Bending machine control method and system

A control method and technology of a bending machine, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of only position programming, inconvenient molds, and high prices, reducing components and wiring, debugging, debugging Ease of use and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

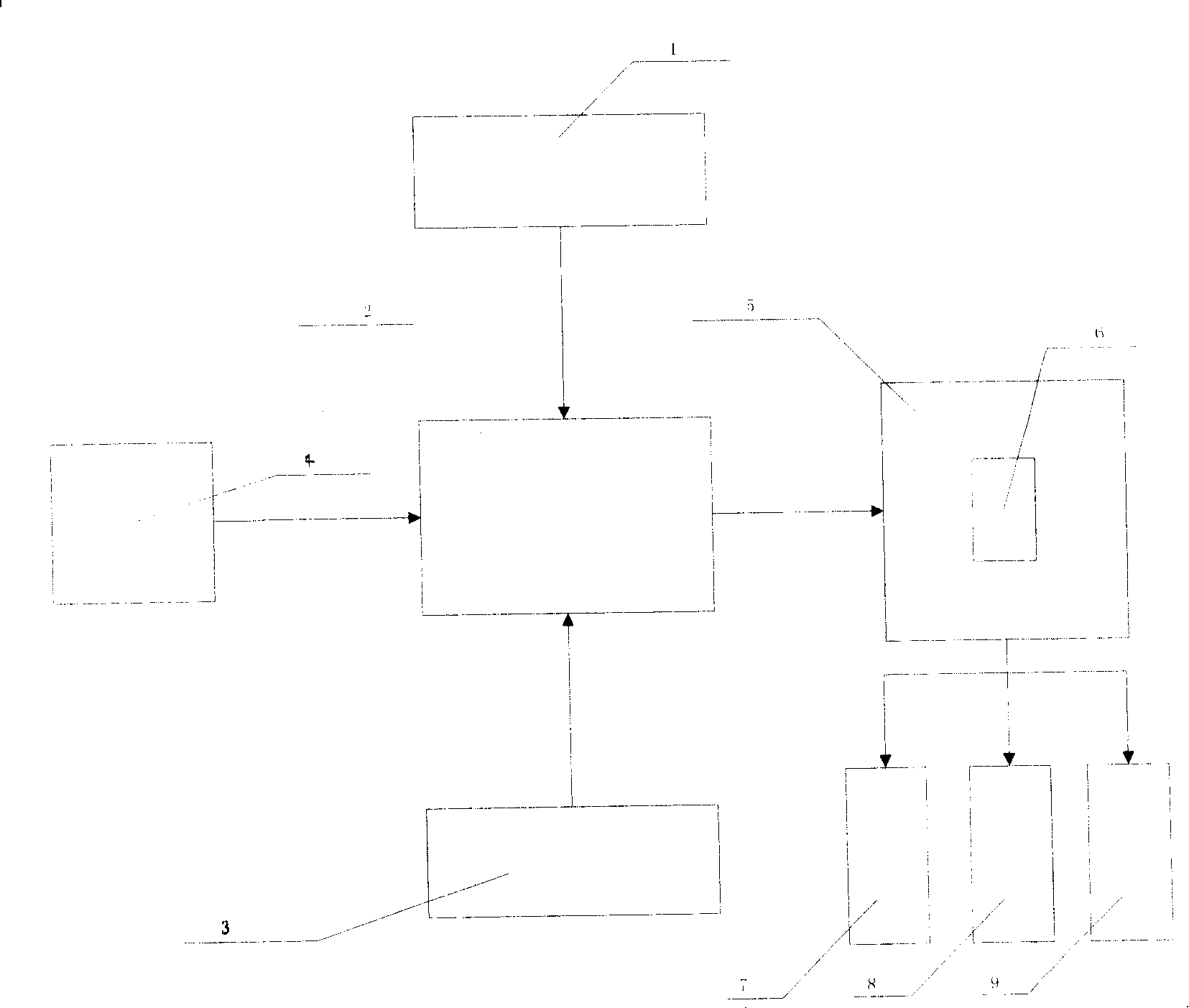

[0036] Such as figure 1 As shown, the present invention includes X-axis photoelectric encoder 1, bending special controller 2, Y-axis photoelectric encoder 3, machine tool electrical input 4, electric control cabinet 5, special driver 6 installed in the electric control cabinet, and drive sliding Block of solenoid valve group 7, X axis motor 8, Y axis motor 9.

[0037] Machine tool electrical input 4 includes control mode 1, control mode 2, oil pump start signal, top dead center, shifting point, clamping point, bottom dead center, pedal up, pedal down, programming lock, step change signal, X-axis front Limit, X-axis rear limit, Y limit, Y-axis rear limit, safety light curtain. Among them, control mode 1 and control mode 2 are used to select the working mode of the slider: single, continuous, and inching.

[0038]When the special bending controller receives the start signal of the oil pump, the system can work. As long as the system is not in the jog working state, the system can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com