Brushless electric machine contrller for electric vehicle

A technology for brushless motors and electric vehicles, which is applied in fields such as excitation or armature current control, electronic commutators, etc., and can solve problems such as not having its own anti-theft function, vehicle structure damage, and noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

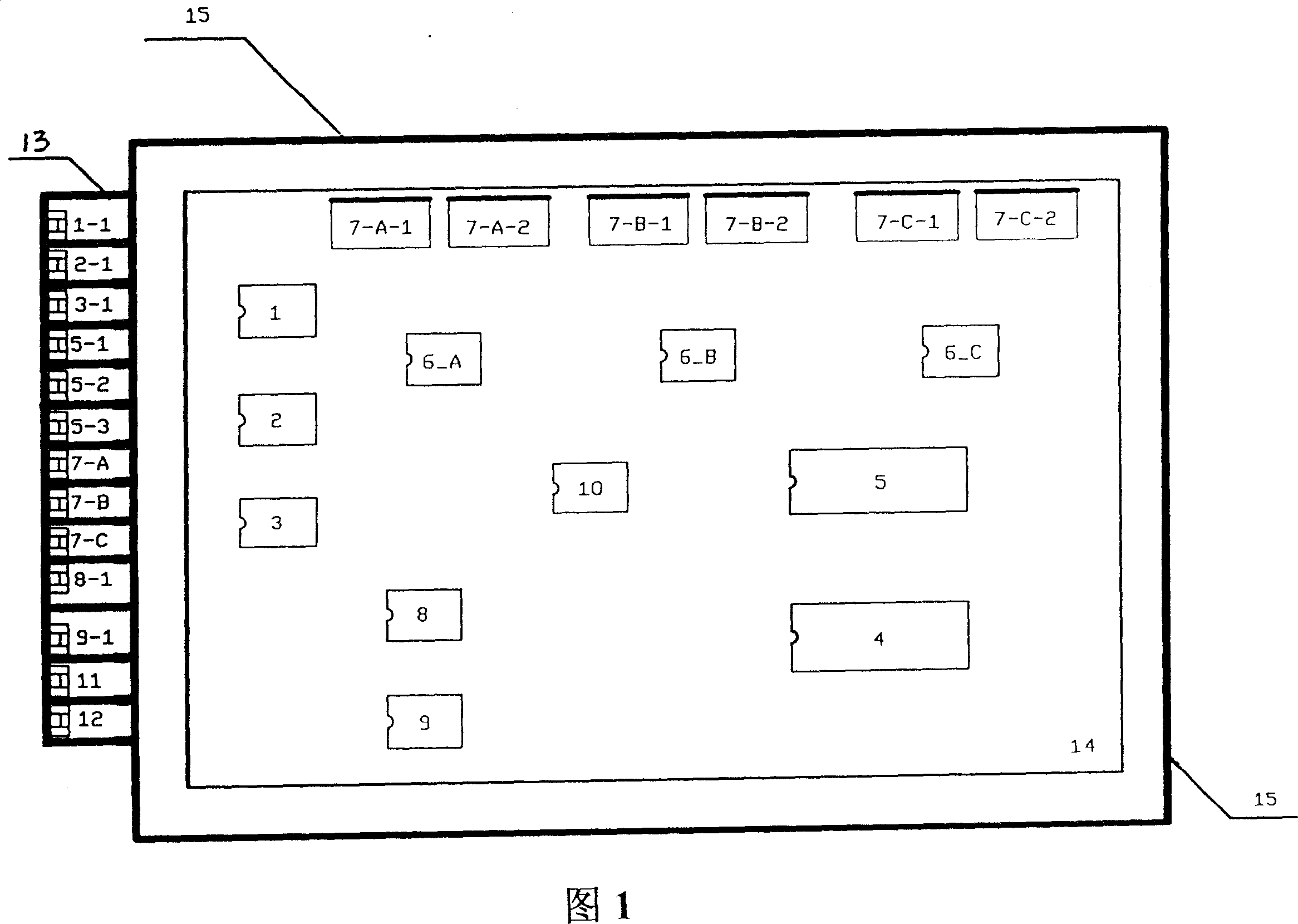

[0025] The present invention is mainly composed of a box body 15 with a control circuit board 14 inside, a fixed integrated wiring port 13 placed on the box body 15, and the like.

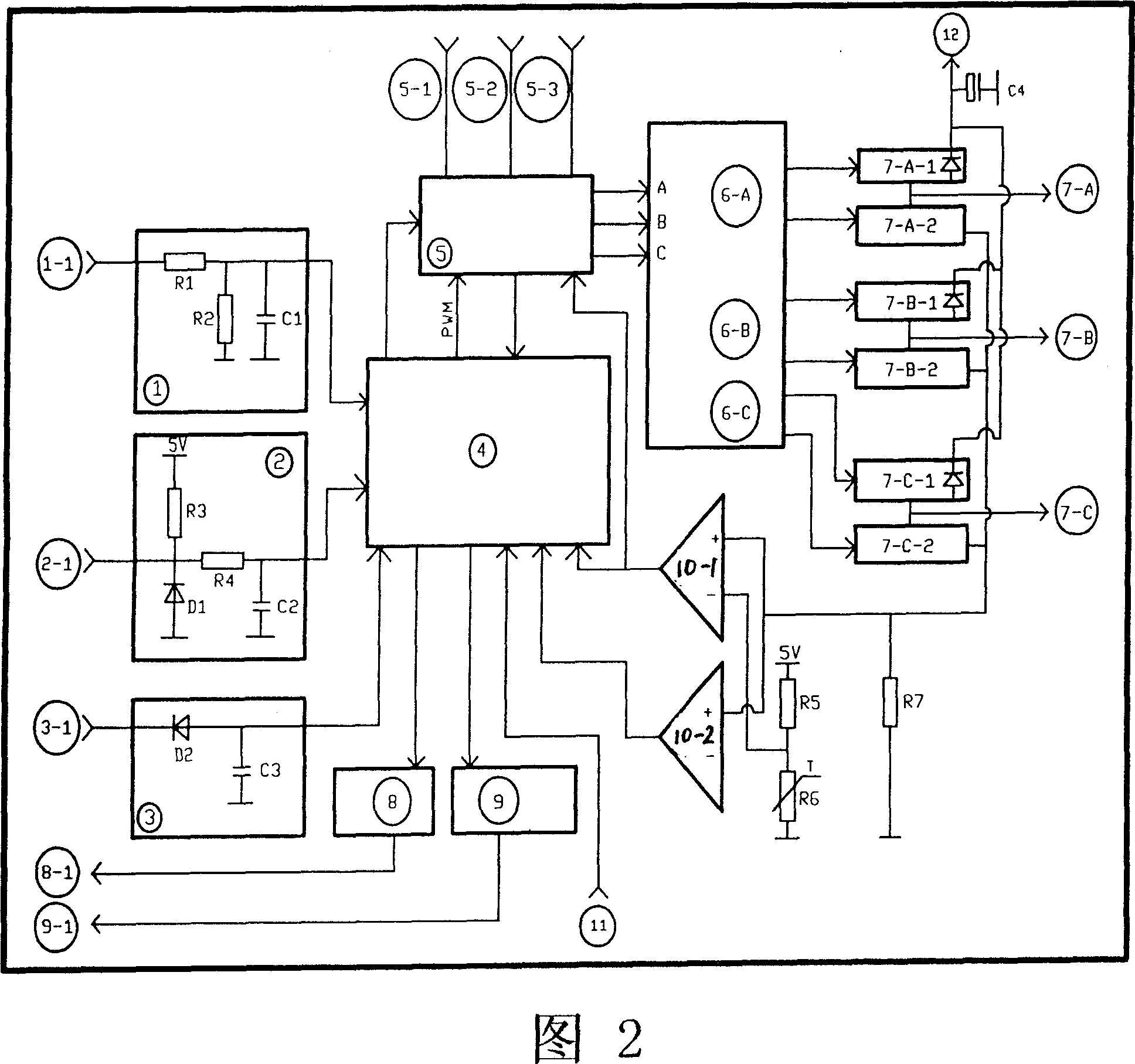

[0026] The control circuit board 14 is provided with a speed regulation value processing circuit 1 composed of a current-limiting resistor R1, a grounding resistor R2, and a filter capacitor C1. Cruise value processing circuit 2 composed of diode D2 and filter capacitor C3, etc., brake signal processing circuit 3, central processing unit 4, Hall decoding and processing logic gate circuit 5, power tube drive circuit 6-A, 6 -B, 6-C, power tube output circuit 7-A-1, 7-A-2, 7-B-1, 7-B-2, 7-C-1, 7-C-2, brake light drive Circuit 8, speaker drive circuit 9, double overcurrent protection circuit 10 composed of comparator 10-1, amplifier 10-2, voltage dividing resistor R5, temperature resistor R6, sampling resistor R7, etc. Central processing unit 4 communicates with power tube output circuits 7-A-1, 7-A-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com