Multi-grade using backheating drain residual heat generator of thermal power generator set

A technology for thermal power units and waste heat power generation, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc. It can solve the problems of untapped potential and explore the energy-saving potential lag of thermal systems, so as to improve the degree of thermodynamic perfection, improve output, and have application prospects broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

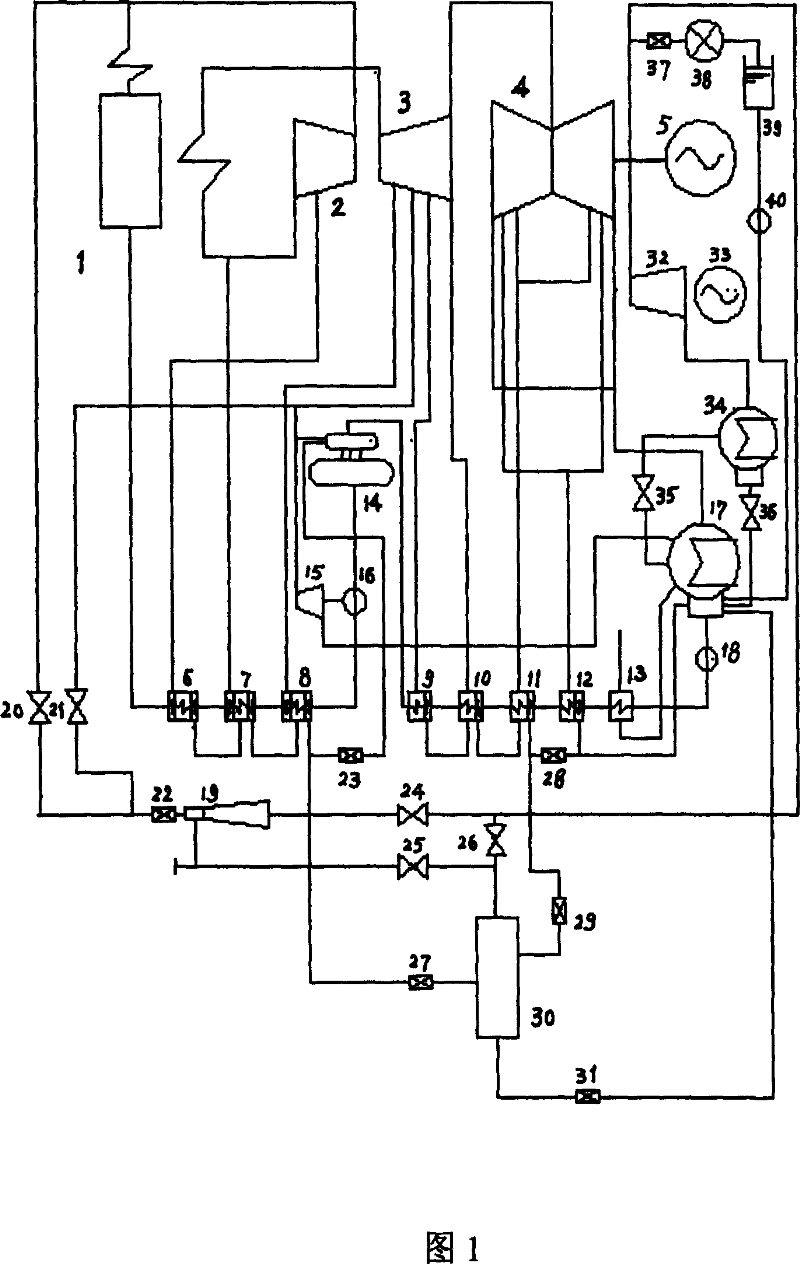

[0008] Figure 1 shows the principle thermodynamic system of the power plant of the present invention. The system shown in the figure combines the heat recovery cycle of the thermal power unit with the thermal system of the multi-stage waste heat power generation device using heat recovery and drainage, in which the steam ejector is combined with the decompression expander to generate low-pressure steam to drive the low-pressure steam turbine. The system shown in Fig. 1 includes a boiler 1 for intermediate reheating of the steam of a thermal power unit. The primary steam generated enters the high-pressure cylinder 2 of the steam turbine for work, and the secondary steam exhausted from the high-pressure cylinder enters the medium-pressure cylinder 3 of the steam turbine after being reheated by the boiler. Work, and then enter the main condenser 17 after the low-pressure cylinder 4 of the steam turbine does work, and complete the conversion of thermal energy and mechanical energy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com