Cold box for cryogenic distilling plant

A technology of low-temperature distillation and distiller, which is applied in household refrigeration equipment, applications, household appliances, etc., and can solve problems such as personnel evacuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

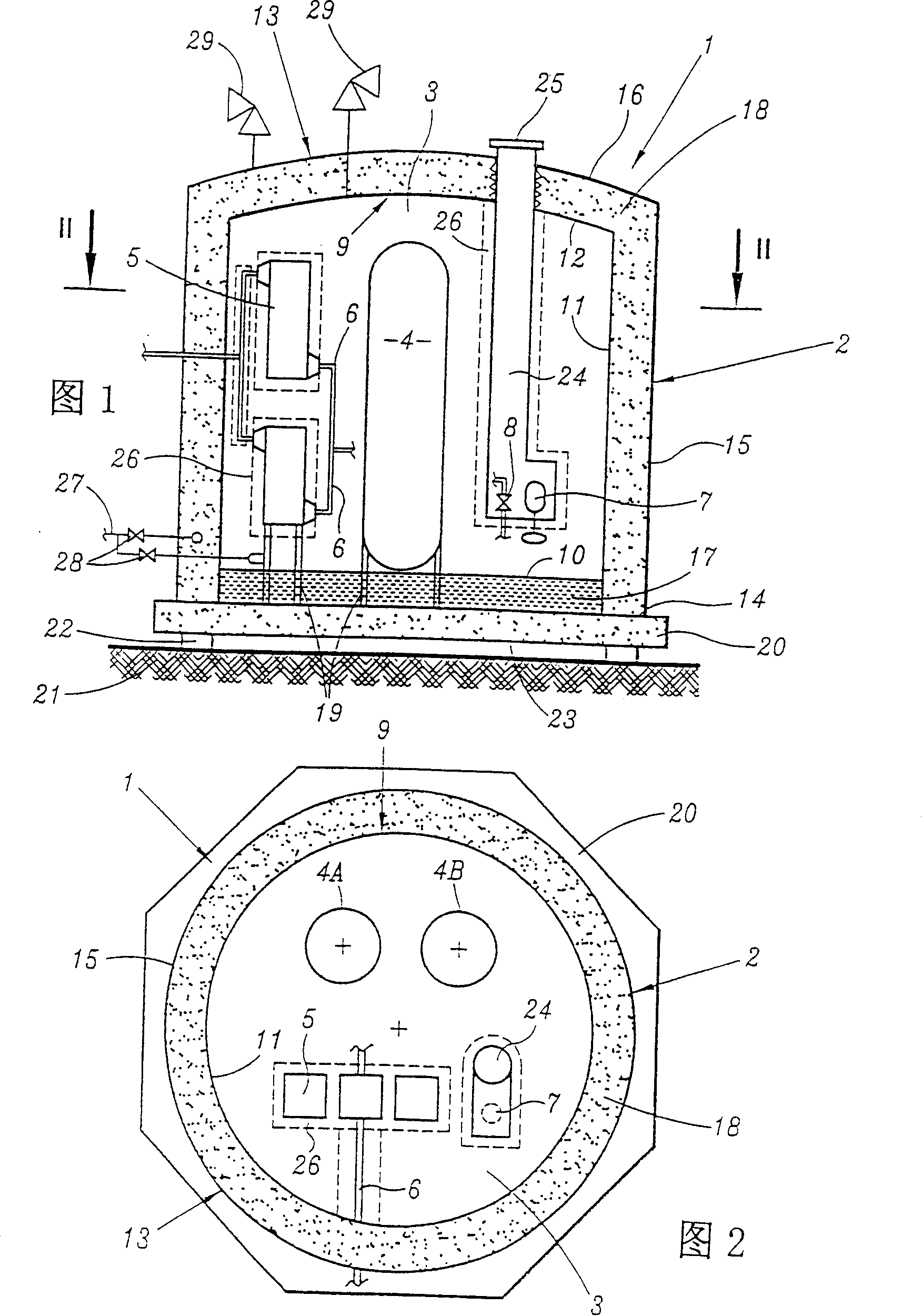

[0023] [23] The air distillation device 1 shown in Fig. 1 and Fig. 2 mainly includes a double-walled hood 2, and in the inner space 3 of the hood, double air distillation towers 4, heat exchangers 5, connecting pipes 6 and cryogenic Accessories, such as cryopump 7, cryogenic valve 8, etc.

[0024] [24] As in the prior art, column 4 consists of two distillation columns, one for medium pressure and one for low pressure. As shown in FIG. 2, the two columns 4A and 4B are placed side by side, but in FIG. 1 they are centered for clarity. Furthermore, the distillation unit naturally includes the full range of commonly used accessories and equipment.

[0025] [25] Cover 2 is a double shell. The inner shell 9 includes a flat bottom 10, a cylindrical side wall 11 and a dome 12, and is made of stainless steel. The housing 13 includes a flat bottom 14, cylindrical side walls 15 and a dome 16, and is made of carbon steel. But the bottom 14 can also be made of stainless steel.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com