Throttle Body Applications in Rally Racing

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rally Throttle Evolution

The evolution of throttle bodies in rally racing has been a journey of continuous innovation and refinement, driven by the relentless pursuit of performance and efficiency. In the early days of rally racing, carburetors were the primary means of fuel delivery and air control. These mechanical devices, while effective, lacked the precision and adaptability required for the demanding conditions of rally competitions.

The introduction of electronic fuel injection systems in the 1980s marked a significant turning point in throttle body technology for rally cars. This shift allowed for more precise control over fuel delivery and air intake, resulting in improved engine performance and fuel efficiency. Early electronic throttle bodies were still mechanically operated but incorporated sensors to provide feedback to the engine control unit (ECU).

As rally racing became more competitive and technologically advanced, the demand for even greater control and responsiveness led to the development of drive-by-wire throttle systems in the late 1990s and early 2000s. These systems replaced the traditional mechanical linkage between the accelerator pedal and the throttle body with electronic sensors and actuators, allowing for instantaneous throttle response and more sophisticated engine management strategies.

The advent of drive-by-wire technology opened up new possibilities for throttle body design and functionality. Rally teams began experimenting with variable geometry throttle bodies, which could alter their shape and airflow characteristics on the fly to optimize performance across different engine speeds and load conditions. This innovation allowed rally cars to maintain peak performance throughout a wider range of operating conditions, a crucial advantage in the diverse terrains and weather conditions encountered in rally events.

In recent years, the focus has shifted towards integrating throttle bodies with advanced aerodynamic systems and turbocharging technologies. Modern rally cars often feature throttle bodies that work in harmony with variable geometry turbochargers and active aerodynamic elements to maximize power output and efficiency. This holistic approach to engine management has resulted in rally cars that are not only more powerful but also more fuel-efficient and environmentally friendly.

The latest developments in throttle body technology for rally racing include the use of 3D-printed components, allowing for rapid prototyping and testing of complex geometries that would be difficult or impossible to manufacture using traditional methods. Additionally, the integration of artificial intelligence and machine learning algorithms into engine management systems has enabled real-time optimization of throttle body performance based on a multitude of sensor inputs and predictive models.

As rally racing continues to evolve, the future of throttle body technology looks set to embrace even more advanced materials, such as carbon fiber and ceramic composites, to reduce weight and improve heat management. Furthermore, the ongoing shift towards hybrid and electric powertrains in motorsports is likely to redefine the role of throttle bodies in rally cars, potentially leading to innovative solutions that blend traditional internal combustion engine technology with electric propulsion systems.

The introduction of electronic fuel injection systems in the 1980s marked a significant turning point in throttle body technology for rally cars. This shift allowed for more precise control over fuel delivery and air intake, resulting in improved engine performance and fuel efficiency. Early electronic throttle bodies were still mechanically operated but incorporated sensors to provide feedback to the engine control unit (ECU).

As rally racing became more competitive and technologically advanced, the demand for even greater control and responsiveness led to the development of drive-by-wire throttle systems in the late 1990s and early 2000s. These systems replaced the traditional mechanical linkage between the accelerator pedal and the throttle body with electronic sensors and actuators, allowing for instantaneous throttle response and more sophisticated engine management strategies.

The advent of drive-by-wire technology opened up new possibilities for throttle body design and functionality. Rally teams began experimenting with variable geometry throttle bodies, which could alter their shape and airflow characteristics on the fly to optimize performance across different engine speeds and load conditions. This innovation allowed rally cars to maintain peak performance throughout a wider range of operating conditions, a crucial advantage in the diverse terrains and weather conditions encountered in rally events.

In recent years, the focus has shifted towards integrating throttle bodies with advanced aerodynamic systems and turbocharging technologies. Modern rally cars often feature throttle bodies that work in harmony with variable geometry turbochargers and active aerodynamic elements to maximize power output and efficiency. This holistic approach to engine management has resulted in rally cars that are not only more powerful but also more fuel-efficient and environmentally friendly.

The latest developments in throttle body technology for rally racing include the use of 3D-printed components, allowing for rapid prototyping and testing of complex geometries that would be difficult or impossible to manufacture using traditional methods. Additionally, the integration of artificial intelligence and machine learning algorithms into engine management systems has enabled real-time optimization of throttle body performance based on a multitude of sensor inputs and predictive models.

As rally racing continues to evolve, the future of throttle body technology looks set to embrace even more advanced materials, such as carbon fiber and ceramic composites, to reduce weight and improve heat management. Furthermore, the ongoing shift towards hybrid and electric powertrains in motorsports is likely to redefine the role of throttle bodies in rally cars, potentially leading to innovative solutions that blend traditional internal combustion engine technology with electric propulsion systems.

Market Demand Analysis

The market demand for throttle body applications in rally racing has been steadily growing, driven by the increasing popularity of motorsports and the continuous pursuit of performance enhancement in rally vehicles. Rally racing, known for its challenging terrains and high-speed competitions, requires precise engine control and optimal power delivery, making throttle bodies a crucial component in vehicle performance.

The global rally racing market has experienced significant expansion in recent years, with a compound annual growth rate (CAGR) of approximately 6% from 2015 to 2020. This growth has directly impacted the demand for high-performance throttle bodies, as teams and manufacturers seek to gain a competitive edge through improved engine responsiveness and power output.

One of the key factors driving market demand is the continuous evolution of rally racing regulations. Governing bodies such as the FIA (Fédération Internationale de l'Automobile) regularly update technical specifications, often focusing on engine performance and efficiency. These changes have led to increased investment in throttle body technology, as teams strive to maximize performance within the constraints of new regulations.

The aftermarket segment for rally racing throttle bodies has also seen substantial growth. Enthusiasts and semi-professional racers are increasingly upgrading their vehicles with high-performance throttle bodies to enhance engine performance and drivability. This trend has created a robust market for aftermarket manufacturers specializing in rally-specific throttle body solutions.

Environmental concerns and the push for sustainability in motorsports have further influenced market demand. Rally organizers and manufacturers are exploring ways to reduce emissions and improve fuel efficiency without compromising performance. This has led to increased interest in advanced throttle body designs that optimize air-fuel mixture and contribute to more efficient engine operation.

The geographical distribution of market demand for rally racing throttle bodies closely follows the popularity of the sport in different regions. Europe, particularly countries with strong rally traditions such as Finland, Sweden, and France, represents a significant portion of the market. North America and Japan also show substantial demand, driven by their active rally racing scenes and automotive enthusiast cultures.

Emerging markets in Eastern Europe, South America, and parts of Asia are experiencing rapid growth in rally racing participation, contributing to the expanding global demand for specialized throttle body applications. These regions present significant opportunities for manufacturers to introduce innovative products tailored to local racing conditions and regulations.

As rally racing continues to evolve, the demand for advanced throttle body technologies is expected to grow further. The integration of electronic throttle control systems, lightweight materials, and precision manufacturing techniques are likely to shape future market trends, offering improved performance, reliability, and customization options for rally teams and enthusiasts alike.

The global rally racing market has experienced significant expansion in recent years, with a compound annual growth rate (CAGR) of approximately 6% from 2015 to 2020. This growth has directly impacted the demand for high-performance throttle bodies, as teams and manufacturers seek to gain a competitive edge through improved engine responsiveness and power output.

One of the key factors driving market demand is the continuous evolution of rally racing regulations. Governing bodies such as the FIA (Fédération Internationale de l'Automobile) regularly update technical specifications, often focusing on engine performance and efficiency. These changes have led to increased investment in throttle body technology, as teams strive to maximize performance within the constraints of new regulations.

The aftermarket segment for rally racing throttle bodies has also seen substantial growth. Enthusiasts and semi-professional racers are increasingly upgrading their vehicles with high-performance throttle bodies to enhance engine performance and drivability. This trend has created a robust market for aftermarket manufacturers specializing in rally-specific throttle body solutions.

Environmental concerns and the push for sustainability in motorsports have further influenced market demand. Rally organizers and manufacturers are exploring ways to reduce emissions and improve fuel efficiency without compromising performance. This has led to increased interest in advanced throttle body designs that optimize air-fuel mixture and contribute to more efficient engine operation.

The geographical distribution of market demand for rally racing throttle bodies closely follows the popularity of the sport in different regions. Europe, particularly countries with strong rally traditions such as Finland, Sweden, and France, represents a significant portion of the market. North America and Japan also show substantial demand, driven by their active rally racing scenes and automotive enthusiast cultures.

Emerging markets in Eastern Europe, South America, and parts of Asia are experiencing rapid growth in rally racing participation, contributing to the expanding global demand for specialized throttle body applications. These regions present significant opportunities for manufacturers to introduce innovative products tailored to local racing conditions and regulations.

As rally racing continues to evolve, the demand for advanced throttle body technologies is expected to grow further. The integration of electronic throttle control systems, lightweight materials, and precision manufacturing techniques are likely to shape future market trends, offering improved performance, reliability, and customization options for rally teams and enthusiasts alike.

Current Tech Challenges

The current technical challenges in throttle body applications for rally racing are multifaceted and demand innovative solutions to enhance performance and reliability in extreme conditions. One of the primary challenges is achieving precise and responsive throttle control across a wide range of engine speeds and loads, which is crucial for rally drivers to maintain optimal power delivery and vehicle control on varied terrains.

Durability and resistance to environmental factors pose significant hurdles in rally racing applications. Throttle bodies must withstand intense vibrations, extreme temperatures, and exposure to dust and debris encountered during off-road competitions. These harsh conditions can lead to premature wear, sticking throttle plates, and sensor malfunctions, compromising both performance and safety.

Another critical challenge is the integration of electronic throttle control systems (drive-by-wire) with traditional mechanical linkages. While electronic systems offer advantages in terms of programmability and potential for advanced traction control, they must be engineered to provide the instantaneous response and tactile feedback that rally drivers rely on. Ensuring fail-safe operation and redundancy in these electronic systems is paramount to prevent catastrophic failures during high-stakes racing events.

Optimizing airflow characteristics within the throttle body presents ongoing difficulties. Engineers strive to minimize turbulence and maximize flow efficiency while maintaining precise control over air intake. This challenge is compounded by the need to accommodate varying atmospheric conditions encountered in rally stages, from high-altitude mountain passes to humid forest environments.

Weight reduction remains a constant focus in rally car development, and throttle body design is no exception. Manufacturers face the challenge of creating lightweight yet robust components that can withstand the rigors of rally racing without compromising performance or reliability. This often involves exploring advanced materials and manufacturing techniques to achieve an optimal balance of strength and weight.

Fuel efficiency and emissions control, while secondary to performance in racing applications, are becoming increasingly important considerations. Rally teams must navigate the balance between maximizing power output and meeting evolving regulations, particularly in series that emphasize sustainability. This necessitates innovative approaches to throttle body design that can optimize fuel delivery and combustion efficiency without sacrificing the responsiveness demanded in competitive racing.

Lastly, the integration of throttle bodies with modern engine management systems presents ongoing challenges. Calibrating throttle response to work seamlessly with turbochargers, anti-lag systems, and sophisticated traction control algorithms requires extensive development and fine-tuning. Engineers must ensure that the throttle body can respond rapidly to both driver inputs and electronic commands from the engine control unit, maintaining optimal performance across all racing conditions.

Durability and resistance to environmental factors pose significant hurdles in rally racing applications. Throttle bodies must withstand intense vibrations, extreme temperatures, and exposure to dust and debris encountered during off-road competitions. These harsh conditions can lead to premature wear, sticking throttle plates, and sensor malfunctions, compromising both performance and safety.

Another critical challenge is the integration of electronic throttle control systems (drive-by-wire) with traditional mechanical linkages. While electronic systems offer advantages in terms of programmability and potential for advanced traction control, they must be engineered to provide the instantaneous response and tactile feedback that rally drivers rely on. Ensuring fail-safe operation and redundancy in these electronic systems is paramount to prevent catastrophic failures during high-stakes racing events.

Optimizing airflow characteristics within the throttle body presents ongoing difficulties. Engineers strive to minimize turbulence and maximize flow efficiency while maintaining precise control over air intake. This challenge is compounded by the need to accommodate varying atmospheric conditions encountered in rally stages, from high-altitude mountain passes to humid forest environments.

Weight reduction remains a constant focus in rally car development, and throttle body design is no exception. Manufacturers face the challenge of creating lightweight yet robust components that can withstand the rigors of rally racing without compromising performance or reliability. This often involves exploring advanced materials and manufacturing techniques to achieve an optimal balance of strength and weight.

Fuel efficiency and emissions control, while secondary to performance in racing applications, are becoming increasingly important considerations. Rally teams must navigate the balance between maximizing power output and meeting evolving regulations, particularly in series that emphasize sustainability. This necessitates innovative approaches to throttle body design that can optimize fuel delivery and combustion efficiency without sacrificing the responsiveness demanded in competitive racing.

Lastly, the integration of throttle bodies with modern engine management systems presents ongoing challenges. Calibrating throttle response to work seamlessly with turbochargers, anti-lag systems, and sophisticated traction control algorithms requires extensive development and fine-tuning. Engineers must ensure that the throttle body can respond rapidly to both driver inputs and electronic commands from the engine control unit, maintaining optimal performance across all racing conditions.

Existing Throttle Tech

01 Throttle body design and construction

Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Various designs focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.- Throttle body design and construction: Throttle bodies are designed to control airflow into an engine's intake manifold. They typically consist of a housing with a butterfly valve that can be opened or closed to regulate air intake. Various designs focus on improving airflow efficiency, reducing turbulence, and enhancing overall engine performance.

- Electronic throttle control systems: Modern throttle bodies often incorporate electronic control systems, replacing traditional mechanical linkages. These systems use sensors and actuators to precisely control throttle position based on driver input and engine management requirements, improving responsiveness and fuel efficiency.

- Idle air control mechanisms: Throttle bodies may include idle air control mechanisms to regulate engine idle speed. These systems bypass the main throttle plate to provide a controlled amount of air during idle conditions, ensuring stable engine operation and smooth transitions between idle and acceleration.

- Throttle body cleaning and maintenance: Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting performance. Various cleaning methods and maintenance procedures are developed to keep throttle bodies functioning optimally, including specialized cleaning solutions and tools for removing buildup without damaging sensitive components.

- Integration with fuel injection systems: Throttle bodies are often integrated with fuel injection systems to optimize air-fuel mixture. This integration can involve positioning fuel injectors near the throttle body, incorporating fuel rails, or designing throttle bodies that work in conjunction with direct injection systems for improved atomization and combustion efficiency.

02 Electronic throttle control systems

Modern throttle bodies often incorporate electronic control systems, replacing mechanical linkages with sensors and actuators. These systems allow for more precise control of the throttle position, improving fuel efficiency and engine response. They can also integrate with other vehicle systems for advanced features like cruise control and traction control.Expand Specific Solutions03 Throttle body cleaning and maintenance

Throttle bodies can accumulate carbon deposits and other contaminants over time, affecting their performance. Various cleaning methods and maintenance procedures have been developed to keep throttle bodies functioning optimally. Some designs incorporate features to reduce deposit buildup or facilitate easier cleaning.Expand Specific Solutions04 Integration with fuel injection systems

Throttle bodies are often integrated with fuel injection systems to optimize air-fuel mixture. This integration can involve positioning fuel injectors near the throttle body, incorporating sensors for air mass measurement, or designing the throttle body to work in conjunction with direct injection systems for improved atomization and fuel distribution.Expand Specific Solutions05 Throttle body advancements for specific applications

Specialized throttle body designs have been developed for specific engine types or applications. These can include multi-valve throttle bodies for high-performance engines, variable geometry designs for improved low-end torque, or compact designs for space-constrained applications like motorcycles or small engines.Expand Specific Solutions

Key Rally Manufacturers

The throttle body market in rally racing is in a mature stage, with established players like Honda Motor Co., Ltd. and Yamaha Motor Co., Ltd. dominating the field. The market size is relatively stable, driven by the niche but passionate rally racing community. Technologically, throttle bodies have reached a high level of sophistication, with companies like Mikuni Corp. and Vitesco Technologies USA LLC pushing the boundaries of performance and efficiency. The competition is fierce, with manufacturers focusing on incremental improvements in response time, durability, and integration with electronic control systems to gain an edge in this specialized market.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed advanced electronic throttle body systems specifically for rally racing applications. Their technology incorporates a high-precision throttle position sensor and fast-acting motor for precise throttle control. The system uses adaptive learning algorithms to optimize throttle response based on driving conditions and driver inputs. Honda's rally-spec throttle bodies feature a dual-spring design for failsafe operation and are constructed from lightweight materials like aluminum and carbon fiber to reduce weight. The company has also implemented anti-icing measures to ensure reliable performance in extreme weather conditions often encountered in rally racing [1][3].

Strengths: Precise throttle control, adaptive optimization, and robust design for harsh rally environments. Weaknesses: May be more complex and expensive than mechanical systems.

Yamaha Motor Co., Ltd.

Technical Solution: Yamaha has developed a rally-specific throttle body system that utilizes their Chip Controlled Throttle (YCC-T) technology. This system employs multiple sensors to monitor throttle position, engine speed, and vehicle speed, allowing for precise fuel metering and throttle control. Yamaha's rally throttle bodies feature a larger bore size to increase airflow and power output. The company has also implemented a quick-response actuator that can adjust throttle opening in milliseconds, crucial for the rapid acceleration and deceleration required in rally racing. Additionally, Yamaha's system includes built-in diagnostics and fail-safe modes to ensure reliability during long and grueling rally stages [2][4].

Strengths: High-performance design, quick throttle response, and integrated safety features. Weaknesses: May require specialized maintenance and tuning.

Core Throttle Patents

A throttle body

PatentActiveIN201711032197A

Innovation

- An asymmetric throttle body with an elongated intake passage cross-section, where the slider moves from a narrower end to a broader end to gradually open or close the passage, reducing sudden changes in engine speed and torque delivery.

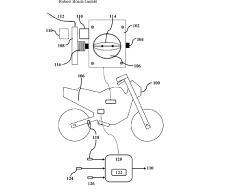

A mechanical throttle body, a controller for a vehicle and method thereof

PatentPendingIN202243056087A

Innovation

- Integration of an electromagnet controlled by a controller that holds the throttle lever in a desired position using magnetic force, allowing for cruise control functionality without modifying the existing mechanical throttle body design, enabling speed adjustments and reducing the overall system cost.

Regulatory Compliance

Regulatory compliance plays a crucial role in the application of throttle bodies in rally racing, ensuring fair competition, driver safety, and environmental responsibility. The Federation Internationale de l'Automobile (FIA) sets the primary regulations governing rally racing, including specifications for throttle bodies and related systems.

FIA regulations typically mandate the use of production-based throttle bodies in many rally classes, limiting modifications to ensure a level playing field. These regulations often specify maximum throttle body diameters, airflow restrictions, and electronic control parameters. For example, in the World Rally Championship (WRC), the maximum throttle diameter is limited to 34mm for turbocharged engines, while naturally aspirated engines may have larger diameters based on engine displacement.

Compliance with these regulations requires careful engineering and design of throttle body systems. Manufacturers must balance performance optimization with adherence to regulatory limits, often employing advanced materials and manufacturing techniques to achieve maximum efficiency within the prescribed boundaries.

Environmental considerations also factor into regulatory compliance for throttle bodies in rally racing. Many racing series now incorporate sustainability initiatives, leading to regulations that promote fuel efficiency and reduced emissions. This has driven innovation in throttle body design, including the development of more precise electronic control systems and improved airflow management.

Safety regulations further impact throttle body applications in rally racing. Fail-safe mechanisms are often required to prevent unintended acceleration in case of system malfunction. These may include mechanical or electronic throttle return springs, redundant position sensors, and sophisticated engine control unit (ECU) programming to detect and mitigate potential issues.

Homologation processes are a critical aspect of regulatory compliance for rally racing throttle bodies. Manufacturers must submit detailed technical specifications and undergo rigorous testing to ensure their components meet all applicable regulations before they can be used in competition. This process often involves extensive documentation, prototype testing, and on-site inspections by regulatory bodies.

Staying compliant with evolving regulations presents ongoing challenges for teams and manufacturers. As technology advances and racing strategies evolve, regulatory bodies continually update their rules to maintain competitive balance and address emerging safety and environmental concerns. This necessitates a proactive approach to throttle body design and development, with teams and suppliers working closely to anticipate and adapt to regulatory changes.

FIA regulations typically mandate the use of production-based throttle bodies in many rally classes, limiting modifications to ensure a level playing field. These regulations often specify maximum throttle body diameters, airflow restrictions, and electronic control parameters. For example, in the World Rally Championship (WRC), the maximum throttle diameter is limited to 34mm for turbocharged engines, while naturally aspirated engines may have larger diameters based on engine displacement.

Compliance with these regulations requires careful engineering and design of throttle body systems. Manufacturers must balance performance optimization with adherence to regulatory limits, often employing advanced materials and manufacturing techniques to achieve maximum efficiency within the prescribed boundaries.

Environmental considerations also factor into regulatory compliance for throttle bodies in rally racing. Many racing series now incorporate sustainability initiatives, leading to regulations that promote fuel efficiency and reduced emissions. This has driven innovation in throttle body design, including the development of more precise electronic control systems and improved airflow management.

Safety regulations further impact throttle body applications in rally racing. Fail-safe mechanisms are often required to prevent unintended acceleration in case of system malfunction. These may include mechanical or electronic throttle return springs, redundant position sensors, and sophisticated engine control unit (ECU) programming to detect and mitigate potential issues.

Homologation processes are a critical aspect of regulatory compliance for rally racing throttle bodies. Manufacturers must submit detailed technical specifications and undergo rigorous testing to ensure their components meet all applicable regulations before they can be used in competition. This process often involves extensive documentation, prototype testing, and on-site inspections by regulatory bodies.

Staying compliant with evolving regulations presents ongoing challenges for teams and manufacturers. As technology advances and racing strategies evolve, regulatory bodies continually update their rules to maintain competitive balance and address emerging safety and environmental concerns. This necessitates a proactive approach to throttle body design and development, with teams and suppliers working closely to anticipate and adapt to regulatory changes.

Environmental Impact

The environmental impact of throttle body applications in rally racing is a complex and multifaceted issue that deserves careful consideration. Rally racing, by its nature, involves high-performance vehicles operating in diverse and often challenging terrains, which can lead to significant environmental consequences.

One of the primary environmental concerns associated with throttle body applications in rally racing is the increased fuel consumption and emissions. High-performance throttle bodies are designed to maximize airflow into the engine, allowing for greater power output. However, this often results in higher fuel consumption rates, leading to increased carbon dioxide emissions and other pollutants. The precise control offered by advanced throttle bodies can potentially mitigate some of these effects, but the overall impact remains substantial.

Noise pollution is another significant environmental factor to consider. Rally cars equipped with high-performance throttle bodies tend to produce more engine noise, which can be disruptive to local ecosystems and wildlife. This is particularly problematic in rally stages that pass through sensitive natural habitats or protected areas. The increased noise levels can cause stress and behavioral changes in animals, potentially affecting their breeding patterns and overall well-being.

The manufacturing process of specialized throttle bodies for rally racing also contributes to the environmental footprint. The production of these components often involves energy-intensive processes and the use of various materials, including metals and plastics. The extraction and processing of these raw materials can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

Furthermore, the frequent replacement and upgrading of throttle bodies in competitive rally racing leads to increased waste generation. As teams strive for peak performance, older or less efficient components are often discarded, contributing to electronic and mechanical waste streams. This rapid turnover of parts raises concerns about resource depletion and the long-term sustainability of such practices in motorsport.

However, it's important to note that advancements in throttle body technology have also led to some positive environmental outcomes. More precise fuel metering and improved engine efficiency can result in better fuel economy and reduced emissions in certain driving conditions. Additionally, the development of electronic throttle control systems has the potential to optimize performance while minimizing environmental impact through more sophisticated engine management.

In conclusion, while throttle body applications in rally racing offer significant performance benefits, their environmental impact is a growing concern. Balancing the demands of competitive motorsport with environmental responsibility remains a challenge for the industry. Future developments in this field will likely focus on finding innovative solutions that maintain high performance standards while minimizing ecological footprints.

One of the primary environmental concerns associated with throttle body applications in rally racing is the increased fuel consumption and emissions. High-performance throttle bodies are designed to maximize airflow into the engine, allowing for greater power output. However, this often results in higher fuel consumption rates, leading to increased carbon dioxide emissions and other pollutants. The precise control offered by advanced throttle bodies can potentially mitigate some of these effects, but the overall impact remains substantial.

Noise pollution is another significant environmental factor to consider. Rally cars equipped with high-performance throttle bodies tend to produce more engine noise, which can be disruptive to local ecosystems and wildlife. This is particularly problematic in rally stages that pass through sensitive natural habitats or protected areas. The increased noise levels can cause stress and behavioral changes in animals, potentially affecting their breeding patterns and overall well-being.

The manufacturing process of specialized throttle bodies for rally racing also contributes to the environmental footprint. The production of these components often involves energy-intensive processes and the use of various materials, including metals and plastics. The extraction and processing of these raw materials can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

Furthermore, the frequent replacement and upgrading of throttle bodies in competitive rally racing leads to increased waste generation. As teams strive for peak performance, older or less efficient components are often discarded, contributing to electronic and mechanical waste streams. This rapid turnover of parts raises concerns about resource depletion and the long-term sustainability of such practices in motorsport.

However, it's important to note that advancements in throttle body technology have also led to some positive environmental outcomes. More precise fuel metering and improved engine efficiency can result in better fuel economy and reduced emissions in certain driving conditions. Additionally, the development of electronic throttle control systems has the potential to optimize performance while minimizing environmental impact through more sophisticated engine management.

In conclusion, while throttle body applications in rally racing offer significant performance benefits, their environmental impact is a growing concern. Balancing the demands of competitive motorsport with environmental responsibility remains a challenge for the industry. Future developments in this field will likely focus on finding innovative solutions that maintain high performance standards while minimizing ecological footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!