Composite spinning component entities including double constituents

A composite spinning, two-component technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems affecting the quality of melt fiber products, fast filter boosting speed, and short component life cycle. problems, to achieve the effect of prolonging the continuous operation time, saving the consumption of raw materials, and improving the production capacity of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

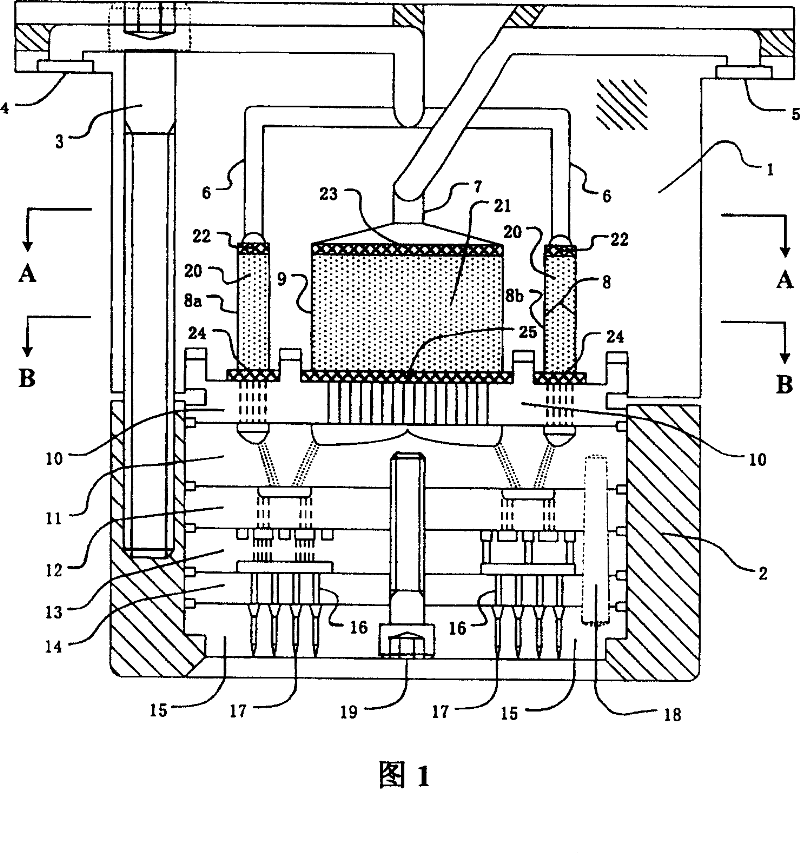

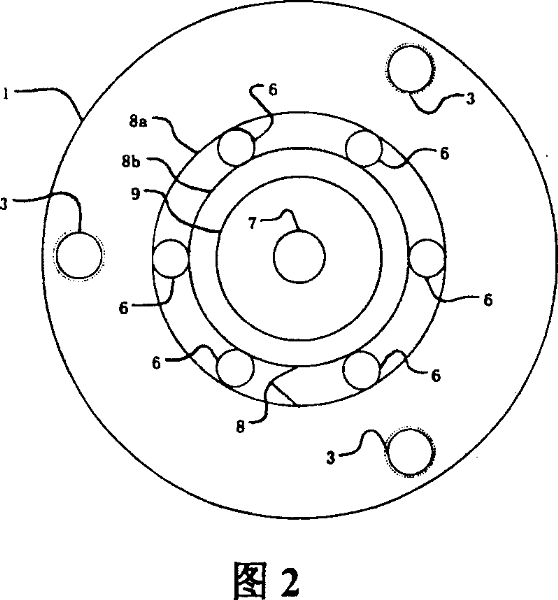

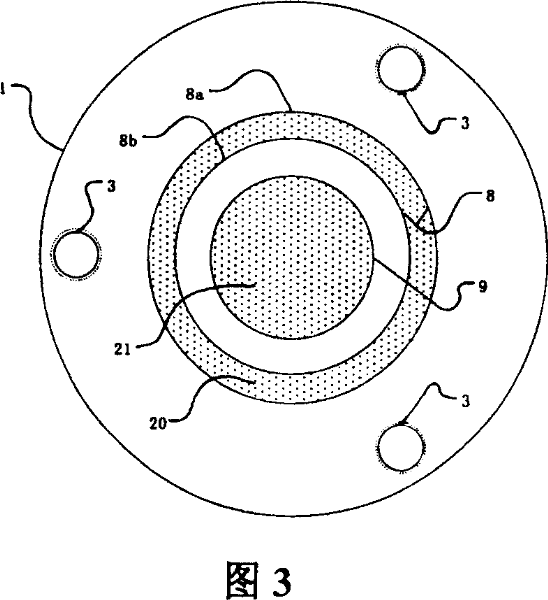

[0021] The present invention will be further described in detail below by taking the production of island-in-sea polyester composite fibers as an example in conjunction with the accompanying drawings.

[0022] As shown in Figures 1 to 3, the assembly as a whole is composed of an upper shell 1 and a lower shell 2 which are fixed with bolts 3 and then enclosed. There are two melt inlets 4 and 5 on the upper side of the upper casing 1, and the PET (polyethylene terephthalate) melt enters the upper casing 1 from the inlet 4, and passes through 3~ Eight connecting pipes 6 enter the annular sand chamber 8; COPET (water-soluble polyester) melt enters the middle position of the upper shell 1 from the inlet 5, and enters the sand tank 9 through the trumpet-shaped connecting pipe 7. The relative positions of the outer wall 8a and the inner wall 8b of the annular sand cavity 8 and the outer wall of the sand tank 9 are concentric circles. The ratio of the radii is: 0.39:1. The ring-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com