Dynamic balance measuring instrument

A measuring instrument and vibration measuring technology, which is applied in the direction of static/dynamic balance testing, measuring devices, instruments, etc., can solve the problems of reducing the accuracy of the measurement system, limiting the measurement accuracy, introducing ground elastic errors, etc., and achieving high dynamic response sensitivity, The effect of small lateral movement and small wave distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

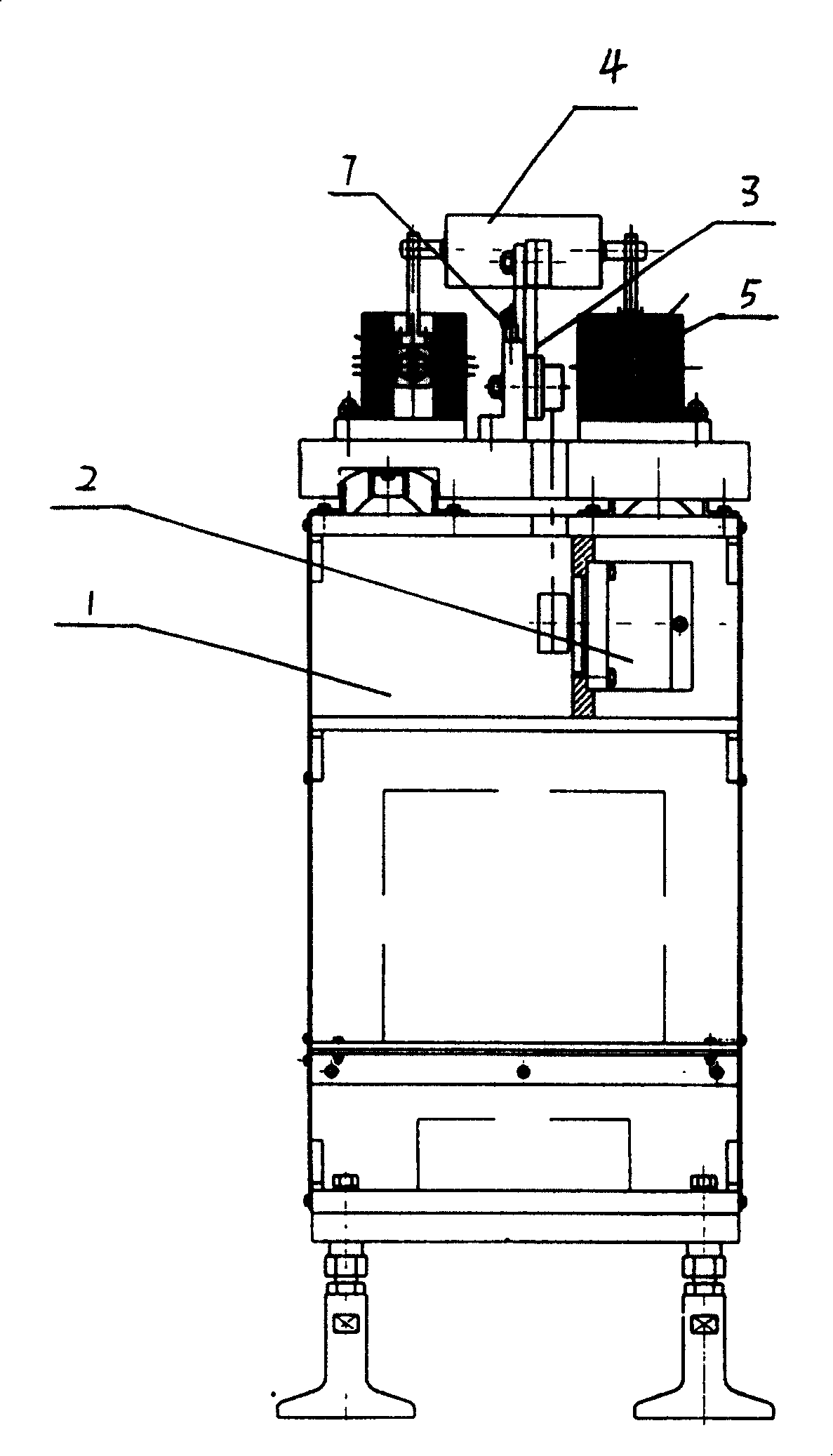

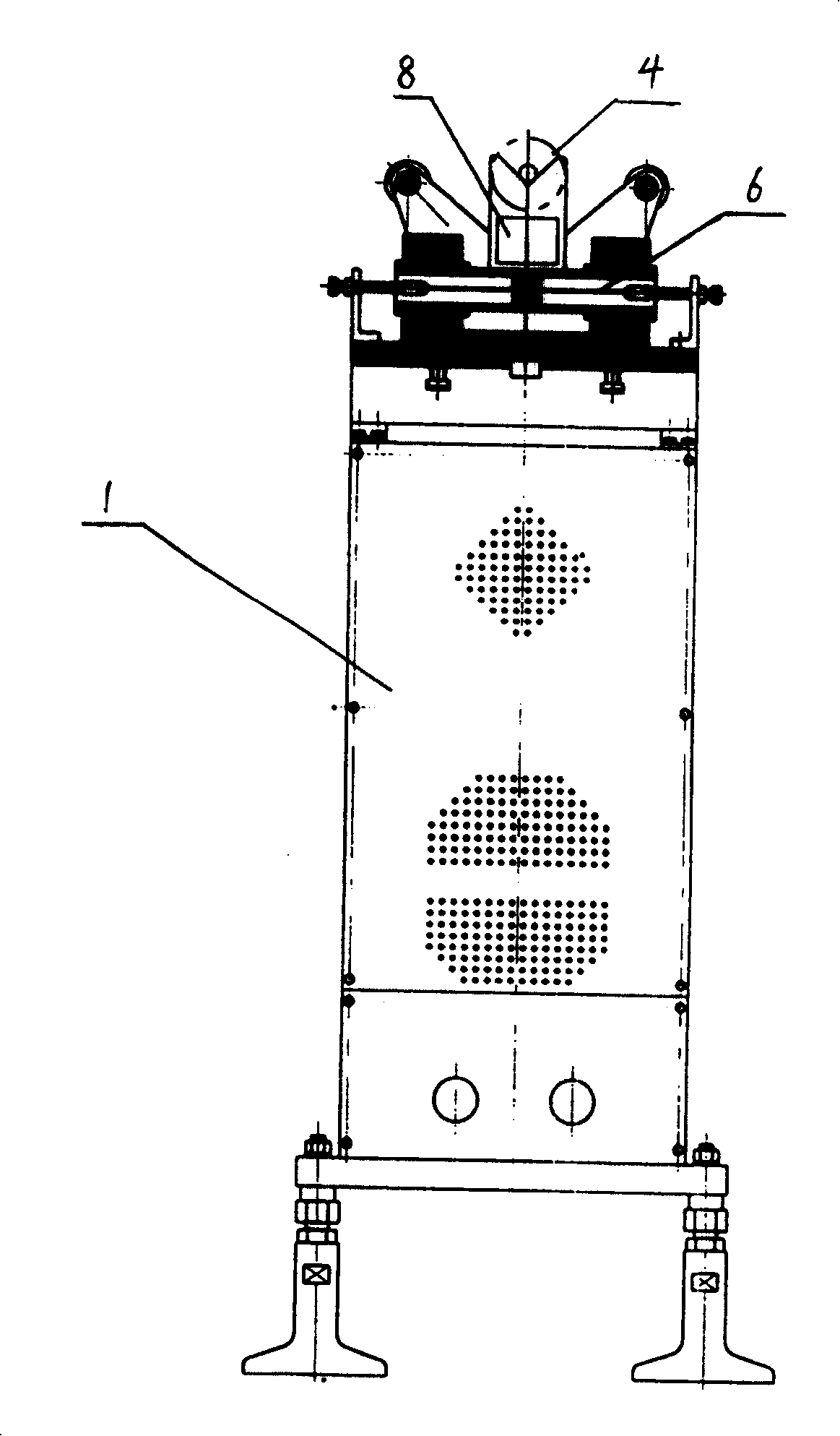

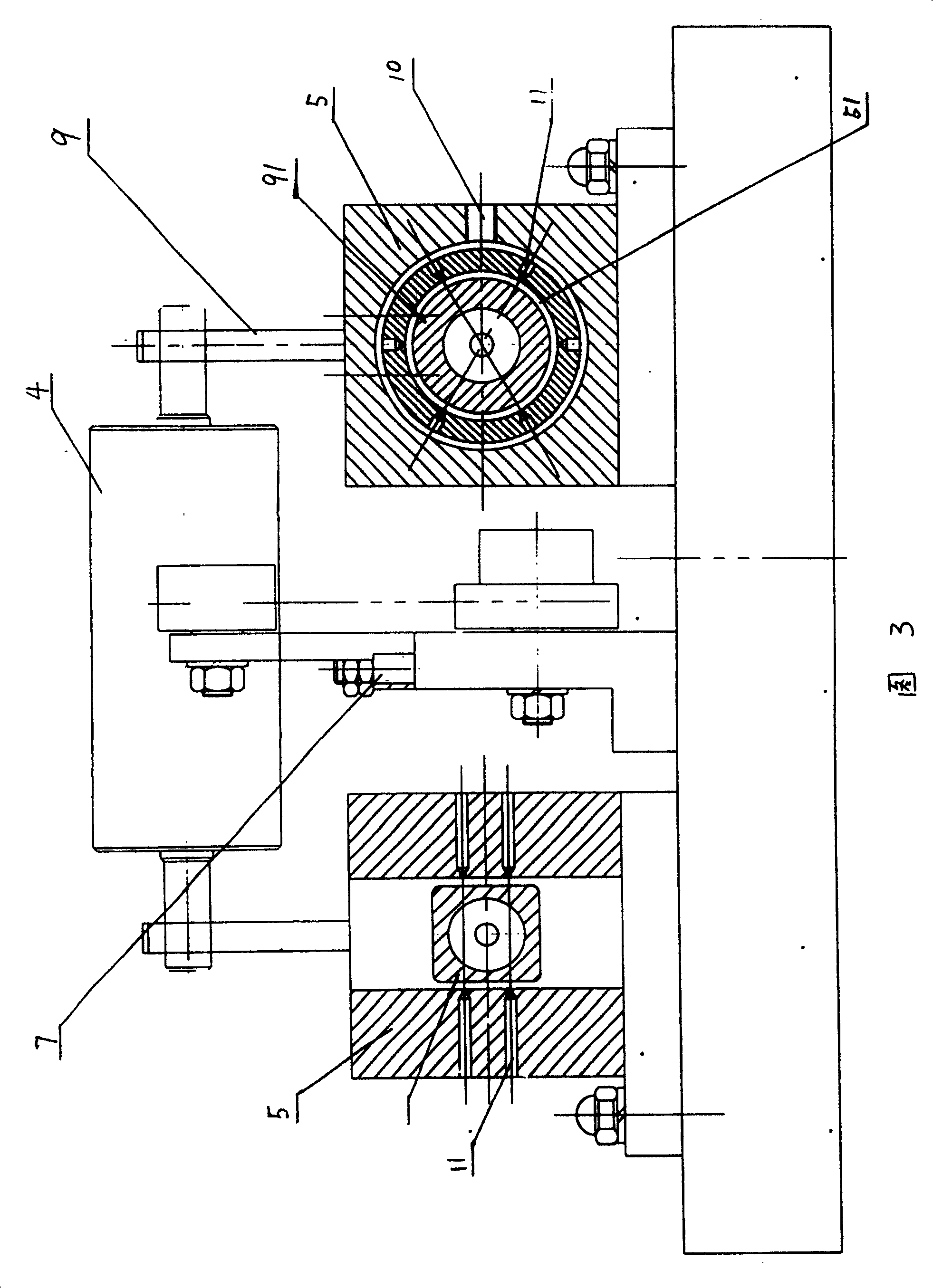

[0016] see figure 1 , figure 2 . The dynamic balance measuring instrument of the present invention comprises a frame 1, the upper part of the frame is a vibration measuring support, a driving motor 2 and a driving belt 3 are housed on the frame, the driving motor drives the driving belt to rotate, and the rotor 4 is placed on the vibration measuring support for laminating The drive belt 3 is driven to rotate by the drive belt 3; the vibration measuring support is composed of two parallel vibrating body mechanisms, and the driving belt 3 is installed between the two vibrating body mechanisms, parallel to the vibrating body mechanisms; A vibration measuring sensor 8 and a phase sensor 7 are installed. When measuring, drive the belt 3 to rotate, and drive the rotor 4 to rotate at a high speed. The unbalance of the rotor causes the vibration measuring support to vibrate, which is transmitted to the vibration measuring sensor 8. The vibration measuring sensor adjusts and analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com