Manufacturing method of additive for composite internal combustion engine oil

A technology for internal combustion engine oil and a manufacturing method, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of complex process flow, high labor intensity, long time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

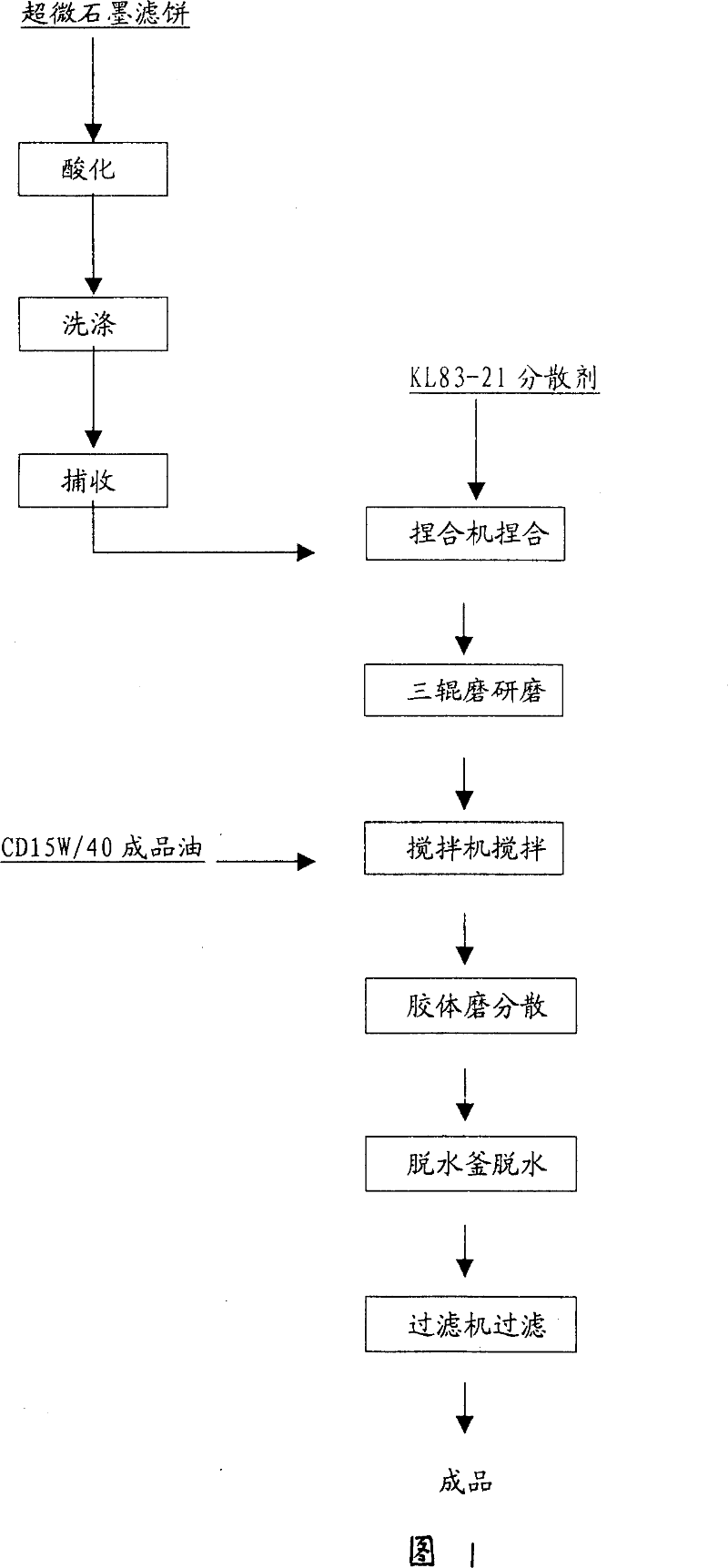

Image

Examples

Embodiment 1

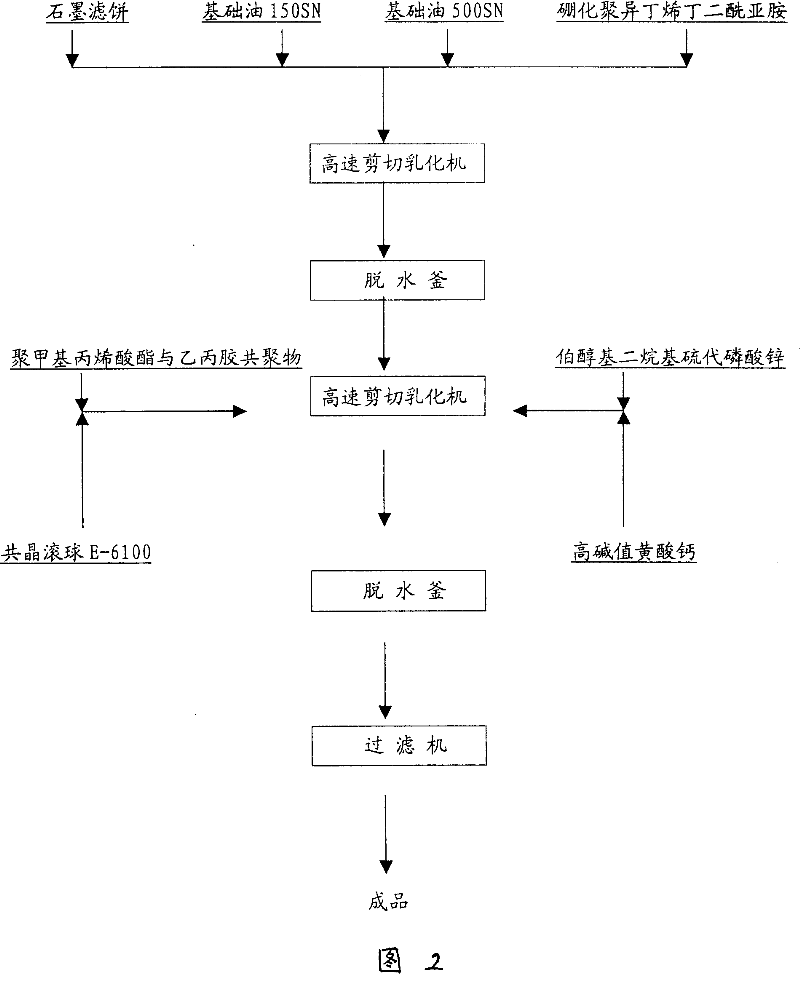

[0018] With reference to Fig. 2, be the graphite of 5 parts, the calcium sulfonate of 5 parts by weight (the same below), the base oil of 10 parts of 500SN, the base oil of 40 parts of 150SN is added in the emulsification kettle and carries out dispersion emulsification After 1 hour, the temperature is automatically raised to 60°C under the action of the high-speed shear emulsifier, and the product is transported to the dehydration kettle for heating, vacuumed and dehydrated under negative pressure. The heating temperature is controlled at about 60°C, and the negative pressure is controlled at 0.08Mpa. After 2 hours, transport the product back to the emulsification kettle, add 10 parts of polymethacrylate and ethylene-propylene rubber copolymer, carry out emulsification and dispersion for 1 hour, and then transport the product back to the dehydration kettle for heat preservation and dehydration for 0.5 hours, and the heat preservation temperature is controlled At 60°C, the prod...

Embodiment 2

[0020] Be the graphite of 10 parts, the monosuccinimide of 10 parts by parts by weight (the same below), the base oil of 13 parts of 500SN, the base oil of 52 parts of 150SN adds in the emulsification kettle and carries out dispersion emulsification 2 hours, in Under the action of the high-speed shear emulsifier, the temperature is automatically raised to 70°C, and the product is transported to the dehydration kettle for heating, vacuumed and dehydrated under negative pressure. The heating temperature is controlled at about 67°C, the negative pressure is controlled at 0.08Pa, and the time is 2.5 hours. Transfer the product back to the emulsification tank, add 15 parts of polymethacrylate, emulsify and disperse for 2 hours, and then transfer the product back to the dehydration tank for heat preservation and dehydration for 1 hour. The temperature of the heat preservation is controlled at about 67°C, and the product is filtered out Finished products, the filter diameter is contro...

Embodiment 3

[0022] Be the graphite of 15 parts, the bis-succinimide of 15 parts by parts by weight (the same below), the base oil of 16 parts of 500SN, the base oil of 64 parts of 150SN adds in the emulsification kettle and carries out dispersion emulsification 3 hours, in Under the action of the emulsifier, the temperature is automatically raised to 80°C, and the product is transported to the dehydration kettle for heating, vacuumed and dehydrated, the heating temperature is controlled at 75°C, the negative pressure is controlled at 0.09Mpa, and the time is 3 hours, and the product is transported again Add 20 parts of dispersed polymethacrylate to the emulsification kettle, emulsify and disperse for 3 hours, then transport the product back to the dehydration kettle for heat preservation and dehydration, and keep the heat preservation temperature at 75°C for 1.5 hours, filter the product out of the finished product, and filter The filter diameter is controlled at no more than 10 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com