Method for detecting sleeve fluid-loss point utilizing direct-reading ultrasound flowmete

An ultrasonic and flowmeter technology, used in liquid/fluid solid measurement, flow/mass flow measurement, and fluid acceleration/deceleration rate measurement, etc., can solve the problems of complex process, high cost, and low success rate of casing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further disclose the technical solution of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

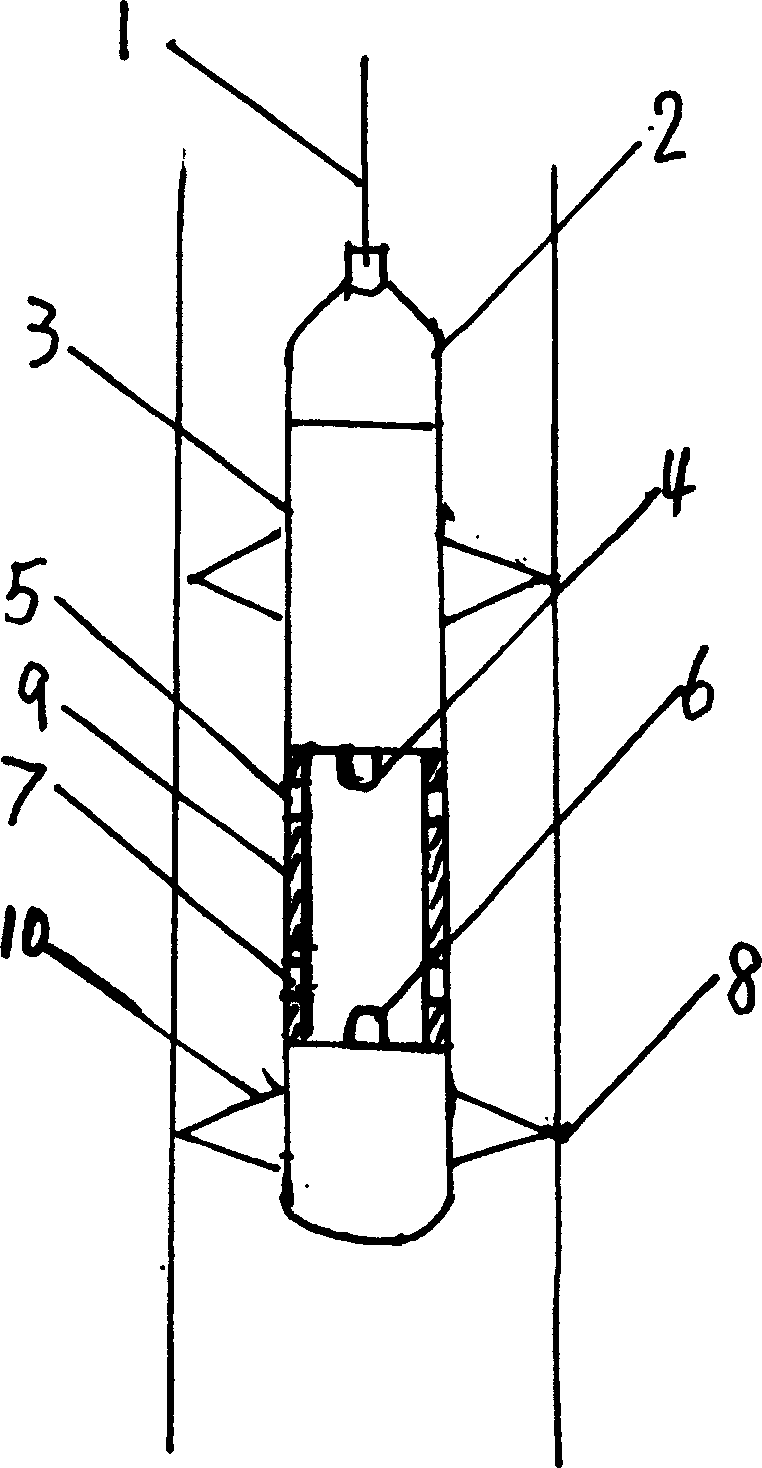

[0025] The invention includes a logging vehicle, a computer, a direct-reading ultrasonic flowmeter 3 and a detection method for a casing leak point, and is characterized in that the interface of the direct-reading ultrasonic flow is connected to the cable 1 on the logging vehicle through a cable joint 2 , the other end of the cable is connected with the computer interface on the logging vehicle through a slip ring, and the direct-reading ultrasonic flowmeter 3 is lowered to the upper part of the perforation section of the oil-water well formation by the logging vehicle, and the flowmeter is connected by the triangular centralizer 10 Support the center of the casing 8, inject water into the well with a steady flow rate of 50 cubic meters per hour, and then lift up the direct-reading ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com