Displacement sensor with single grating

A technology of displacement sensor and single grating, applied in the field of sensors, can solve the problems of high cost, complex optical path and circuit, and lack of popularization and promotion, and achieve the effects of wide application range, low cost, and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

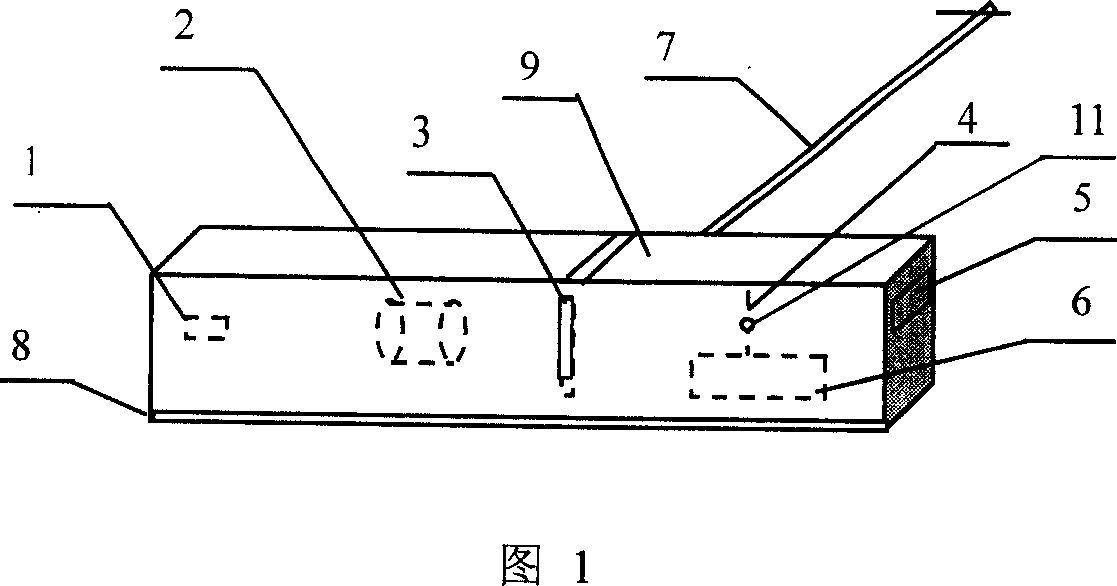

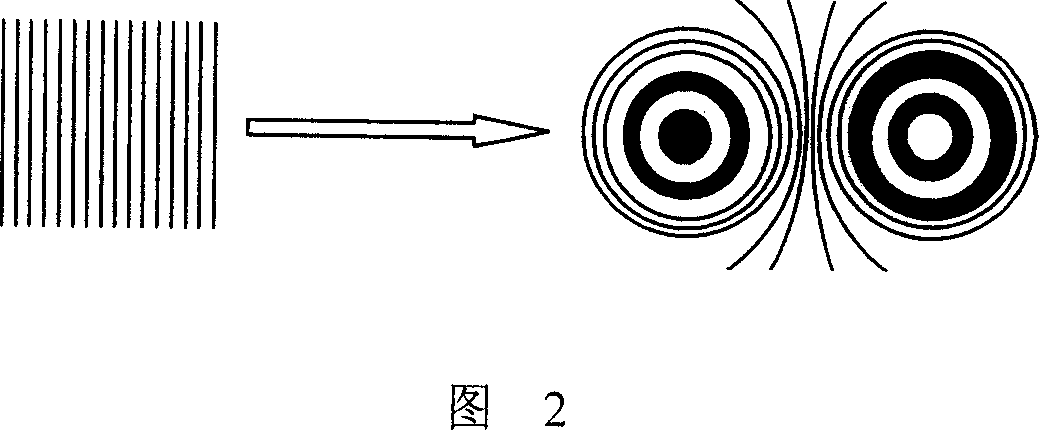

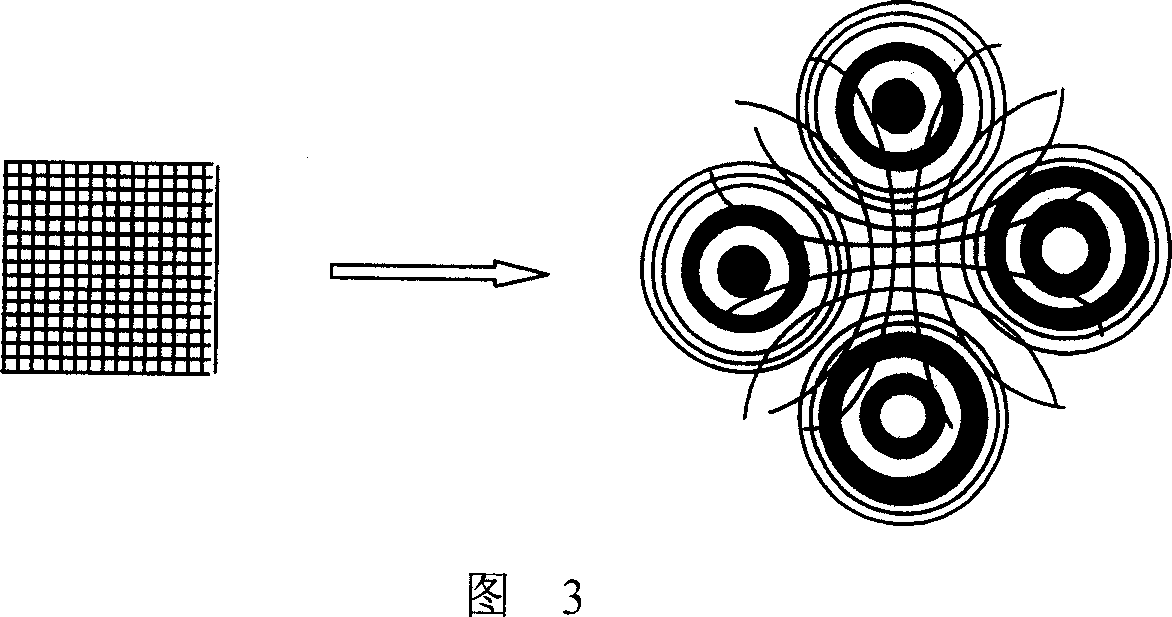

[0022] A single grating displacement sensor of the present invention, as shown in Figure 1: an optical lens 2 is set between the light source 1 and the grating 3, the extended light of the light source 1 is focused on the grating 3 through the optical lens 2, and then projected on the light screen 4 superior. A photosensitive probe 11 is arranged on the light screen 4 and connected to the circuit 6 and the display system 5 . The light source 1 of the sensor is a laser pointer, the optical lens 2 is a common convex lens, the light screen 4 is frosted glass, they are fixed on the base 8, the grating 3 is a transmissive one-dimensional sinusoidal grating, and a horizontal one-dimensional slide bar 7 are connected into one body, and the photosensitive probe 11 adopts a photosensitive diode. The optical lens focuses an expanded light on the grating and adjusts it appropriately. After the grating is processed by this light, the grid lines of the grating are enlarged and deformed, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com