How Throttle Body Technology Enhances Desert Racing Performance

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution in Desert Racing

The evolution of throttle body technology in desert racing has been a significant factor in enhancing vehicle performance under extreme conditions. Initially, carburetors were the primary means of fuel delivery in off-road racing vehicles. However, as the demands for power, efficiency, and reliability increased, throttle body injection systems emerged as a superior alternative.

In the early stages of desert racing, carburetors were prone to issues such as fuel starvation during steep climbs or descents, and sensitivity to altitude changes. The introduction of throttle body injection systems in the 1980s marked a turning point in desert racing technology. These systems offered more precise fuel metering and better adaptability to varying environmental conditions.

The first generation of throttle body injection systems in desert racing vehicles featured single-point injection, where a single injector was mounted in the throttle body. This design provided improved fuel atomization and more consistent fuel delivery compared to carburetors. As technology progressed, multi-point injection systems were introduced, with individual injectors for each cylinder, further enhancing fuel distribution and engine performance.

Throughout the 1990s and early 2000s, throttle body technology in desert racing saw significant advancements in materials and design. Lightweight alloys and composite materials were incorporated to reduce overall weight while maintaining durability. Improved airflow designs and larger throttle bores allowed for increased air intake, directly translating to higher horsepower outputs.

The integration of electronic control units (ECUs) with throttle bodies revolutionized desert racing performance. These sophisticated systems enabled real-time adjustments to fuel delivery based on various parameters such as engine load, temperature, and altitude. This adaptability proved crucial in maintaining optimal performance across the diverse terrains and conditions encountered in desert racing.

Recent developments in throttle body technology for desert racing have focused on enhancing throttle response and maximizing airflow efficiency. Variable geometry throttle bodies, which can alter their shape to optimize airflow at different engine speeds, have been introduced in high-performance racing applications. Additionally, advanced coating technologies have been employed to reduce friction and improve wear resistance, ensuring consistent performance over extended race durations.

The evolution of throttle body technology in desert racing continues to push the boundaries of performance and reliability. Current research is exploring the potential of 3D-printed throttle bodies with complex internal geometries that were previously impossible to manufacture. These innovations promise even greater precision in air and fuel management, potentially leading to further improvements in power output and fuel efficiency for desert racing vehicles.

In the early stages of desert racing, carburetors were prone to issues such as fuel starvation during steep climbs or descents, and sensitivity to altitude changes. The introduction of throttle body injection systems in the 1980s marked a turning point in desert racing technology. These systems offered more precise fuel metering and better adaptability to varying environmental conditions.

The first generation of throttle body injection systems in desert racing vehicles featured single-point injection, where a single injector was mounted in the throttle body. This design provided improved fuel atomization and more consistent fuel delivery compared to carburetors. As technology progressed, multi-point injection systems were introduced, with individual injectors for each cylinder, further enhancing fuel distribution and engine performance.

Throughout the 1990s and early 2000s, throttle body technology in desert racing saw significant advancements in materials and design. Lightweight alloys and composite materials were incorporated to reduce overall weight while maintaining durability. Improved airflow designs and larger throttle bores allowed for increased air intake, directly translating to higher horsepower outputs.

The integration of electronic control units (ECUs) with throttle bodies revolutionized desert racing performance. These sophisticated systems enabled real-time adjustments to fuel delivery based on various parameters such as engine load, temperature, and altitude. This adaptability proved crucial in maintaining optimal performance across the diverse terrains and conditions encountered in desert racing.

Recent developments in throttle body technology for desert racing have focused on enhancing throttle response and maximizing airflow efficiency. Variable geometry throttle bodies, which can alter their shape to optimize airflow at different engine speeds, have been introduced in high-performance racing applications. Additionally, advanced coating technologies have been employed to reduce friction and improve wear resistance, ensuring consistent performance over extended race durations.

The evolution of throttle body technology in desert racing continues to push the boundaries of performance and reliability. Current research is exploring the potential of 3D-printed throttle bodies with complex internal geometries that were previously impossible to manufacture. These innovations promise even greater precision in air and fuel management, potentially leading to further improvements in power output and fuel efficiency for desert racing vehicles.

Market Analysis for High-Performance Racing Components

The high-performance racing components market, particularly for desert racing, has been experiencing significant growth in recent years. This surge is driven by the increasing popularity of off-road motorsports and the continuous demand for enhanced vehicle performance in extreme conditions. The throttle body, a critical component in engine management systems, plays a crucial role in optimizing desert racing performance.

Market analysis reveals that the global off-road vehicle market, which includes desert racing vehicles, is projected to reach substantial value in the coming years. This growth is attributed to the rising interest in adventure sports and recreational activities, as well as the technological advancements in vehicle components. The throttle body segment within this market is expected to witness robust growth due to its direct impact on engine performance and fuel efficiency.

Desert racing presents unique challenges that demand specialized high-performance components. The harsh environment, characterized by extreme temperatures, dust, and unpredictable terrain, requires durable and efficient engine systems. Throttle bodies designed for desert racing must withstand these conditions while delivering precise air-fuel mixture control and responsive throttle action.

The market for high-performance throttle bodies in desert racing is primarily driven by professional racing teams and enthusiasts seeking to gain a competitive edge. These consumers are willing to invest in premium components that offer measurable performance improvements. The demand is further fueled by the trickle-down effect, where technologies developed for professional racing eventually make their way into consumer off-road vehicles.

Key players in the high-performance racing components market include established automotive parts manufacturers and specialized racing equipment providers. These companies are continuously innovating to develop throttle bodies that offer better airflow, improved throttle response, and enhanced durability for desert racing applications. The market is also seeing an influx of smaller, specialized manufacturers focusing exclusively on high-performance off-road components.

The aftermarket segment for high-performance throttle bodies is particularly strong, as racers and enthusiasts often upgrade their stock components to achieve better performance. This trend is supported by the growing DIY culture in the racing community and the availability of plug-and-play solutions that simplify installation and tuning processes.

Technological advancements in throttle body design, such as the integration of electronic throttle control systems and the use of lightweight, heat-resistant materials, are expected to drive market growth further. These innovations address the specific needs of desert racing, offering improved reliability and performance under extreme conditions.

Market analysis reveals that the global off-road vehicle market, which includes desert racing vehicles, is projected to reach substantial value in the coming years. This growth is attributed to the rising interest in adventure sports and recreational activities, as well as the technological advancements in vehicle components. The throttle body segment within this market is expected to witness robust growth due to its direct impact on engine performance and fuel efficiency.

Desert racing presents unique challenges that demand specialized high-performance components. The harsh environment, characterized by extreme temperatures, dust, and unpredictable terrain, requires durable and efficient engine systems. Throttle bodies designed for desert racing must withstand these conditions while delivering precise air-fuel mixture control and responsive throttle action.

The market for high-performance throttle bodies in desert racing is primarily driven by professional racing teams and enthusiasts seeking to gain a competitive edge. These consumers are willing to invest in premium components that offer measurable performance improvements. The demand is further fueled by the trickle-down effect, where technologies developed for professional racing eventually make their way into consumer off-road vehicles.

Key players in the high-performance racing components market include established automotive parts manufacturers and specialized racing equipment providers. These companies are continuously innovating to develop throttle bodies that offer better airflow, improved throttle response, and enhanced durability for desert racing applications. The market is also seeing an influx of smaller, specialized manufacturers focusing exclusively on high-performance off-road components.

The aftermarket segment for high-performance throttle bodies is particularly strong, as racers and enthusiasts often upgrade their stock components to achieve better performance. This trend is supported by the growing DIY culture in the racing community and the availability of plug-and-play solutions that simplify installation and tuning processes.

Technological advancements in throttle body design, such as the integration of electronic throttle control systems and the use of lightweight, heat-resistant materials, are expected to drive market growth further. These innovations address the specific needs of desert racing, offering improved reliability and performance under extreme conditions.

Current Throttle Body Tech Challenges in Extreme Environments

Desert racing presents unique challenges for throttle body technology due to the extreme environmental conditions encountered. The harsh desert climate, characterized by high temperatures, fine dust particles, and rapid temperature fluctuations, puts significant stress on throttle body components and their performance.

One of the primary challenges is the accumulation of dust and debris within the throttle body system. The fine sand and dust particles prevalent in desert environments can easily infiltrate the throttle body, leading to increased wear and tear on moving parts. This accumulation can result in reduced throttle response, inconsistent air-fuel mixture, and potential engine performance issues. Developing effective filtration systems that can withstand prolonged exposure to these conditions while maintaining optimal airflow is a significant technical hurdle.

Thermal management poses another critical challenge for throttle body technology in desert racing. The extreme heat encountered during races can cause thermal expansion of components, potentially leading to misalignment or binding of moving parts. Additionally, rapid temperature changes between day and night can cause condensation within the throttle body, potentially leading to corrosion or electrical issues in electronic throttle control systems.

The demand for precise throttle control in desert racing conditions further complicates the technological landscape. Racers require instantaneous throttle response to navigate challenging terrain, but the harsh environment can compromise the accuracy and reliability of throttle position sensors and actuators. Developing robust electronic throttle control systems that can maintain precision and responsiveness under extreme conditions remains a significant challenge.

Durability and reliability are paramount concerns in desert racing, where vehicle failures can have severe consequences. Throttle body components must withstand prolonged exposure to high temperatures, vibrations, and impacts associated with off-road racing. This necessitates the development of advanced materials and manufacturing techniques to create throttle bodies that can maintain performance and structural integrity over extended periods in harsh conditions.

Furthermore, the need for increased power output in desert racing vehicles places additional demands on throttle body technology. Larger throttle bodies are often required to accommodate higher airflow rates, but this can lead to challenges in maintaining smooth throttle response at lower engine speeds. Balancing the need for increased airflow with precise control across the entire operating range remains a significant technical challenge.

Lastly, the integration of throttle body technology with other engine management systems in desert racing vehicles presents its own set of challenges. Ensuring seamless communication and coordination between the throttle body, engine control unit, and other performance-enhancing technologies is crucial for optimizing overall vehicle performance in extreme racing conditions.

One of the primary challenges is the accumulation of dust and debris within the throttle body system. The fine sand and dust particles prevalent in desert environments can easily infiltrate the throttle body, leading to increased wear and tear on moving parts. This accumulation can result in reduced throttle response, inconsistent air-fuel mixture, and potential engine performance issues. Developing effective filtration systems that can withstand prolonged exposure to these conditions while maintaining optimal airflow is a significant technical hurdle.

Thermal management poses another critical challenge for throttle body technology in desert racing. The extreme heat encountered during races can cause thermal expansion of components, potentially leading to misalignment or binding of moving parts. Additionally, rapid temperature changes between day and night can cause condensation within the throttle body, potentially leading to corrosion or electrical issues in electronic throttle control systems.

The demand for precise throttle control in desert racing conditions further complicates the technological landscape. Racers require instantaneous throttle response to navigate challenging terrain, but the harsh environment can compromise the accuracy and reliability of throttle position sensors and actuators. Developing robust electronic throttle control systems that can maintain precision and responsiveness under extreme conditions remains a significant challenge.

Durability and reliability are paramount concerns in desert racing, where vehicle failures can have severe consequences. Throttle body components must withstand prolonged exposure to high temperatures, vibrations, and impacts associated with off-road racing. This necessitates the development of advanced materials and manufacturing techniques to create throttle bodies that can maintain performance and structural integrity over extended periods in harsh conditions.

Furthermore, the need for increased power output in desert racing vehicles places additional demands on throttle body technology. Larger throttle bodies are often required to accommodate higher airflow rates, but this can lead to challenges in maintaining smooth throttle response at lower engine speeds. Balancing the need for increased airflow with precise control across the entire operating range remains a significant technical challenge.

Lastly, the integration of throttle body technology with other engine management systems in desert racing vehicles presents its own set of challenges. Ensuring seamless communication and coordination between the throttle body, engine control unit, and other performance-enhancing technologies is crucial for optimizing overall vehicle performance in extreme racing conditions.

Existing Throttle Body Solutions for Desert Racing

01 Throttle body design improvements

Various design improvements to throttle bodies can enhance performance. These may include optimizing the shape and size of the throttle bore, improving airflow characteristics, and incorporating advanced materials for better durability and efficiency. Such enhancements can lead to more precise control over air intake and improved engine response.- Throttle body design improvements: Various design improvements to throttle bodies can enhance performance. These may include optimizing the shape and size of the throttle bore, improving airflow characteristics, and incorporating advanced materials for better durability and efficiency. Such enhancements can lead to more precise control of air intake and improved engine response.

- Electronic throttle control systems: Implementation of electronic throttle control systems can significantly improve throttle body performance. These systems use sensors and actuators to precisely control throttle position, resulting in better fuel efficiency, smoother acceleration, and improved overall engine performance. Advanced electronic control units can also integrate with other engine management systems for optimal operation.

- Throttle body cleaning and maintenance: Regular cleaning and maintenance of throttle bodies are crucial for maintaining optimal performance. This includes removing carbon deposits, ensuring proper lubrication of moving parts, and checking for wear or damage. Improved cleaning methods and materials can help extend the life of throttle bodies and maintain their efficiency over time.

- Integration of additional features: Incorporating additional features into throttle bodies can enhance their functionality and performance. This may include integrated sensors for more accurate readings, built-in idle air control valves, or advanced sealing mechanisms to prevent air leaks. These integrated features can lead to more compact designs and improved overall engine performance.

- Throttle body materials and manufacturing: Advancements in materials and manufacturing processes can lead to improved throttle body performance. Using lightweight yet durable materials can reduce overall weight and improve responsiveness. Precision manufacturing techniques, such as CNC machining or 3D printing, can produce more accurate and consistent throttle body components, resulting in better performance and reliability.

02 Electronic throttle control systems

Implementation of electronic throttle control systems can significantly improve throttle body performance. These systems use sensors and actuators to precisely control throttle position, allowing for better fuel efficiency, smoother acceleration, and improved overall engine performance. They can also integrate with other vehicle systems for enhanced functionality.Expand Specific Solutions03 Throttle body cleaning and maintenance

Regular cleaning and maintenance of throttle bodies are crucial for maintaining optimal performance. This includes removing carbon deposits, ensuring proper lubrication of moving parts, and checking for wear or damage. Proper maintenance can prevent issues such as sticking throttles, irregular idle, and reduced fuel efficiency.Expand Specific Solutions04 Integration of additional features

Incorporating additional features into throttle bodies can enhance their performance and functionality. This may include integrating idle air control valves, throttle position sensors, or air temperature sensors directly into the throttle body assembly. Such integration can lead to more compact designs, improved reliability, and better overall system performance.Expand Specific Solutions05 Advanced manufacturing techniques

Utilizing advanced manufacturing techniques can improve throttle body performance. These may include precision machining, 3D printing for prototyping or production of complex geometries, and the use of advanced coatings or surface treatments. Such techniques can result in tighter tolerances, improved durability, and enhanced aerodynamic properties of the throttle body.Expand Specific Solutions

Key Manufacturers in Racing Throttle Body Industry

The throttle body technology market for desert racing performance is in a growth phase, driven by increasing demand for high-performance off-road vehicles. The market size is expanding as more manufacturers enter the space, with key players like Toyota, Ford, and General Motors leading innovation. Technological maturity varies, with established companies like Bosch and Mikuni offering advanced solutions, while newer entrants like BYD and CF Moto are rapidly developing capabilities. The competitive landscape is diverse, featuring traditional automotive giants alongside specialized racing component manufacturers, all striving to enhance desert racing vehicle performance through improved throttle body designs.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced electronic throttle body system for desert racing applications. This system utilizes a high-precision servo motor to control throttle opening, allowing for more precise and responsive throttle control in harsh desert conditions[1]. The system incorporates dust-resistant seals and high-temperature lubricants to withstand the extreme environment. Toyota's throttle body also features adaptive learning algorithms that adjust throttle response based on driving conditions and driver input, optimizing performance and fuel efficiency during long desert races[3]. Additionally, the system integrates with Toyota's engine management system to provide real-time adjustments for altitude changes, common in desert terrain[5].

Strengths: Precise throttle control, durability in harsh environments, adaptive performance. Weaknesses: Potentially higher cost, increased complexity compared to mechanical systems.

GM Global Technology Operations LLC

Technical Solution: GM has engineered a specialized throttle body technology for desert racing, focusing on durability and performance. Their system incorporates a dual-bore design that allows for improved airflow and throttle response, crucial for maintaining power in sandy conditions[2]. The throttle body is constructed with corrosion-resistant materials and features a self-cleaning mechanism to prevent sand and dust accumulation. GM's technology also includes an integrated air temperature sensor for more accurate fuel metering in varying desert temperatures[4]. The system is designed to work seamlessly with GM's electronic stability control and traction control systems, providing enhanced vehicle dynamics in loose terrain[6].

Strengths: Enhanced airflow, durability in sandy conditions, integrated vehicle systems. Weaknesses: May require more frequent maintenance due to complex design.

Innovative Throttle Body Designs for Harsh Conditions

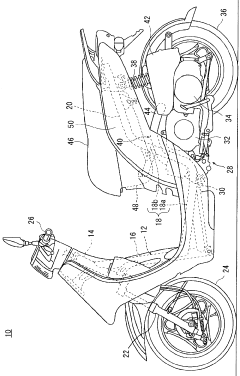

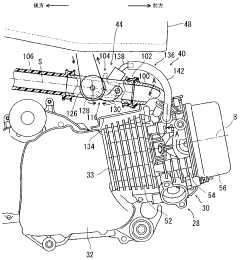

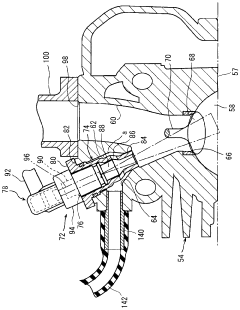

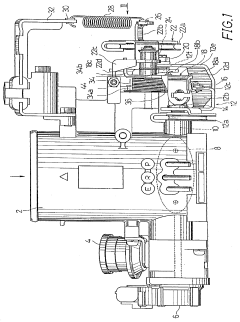

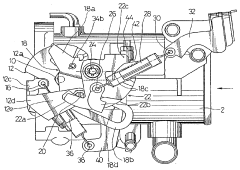

Throttle body and powered two-wheeled vehicle provided therewith

PatentWO2010113981A1

Innovation

- A throttle body design featuring butterfly-type first and second throttle valves with a tubular portion, through hole, and branch pipe to improve intake air flow between the valves, ensuring efficient air introduction into an auxiliary passage, which enhances fuel atomization and efficiency.

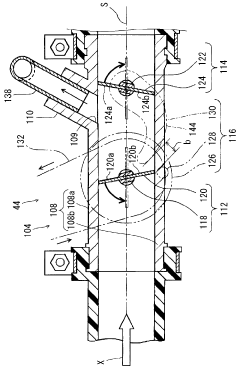

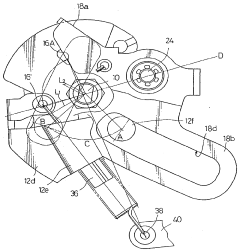

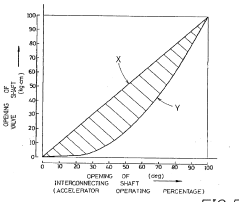

Throttle body having interconnecting lever for converting an operational amount of accelerator to an opening of throttle valve

PatentInactiveUS4945874A

Innovation

- Incorporating a tension spring to stabilize the throttle valve, using a spiral spring for consistent force, and an eccentric mounting member for cam follower adjustment, along with separating the interconnecting lever into two parts to decouple auto speed control from the accelerator pedal, ensuring smooth operation and fine adjustment capabilities.

Environmental Impact of Racing Technology

The environmental impact of racing technology, particularly in desert racing, is a complex and multifaceted issue that deserves careful consideration. While throttle body technology has significantly enhanced desert racing performance, it also contributes to the environmental footprint of these events.

One of the primary environmental concerns associated with desert racing is air pollution. The high-performance engines used in these races, equipped with advanced throttle body systems, emit substantial amounts of carbon dioxide and other greenhouse gases. These emissions contribute to climate change and can have localized effects on air quality in the racing areas. Additionally, the fine particulate matter produced by these engines can have negative impacts on both human health and local ecosystems.

Soil erosion and habitat disruption are also significant environmental issues in desert racing. The powerful acceleration and high speeds enabled by modern throttle body technology lead to increased soil disturbance and erosion. This can result in long-lasting damage to fragile desert ecosystems, affecting plant and animal life in the racing areas and beyond.

Water consumption is another environmental concern in desert racing. High-performance engines generate considerable heat, requiring efficient cooling systems. The water used for cooling and maintenance of these vehicles can strain local water resources, particularly in arid regions where water is already scarce.

Noise pollution is an often-overlooked environmental impact of racing technology. The high-revving engines facilitated by advanced throttle bodies produce significant noise levels, which can disrupt wildlife behavior and breeding patterns in desert ecosystems.

However, it's important to note that advancements in throttle body technology have also led to improvements in fuel efficiency and engine performance. These improvements can potentially reduce the overall environmental impact per race, as more efficient engines consume less fuel and produce fewer emissions for a given distance.

The racing industry has begun to recognize these environmental challenges and is taking steps to mitigate them. This includes the development of more environmentally friendly fuels, the implementation of stricter emissions standards for racing vehicles, and the adoption of course designs that minimize habitat disruption. Some racing organizations are also investing in habitat restoration projects to offset the environmental impact of their events.

In conclusion, while throttle body technology has undoubtedly enhanced desert racing performance, it has also contributed to various environmental challenges. Balancing the excitement and technological advancements of racing with environmental stewardship remains an ongoing challenge for the industry.

One of the primary environmental concerns associated with desert racing is air pollution. The high-performance engines used in these races, equipped with advanced throttle body systems, emit substantial amounts of carbon dioxide and other greenhouse gases. These emissions contribute to climate change and can have localized effects on air quality in the racing areas. Additionally, the fine particulate matter produced by these engines can have negative impacts on both human health and local ecosystems.

Soil erosion and habitat disruption are also significant environmental issues in desert racing. The powerful acceleration and high speeds enabled by modern throttle body technology lead to increased soil disturbance and erosion. This can result in long-lasting damage to fragile desert ecosystems, affecting plant and animal life in the racing areas and beyond.

Water consumption is another environmental concern in desert racing. High-performance engines generate considerable heat, requiring efficient cooling systems. The water used for cooling and maintenance of these vehicles can strain local water resources, particularly in arid regions where water is already scarce.

Noise pollution is an often-overlooked environmental impact of racing technology. The high-revving engines facilitated by advanced throttle bodies produce significant noise levels, which can disrupt wildlife behavior and breeding patterns in desert ecosystems.

However, it's important to note that advancements in throttle body technology have also led to improvements in fuel efficiency and engine performance. These improvements can potentially reduce the overall environmental impact per race, as more efficient engines consume less fuel and produce fewer emissions for a given distance.

The racing industry has begun to recognize these environmental challenges and is taking steps to mitigate them. This includes the development of more environmentally friendly fuels, the implementation of stricter emissions standards for racing vehicles, and the adoption of course designs that minimize habitat disruption. Some racing organizations are also investing in habitat restoration projects to offset the environmental impact of their events.

In conclusion, while throttle body technology has undoubtedly enhanced desert racing performance, it has also contributed to various environmental challenges. Balancing the excitement and technological advancements of racing with environmental stewardship remains an ongoing challenge for the industry.

Safety Regulations in Motorsport Equipment

Safety regulations in motorsport equipment play a crucial role in protecting drivers and enhancing the overall performance of desert racing vehicles, including those equipped with advanced throttle body technology. These regulations are designed to ensure that all components, including the throttle body, meet stringent safety standards while maximizing performance potential.

In desert racing, where extreme conditions and high speeds are the norm, safety regulations for throttle bodies focus on several key areas. Firstly, they mandate the use of fail-safe mechanisms to prevent unintended acceleration. This often includes redundant sensors and electronic control systems that can detect malfunctions and automatically reduce engine power if necessary.

Additionally, regulations typically require throttle bodies to be constructed from materials that can withstand the harsh desert environment, including extreme temperatures and abrasive sand particles. This ensures the longevity and reliability of the component throughout grueling races.

Another important aspect of safety regulations pertains to the throttle body's response characteristics. Guidelines often specify maximum rates of throttle opening and closing to prevent sudden, potentially dangerous changes in engine power output. This is particularly crucial in desert racing, where maintaining control over varying terrain is essential for driver safety.

Electromagnetic compatibility (EMC) requirements are also a significant part of safety regulations for throttle body systems. These rules ensure that the electronic components of the throttle body do not interfere with other critical vehicle systems, such as communication equipment or engine management computers.

Furthermore, safety regulations often mandate regular inspection and calibration of throttle bodies. This helps maintain optimal performance while ensuring that wear and tear do not compromise safety features. Specific protocols for pre-race checks and post-race inspections are typically outlined in the regulations.

Fuel delivery systems, including throttle bodies, are subject to strict regulations regarding fuel containment and fire prevention. This includes specifications for materials used in seals and gaskets, as well as requirements for fuel line connections and ventilation systems.

Lastly, safety regulations often address the integration of throttle body technology with other vehicle systems. This includes guidelines for how throttle control interacts with traction control systems, anti-lock brakes, and stability control mechanisms, ensuring that these systems work in harmony to enhance both performance and safety in challenging desert racing conditions.

In desert racing, where extreme conditions and high speeds are the norm, safety regulations for throttle bodies focus on several key areas. Firstly, they mandate the use of fail-safe mechanisms to prevent unintended acceleration. This often includes redundant sensors and electronic control systems that can detect malfunctions and automatically reduce engine power if necessary.

Additionally, regulations typically require throttle bodies to be constructed from materials that can withstand the harsh desert environment, including extreme temperatures and abrasive sand particles. This ensures the longevity and reliability of the component throughout grueling races.

Another important aspect of safety regulations pertains to the throttle body's response characteristics. Guidelines often specify maximum rates of throttle opening and closing to prevent sudden, potentially dangerous changes in engine power output. This is particularly crucial in desert racing, where maintaining control over varying terrain is essential for driver safety.

Electromagnetic compatibility (EMC) requirements are also a significant part of safety regulations for throttle body systems. These rules ensure that the electronic components of the throttle body do not interfere with other critical vehicle systems, such as communication equipment or engine management computers.

Furthermore, safety regulations often mandate regular inspection and calibration of throttle bodies. This helps maintain optimal performance while ensuring that wear and tear do not compromise safety features. Specific protocols for pre-race checks and post-race inspections are typically outlined in the regulations.

Fuel delivery systems, including throttle bodies, are subject to strict regulations regarding fuel containment and fire prevention. This includes specifications for materials used in seals and gaskets, as well as requirements for fuel line connections and ventilation systems.

Lastly, safety regulations often address the integration of throttle body technology with other vehicle systems. This includes guidelines for how throttle control interacts with traction control systems, anti-lock brakes, and stability control mechanisms, ensuring that these systems work in harmony to enhance both performance and safety in challenging desert racing conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!