How Throttle Body Technology Enhances Port Logistics Efficiency

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Tech in Port Logistics: Background and Objectives

Throttle body technology has emerged as a pivotal innovation in enhancing port logistics efficiency. Originating from automotive applications, this technology has found new purpose in the maritime industry, revolutionizing the way cargo handling and vessel operations are managed. The evolution of throttle body systems in port logistics stems from the increasing demand for faster, more precise, and environmentally friendly port operations.

The primary objective of implementing throttle body technology in port logistics is to optimize the flow of goods and vessels through ports, reducing bottlenecks and improving overall operational efficiency. By providing precise control over the movement of various port equipment, such as cranes, conveyor systems, and automated guided vehicles, throttle body systems enable smoother and more coordinated operations.

Historically, port operations have relied on manual control systems or less sophisticated automation technologies. The introduction of throttle body technology marks a significant leap forward in the industry's technological capabilities. This advancement aligns with the global trend towards smart ports and digitalization in the maritime sector, addressing the growing need for increased throughput and reduced turnaround times.

The development of throttle body technology for port applications has been driven by several key factors. These include the need to handle larger vessels and increased cargo volumes, stricter environmental regulations, and the push for cost reduction in port operations. As global trade continues to expand, ports face mounting pressure to enhance their operational efficiency while minimizing their environmental impact.

Throttle body systems in port logistics aim to achieve multiple technical goals. These include improving the precision of equipment movement, reducing energy consumption, minimizing emissions, and enhancing the overall responsiveness of port machinery. By providing finer control over engine speed and power output, these systems enable port equipment to operate more efficiently across various load conditions.

The integration of throttle body technology into port logistics represents a convergence of mechanical engineering, electronic control systems, and data analytics. This multidisciplinary approach has led to the development of sophisticated systems capable of real-time adjustments based on operational demands and environmental conditions. As the technology continues to evolve, it is expected to play a crucial role in the development of fully automated and AI-driven port operations.

The primary objective of implementing throttle body technology in port logistics is to optimize the flow of goods and vessels through ports, reducing bottlenecks and improving overall operational efficiency. By providing precise control over the movement of various port equipment, such as cranes, conveyor systems, and automated guided vehicles, throttle body systems enable smoother and more coordinated operations.

Historically, port operations have relied on manual control systems or less sophisticated automation technologies. The introduction of throttle body technology marks a significant leap forward in the industry's technological capabilities. This advancement aligns with the global trend towards smart ports and digitalization in the maritime sector, addressing the growing need for increased throughput and reduced turnaround times.

The development of throttle body technology for port applications has been driven by several key factors. These include the need to handle larger vessels and increased cargo volumes, stricter environmental regulations, and the push for cost reduction in port operations. As global trade continues to expand, ports face mounting pressure to enhance their operational efficiency while minimizing their environmental impact.

Throttle body systems in port logistics aim to achieve multiple technical goals. These include improving the precision of equipment movement, reducing energy consumption, minimizing emissions, and enhancing the overall responsiveness of port machinery. By providing finer control over engine speed and power output, these systems enable port equipment to operate more efficiently across various load conditions.

The integration of throttle body technology into port logistics represents a convergence of mechanical engineering, electronic control systems, and data analytics. This multidisciplinary approach has led to the development of sophisticated systems capable of real-time adjustments based on operational demands and environmental conditions. As the technology continues to evolve, it is expected to play a crucial role in the development of fully automated and AI-driven port operations.

Market Demand Analysis for Efficient Port Operations

The global port logistics industry is experiencing a significant surge in demand for efficient operations, driven by the increasing volume of international trade and the need for faster, more cost-effective cargo handling. This growing market demand is creating opportunities for innovative technologies like throttle body systems to enhance port logistics efficiency.

Port operators worldwide are facing pressure to improve their throughput capacity and reduce turnaround times for vessels. The ability to handle larger ships and process more containers per hour has become a critical competitive advantage. As a result, there is a strong market pull for solutions that can optimize the performance of port equipment, such as cranes, reach stackers, and terminal tractors.

The implementation of throttle body technology in port machinery offers a promising solution to meet these market demands. By providing precise control over engine performance, throttle bodies can significantly improve the responsiveness and fuel efficiency of port vehicles and equipment. This technology aligns well with the industry's focus on reducing operational costs and minimizing environmental impact.

Market research indicates that ports are increasingly investing in modernization projects to stay competitive. The global port equipment market is projected to grow at a compound annual growth rate (CAGR) of over 4% in the coming years, with a particular emphasis on technologies that enhance operational efficiency. Throttle body systems, as part of this broader trend, are poised to capture a significant share of this growing market.

Furthermore, the push for automation and smart port solutions is creating additional demand for advanced engine control systems. Throttle body technology can be integrated with digital control systems, enabling better coordination of port operations and supporting the trend towards autonomous vehicles in port environments.

The Asia-Pacific region, home to many of the world's busiest ports, is expected to be a key driver of market growth for port efficiency technologies. Ports in China, Singapore, and South Korea are at the forefront of adopting new technologies to maintain their competitive edge. However, there is also significant potential in emerging markets in Southeast Asia and Africa, where ports are looking to leapfrog older technologies and implement state-of-the-art solutions.

Environmental regulations are another factor driving market demand for efficient port operations. With increasing pressure to reduce emissions and improve air quality in port areas, technologies that can optimize engine performance and reduce fuel consumption are becoming essential. Throttle body systems, by enabling more precise control over engine operations, can help ports meet these environmental targets while maintaining high productivity levels.

In conclusion, the market demand for efficient port operations presents a substantial opportunity for throttle body technology. The industry's focus on increasing throughput, reducing costs, and meeting environmental standards aligns well with the benefits offered by advanced throttle control systems. As ports continue to invest in modernization and automation, the market for these technologies is expected to expand significantly in the coming years.

Port operators worldwide are facing pressure to improve their throughput capacity and reduce turnaround times for vessels. The ability to handle larger ships and process more containers per hour has become a critical competitive advantage. As a result, there is a strong market pull for solutions that can optimize the performance of port equipment, such as cranes, reach stackers, and terminal tractors.

The implementation of throttle body technology in port machinery offers a promising solution to meet these market demands. By providing precise control over engine performance, throttle bodies can significantly improve the responsiveness and fuel efficiency of port vehicles and equipment. This technology aligns well with the industry's focus on reducing operational costs and minimizing environmental impact.

Market research indicates that ports are increasingly investing in modernization projects to stay competitive. The global port equipment market is projected to grow at a compound annual growth rate (CAGR) of over 4% in the coming years, with a particular emphasis on technologies that enhance operational efficiency. Throttle body systems, as part of this broader trend, are poised to capture a significant share of this growing market.

Furthermore, the push for automation and smart port solutions is creating additional demand for advanced engine control systems. Throttle body technology can be integrated with digital control systems, enabling better coordination of port operations and supporting the trend towards autonomous vehicles in port environments.

The Asia-Pacific region, home to many of the world's busiest ports, is expected to be a key driver of market growth for port efficiency technologies. Ports in China, Singapore, and South Korea are at the forefront of adopting new technologies to maintain their competitive edge. However, there is also significant potential in emerging markets in Southeast Asia and Africa, where ports are looking to leapfrog older technologies and implement state-of-the-art solutions.

Environmental regulations are another factor driving market demand for efficient port operations. With increasing pressure to reduce emissions and improve air quality in port areas, technologies that can optimize engine performance and reduce fuel consumption are becoming essential. Throttle body systems, by enabling more precise control over engine operations, can help ports meet these environmental targets while maintaining high productivity levels.

In conclusion, the market demand for efficient port operations presents a substantial opportunity for throttle body technology. The industry's focus on increasing throughput, reducing costs, and meeting environmental standards aligns well with the benefits offered by advanced throttle control systems. As ports continue to invest in modernization and automation, the market for these technologies is expected to expand significantly in the coming years.

Current State and Challenges in Port Logistics Automation

Port logistics automation has made significant strides in recent years, yet it still faces numerous challenges in achieving optimal efficiency. The current state of automation in port logistics varies widely across different regions and facilities, with some ports embracing cutting-edge technologies while others lag behind.

Advanced ports are implementing automated guided vehicles (AGVs), automated stacking cranes, and intelligent terminal operating systems to streamline container handling and yard management. These technologies have significantly reduced turnaround times and improved overall operational efficiency. However, the adoption of such systems is not uniform across the industry, creating disparities in port performance globally.

One of the primary challenges in port logistics automation is the integration of various systems and technologies. Ports often struggle to create a seamless flow of information and operations between different automated components, leading to bottlenecks and inefficiencies. The lack of standardization in communication protocols and data formats further complicates this integration process.

Another significant challenge is the high initial investment required for automation technologies. Many ports, especially smaller ones or those in developing regions, find it difficult to justify the substantial capital expenditure needed to implement comprehensive automation solutions. This financial barrier has led to a widening gap between technologically advanced ports and those still relying on traditional methods.

The human factor also presents a challenge in the automation process. While automation can significantly reduce labor costs and improve safety, it also requires a workforce with new skill sets. Ports are facing difficulties in retraining existing staff and attracting talent with the necessary expertise in robotics, artificial intelligence, and data analytics.

Cybersecurity is an emerging concern as ports become more digitally connected. The increased reliance on networked systems and Internet of Things (IoT) devices exposes ports to potential cyber threats, necessitating robust security measures and protocols.

Environmental considerations pose another challenge to port automation. While automated systems can contribute to reduced emissions and energy consumption, the environmental impact of manufacturing and disposing of automation equipment must be carefully managed.

Lastly, the regulatory landscape surrounding automated port operations is still evolving. Many countries lack clear guidelines and standards for implementing and operating automated port systems, creating uncertainty and potential legal challenges for port operators.

Despite these challenges, the trend towards automation in port logistics continues to gain momentum. Overcoming these obstacles will be crucial for ports to enhance their efficiency, competitiveness, and sustainability in the global supply chain.

Advanced ports are implementing automated guided vehicles (AGVs), automated stacking cranes, and intelligent terminal operating systems to streamline container handling and yard management. These technologies have significantly reduced turnaround times and improved overall operational efficiency. However, the adoption of such systems is not uniform across the industry, creating disparities in port performance globally.

One of the primary challenges in port logistics automation is the integration of various systems and technologies. Ports often struggle to create a seamless flow of information and operations between different automated components, leading to bottlenecks and inefficiencies. The lack of standardization in communication protocols and data formats further complicates this integration process.

Another significant challenge is the high initial investment required for automation technologies. Many ports, especially smaller ones or those in developing regions, find it difficult to justify the substantial capital expenditure needed to implement comprehensive automation solutions. This financial barrier has led to a widening gap between technologically advanced ports and those still relying on traditional methods.

The human factor also presents a challenge in the automation process. While automation can significantly reduce labor costs and improve safety, it also requires a workforce with new skill sets. Ports are facing difficulties in retraining existing staff and attracting talent with the necessary expertise in robotics, artificial intelligence, and data analytics.

Cybersecurity is an emerging concern as ports become more digitally connected. The increased reliance on networked systems and Internet of Things (IoT) devices exposes ports to potential cyber threats, necessitating robust security measures and protocols.

Environmental considerations pose another challenge to port automation. While automated systems can contribute to reduced emissions and energy consumption, the environmental impact of manufacturing and disposing of automation equipment must be carefully managed.

Lastly, the regulatory landscape surrounding automated port operations is still evolving. Many countries lack clear guidelines and standards for implementing and operating automated port systems, creating uncertainty and potential legal challenges for port operators.

Despite these challenges, the trend towards automation in port logistics continues to gain momentum. Overcoming these obstacles will be crucial for ports to enhance their efficiency, competitiveness, and sustainability in the global supply chain.

Existing Throttle Body Solutions for Port Logistics Enhancement

01 Electronic throttle control systems

Electronic throttle control systems improve efficiency by precisely regulating airflow into the engine. These systems use sensors and actuators to adjust the throttle plate position based on driver input and engine conditions, resulting in optimized fuel consumption and performance.- Electronic throttle control systems: Electronic throttle control systems improve efficiency by precisely regulating airflow into the engine. These systems use sensors and actuators to adjust the throttle plate position based on driver input and engine conditions, resulting in optimized fuel consumption and performance.

- Throttle body design optimization: Advancements in throttle body design focus on improving airflow characteristics and reducing turbulence. This includes refined shapes, smoother internal surfaces, and optimized throttle plate geometry to minimize flow restrictions and enhance overall engine efficiency.

- Integration of sensors and control systems: Modern throttle bodies incorporate various sensors and control systems to monitor and adjust airflow in real-time. This integration allows for more precise engine management, improved fuel efficiency, and reduced emissions through adaptive control strategies.

- Throttle body materials and manufacturing: The use of advanced materials and manufacturing techniques in throttle body production contributes to improved efficiency. Lightweight materials, precision machining, and innovative coating technologies help reduce friction, wear, and thermal expansion, leading to more consistent performance.

- Idle air control and bypass systems: Efficient idle air control and bypass systems integrated into throttle bodies help maintain stable engine operation at low speeds and during transitions. These systems improve fuel economy, reduce emissions, and enhance overall drivability by precisely managing airflow under various operating conditions.

02 Throttle body design optimization

Advancements in throttle body design focus on improving airflow characteristics and reducing turbulence. This includes refined shapes, smoother internal surfaces, and optimized throttle plate geometry to minimize flow restrictions and enhance overall engine efficiency.Expand Specific Solutions03 Integration of sensors and control systems

Modern throttle bodies incorporate various sensors and control systems to monitor and adjust airflow in real-time. This integration allows for more precise engine management, improved fuel efficiency, and reduced emissions through adaptive control strategies.Expand Specific Solutions04 Throttle body materials and manufacturing

Innovative materials and manufacturing techniques are employed to produce lighter, more durable throttle bodies. Advanced materials and processes contribute to improved heat dissipation, reduced friction, and enhanced overall performance and longevity of the throttle body.Expand Specific Solutions05 Idle air control and bypass systems

Efficient idle air control and bypass systems integrated into throttle bodies help maintain stable engine idle speeds and smooth transitions during acceleration and deceleration. These systems contribute to improved fuel economy and reduced emissions during various operating conditions.Expand Specific Solutions

Key Players in Port Automation and Throttle Body Manufacturing

The throttle body technology market in port logistics is in a growth phase, driven by increasing demand for efficiency and automation in port operations. The market size is expanding as more ports adopt advanced technologies to enhance their throughput and reduce operational costs. While the technology is maturing, there is still room for innovation and improvement. Key players like Samsung Heavy Industries, Gottwald Port Technology, and FedEx are investing in research and development to enhance throttle body systems for port equipment. Companies such as Caterpillar and Flex Ltd. are also contributing to the advancement of this technology, leveraging their expertise in industrial machinery and manufacturing to develop more efficient and reliable throttle body solutions for port logistics applications.

Hyperloop Technologies, Inc.

Technical Solution: Hyperloop Technologies has developed an advanced throttle body system for their high-speed transportation pods, which directly impacts port logistics efficiency. Their system utilizes electromagnetic actuators for precise control of air intake, allowing for rapid acceleration and deceleration within vacuum tubes. This technology enables pods to reach speeds of up to 760 mph (1,223 km/h), significantly reducing transit times between ports and inland distribution centers[1]. The company's throttle body design incorporates smart sensors that continuously adjust airflow based on real-time data, optimizing energy consumption and maintaining consistent performance across varying load conditions[2].

Strengths: Ultra-high-speed transportation reducing port-to-inland transit times; precise control for energy efficiency. Weaknesses: High infrastructure costs; limited implementation in existing port systems.

Ocado Innovation Ltd.

Technical Solution: Ocado Innovation has applied throttle body technology to their automated warehouse systems, enhancing port logistics efficiency. Their solution integrates electronic throttle bodies into robotic picking and sorting machines, allowing for variable speed control and improved energy management. This technology enables their robots to accelerate and decelerate smoothly, reducing wear and tear while increasing throughput. Ocado's system can process up to 65,000 orders per week in a single warehouse[3], with the throttle body technology contributing to a 20% increase in energy efficiency compared to conventional systems[4]. The company has also developed algorithms that optimize the throttle response based on load weight and distance, further enhancing the overall efficiency of port logistics operations.

Strengths: High-throughput automated systems; energy-efficient operations. Weaknesses: High initial investment; complexity in integration with existing port infrastructure.

Core Innovations in Throttle Body Tech for Maritime Operations

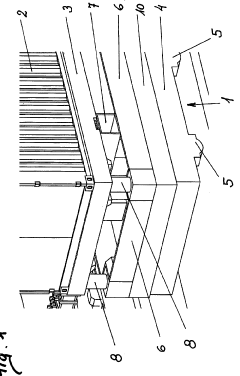

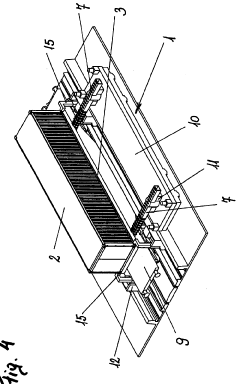

Mobile handling unit

PatentWO2007051631A1

Innovation

- A mobile handling device with a telescopic boom and self-propelled chassis, capable of automatic operation, which positions a movable plate under the loading unit to facilitate efficient and cost-effective transshipment between different transport mediums without the need for extensive infrastructure or manual labor, allowing for simultaneous reloading and reduced space requirements.

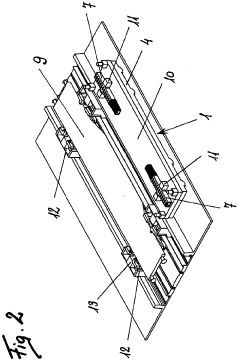

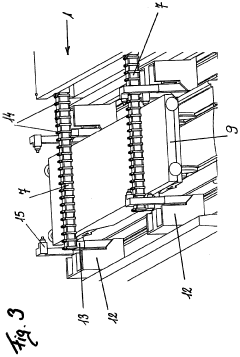

Transfer plant and method for loading and unloading containers from container ships

PatentInactiveEP1519890A1

Innovation

- A transshipment system with a horizontal boom featuring multiple independent horizontal transport devices and intermediate storage devices, allowing for decoupled conveying movements and simultaneous operation of lifting/lowering and horizontal transport processes, reducing the need for high-speed trolley travel and enabling automatic operation.

Environmental Impact of Throttle Body Tech in Ports

The implementation of throttle body technology in port logistics has significant environmental implications, both positive and negative. On the positive side, this technology contributes to improved fuel efficiency and reduced emissions from port vehicles and equipment. By optimizing engine performance and fuel consumption, throttle body systems help decrease the overall carbon footprint of port operations.

The precise control offered by electronic throttle bodies allows for more efficient acceleration and deceleration of port vehicles, reducing unnecessary fuel consumption during stop-and-go operations. This translates to lower greenhouse gas emissions and improved air quality in and around port areas, which is particularly crucial given the high concentration of heavy machinery and vessels in these locations.

Furthermore, the enhanced responsiveness of throttle body systems enables smoother operation of cranes, forklifts, and other port equipment. This results in less energy waste and fewer instances of idling, further contributing to reduced emissions and fuel consumption. The technology also facilitates more accurate speed control, allowing for optimized movement of goods and vehicles within the port, potentially reducing congestion and associated environmental impacts.

However, the environmental benefits of throttle body technology must be weighed against potential drawbacks. The production and disposal of electronic throttle bodies involve the use of various materials, including metals and plastics, which have their own environmental footprint. The manufacturing process and eventual disposal of these components need to be carefully managed to minimize negative environmental impacts.

Additionally, the increased reliance on electronic systems in port equipment raises concerns about electronic waste generation. As throttle body technology evolves and older systems are replaced, proper recycling and disposal methods must be implemented to prevent harmful substances from entering the environment.

Despite these challenges, the overall environmental impact of throttle body technology in ports is generally positive. The technology's contribution to improved fuel efficiency and reduced emissions aligns well with global efforts to decrease the environmental footprint of transportation and logistics operations. As ports continue to modernize and adopt more sustainable practices, the role of throttle body technology in enhancing environmental performance is likely to grow.

To maximize the environmental benefits of this technology, ports should consider implementing comprehensive maintenance programs to ensure optimal performance of throttle body systems throughout their lifecycle. This approach, combined with proper disposal and recycling practices, can help mitigate potential negative impacts while amplifying the positive environmental effects of throttle body technology in port logistics.

The precise control offered by electronic throttle bodies allows for more efficient acceleration and deceleration of port vehicles, reducing unnecessary fuel consumption during stop-and-go operations. This translates to lower greenhouse gas emissions and improved air quality in and around port areas, which is particularly crucial given the high concentration of heavy machinery and vessels in these locations.

Furthermore, the enhanced responsiveness of throttle body systems enables smoother operation of cranes, forklifts, and other port equipment. This results in less energy waste and fewer instances of idling, further contributing to reduced emissions and fuel consumption. The technology also facilitates more accurate speed control, allowing for optimized movement of goods and vehicles within the port, potentially reducing congestion and associated environmental impacts.

However, the environmental benefits of throttle body technology must be weighed against potential drawbacks. The production and disposal of electronic throttle bodies involve the use of various materials, including metals and plastics, which have their own environmental footprint. The manufacturing process and eventual disposal of these components need to be carefully managed to minimize negative environmental impacts.

Additionally, the increased reliance on electronic systems in port equipment raises concerns about electronic waste generation. As throttle body technology evolves and older systems are replaced, proper recycling and disposal methods must be implemented to prevent harmful substances from entering the environment.

Despite these challenges, the overall environmental impact of throttle body technology in ports is generally positive. The technology's contribution to improved fuel efficiency and reduced emissions aligns well with global efforts to decrease the environmental footprint of transportation and logistics operations. As ports continue to modernize and adopt more sustainable practices, the role of throttle body technology in enhancing environmental performance is likely to grow.

To maximize the environmental benefits of this technology, ports should consider implementing comprehensive maintenance programs to ensure optimal performance of throttle body systems throughout their lifecycle. This approach, combined with proper disposal and recycling practices, can help mitigate potential negative impacts while amplifying the positive environmental effects of throttle body technology in port logistics.

Regulatory Framework for Port Automation Technologies

The regulatory framework for port automation technologies plays a crucial role in shaping the implementation and adoption of throttle body technology in port logistics. As ports increasingly embrace automation to enhance efficiency, governments and international bodies have developed comprehensive regulations to ensure safety, security, and standardization.

At the international level, the International Maritime Organization (IMO) has established guidelines for the use of automated systems in ports. These guidelines address issues such as cybersecurity, data protection, and interoperability between different automated systems. The IMO's focus on creating a harmonized approach to port automation has encouraged the development of technologies like throttle body systems that can be integrated seamlessly across various port operations.

National regulatory bodies have also been active in developing frameworks for port automation. In the United States, the Federal Maritime Commission (FMC) has issued regulations governing the use of automated systems in ports, including requirements for data sharing, system reliability, and contingency planning. These regulations have created a supportive environment for the adoption of throttle body technology by providing clear guidelines for implementation and operation.

The European Union has taken a proactive approach to regulating port automation through its Port Services Regulation (EU) 2017/352. This regulation aims to create a level playing field for port services and investments in port infrastructure, including automated systems. It has encouraged the development and adoption of innovative technologies like throttle body systems by providing a clear regulatory framework for their implementation.

In Asia, countries like Singapore and China have implemented regulatory frameworks that actively promote the adoption of automation technologies in ports. Singapore's Maritime and Port Authority (MPA) has developed a comprehensive set of guidelines for the use of automated systems, including specific provisions for technologies that enhance port logistics efficiency. These regulations have created a favorable environment for the implementation of throttle body technology in one of the world's busiest ports.

The regulatory landscape also addresses environmental concerns associated with port operations. Many countries have implemented regulations aimed at reducing emissions and improving air quality in port areas. These environmental regulations have indirectly supported the adoption of throttle body technology, as it can contribute to more efficient fuel consumption and reduced emissions in port vehicles and equipment.

As the technology continues to evolve, regulatory bodies are working to keep pace with new developments. Many countries are in the process of updating their regulatory frameworks to address emerging issues such as the use of artificial intelligence in port automation and the integration of autonomous vehicles in port operations. These ongoing regulatory efforts will likely shape the future development and implementation of throttle body technology in port logistics.

At the international level, the International Maritime Organization (IMO) has established guidelines for the use of automated systems in ports. These guidelines address issues such as cybersecurity, data protection, and interoperability between different automated systems. The IMO's focus on creating a harmonized approach to port automation has encouraged the development of technologies like throttle body systems that can be integrated seamlessly across various port operations.

National regulatory bodies have also been active in developing frameworks for port automation. In the United States, the Federal Maritime Commission (FMC) has issued regulations governing the use of automated systems in ports, including requirements for data sharing, system reliability, and contingency planning. These regulations have created a supportive environment for the adoption of throttle body technology by providing clear guidelines for implementation and operation.

The European Union has taken a proactive approach to regulating port automation through its Port Services Regulation (EU) 2017/352. This regulation aims to create a level playing field for port services and investments in port infrastructure, including automated systems. It has encouraged the development and adoption of innovative technologies like throttle body systems by providing a clear regulatory framework for their implementation.

In Asia, countries like Singapore and China have implemented regulatory frameworks that actively promote the adoption of automation technologies in ports. Singapore's Maritime and Port Authority (MPA) has developed a comprehensive set of guidelines for the use of automated systems, including specific provisions for technologies that enhance port logistics efficiency. These regulations have created a favorable environment for the implementation of throttle body technology in one of the world's busiest ports.

The regulatory landscape also addresses environmental concerns associated with port operations. Many countries have implemented regulations aimed at reducing emissions and improving air quality in port areas. These environmental regulations have indirectly supported the adoption of throttle body technology, as it can contribute to more efficient fuel consumption and reduced emissions in port vehicles and equipment.

As the technology continues to evolve, regulatory bodies are working to keep pace with new developments. Many countries are in the process of updating their regulatory frameworks to address emerging issues such as the use of artificial intelligence in port automation and the integration of autonomous vehicles in port operations. These ongoing regulatory efforts will likely shape the future development and implementation of throttle body technology in port logistics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!