Safety valve for timer

A safety valve and timer technology, applied in the field of safety valves, can solve problems such as the deterioration of the sealing characteristics of the safety valve, and achieve the effect of good sealing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

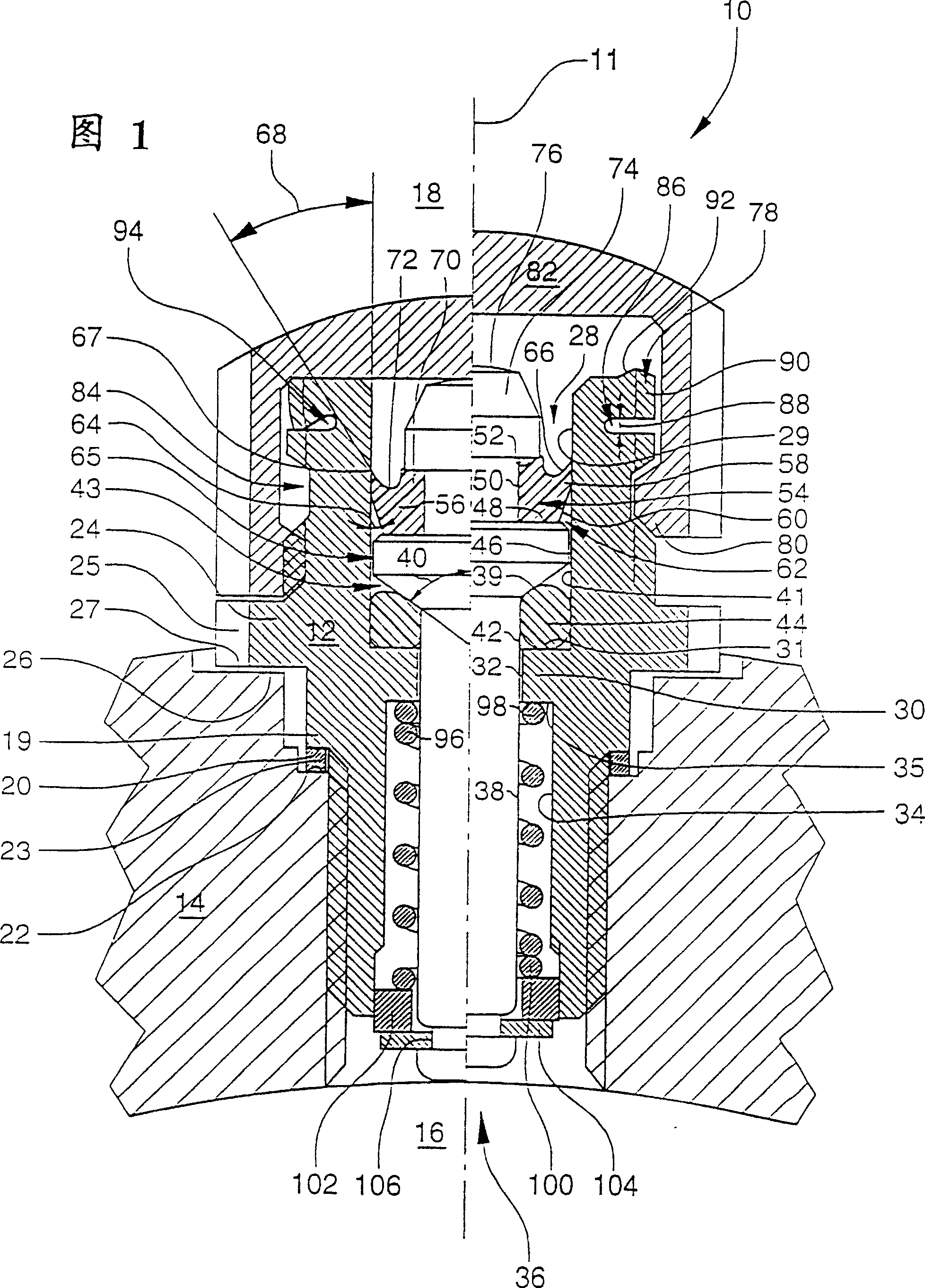

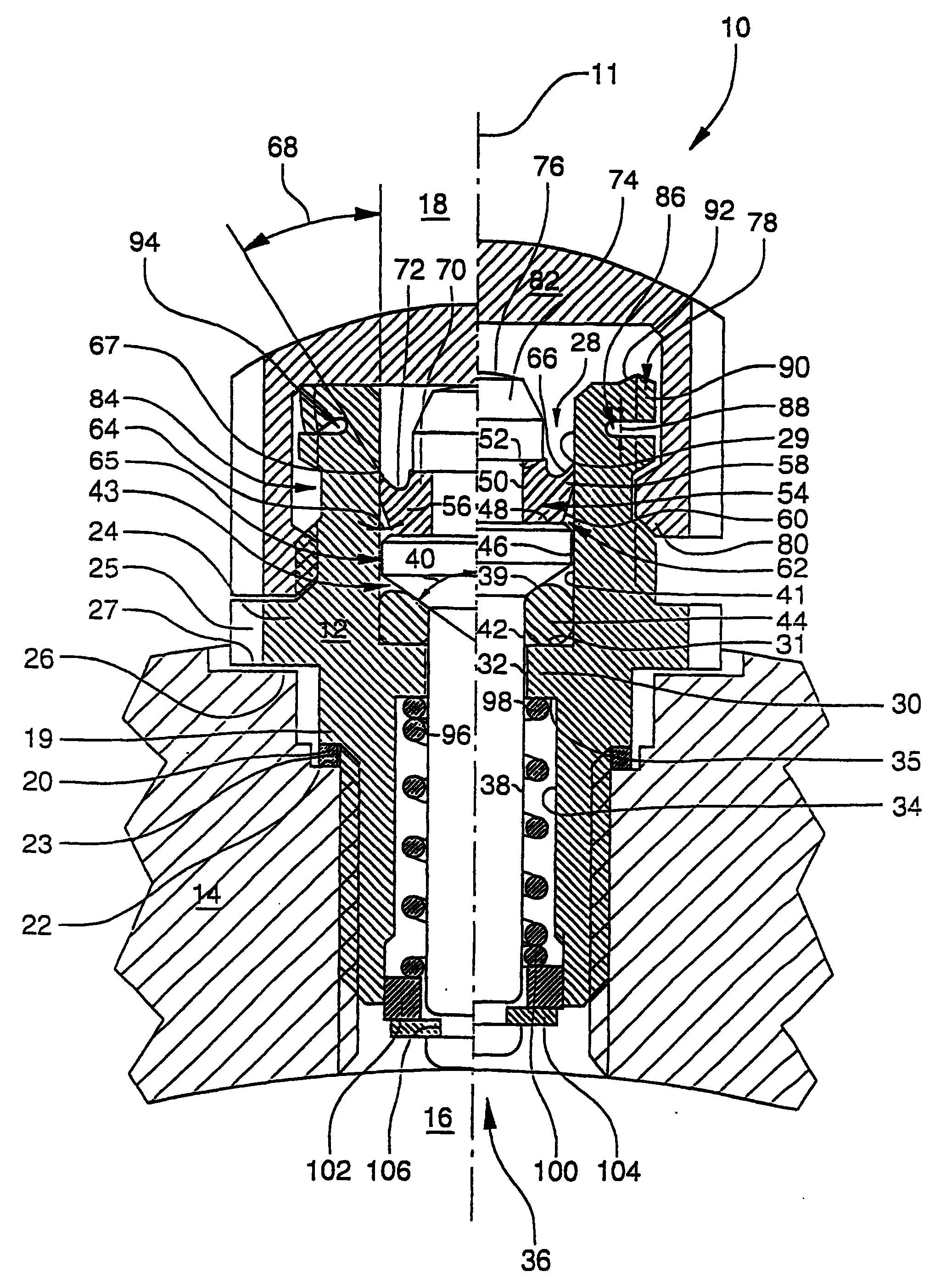

[0043] Figure 1 shows one embodiment of the safety valve of the present invention. The safety valve 10 is substantially rotationally symmetric with respect to the axis 11 and comprises a continuous hollow sleeve 12 screwed onto the only partially shown central part 14 or the exterior of the timepiece. An interior space 16 located below the figure is formed in the timepiece, which space is airtightly separated from the environment 18 located above the figure.

[0044] The outer side of the sleeve 12 includes a shoulder 19 with a bearing surface 20 which is annular relative to the axis and faces the housing 14 . A metal sealing ring 23 is arranged between this bearing surface and the corresponding annular bearing surface 22 of the housing 14 , the sealing ring 23 in this position isolating the space 16 from the environment 18 .

[0045] In order to screw the sleeve 12 , or rather the safety valve 10 , into the central part using, for example, a fitting key, the sleeve 12 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com