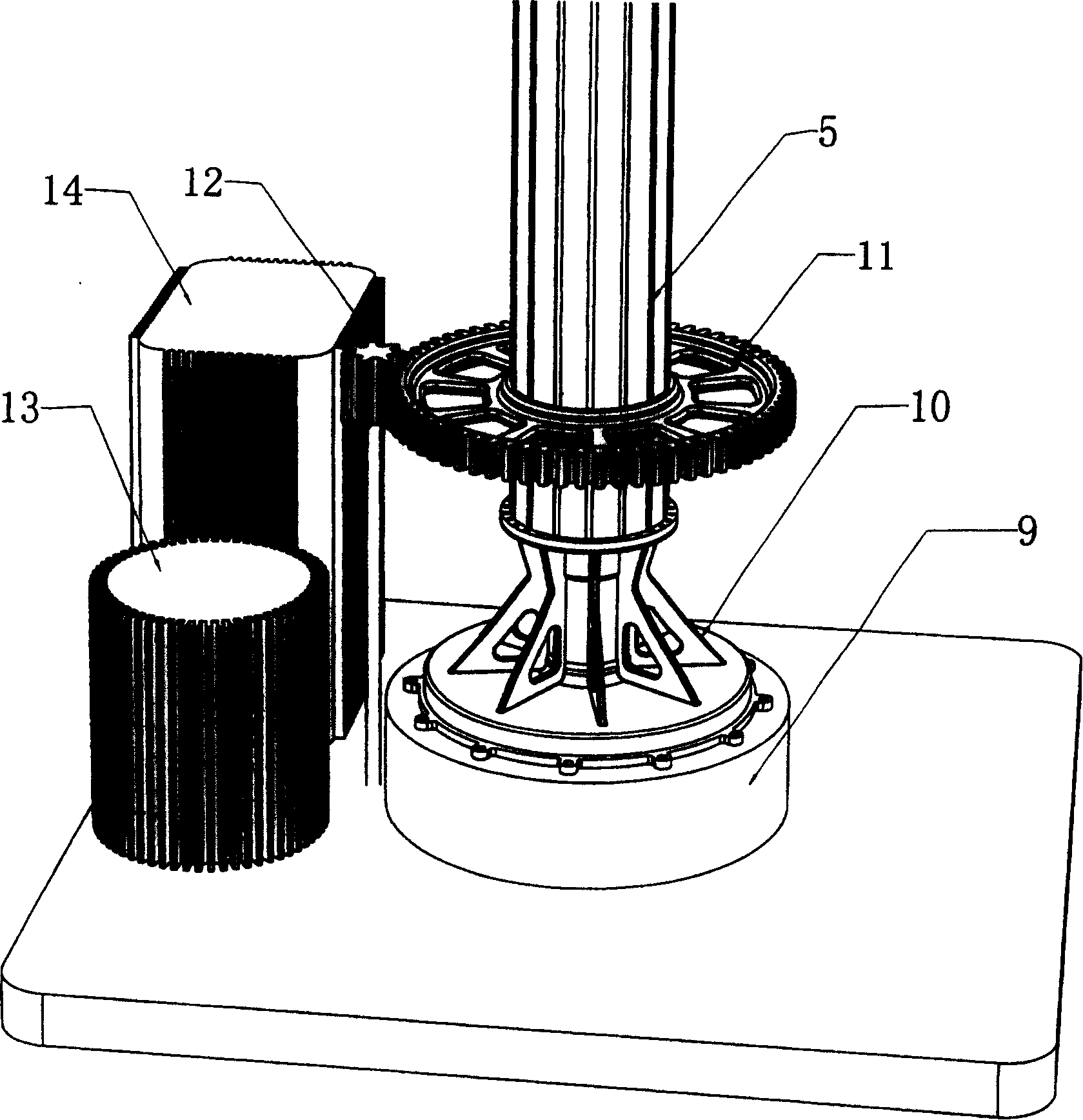

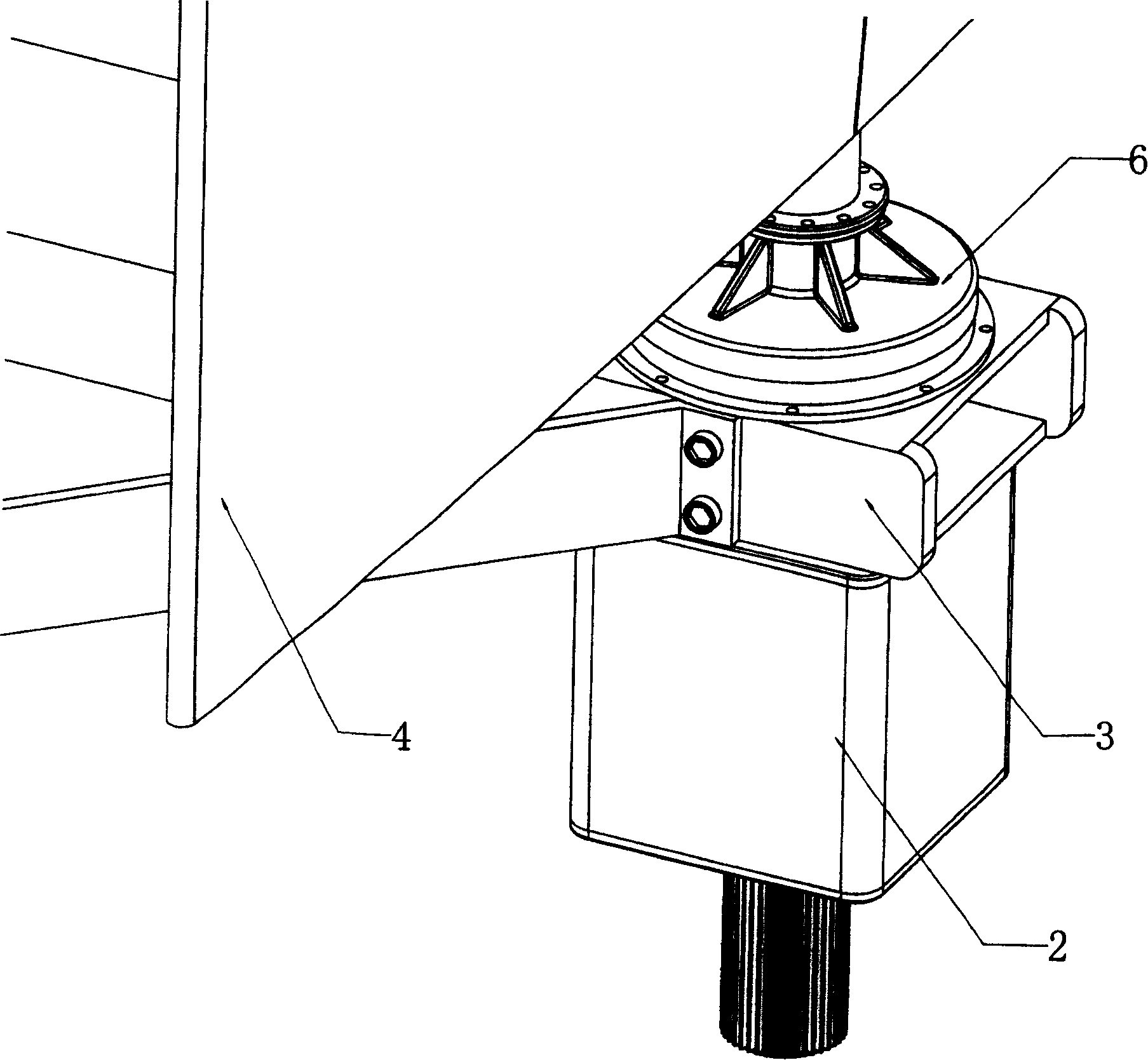

[0040] Such as Picture 1-1 , 1-2 , 1-3, 1-4, 1-5, the vertical axis wind power generator of the present invention is constituted like this: the whole is cylindrical, and there is a central column connected by central support column 5 in the center, and its There are multi-layered sail support discs 3, and four couplings 6 that can rotate around their own vertical axes are arranged on the edge of the sail support disc 3. The coupling 6 is a composite thrust bearing structure, and the thrust of the couplings 6 The installation hole A603 on the chassis 601 under the bearing is installed together with the sail blade support plate 3, and then the coupling 6 and the segmented sail blades 4 are connected through a flange to form a coaxial and same direction composite sail blade, specifically : the top of the coupling 6 is connected t...

Embodiment 2

[0056] The difference from Embodiment 1 is that as shown in Figures 1-6, an outer ring 16 is set on the outer wall of the central support column 5 at the top of the generator room 1, and a plurality of idlers 17 are installed on the top of the generator room, and are connected with the outer ring 16. The ring 16 abuts to strengthen the stability of the central support column 5 in motion. The front view of the idler 17 is shown in Figure 1-6-1, and the top view is shown in Figure 1-6-2.

[0057] The present invention can directly fix the permanent magnet material 15 on the upper and lower chassis of the shaft coupling thrust bearing and the main thrust bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com