Sand-proof tube for oilfield

A technology for sand control pipes and oil fields, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc. The effect of improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

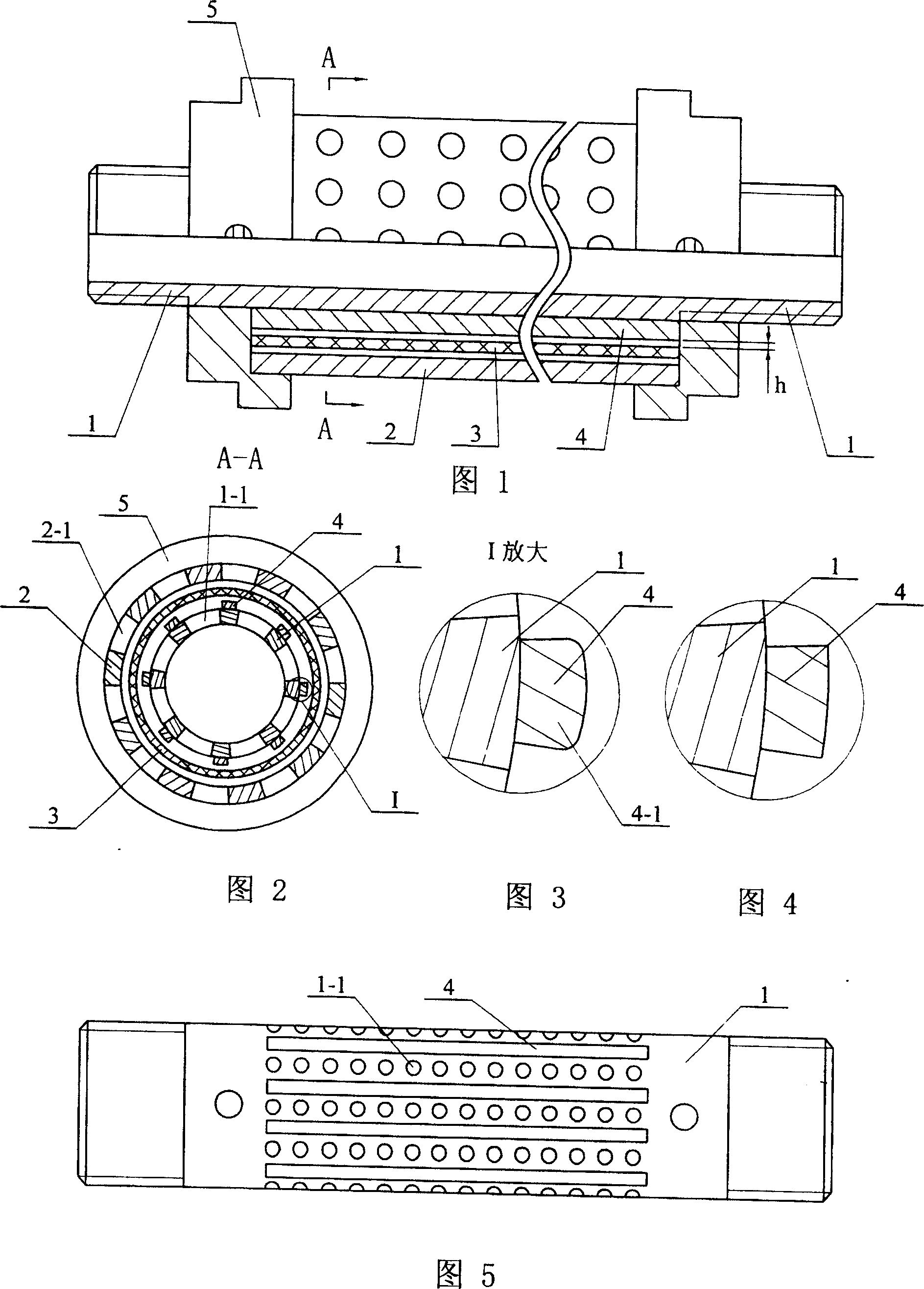

[0005] Specific embodiment 1: Referring to Fig. 1 and Fig. 2, this embodiment is an oil field sand control pipe, which includes an inner pipe 1, an outer pipe 2, and a net sleeve 3 arranged between the inner pipe 1 and the outer pipe 2, and the outer pipe 2 Clamps 5 are installed at both ends of the inner tube 1, and a slat 4 is axially fixed on the outer wall of the inner tube 1, and a net cover 3 is arranged on the outside of the slat 4, and the inner surface of the net cover 3 and the outer surface of the slat 4 The distance h is 1-2 mm, and the gap between the mesh sleeve (3) and the outer pipe (2) is 1-2 mm. Appropriate gaps are left between the net sleeve and the slats 4 and the outer tube. This gap allows the net sleeve to have free rotation space. This space for the net sleeve to rotate will make the net sleeve clamp on the net during the vibration process. The sand and gravel in the casing are removed, thereby avoiding the blockage of the mesh casing in a large area a...

specific Embodiment approach 2

[0006] Specific embodiment two: with reference to Fig. 3, the slats 4 of the present embodiment are evenly distributed on the outer wall circumference of the inner tube 1, the upper surface 4-1 of the slats 4 is a circular arc surface, and the lower surface of the slats 4 is in line with the inner wall. The outer wall of the tube 1 is adapted to the arc surface. The lower surface of the slat 4 is set as an arc surface adapted to the outer wall of the inner tube 1, which can ensure that the connection between the slat 4 and the inner tube is more firmly; the upper surface of the slat 4 is set as an arc surface, which can avoid During the vibration process, the mesh sleeve rubs against the slats and the mesh sleeve is damaged, thus ensuring the service life of the mesh sleeve.

specific Embodiment approach 3

[0007] Embodiment 3: Referring to FIG. 4 , the cross section of the slat 4 in this embodiment is rectangular, and the lower surface of the slat 4 is compatible with the outer wall of the inner tube 1 . The lower surface of the slat 4 is adapted to the outer wall of the inner pipe 1, which can ensure a firm connection between the slat and the inner pipe; under the condition that the mesh cover does not rub against the slat, the slat with a rectangular cross-section has the advantages of convenient processing. , The advantages of saving processing time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com