Composite power system of outer jointed auxiliary power

A technology of auxiliary power and power system, which is applied in the field of mechanical power system, can solve the problems of power transmission partition, volume expansion, unsmooth connection, etc., and achieve the effect of simplifying structure, reducing cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

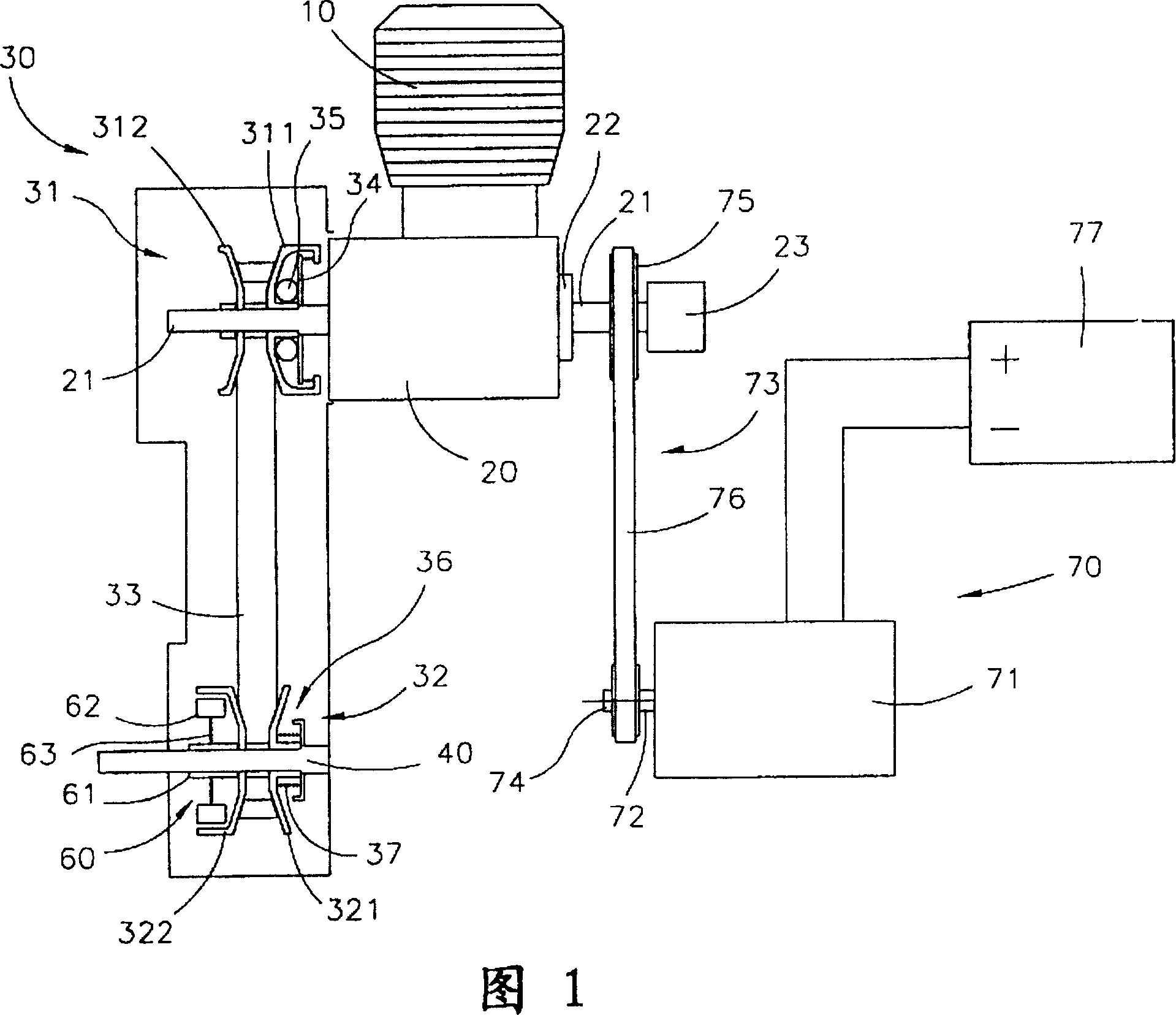

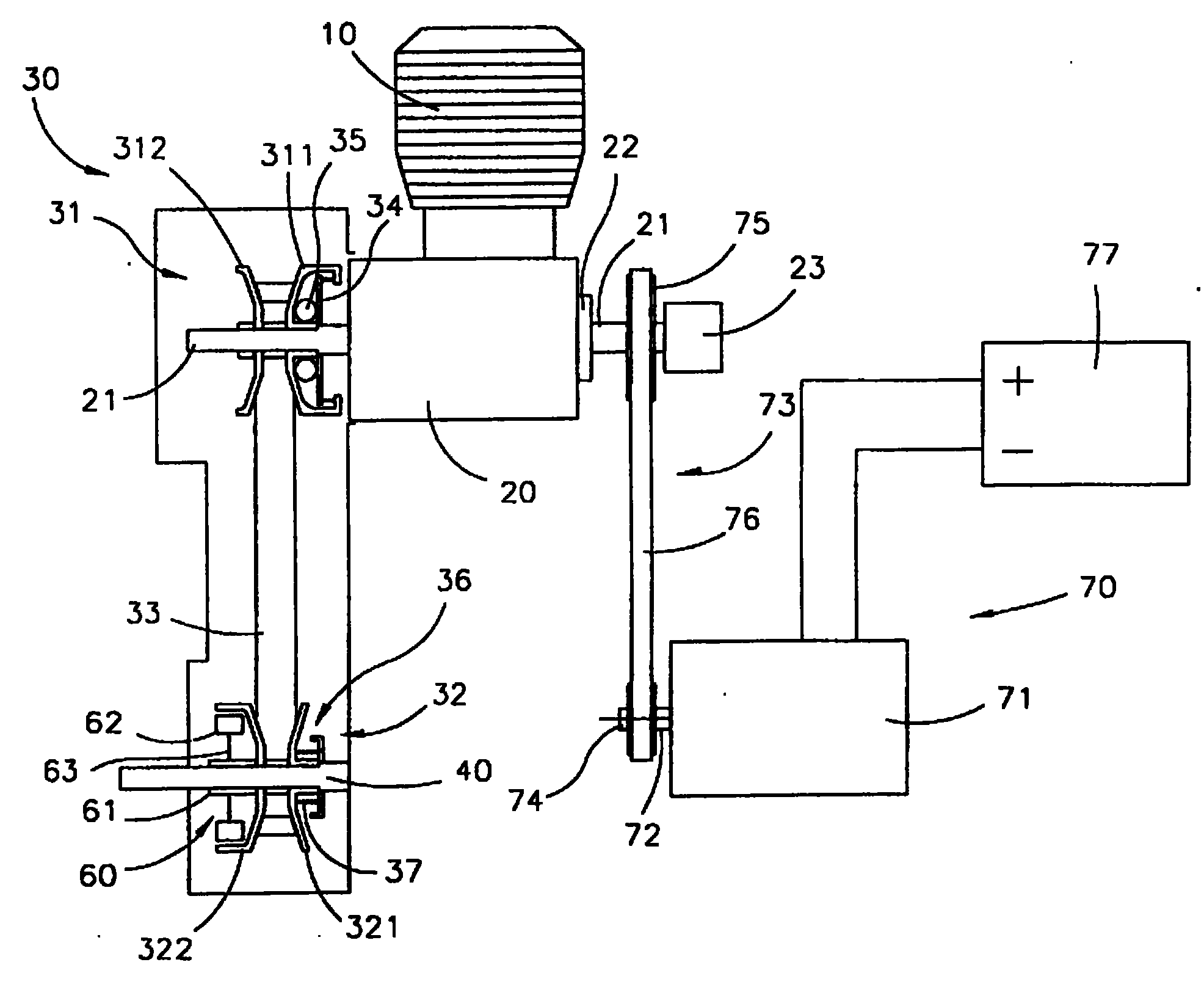

[0056] As shown in Figure 1, the present invention mainly includes: a first power unit 10, a transmission box 20, a first transmission mechanism 30, an output shaft 40; and an auxiliary power unit 70 and a second transmission mechanism 73; wherein the first The power of the power unit 10 can drive the first drive shaft 21 to rotate through the inside of the transmission box 20; the first drive shaft 21 is connected to the first transmission mechanism 30, and can drive the output shaft 40 through the first transmission mechanism 30 Rotate, and then output power through the output shaft 40 to drive the driving wheels of the vehicle, so that the vehicle moves forward.

[0057] The first power unit 10 can be any type of power unit, and the embodiment shown in the figures is an internal combustion engine. The transmission box 20 can be a crankshaft mechanism. The first power unit 10 drives the first drive shaft 21 to rotate through the crankshaft and reduction gear set (not shown),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com