Modular, high volume and high pressure liquid disinfection using UV radiation

A radiation source, fluid technology, applied in disinfection, sanitary equipment for toilets, irradiation, etc., can solve problems such as reduced effectiveness, increased system cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

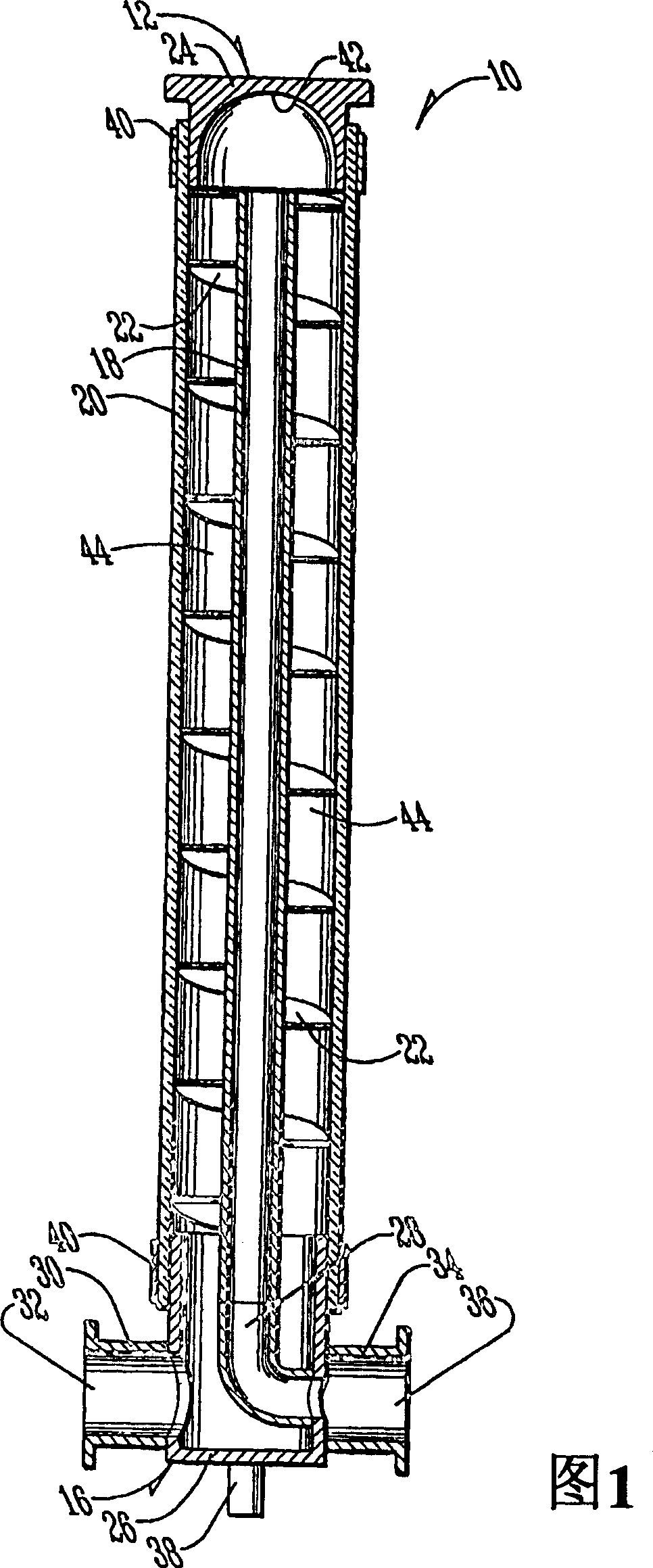

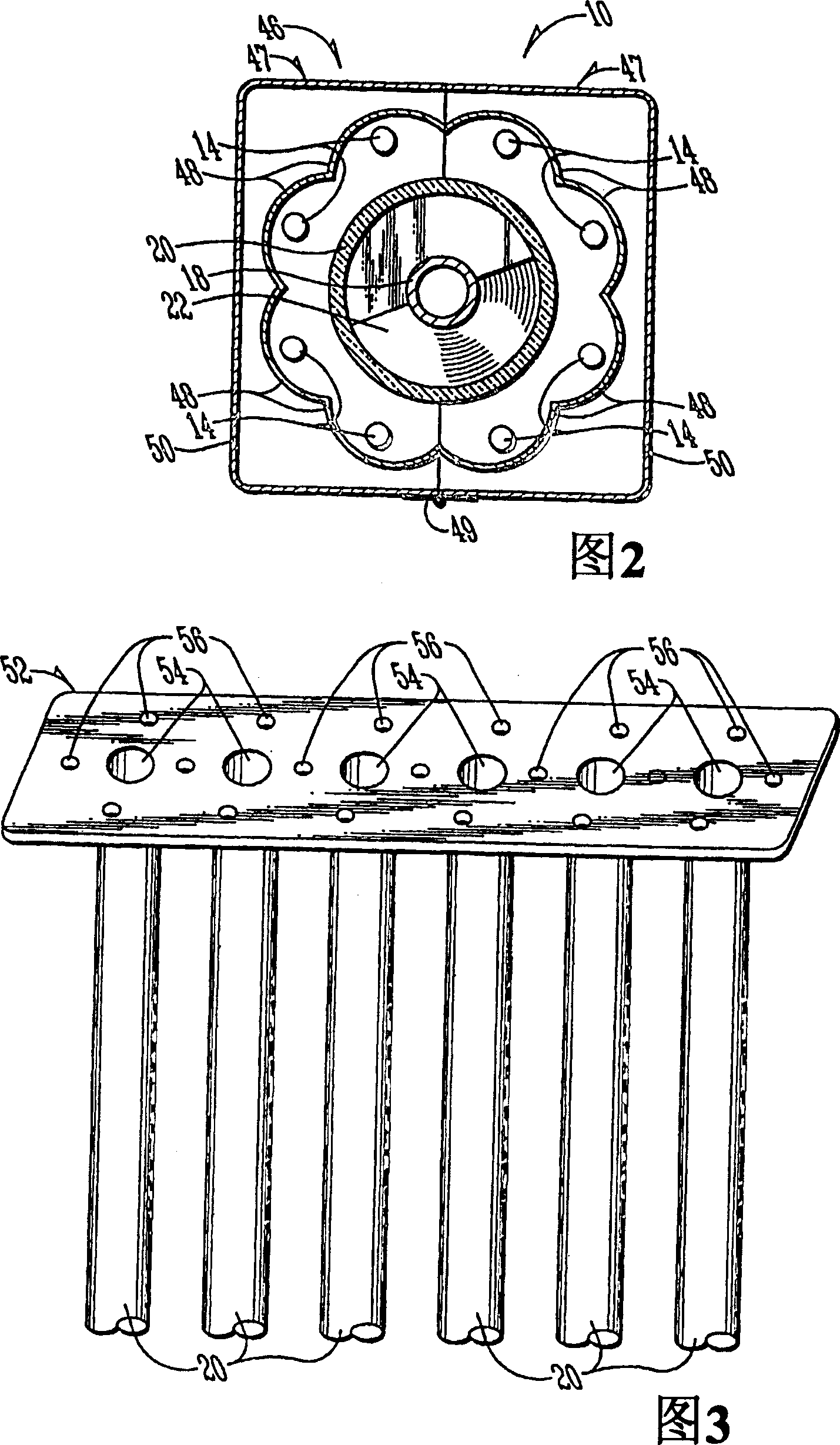

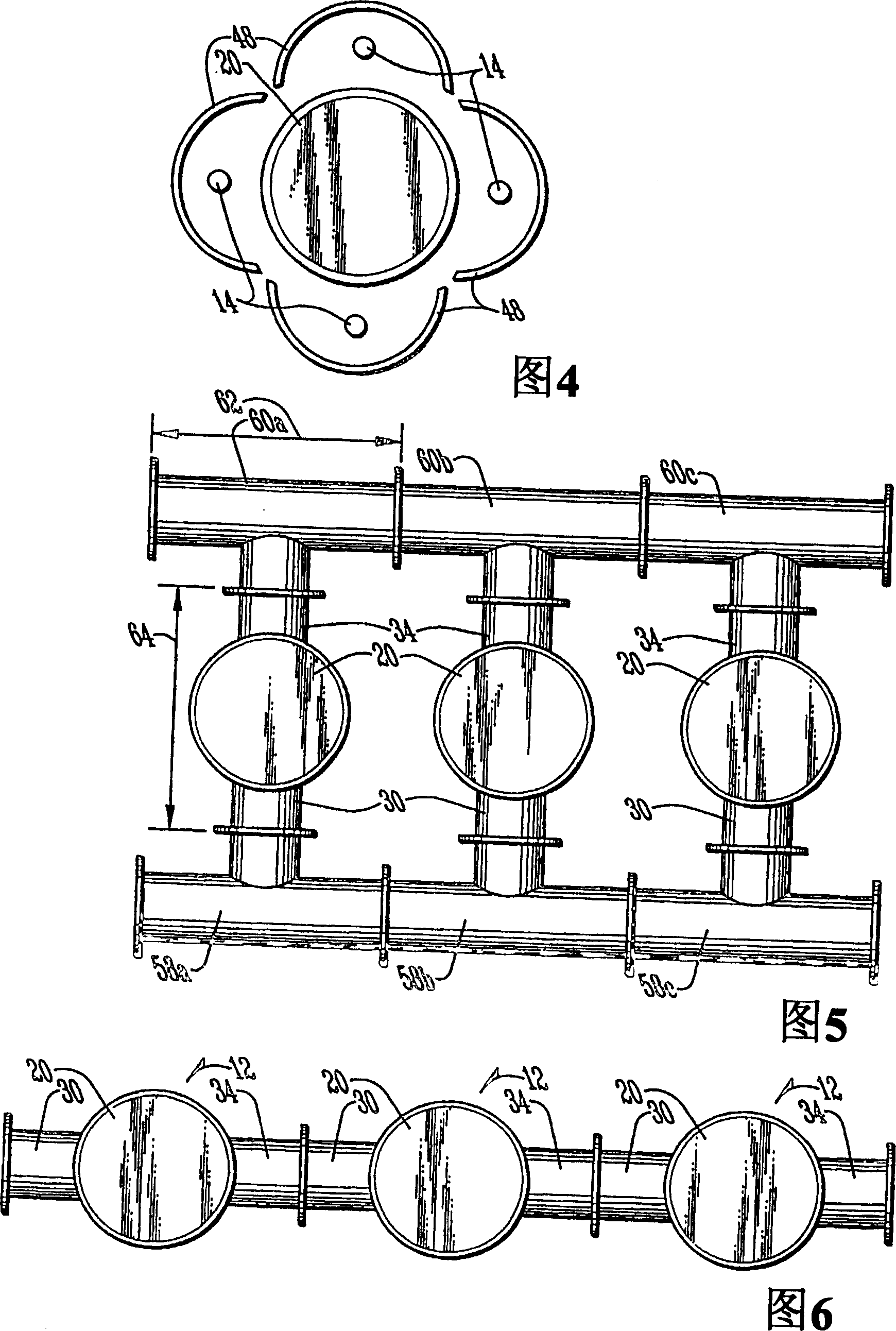

[0024] Referring to Figure 1, the reference numeral 10 generally designates the radiation treatment apparatus of the above-described invention. The apparatus 10 comprises a treatment chamber 12 and a radiation source 14 arranged in the immediate surroundings thereof.

[0025] The process chamber includes a header 16 , inner and outer tubing 18 , 20 , static mixer 22 , and end cap 24 . The header 16 has an outer housing 26 , an inner header conduit 28 , an input tube 30 having an input hole 32 , and an output tube 34 having an output hole 36 . The outer casing 26 is open at the top and closed at the bottom, and two side holes are arranged on opposite sides thereof, one of which is larger than the other. A mount 38 is attached to the bottom wall of the outer housing 26 . The inlet tube 30 is connected to the outer housing 26 in alignment with the larger of the two side holes. The output tube 34 is connected to the outer housing 26 in alignment with the smaller of the two othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com