Back action mechanism of belt type stepless gear

A transmission and reverse gear technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of being unable to use low-cost and smooth-shifting belt-type stepless speed change mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

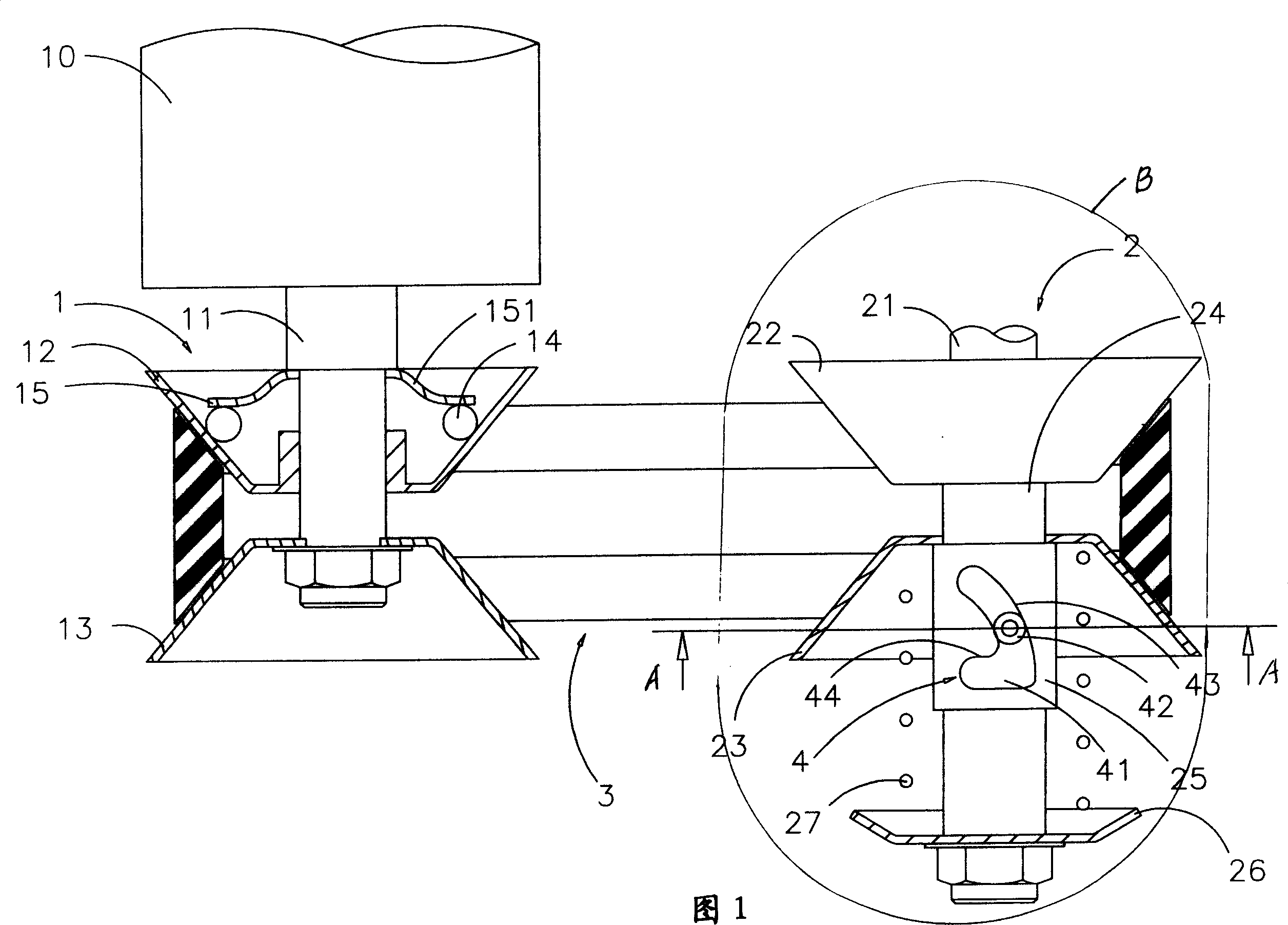

[0035] As shown in FIG. 1 , the present invention includes a front pulley 1 , a power source 10 , a rear pulley 2 , a band 3 and a torsion cam group 4 .

[0036] The front pulley 1 and the power source 10 are set on the front rotating shaft 11 .

[0037] The power source 10 is an engine or an electric motor capable of outputting forward and reverse rotation power.

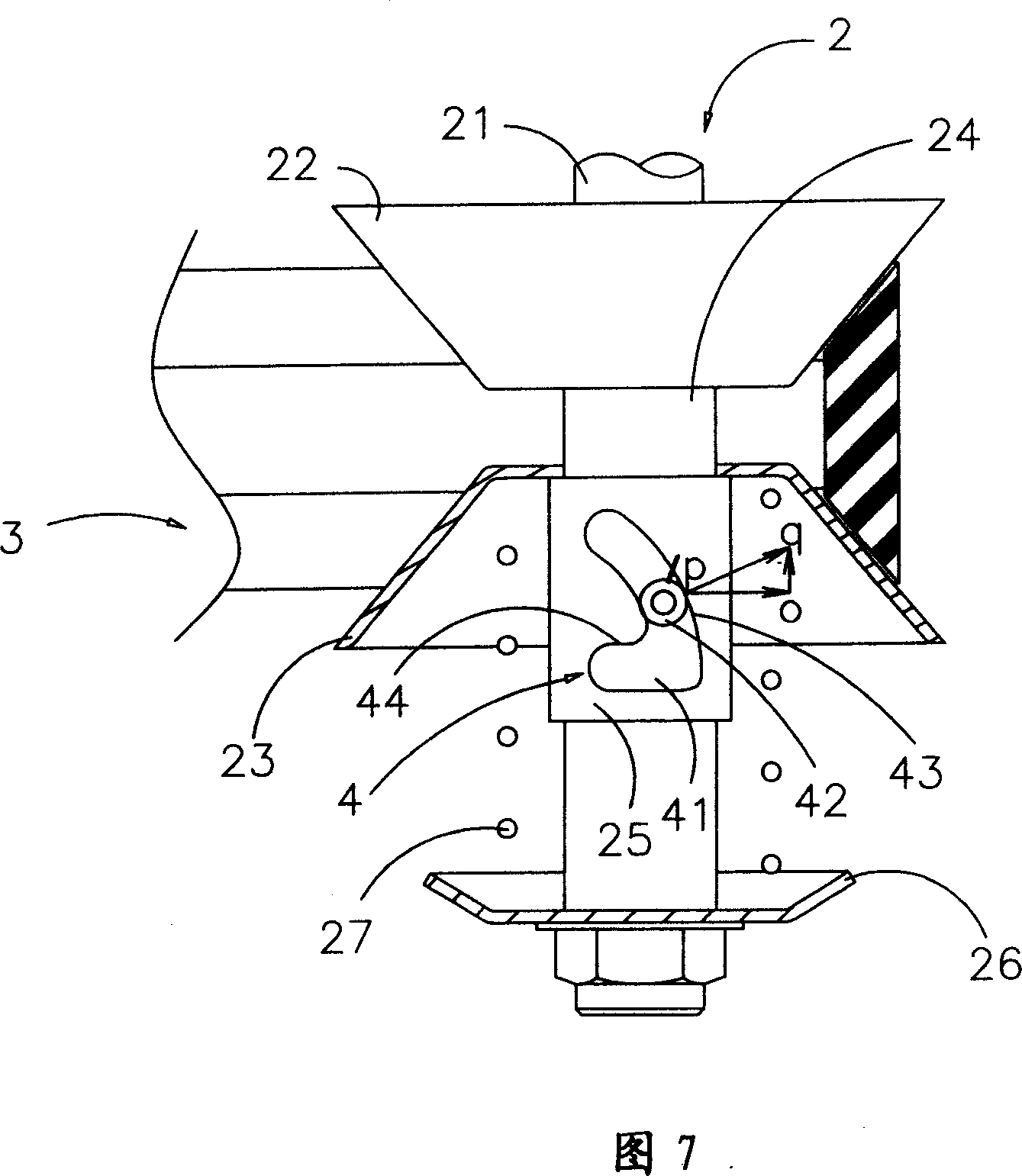

[0038] 2 sets of rear pulleys are arranged on the rear rotating shaft 21 .

[0039] The belt loop 3 is a V-shaped belt or a composite metal chain belt, which is sheathed on the front pulley 1 and the rear pulley 2 .

[0040] The torsion cam group 4 is located on the rear pulley 2 . By means of the above components, the belt type continuously variable transmission can output forward and reverse power.

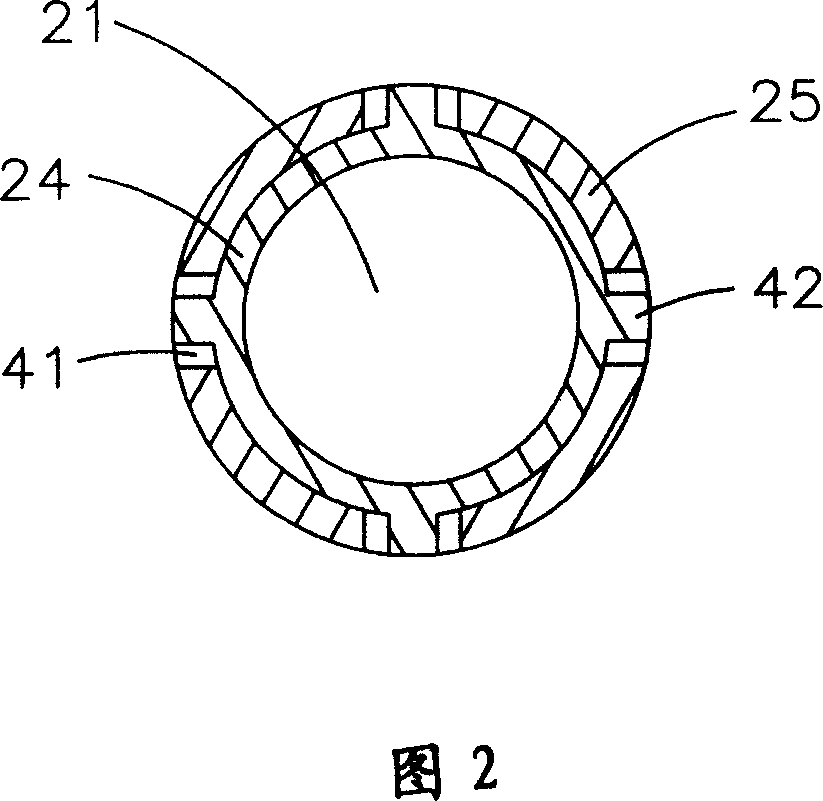

[0041]As shown in Fig. 1 and Fig. 2, the front pulley 1 assembled on the front rotating shaft 11 is made up of a front movable half-wheel 12 and a front fixed half-wheel 13. The front movable half wheel 12 is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com