Embeddable corrosion monitoring-instrument for steel reinforced structures

An internal corrosion, instrument technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, alarms, etc., can solve problems such as affecting the accuracy of readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

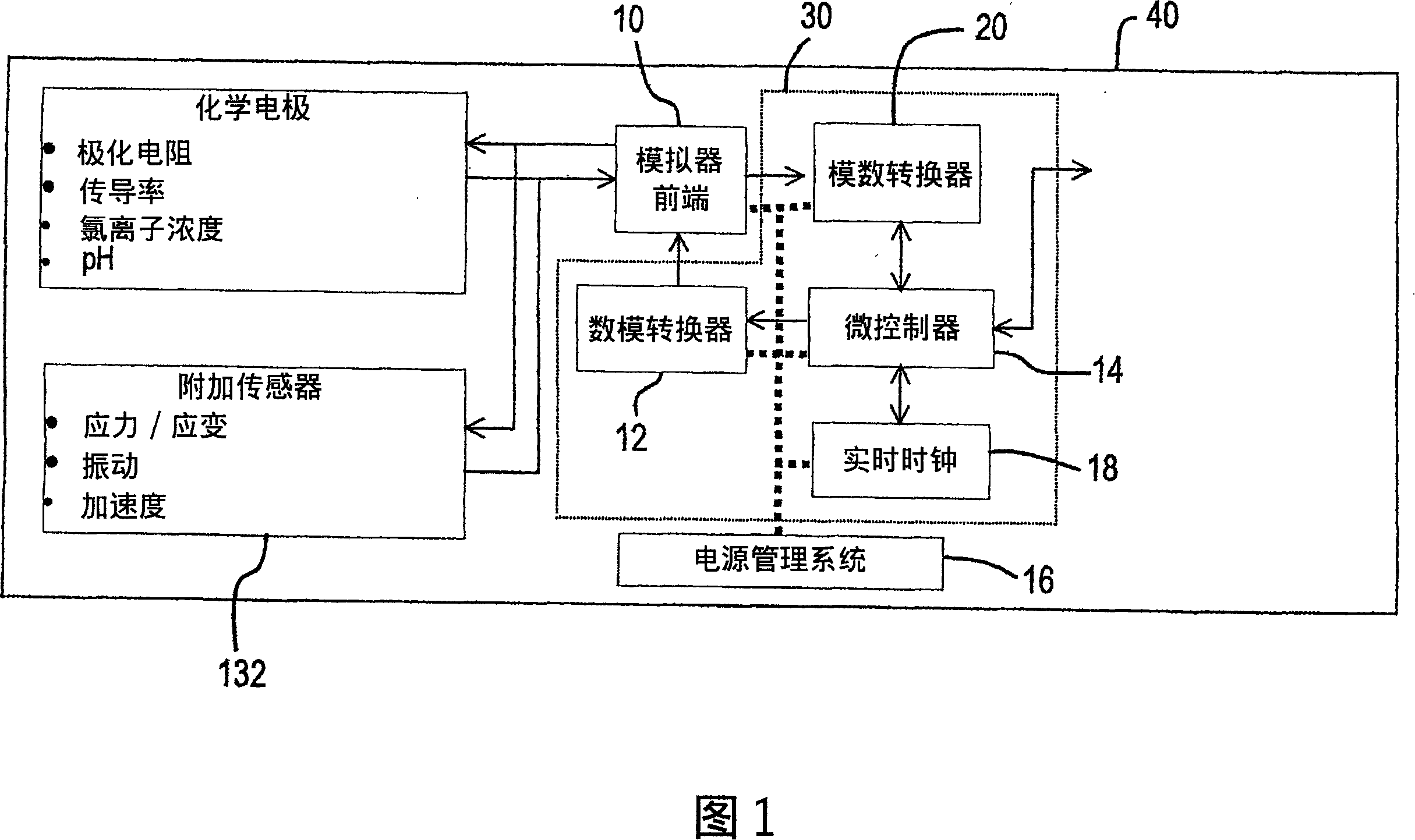

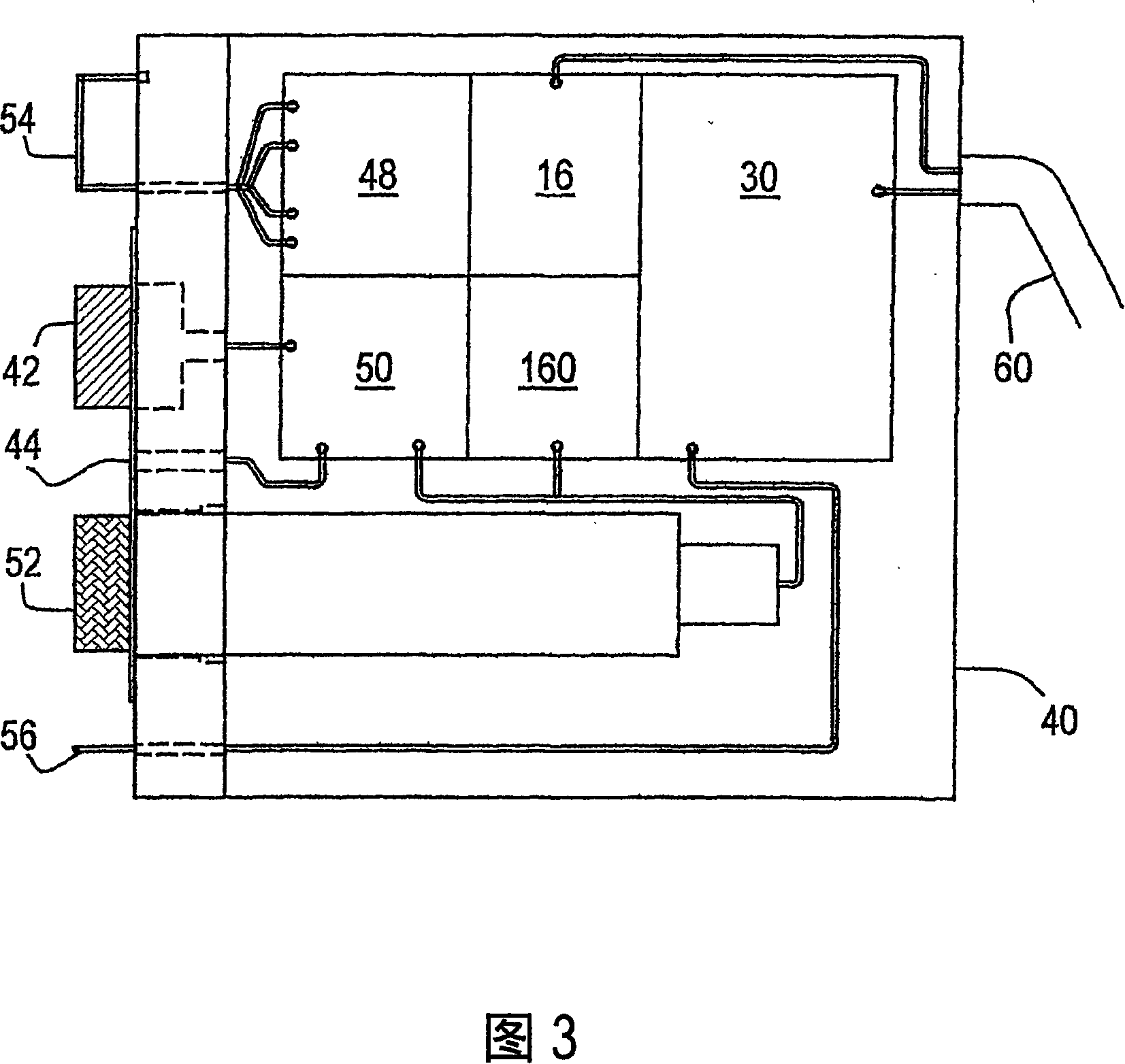

[0030] The present invention discloses an embeddable corrosion measuring instrument which can provide information on corrosion rate, corrosion voltage, electrical conductivity and chloride ion concentration, pH value, vibration level, stress and strain degree and temperature of steel reinforcement structure. By comprehensive monitoring of the steel, without reference to surrounding materials, the device of the invention can be used in a greater number of structures than prior art devices. Many prior art devices require a direct electrical connection to the strengthening steel within the structure, using the structural steel as a reference material. Because the instruments of the present invention do not require close proximity to the steel within the structure, the instruments can be dispersed in critical areas within the structure, regardless of steel distribution. This is accomplished by a sacrificial working electrode within the instrument, thus enabling readings to be take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com