Fluid bearing device and disc-rotation device using same

A fluid bearing, bearing hole technology, applied in bearings, electromechanical devices, bearing components, etc., can solve problems such as friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

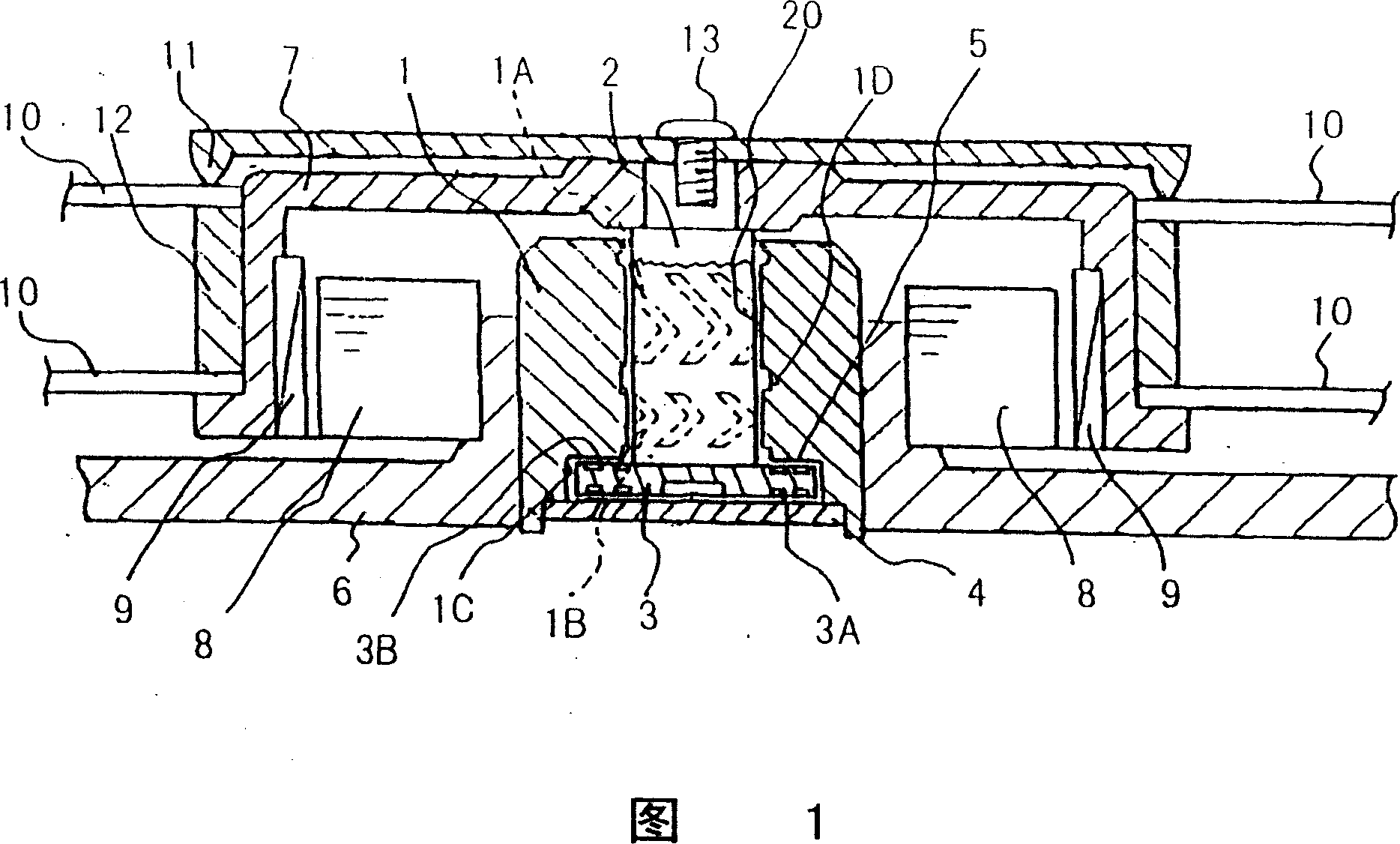

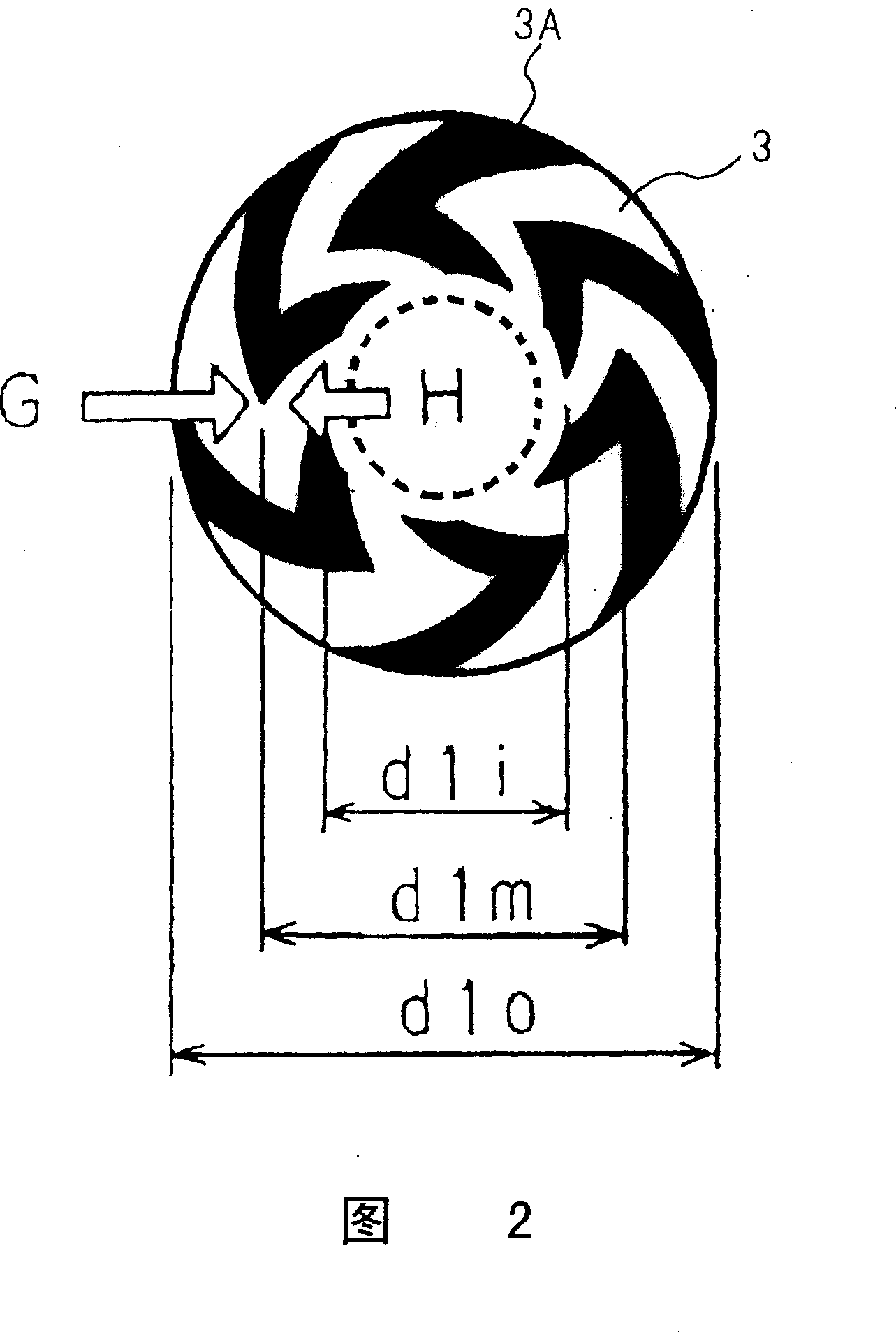

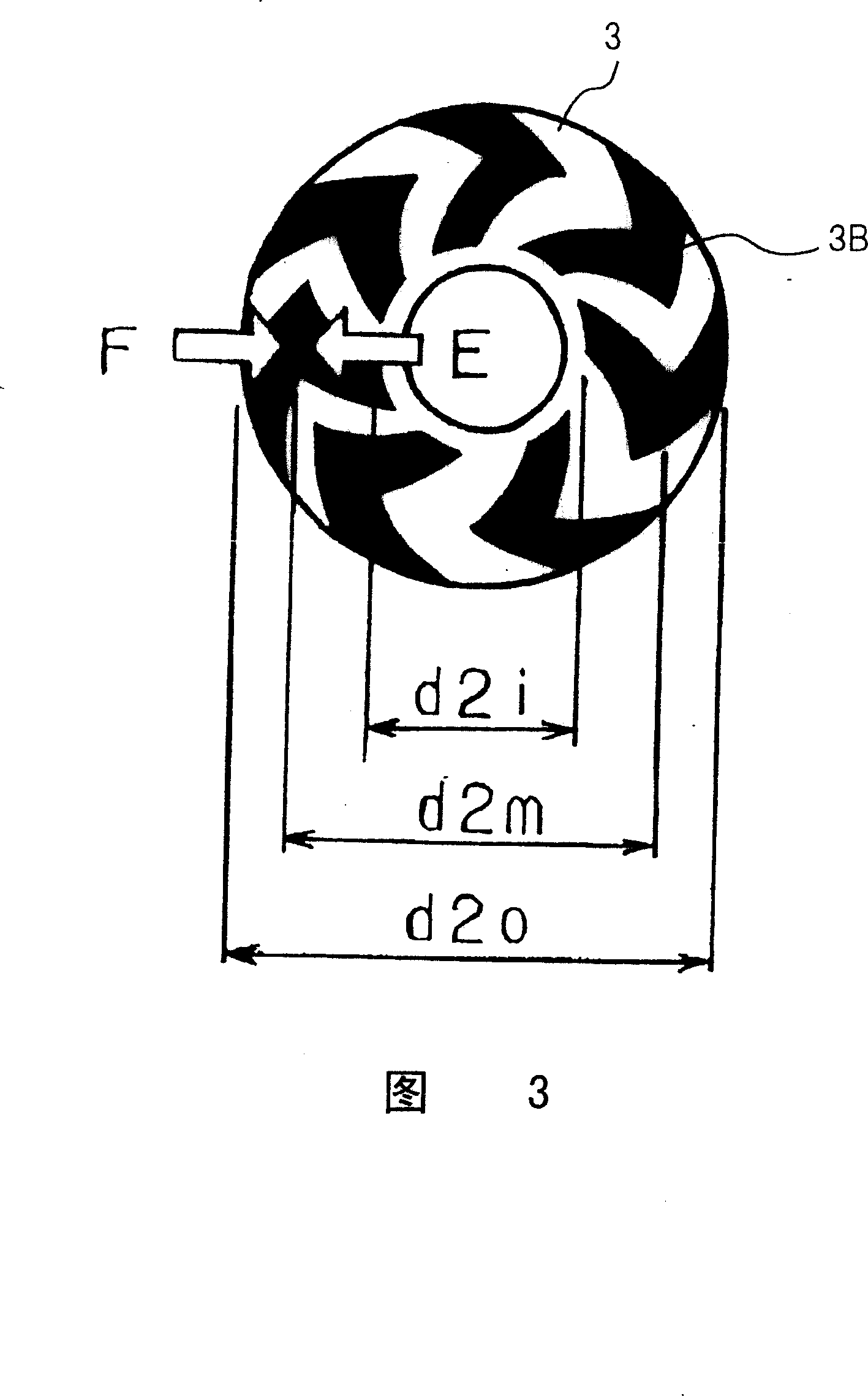

[0035] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS A preferred embodiment of the fluid bearing device of the present invention will be described below with reference to FIGS. 1 to 10. FIG. FIG. 1 is a cross-sectional view showing a fluid bearing device according to an embodiment of the present invention. In FIG. 1 , a bushing 1 has a bearing hole 20 approximately at the center, and herringbone-shaped dynamic pressure generating grooves 1A, 1B are formed on the inner peripheral surface of the bearing hole 20 . A recessed portion 1C is formed at the lower end portion of the boss 1 . The shaft 2 is rotatably inserted into the bearing hole 20 . The flange 3 is fixed to the lower end portion of the shaft 2 so as to fit into the recess 1C of the lower portion of the sleeve 1 . The thrust plate 4 is fixed in the recess 1C of the bushing 1 by laser welding, precision riveting, bonding and other fixing methods, so that the recess 1C including the flange 3 is sealed. The shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com