Throttle Body Optimization for Waste Management Systems

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution

The throttle body has undergone significant evolution in waste management systems, transitioning from simple mechanical devices to sophisticated electronic components. Initially, throttle bodies in waste management vehicles were purely mechanical, controlled by cables connected to the accelerator pedal. These early designs were prone to wear and tear, requiring frequent maintenance and adjustment.

As electronic fuel injection systems became more prevalent in the 1980s and 1990s, throttle bodies began incorporating electronic controls. This shift marked a crucial turning point, allowing for more precise control over engine performance and emissions. The introduction of drive-by-wire technology in the late 1990s further revolutionized throttle body design, eliminating the need for mechanical linkages entirely.

In the context of waste management systems, the evolution of throttle bodies has been closely tied to the need for improved fuel efficiency and reduced emissions. Modern throttle bodies in waste collection vehicles now incorporate advanced sensors and actuators, enabling real-time adjustments based on engine load, vehicle speed, and environmental conditions. This level of control is particularly crucial in stop-and-go urban environments where waste collection vehicles operate.

The integration of throttle bodies with engine management systems has led to the development of intelligent throttle control algorithms. These algorithms optimize fuel delivery and air intake based on the specific operational demands of waste management vehicles, such as frequent stops, idling periods, and varying load conditions. This optimization has resulted in significant improvements in fuel economy and reduced emissions, aligning with increasingly stringent environmental regulations.

Recent advancements have seen the incorporation of variable geometry throttle bodies in some waste management vehicle applications. These designs allow for dynamic adjustment of the throttle opening size, providing optimal airflow across a wider range of operating conditions. This innovation has further enhanced engine performance and efficiency, particularly during low-speed operation and when the vehicle is under heavy load.

The latest generation of throttle bodies in waste management systems also features enhanced durability and reliability. Given the harsh operating conditions and extended service hours of waste collection vehicles, manufacturers have focused on developing throttle bodies with improved corrosion resistance, thermal management, and wear characteristics. This evolution has led to reduced maintenance requirements and increased uptime for waste management fleets.

Looking forward, the throttle body evolution in waste management systems is likely to continue, with a focus on further integration with hybrid and electric powertrain technologies. As the industry moves towards more sustainable solutions, throttle bodies will play a crucial role in optimizing the performance of range-extended electric vehicles and hybrid waste collection trucks, balancing power delivery between conventional engines and electric motors.

As electronic fuel injection systems became more prevalent in the 1980s and 1990s, throttle bodies began incorporating electronic controls. This shift marked a crucial turning point, allowing for more precise control over engine performance and emissions. The introduction of drive-by-wire technology in the late 1990s further revolutionized throttle body design, eliminating the need for mechanical linkages entirely.

In the context of waste management systems, the evolution of throttle bodies has been closely tied to the need for improved fuel efficiency and reduced emissions. Modern throttle bodies in waste collection vehicles now incorporate advanced sensors and actuators, enabling real-time adjustments based on engine load, vehicle speed, and environmental conditions. This level of control is particularly crucial in stop-and-go urban environments where waste collection vehicles operate.

The integration of throttle bodies with engine management systems has led to the development of intelligent throttle control algorithms. These algorithms optimize fuel delivery and air intake based on the specific operational demands of waste management vehicles, such as frequent stops, idling periods, and varying load conditions. This optimization has resulted in significant improvements in fuel economy and reduced emissions, aligning with increasingly stringent environmental regulations.

Recent advancements have seen the incorporation of variable geometry throttle bodies in some waste management vehicle applications. These designs allow for dynamic adjustment of the throttle opening size, providing optimal airflow across a wider range of operating conditions. This innovation has further enhanced engine performance and efficiency, particularly during low-speed operation and when the vehicle is under heavy load.

The latest generation of throttle bodies in waste management systems also features enhanced durability and reliability. Given the harsh operating conditions and extended service hours of waste collection vehicles, manufacturers have focused on developing throttle bodies with improved corrosion resistance, thermal management, and wear characteristics. This evolution has led to reduced maintenance requirements and increased uptime for waste management fleets.

Looking forward, the throttle body evolution in waste management systems is likely to continue, with a focus on further integration with hybrid and electric powertrain technologies. As the industry moves towards more sustainable solutions, throttle bodies will play a crucial role in optimizing the performance of range-extended electric vehicles and hybrid waste collection trucks, balancing power delivery between conventional engines and electric motors.

Market Demand Analysis

The market demand for throttle body optimization in waste management systems has been steadily increasing due to the growing emphasis on environmental sustainability and operational efficiency. Waste management companies are increasingly seeking ways to reduce emissions, improve fuel efficiency, and enhance overall system performance. This has led to a significant rise in the adoption of advanced throttle body technologies across the waste management sector.

The global waste management market is projected to reach $530 billion by 2025, with a compound annual growth rate of 6.4% from 2020 to 2025. A substantial portion of this growth is attributed to the implementation of innovative technologies, including optimized throttle bodies in waste collection and processing equipment. The demand for these optimized systems is particularly strong in developed regions such as North America and Europe, where stringent environmental regulations drive the need for more efficient and cleaner waste management operations.

In the United States alone, the waste management industry generates over $85 billion in annual revenue, with a significant portion allocated to equipment upgrades and technological advancements. The market for throttle body optimization in this sector is expected to grow at a rate of 4.8% annually over the next five years, reflecting the industry's commitment to improving operational efficiency and reducing environmental impact.

Emerging economies, particularly in Asia-Pacific and Latin America, are also showing increased interest in throttle body optimization for waste management systems. As these regions grapple with rapid urbanization and growing waste volumes, there is a pressing need for more efficient and environmentally friendly waste management solutions. This trend is expected to drive market growth in these regions at a rate of 7.2% annually over the next decade.

The demand for throttle body optimization is further fueled by the rising focus on smart cities and IoT-enabled waste management systems. These advanced systems require precise control over vehicle and equipment performance, making optimized throttle bodies an essential component. The smart waste management market is projected to reach $3.6 billion by 2027, with throttle body optimization playing a crucial role in this growth.

Additionally, the increasing adoption of electric and hybrid waste collection vehicles is creating new opportunities for throttle body optimization. These vehicles require sophisticated throttle control systems to maximize energy efficiency and range, further driving demand in this sector. The electric waste collection vehicle market is expected to grow at a CAGR of 14.3% from 2021 to 2028, presenting significant opportunities for throttle body optimization technologies.

The global waste management market is projected to reach $530 billion by 2025, with a compound annual growth rate of 6.4% from 2020 to 2025. A substantial portion of this growth is attributed to the implementation of innovative technologies, including optimized throttle bodies in waste collection and processing equipment. The demand for these optimized systems is particularly strong in developed regions such as North America and Europe, where stringent environmental regulations drive the need for more efficient and cleaner waste management operations.

In the United States alone, the waste management industry generates over $85 billion in annual revenue, with a significant portion allocated to equipment upgrades and technological advancements. The market for throttle body optimization in this sector is expected to grow at a rate of 4.8% annually over the next five years, reflecting the industry's commitment to improving operational efficiency and reducing environmental impact.

Emerging economies, particularly in Asia-Pacific and Latin America, are also showing increased interest in throttle body optimization for waste management systems. As these regions grapple with rapid urbanization and growing waste volumes, there is a pressing need for more efficient and environmentally friendly waste management solutions. This trend is expected to drive market growth in these regions at a rate of 7.2% annually over the next decade.

The demand for throttle body optimization is further fueled by the rising focus on smart cities and IoT-enabled waste management systems. These advanced systems require precise control over vehicle and equipment performance, making optimized throttle bodies an essential component. The smart waste management market is projected to reach $3.6 billion by 2027, with throttle body optimization playing a crucial role in this growth.

Additionally, the increasing adoption of electric and hybrid waste collection vehicles is creating new opportunities for throttle body optimization. These vehicles require sophisticated throttle control systems to maximize energy efficiency and range, further driving demand in this sector. The electric waste collection vehicle market is expected to grow at a CAGR of 14.3% from 2021 to 2028, presenting significant opportunities for throttle body optimization technologies.

Technical Challenges

The optimization of throttle bodies in waste management systems faces several significant technical challenges that require innovative solutions. One of the primary obstacles is the need for precise control over airflow in varying environmental conditions. Waste management systems often operate in diverse settings, from landfills to recycling facilities, where temperature, humidity, and particulate matter can fluctuate dramatically. These variations can affect the performance of throttle bodies, leading to inconsistent waste processing and reduced efficiency.

Another critical challenge lies in the corrosive nature of waste materials. The throttle bodies in waste management systems are exposed to a wide range of chemicals and abrasive substances, which can rapidly degrade components and compromise functionality. Developing materials and coatings that can withstand these harsh conditions while maintaining optimal performance is a complex engineering task that demands continuous research and development.

The integration of smart technologies into throttle body systems presents both opportunities and challenges. While sensors and IoT connectivity can enhance control and monitoring capabilities, they also introduce new vulnerabilities to system failures and cybersecurity risks. Balancing the benefits of advanced technology with the need for robust, fail-safe operation is a delicate engineering challenge that requires careful consideration.

Energy efficiency is another crucial aspect that engineers must address. Waste management systems are often large-scale operations with significant energy demands. Optimizing throttle bodies to minimize energy consumption while maintaining or improving performance is essential for both environmental and economic reasons. This optimization process involves complex fluid dynamics and mechanical engineering principles to achieve the ideal balance between power and efficiency.

Scalability and adaptability pose additional technical hurdles. Waste management systems vary greatly in size and capacity, from small municipal operations to large industrial facilities. Developing throttle body solutions that can be effectively scaled and adapted to different system requirements without compromising performance or efficiency is a significant engineering challenge. This includes designing modular components and flexible control systems that can be easily customized for specific applications.

Lastly, the regulatory landscape surrounding waste management is constantly evolving, with increasingly stringent environmental standards. Throttle body optimization must not only meet current regulations but also anticipate future requirements. This forward-looking approach necessitates ongoing research into emission reduction technologies and cleaner processing methods, adding another layer of complexity to the development process.

Another critical challenge lies in the corrosive nature of waste materials. The throttle bodies in waste management systems are exposed to a wide range of chemicals and abrasive substances, which can rapidly degrade components and compromise functionality. Developing materials and coatings that can withstand these harsh conditions while maintaining optimal performance is a complex engineering task that demands continuous research and development.

The integration of smart technologies into throttle body systems presents both opportunities and challenges. While sensors and IoT connectivity can enhance control and monitoring capabilities, they also introduce new vulnerabilities to system failures and cybersecurity risks. Balancing the benefits of advanced technology with the need for robust, fail-safe operation is a delicate engineering challenge that requires careful consideration.

Energy efficiency is another crucial aspect that engineers must address. Waste management systems are often large-scale operations with significant energy demands. Optimizing throttle bodies to minimize energy consumption while maintaining or improving performance is essential for both environmental and economic reasons. This optimization process involves complex fluid dynamics and mechanical engineering principles to achieve the ideal balance between power and efficiency.

Scalability and adaptability pose additional technical hurdles. Waste management systems vary greatly in size and capacity, from small municipal operations to large industrial facilities. Developing throttle body solutions that can be effectively scaled and adapted to different system requirements without compromising performance or efficiency is a significant engineering challenge. This includes designing modular components and flexible control systems that can be easily customized for specific applications.

Lastly, the regulatory landscape surrounding waste management is constantly evolving, with increasingly stringent environmental standards. Throttle body optimization must not only meet current regulations but also anticipate future requirements. This forward-looking approach necessitates ongoing research into emission reduction technologies and cleaner processing methods, adding another layer of complexity to the development process.

Current Solutions

01 Throttle body design optimization

Optimizing the design of throttle bodies to improve airflow and engine performance. This includes modifications to the shape, size, and internal components of the throttle body to enhance air intake efficiency and responsiveness.- Throttle body design optimization: Optimizing the design of throttle bodies involves improving airflow characteristics, reducing turbulence, and enhancing overall engine performance. This can include modifications to the shape, size, and internal geometry of the throttle body to maximize efficiency and responsiveness.

- Electronic throttle control systems: Implementation of electronic throttle control systems for precise management of airflow into the engine. These systems use sensors and actuators to adjust throttle position based on various inputs, improving fuel efficiency and engine performance.

- Throttle body cleaning and maintenance: Development of methods and devices for cleaning and maintaining throttle bodies to prevent carbon buildup and ensure optimal performance. This includes automated cleaning systems and specialized cleaning solutions to remove deposits that can affect throttle operation.

- Integration with engine management systems: Enhancing the integration of throttle bodies with engine management systems for improved coordination between air intake, fuel injection, and ignition timing. This involves advanced algorithms and communication protocols to optimize overall engine performance.

- Throttle body materials and manufacturing: Advancements in materials and manufacturing processes for throttle bodies, focusing on lightweight, durable materials and precision manufacturing techniques. This includes the use of advanced alloys and 3D printing technologies to create more efficient and reliable throttle bodies.

02 Electronic throttle control systems

Implementation of electronic throttle control systems to improve precision and responsiveness. These systems use sensors and actuators to regulate airflow more accurately, enhancing fuel efficiency and engine performance.Expand Specific Solutions03 Throttle body cleaning and maintenance

Development of methods and devices for cleaning and maintaining throttle bodies to ensure optimal performance. This includes automated cleaning systems and specialized tools to remove carbon deposits and other contaminants that can affect throttle operation.Expand Specific Solutions04 Integration with engine management systems

Improving the integration of throttle bodies with engine management systems for better overall performance. This involves optimizing communication between the throttle body and other engine components to enhance fuel efficiency, emissions control, and power output.Expand Specific Solutions05 Adaptive throttle control algorithms

Development of adaptive throttle control algorithms that adjust throttle response based on driving conditions and driver input. These algorithms optimize throttle performance in real-time, improving drivability and fuel efficiency across various operating conditions.Expand Specific Solutions

Key Industry Players

The throttle body optimization market for waste management systems is in a growth phase, driven by increasing environmental regulations and the need for more efficient waste processing. The market size is expanding, with potential for significant growth in the coming years. Technologically, the field is advancing rapidly, with major players like Toyota, GM, and Volkswagen investing in research and development. Companies such as Caterpillar and Weichai Power are also making strides in engine optimization for waste management applications. The involvement of diverse players, from automotive giants to specialized engineering firms like AVL List, indicates a maturing technology landscape with room for innovation and market expansion.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced electronic throttle body system for waste management vehicles, incorporating precise control algorithms and robust sensors. This system optimizes fuel injection and air intake in real-time, adapting to varying load conditions typical in waste collection operations. The throttle body uses a high-precision stepper motor for accurate positioning, ensuring optimal air-fuel mixture across different engine speeds and loads[1]. Bosch's system also integrates with the vehicle's onboard diagnostics, allowing for predictive maintenance and reduced downtime[3]. The throttle body is designed with corrosion-resistant materials to withstand the harsh environments often encountered in waste management applications[5].

Strengths: Precise control, adaptability to varying loads, integration with vehicle diagnostics. Weaknesses: Potentially higher initial cost, may require specialized maintenance.

Weichai Power

Technical Solution: Weichai Power has developed a robust throttle body optimization system tailored for heavy-duty waste management vehicles. Their approach focuses on durability and efficiency in challenging environments. The throttle body incorporates a reinforced shaft and bearings capable of withstanding high-vibration conditions common in waste processing machinery[13]. Weichai's system features an adaptive learning algorithm that optimizes throttle response based on historical operational data, improving fuel efficiency over time[15]. The throttle body is also equipped with a multi-stage filtration system to prevent contamination from fine particulates, ensuring consistent performance in dusty waste management settings[17]. Additionally, Weichai has implemented a thermal management system within the throttle body to maintain optimal operating temperatures, enhancing overall engine efficiency and longevity[19].

Strengths: Exceptional durability, adaptive performance optimization, resistance to contamination. Weaknesses: May have a higher initial cost, could be overbuilt for lighter duty applications.

Core Innovations

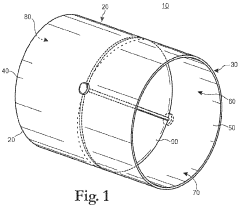

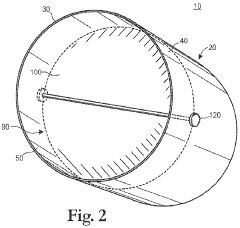

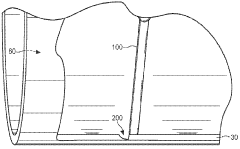

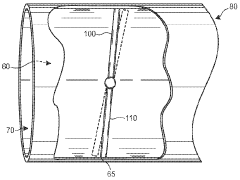

Throttle body and a method to modify a throttle body

PatentWO2010148153A2

Innovation

- Modifying the throttle body with at least one groove near the throttle plate to enhance fluid flow turbulence, creating a more complete waveform that improves air-fuel mixture vaporization and blending, thereby increasing horsepower, torque, and reducing emissions.

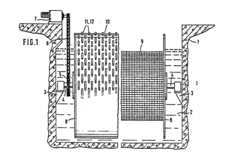

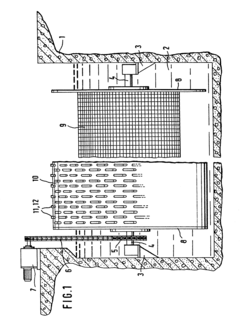

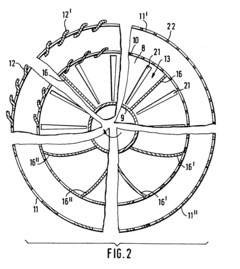

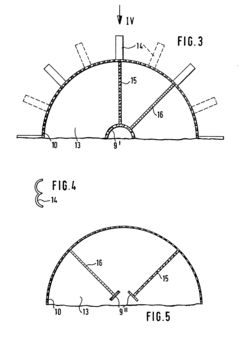

Mechanical and biological installation, and process for waste water purification

PatentInactiveEP0131236A1

Innovation

- A rotating immersion body with a concentric inner and outer pipe system, where the outer pipe is profiled to create a swirled sewage-air mixture, and filled with fillers that allow for efficient oxygen and kinetic energy introduction, ensuring constant submersion and preventing sludge settlement.

Environmental Impact

The optimization of throttle bodies in waste management systems has significant environmental implications. These systems play a crucial role in controlling emissions and improving overall efficiency, thereby reducing the ecological footprint of waste processing facilities. By fine-tuning throttle bodies, waste management operations can achieve more precise control over air and fuel mixtures, leading to more complete combustion and reduced pollutant emissions.

One of the primary environmental benefits of optimized throttle bodies is the reduction of greenhouse gas emissions. Improved combustion efficiency results in lower carbon dioxide and methane emissions, two potent greenhouse gases associated with waste management processes. This reduction contributes to mitigating climate change impacts and helps waste management facilities comply with increasingly stringent environmental regulations.

Furthermore, optimized throttle bodies can lead to a decrease in the release of particulate matter and other harmful pollutants. This improvement in air quality has far-reaching effects on both human health and surrounding ecosystems. Reduced emissions of nitrogen oxides and sulfur dioxide, for instance, can help prevent acid rain formation and minimize the impact on local flora and fauna.

Energy efficiency is another critical environmental aspect influenced by throttle body optimization. More efficient combustion processes require less fuel input for the same waste processing output, resulting in lower overall energy consumption. This reduction in energy usage not only decreases the carbon footprint of waste management facilities but also conserves valuable resources and reduces operational costs.

The environmental benefits extend to water conservation as well. Optimized throttle bodies can lead to more efficient cooling systems, reducing the amount of water required for temperature regulation in waste processing equipment. This water savings is particularly significant in regions facing water scarcity or drought conditions.

Lastly, the improved control over waste incineration processes enabled by optimized throttle bodies can result in more complete waste destruction. This efficiency reduces the volume of residual waste and potentially hazardous byproducts, minimizing the need for landfill space and decreasing the risk of soil and groundwater contamination. The overall result is a more sustainable and environmentally friendly waste management system that aligns with circular economy principles and supports long-term ecological preservation efforts.

One of the primary environmental benefits of optimized throttle bodies is the reduction of greenhouse gas emissions. Improved combustion efficiency results in lower carbon dioxide and methane emissions, two potent greenhouse gases associated with waste management processes. This reduction contributes to mitigating climate change impacts and helps waste management facilities comply with increasingly stringent environmental regulations.

Furthermore, optimized throttle bodies can lead to a decrease in the release of particulate matter and other harmful pollutants. This improvement in air quality has far-reaching effects on both human health and surrounding ecosystems. Reduced emissions of nitrogen oxides and sulfur dioxide, for instance, can help prevent acid rain formation and minimize the impact on local flora and fauna.

Energy efficiency is another critical environmental aspect influenced by throttle body optimization. More efficient combustion processes require less fuel input for the same waste processing output, resulting in lower overall energy consumption. This reduction in energy usage not only decreases the carbon footprint of waste management facilities but also conserves valuable resources and reduces operational costs.

The environmental benefits extend to water conservation as well. Optimized throttle bodies can lead to more efficient cooling systems, reducing the amount of water required for temperature regulation in waste processing equipment. This water savings is particularly significant in regions facing water scarcity or drought conditions.

Lastly, the improved control over waste incineration processes enabled by optimized throttle bodies can result in more complete waste destruction. This efficiency reduces the volume of residual waste and potentially hazardous byproducts, minimizing the need for landfill space and decreasing the risk of soil and groundwater contamination. The overall result is a more sustainable and environmentally friendly waste management system that aligns with circular economy principles and supports long-term ecological preservation efforts.

Regulatory Compliance

Regulatory compliance plays a crucial role in the optimization of throttle bodies for waste management systems. As environmental concerns continue to grow, governments worldwide have implemented stringent regulations to control emissions and improve waste management practices. These regulations directly impact the design and operation of throttle bodies in waste management systems, necessitating careful consideration and adherence to compliance standards.

In the United States, the Environmental Protection Agency (EPA) sets forth guidelines for waste management systems, including specifications for throttle body performance. These regulations aim to minimize harmful emissions and maximize energy efficiency. The Clean Air Act and its amendments provide the framework for emission standards, requiring waste management facilities to implement advanced throttle body technologies that can precisely control air flow and fuel mixture ratios.

Similarly, the European Union has established the Waste Framework Directive and the Industrial Emissions Directive, which outline comprehensive requirements for waste treatment facilities. These directives emphasize the importance of Best Available Techniques (BAT) in waste management processes, including the use of optimized throttle bodies to reduce environmental impact and improve overall system efficiency.

Compliance with these regulations often requires waste management facilities to implement sophisticated monitoring and control systems for their throttle bodies. Real-time data collection and analysis are essential to ensure that emissions remain within acceptable limits and that the system operates at peak efficiency. This has led to the development of advanced sensors and control algorithms specifically designed for waste management applications.

Furthermore, regulatory bodies frequently update their standards to reflect advancements in technology and evolving environmental concerns. As a result, waste management facilities must continuously evaluate and upgrade their throttle body systems to maintain compliance. This ongoing process drives innovation in throttle body design, encouraging manufacturers to develop more efficient and environmentally friendly solutions.

The global nature of environmental regulations also necessitates consideration of international standards when optimizing throttle bodies for waste management systems. Organizations such as the International Organization for Standardization (ISO) provide guidelines that help ensure consistency and compatibility across different regions. Adherence to these international standards can facilitate the adoption of optimized throttle body technologies in diverse markets and regulatory environments.

In conclusion, regulatory compliance serves as a critical driver for throttle body optimization in waste management systems. It not only ensures environmental protection but also promotes technological advancement and operational efficiency. As regulations continue to evolve, the waste management industry must remain proactive in developing and implementing innovative throttle body solutions that meet or exceed compliance requirements.

In the United States, the Environmental Protection Agency (EPA) sets forth guidelines for waste management systems, including specifications for throttle body performance. These regulations aim to minimize harmful emissions and maximize energy efficiency. The Clean Air Act and its amendments provide the framework for emission standards, requiring waste management facilities to implement advanced throttle body technologies that can precisely control air flow and fuel mixture ratios.

Similarly, the European Union has established the Waste Framework Directive and the Industrial Emissions Directive, which outline comprehensive requirements for waste treatment facilities. These directives emphasize the importance of Best Available Techniques (BAT) in waste management processes, including the use of optimized throttle bodies to reduce environmental impact and improve overall system efficiency.

Compliance with these regulations often requires waste management facilities to implement sophisticated monitoring and control systems for their throttle bodies. Real-time data collection and analysis are essential to ensure that emissions remain within acceptable limits and that the system operates at peak efficiency. This has led to the development of advanced sensors and control algorithms specifically designed for waste management applications.

Furthermore, regulatory bodies frequently update their standards to reflect advancements in technology and evolving environmental concerns. As a result, waste management facilities must continuously evaluate and upgrade their throttle body systems to maintain compliance. This ongoing process drives innovation in throttle body design, encouraging manufacturers to develop more efficient and environmentally friendly solutions.

The global nature of environmental regulations also necessitates consideration of international standards when optimizing throttle bodies for waste management systems. Organizations such as the International Organization for Standardization (ISO) provide guidelines that help ensure consistency and compatibility across different regions. Adherence to these international standards can facilitate the adoption of optimized throttle body technologies in diverse markets and regulatory environments.

In conclusion, regulatory compliance serves as a critical driver for throttle body optimization in waste management systems. It not only ensures environmental protection but also promotes technological advancement and operational efficiency. As regulations continue to evolve, the waste management industry must remain proactive in developing and implementing innovative throttle body solutions that meet or exceed compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!