Self controlling location seeding mechine

The technology of a seeder and a seeding device is applied in the direction of interval quantitative seeding machinery, fertilizer and seeding equipment, agricultural machinery and equipment, etc. It can solve the problems of inconsistent width of furrows, insufficient film spreading, uneven seeds, etc., and achieve the best seeding depth. Consistent, conducive to water absorption, uniform seeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

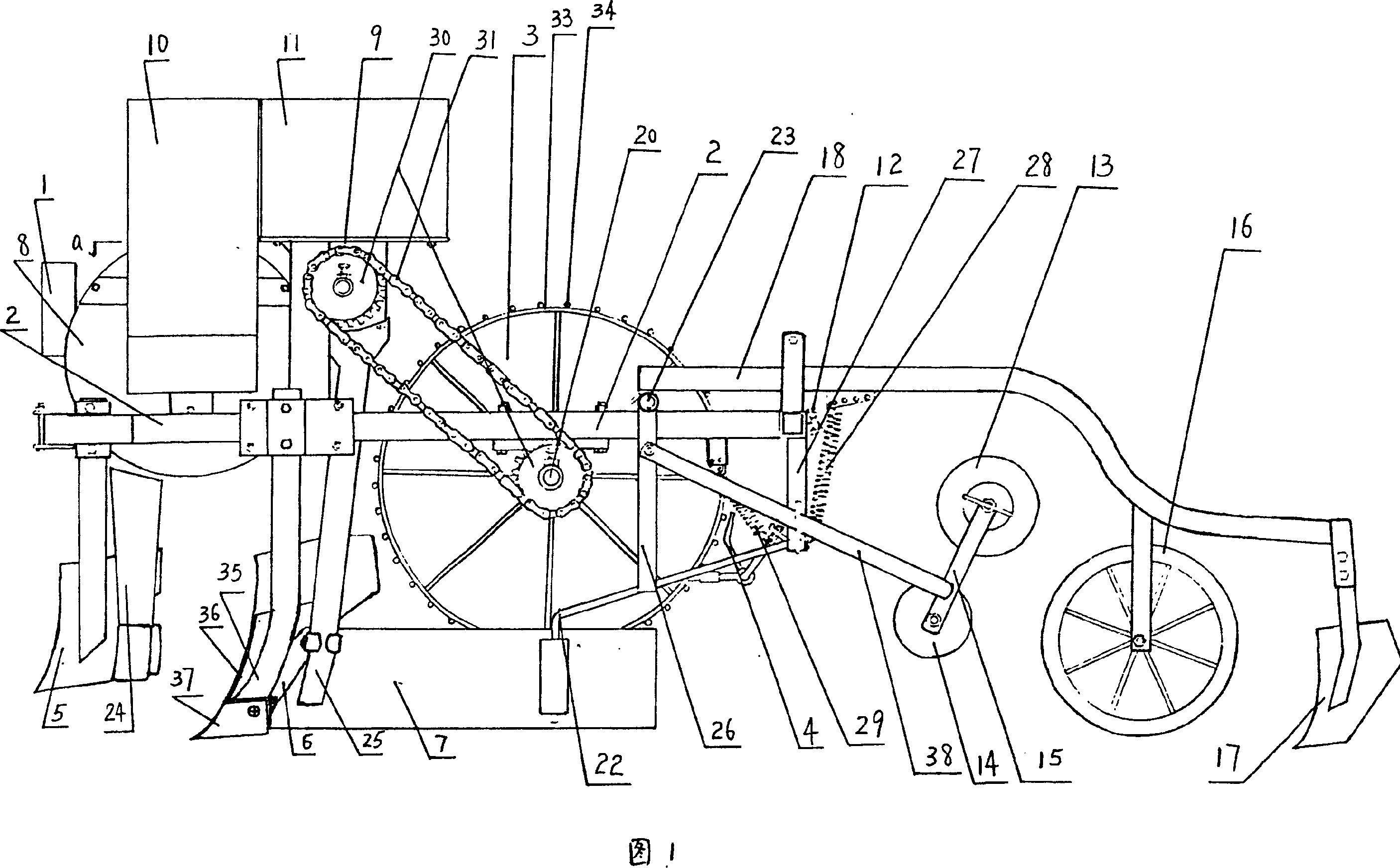

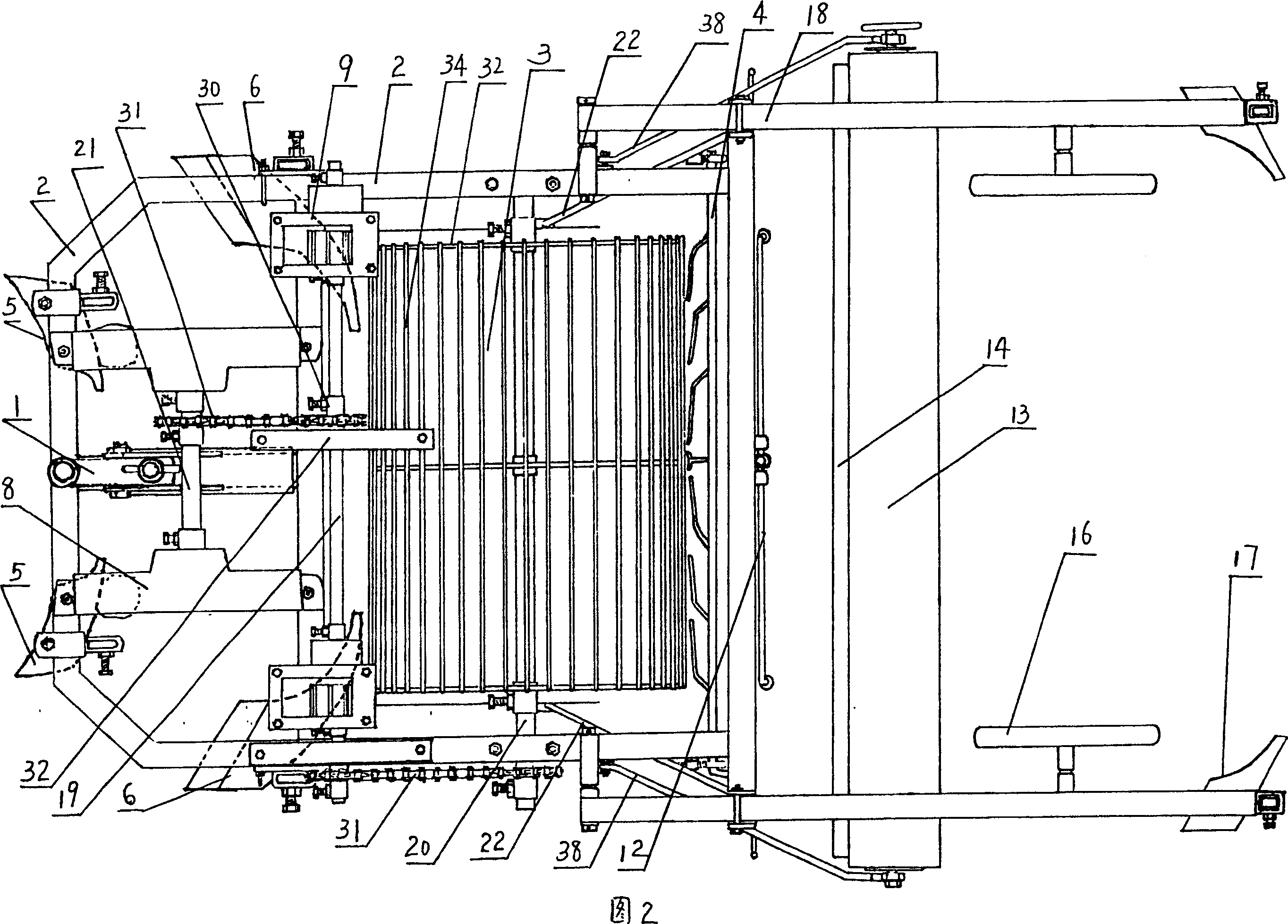

[0018]Embodiment: a kind of self-control positioning seeder (referring to Fig. 1-Fig. 4), it comprises frame 2, the front portion of frame 2 is provided with two pairs of plows, and front pair is two ridge-supporting sowing plows 5, is located at The two sides of the frame are symmetrical to each other, and the back pair is two ridge-supporting and fertilizing plows 6, which are symmetrical to each other on both sides of the frame. The ridge-supporting sowing plow 5 and the ridge-supporting fertilization plow 6 have the same structure, and both include a plow handle 35 and a plow wall 36, and the plow wall 36 connects to the plow point 37, and the plow point 37 is V-shaped (the ridge-supporting sowing plow 5 can also be a disc shaped plow). After each ridge fertilization plow 6 is connected with a plastic ridge plate 7, the outer side of the plastic ridge plate 7 blocks the plastic ridge plate 7 by the plastic ridge plate fixing frame 22 to avoid moving outwards, and the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com