How Throttle Body Design Enhances Solar Panel Efficiency

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Panel Efficiency Goals

Solar panel efficiency has been a critical focus in the renewable energy sector, with continuous efforts to maximize energy conversion and output. The primary goal is to increase the percentage of sunlight that can be effectively converted into usable electricity. Currently, commercial solar panels typically achieve efficiencies between 15% to 22%, with high-end models reaching up to 25%. However, researchers and industry leaders are striving to push these boundaries further.

One of the key objectives is to surpass the 30% efficiency mark for commercially viable solar panels. This ambitious target requires significant advancements in materials science, cell design, and manufacturing processes. Achieving this milestone would represent a major leap in solar technology, potentially revolutionizing the economics of solar energy adoption.

Another important goal is to improve the performance of solar panels under various environmental conditions. This includes enhancing their efficiency in low-light situations, such as during cloudy days or in regions with less direct sunlight. Additionally, there is a focus on maintaining high efficiency levels even as temperatures fluctuate, addressing the issue of efficiency loss in hot climates.

Durability and longevity are also crucial aspects of solar panel efficiency goals. Researchers aim to develop panels that can maintain their peak performance over extended periods, ideally 25 to 30 years or more. This involves improving resistance to degradation factors like UV radiation, temperature cycling, and physical stress.

Cost-effectiveness remains a paramount consideration in efficiency improvements. The industry is working towards achieving higher efficiencies without significantly increasing production costs, aiming to reduce the overall cost per watt of solar energy. This balance between performance and affordability is essential for wider adoption of solar technology.

Emerging technologies like multi-junction cells and perovskite materials are at the forefront of efficiency enhancement efforts. These innovations promise to break through current efficiency limitations, with some laboratory prototypes already demonstrating efficiencies above 40%. The challenge lies in translating these laboratory successes into commercially viable products.

Integrating smart technologies and IoT capabilities into solar panels is another goal aimed at optimizing overall system efficiency. This includes developing panels with built-in monitoring systems, self-cleaning mechanisms, and adaptive positioning to maximize sunlight exposure throughout the day.

In the context of throttle body design enhancing solar panel efficiency, the goals likely focus on improving the panels' ability to manage heat and airflow. This could involve developing systems that regulate temperature more effectively, potentially using principles similar to automotive throttle bodies to control air and heat distribution across the panel surface, thereby maintaining optimal operating conditions for maximum efficiency.

One of the key objectives is to surpass the 30% efficiency mark for commercially viable solar panels. This ambitious target requires significant advancements in materials science, cell design, and manufacturing processes. Achieving this milestone would represent a major leap in solar technology, potentially revolutionizing the economics of solar energy adoption.

Another important goal is to improve the performance of solar panels under various environmental conditions. This includes enhancing their efficiency in low-light situations, such as during cloudy days or in regions with less direct sunlight. Additionally, there is a focus on maintaining high efficiency levels even as temperatures fluctuate, addressing the issue of efficiency loss in hot climates.

Durability and longevity are also crucial aspects of solar panel efficiency goals. Researchers aim to develop panels that can maintain their peak performance over extended periods, ideally 25 to 30 years or more. This involves improving resistance to degradation factors like UV radiation, temperature cycling, and physical stress.

Cost-effectiveness remains a paramount consideration in efficiency improvements. The industry is working towards achieving higher efficiencies without significantly increasing production costs, aiming to reduce the overall cost per watt of solar energy. This balance between performance and affordability is essential for wider adoption of solar technology.

Emerging technologies like multi-junction cells and perovskite materials are at the forefront of efficiency enhancement efforts. These innovations promise to break through current efficiency limitations, with some laboratory prototypes already demonstrating efficiencies above 40%. The challenge lies in translating these laboratory successes into commercially viable products.

Integrating smart technologies and IoT capabilities into solar panels is another goal aimed at optimizing overall system efficiency. This includes developing panels with built-in monitoring systems, self-cleaning mechanisms, and adaptive positioning to maximize sunlight exposure throughout the day.

In the context of throttle body design enhancing solar panel efficiency, the goals likely focus on improving the panels' ability to manage heat and airflow. This could involve developing systems that regulate temperature more effectively, potentially using principles similar to automotive throttle bodies to control air and heat distribution across the panel surface, thereby maintaining optimal operating conditions for maximum efficiency.

Market Demand Analysis

The market demand for solar panel efficiency enhancement technologies, including innovative throttle body designs, has been steadily growing in recent years. This surge is primarily driven by the increasing global focus on renewable energy sources and the need to maximize the performance of existing solar installations. As governments worldwide implement stricter environmental regulations and set ambitious renewable energy targets, the solar industry is under pressure to deliver more efficient and cost-effective solutions.

The potential market size for solar panel efficiency enhancement technologies is substantial. The global solar panel market was valued at approximately $170 billion in 2021 and is projected to reach $300 billion by 2030, with a compound annual growth rate (CAGR) of 7.2%. Within this broader market, the demand for efficiency-boosting technologies is expected to grow even faster, as solar farm operators and residential users seek to maximize their return on investment.

Throttle body design, traditionally associated with internal combustion engines, has emerged as an unexpected yet promising avenue for enhancing solar panel efficiency. This innovative approach addresses one of the key challenges in solar energy production: the loss of efficiency due to overheating. By adapting throttle body principles to manage airflow and temperature around solar panels, manufacturers can potentially increase energy output by 5-10% under optimal conditions.

The market for this specific technology is still in its nascent stages, but early adopters in regions with high solar irradiance, such as the Middle East, Australia, and the southwestern United States, have shown significant interest. These areas, where solar panel efficiency is crucial due to intense heat, represent the initial target markets for throttle body-enhanced solar panels.

Industry trends indicate a growing preference for integrated solutions that combine multiple efficiency-enhancing technologies. This trend favors the development of throttle body designs that can be seamlessly incorporated into existing solar panel systems or integrated into new, high-efficiency panels during manufacturing. The ability to retrofit existing installations with this technology could open up a substantial market segment, as it allows solar farm operators to upgrade their systems without complete replacement.

The demand for this technology is further bolstered by the increasing focus on sustainable urban development and smart cities. As urban areas seek to maximize their renewable energy generation within limited spaces, technologies that can enhance the efficiency of rooftop and building-integrated photovoltaic systems become increasingly valuable. Throttle body designs that can improve the performance of these space-constrained installations are likely to see strong demand in urban markets worldwide.

The potential market size for solar panel efficiency enhancement technologies is substantial. The global solar panel market was valued at approximately $170 billion in 2021 and is projected to reach $300 billion by 2030, with a compound annual growth rate (CAGR) of 7.2%. Within this broader market, the demand for efficiency-boosting technologies is expected to grow even faster, as solar farm operators and residential users seek to maximize their return on investment.

Throttle body design, traditionally associated with internal combustion engines, has emerged as an unexpected yet promising avenue for enhancing solar panel efficiency. This innovative approach addresses one of the key challenges in solar energy production: the loss of efficiency due to overheating. By adapting throttle body principles to manage airflow and temperature around solar panels, manufacturers can potentially increase energy output by 5-10% under optimal conditions.

The market for this specific technology is still in its nascent stages, but early adopters in regions with high solar irradiance, such as the Middle East, Australia, and the southwestern United States, have shown significant interest. These areas, where solar panel efficiency is crucial due to intense heat, represent the initial target markets for throttle body-enhanced solar panels.

Industry trends indicate a growing preference for integrated solutions that combine multiple efficiency-enhancing technologies. This trend favors the development of throttle body designs that can be seamlessly incorporated into existing solar panel systems or integrated into new, high-efficiency panels during manufacturing. The ability to retrofit existing installations with this technology could open up a substantial market segment, as it allows solar farm operators to upgrade their systems without complete replacement.

The demand for this technology is further bolstered by the increasing focus on sustainable urban development and smart cities. As urban areas seek to maximize their renewable energy generation within limited spaces, technologies that can enhance the efficiency of rooftop and building-integrated photovoltaic systems become increasingly valuable. Throttle body designs that can improve the performance of these space-constrained installations are likely to see strong demand in urban markets worldwide.

Current Challenges

The integration of throttle body design principles into solar panel technology presents several significant challenges that researchers and engineers are currently grappling with. One of the primary obstacles is the fundamental difference in operational environments between automotive throttle bodies and solar panels. While throttle bodies are designed to regulate airflow in internal combustion engines, solar panels operate in static, open-air conditions. This disparity necessitates a complete reimagining of how throttle body concepts can be adapted to enhance solar panel efficiency.

Another major challenge lies in the materials science aspect of this integration. Traditional throttle bodies are typically made of metal alloys designed to withstand high temperatures and pressures. Solar panels, on the other hand, require materials that are lightweight, durable, and highly transparent to maximize sunlight absorption. Developing composite materials that can incorporate the beneficial aspects of throttle body design while maintaining the essential properties of solar panels is a complex undertaking.

The issue of scalability also presents a significant hurdle. Throttle bodies are relatively small components, whereas solar panels often cover large surface areas. Scaling up throttle body-inspired designs to accommodate the size requirements of solar panels without compromising efficiency or structural integrity is a formidable engineering challenge. This scaling process must also consider the cost-effectiveness of production to ensure commercial viability.

Energy loss during the conversion process is another critical concern. While throttle bodies are designed to optimize airflow, their adaptation to solar panels must focus on maximizing photon capture and conversion to electrical energy. Minimizing energy losses at the interface between the throttle body-inspired structures and the photovoltaic cells is crucial for overall system efficiency.

Furthermore, the dynamic nature of solar energy poses unique challenges. Unlike the controlled environment of an engine, solar panels must contend with varying light conditions, weather patterns, and seasonal changes. Developing adaptive systems that can optimize efficiency across these fluctuating conditions while incorporating throttle body design principles adds another layer of complexity to the research.

Lastly, the integration of throttle body concepts must not compromise the durability and longevity of solar panels. Solar installations are expected to operate efficiently for decades, often in harsh environmental conditions. Ensuring that any throttle body-inspired enhancements do not reduce the lifespan or increase the maintenance requirements of solar panels is a critical consideration in the development process.

Another major challenge lies in the materials science aspect of this integration. Traditional throttle bodies are typically made of metal alloys designed to withstand high temperatures and pressures. Solar panels, on the other hand, require materials that are lightweight, durable, and highly transparent to maximize sunlight absorption. Developing composite materials that can incorporate the beneficial aspects of throttle body design while maintaining the essential properties of solar panels is a complex undertaking.

The issue of scalability also presents a significant hurdle. Throttle bodies are relatively small components, whereas solar panels often cover large surface areas. Scaling up throttle body-inspired designs to accommodate the size requirements of solar panels without compromising efficiency or structural integrity is a formidable engineering challenge. This scaling process must also consider the cost-effectiveness of production to ensure commercial viability.

Energy loss during the conversion process is another critical concern. While throttle bodies are designed to optimize airflow, their adaptation to solar panels must focus on maximizing photon capture and conversion to electrical energy. Minimizing energy losses at the interface between the throttle body-inspired structures and the photovoltaic cells is crucial for overall system efficiency.

Furthermore, the dynamic nature of solar energy poses unique challenges. Unlike the controlled environment of an engine, solar panels must contend with varying light conditions, weather patterns, and seasonal changes. Developing adaptive systems that can optimize efficiency across these fluctuating conditions while incorporating throttle body design principles adds another layer of complexity to the research.

Lastly, the integration of throttle body concepts must not compromise the durability and longevity of solar panels. Solar installations are expected to operate efficiently for decades, often in harsh environmental conditions. Ensuring that any throttle body-inspired enhancements do not reduce the lifespan or increase the maintenance requirements of solar panels is a critical consideration in the development process.

Existing Throttle Solutions

01 Throttle body design improvements

Various design improvements can enhance throttle body efficiency. These include optimizing the shape and size of the throttle bore, improving airflow characteristics, and reducing turbulence. Advanced manufacturing techniques and materials can also contribute to better performance and durability of the throttle body.- Improved throttle body design: Enhanced throttle body designs focus on optimizing airflow and reducing turbulence. This includes modifications to the shape and size of the throttle bore, as well as improvements to the throttle plate and its positioning. These design changes aim to increase overall efficiency and responsiveness of the throttle body.

- Electronic throttle control systems: Implementation of electronic throttle control systems improves throttle body efficiency by providing more precise control over airflow. These systems use sensors and actuators to adjust throttle position based on various engine parameters, resulting in improved fuel economy and performance.

- Throttle body cleaning and maintenance: Regular cleaning and maintenance of throttle bodies can significantly improve their efficiency. This includes removing carbon deposits, adjusting idle speed, and ensuring proper lubrication of moving parts. Proper maintenance helps maintain optimal airflow and prevents performance degradation over time.

- Integration of additional components: Incorporating additional components into the throttle body design can enhance overall efficiency. This may include integrating idle air control valves, air temperature sensors, or pressure sensors directly into the throttle body assembly. Such integration can improve response times and reduce potential points of failure.

- Material selection and manufacturing techniques: Utilizing advanced materials and manufacturing techniques can improve throttle body efficiency. This includes the use of lightweight alloys, precision machining, and advanced coating technologies to reduce friction, improve durability, and enhance overall performance of the throttle body.

02 Electronic throttle control systems

Electronic throttle control systems can significantly improve throttle body efficiency. These systems use sensors and actuators to precisely control throttle position, resulting in better fuel economy, improved engine response, and reduced emissions. Integration with engine management systems allows for more sophisticated control strategies.Expand Specific Solutions03 Throttle body cleaning and maintenance

Regular cleaning and maintenance of the throttle body can improve its efficiency. This includes removing carbon deposits, ensuring proper lubrication of moving parts, and checking for wear or damage. Specialized cleaning solutions and techniques can be used to maintain optimal performance without causing damage to sensitive components.Expand Specific Solutions04 Integration of additional components

Integrating additional components into the throttle body can enhance overall efficiency. This may include incorporating idle air control valves, sensors for measuring airflow or temperature, or even fuel injection components. Such integration can lead to more compact designs and improved system performance.Expand Specific Solutions05 Advanced materials and coatings

The use of advanced materials and coatings can improve throttle body efficiency. This includes utilizing lightweight alloys to reduce overall weight, applying low-friction coatings to moving parts, and using corrosion-resistant materials to extend the lifespan of the throttle body. These improvements can lead to better performance and reduced maintenance requirements.Expand Specific Solutions

Key Industry Players

The competition landscape for enhancing solar panel efficiency through throttle body design is in its early stages, with the market showing potential for significant growth. The technology is still emerging, as evidenced by the diverse range of companies involved, including automotive giants like Toyota, Mercedes-Benz, and Boeing, as well as specialized solar energy firms like SolarEdge and AZUR Space. The market size is expected to expand as the demand for more efficient solar energy solutions increases. Companies like Sono Motors and Smart Flower Energy Technology are pioneering innovative approaches, while established players such as Mitsubishi Electric and LG Electronics are leveraging their expertise to develop advanced solar technologies.

LG Electronics, Inc.

Technical Solution: LG Electronics, before exiting the solar panel business in 2022, had developed several innovations to enhance solar panel efficiency. Their NeON series utilized CELLO technology, which replaced three busbars with 12 thin wires to reduce electrical loss and increase light absorption[6]. LG also implemented bifacial cell technology in some models, allowing panels to capture light from both sides, potentially increasing energy yield by up to 30% in optimal conditions[7]. While not employing throttle body design, LG's approach focused on cell structure and panel design to maximize efficiency and performance under various conditions.

Strengths: Innovative cell and panel designs, high efficiency ratings, bifacial technology for increased energy yield. Weaknesses: No longer in production, potentially higher costs compared to standard panels.

Sono Motors GmbH

Technical Solution: Sono Motors has developed an innovative approach to integrating solar cells into electric vehicles, which, while not directly related to throttle body design, demonstrates novel ways of enhancing solar panel efficiency and application. Their Sion electric car features solar cells embedded in the vehicle's body panels, using polymer-based solar technology that is lighter and more flexible than traditional glass-based panels[8]. This integration allows for energy generation while driving or parked, potentially adding up to 245 km (152 miles) of range per week under optimal conditions[9]. Sono's approach focuses on maximizing the surface area available for solar energy capture and integrating it seamlessly into the vehicle's design.

Strengths: Innovative application of solar technology, increases EV range, utilizes typically unused surfaces for energy generation. Weaknesses: Efficiency may be lower than traditional panels, potential durability concerns in automotive applications.

Core Throttle Innovations

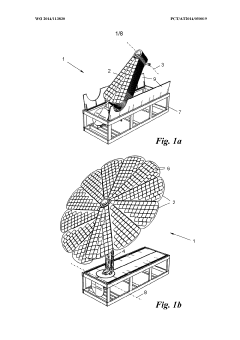

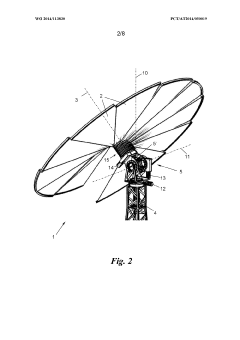

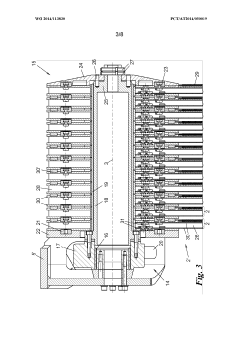

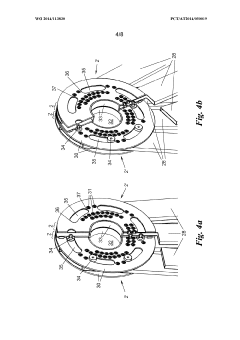

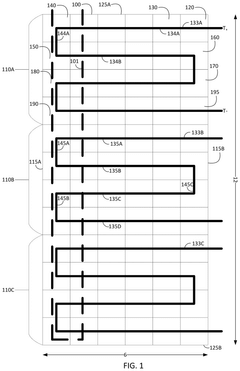

Solar module

PatentWO2014113830A1

Innovation

- The solar module design features drivers and stops exclusively on the axial end sections of adjacent panels, allowing radially projecting sections to swing out unhindered, enhancing wind resistance and service life, with disk-shaped end sections and a driver/stop construction that minimizes friction and axial space requirements.

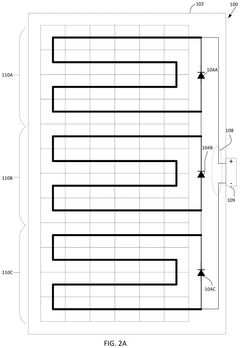

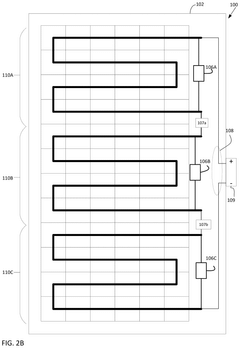

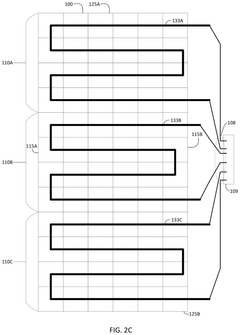

Solar Panel Arrangement

PatentPendingUS20250107249A1

Innovation

- The solar panel design incorporates substrings of photovoltaic cells oriented horizontally, allowing higher substrings to operate even when lower substrings are shaded or blocked, thereby increasing overall productivity.

Environmental Impact

The environmental impact of solar panel efficiency improvements through throttle body design is a crucial aspect to consider in the development of sustainable energy solutions. By enhancing the efficiency of solar panels, this innovative approach contributes significantly to reducing the overall environmental footprint of solar energy production.

One of the primary environmental benefits of increased solar panel efficiency is the reduction in land use requirements. As panels become more efficient, fewer units are needed to generate the same amount of electricity, leading to a decrease in the total area required for solar installations. This reduction in land use helps preserve natural habitats and ecosystems, minimizing the impact on local flora and fauna.

Moreover, improved efficiency translates to a lower demand for raw materials in solar panel production. With fewer panels needed to achieve the same energy output, there is a corresponding decrease in the extraction and processing of materials such as silicon, glass, and metals. This reduction in material consumption contributes to the conservation of natural resources and reduces the environmental impact associated with mining and manufacturing processes.

The enhanced efficiency also leads to a decrease in the overall carbon footprint of solar energy production. By generating more electricity from the same amount of sunlight, solar panels with improved throttle body designs can offset a larger portion of fossil fuel-based energy production. This results in a more significant reduction in greenhouse gas emissions, helping to mitigate climate change and its associated environmental impacts.

Water conservation is another important environmental benefit of increased solar panel efficiency. Traditional power generation methods, such as coal or nuclear plants, require substantial amounts of water for cooling purposes. In contrast, solar panels with improved efficiency can generate more electricity without additional water consumption, contributing to the preservation of water resources in regions where they are scarce.

Furthermore, the enhanced efficiency of solar panels through throttle body design improvements can lead to a reduction in electronic waste. As panels become more efficient and durable, their lifespan is extended, reducing the frequency of replacements and the associated waste generation. This contributes to a more sustainable lifecycle for solar energy systems and minimizes the environmental impact of disposal and recycling processes.

The improved efficiency also has indirect environmental benefits. By making solar energy more cost-effective and accessible, it encourages wider adoption of renewable energy sources. This shift away from fossil fuels helps reduce air and water pollution associated with traditional power generation methods, leading to improved air and water quality in surrounding ecosystems.

One of the primary environmental benefits of increased solar panel efficiency is the reduction in land use requirements. As panels become more efficient, fewer units are needed to generate the same amount of electricity, leading to a decrease in the total area required for solar installations. This reduction in land use helps preserve natural habitats and ecosystems, minimizing the impact on local flora and fauna.

Moreover, improved efficiency translates to a lower demand for raw materials in solar panel production. With fewer panels needed to achieve the same energy output, there is a corresponding decrease in the extraction and processing of materials such as silicon, glass, and metals. This reduction in material consumption contributes to the conservation of natural resources and reduces the environmental impact associated with mining and manufacturing processes.

The enhanced efficiency also leads to a decrease in the overall carbon footprint of solar energy production. By generating more electricity from the same amount of sunlight, solar panels with improved throttle body designs can offset a larger portion of fossil fuel-based energy production. This results in a more significant reduction in greenhouse gas emissions, helping to mitigate climate change and its associated environmental impacts.

Water conservation is another important environmental benefit of increased solar panel efficiency. Traditional power generation methods, such as coal or nuclear plants, require substantial amounts of water for cooling purposes. In contrast, solar panels with improved efficiency can generate more electricity without additional water consumption, contributing to the preservation of water resources in regions where they are scarce.

Furthermore, the enhanced efficiency of solar panels through throttle body design improvements can lead to a reduction in electronic waste. As panels become more efficient and durable, their lifespan is extended, reducing the frequency of replacements and the associated waste generation. This contributes to a more sustainable lifecycle for solar energy systems and minimizes the environmental impact of disposal and recycling processes.

The improved efficiency also has indirect environmental benefits. By making solar energy more cost-effective and accessible, it encourages wider adoption of renewable energy sources. This shift away from fossil fuels helps reduce air and water pollution associated with traditional power generation methods, leading to improved air and water quality in surrounding ecosystems.

Cost-Benefit Analysis

The cost-benefit analysis of implementing throttle body design in solar panels reveals a complex interplay of financial considerations and performance enhancements. Initial investment costs for integrating throttle body technology into solar panel systems are significant, primarily due to the need for specialized manufacturing processes and materials. These upfront expenses include redesigning panel structures, incorporating precision-engineered throttle mechanisms, and potentially modifying existing production lines.

However, the long-term benefits of this innovation are substantial. Enhanced solar panel efficiency translates to increased energy output per unit area, potentially reducing the overall number of panels required for a given power generation target. This reduction in panel quantity can lead to savings in installation costs, land use, and associated infrastructure expenses. Moreover, the improved energy conversion rates result in higher electricity generation over the panel's lifetime, increasing the return on investment for solar farm operators and individual consumers alike.

Maintenance costs present a nuanced picture. While the introduction of moving parts in the form of throttle bodies may initially suggest higher maintenance requirements, advanced materials and precision engineering can mitigate these concerns. The potential for self-cleaning mechanisms within the throttle design could actually reduce long-term maintenance needs and associated costs compared to traditional static panel designs.

Energy storage considerations also factor into the cost-benefit equation. The ability of throttle body-equipped panels to more efficiently capture and convert solar energy during peak hours could reduce the reliance on expensive energy storage solutions, offering additional cost savings in large-scale solar installations.

From an environmental perspective, the increased efficiency of throttle body-enhanced panels contributes to a reduced carbon footprint per unit of energy produced. This aligns with global sustainability goals and may offer financial benefits through carbon credits or green energy incentives in certain markets.

The scalability of throttle body technology in solar panels presents opportunities for economies of scale. As production volumes increase and manufacturing processes are optimized, the per-unit cost of implementing this technology is expected to decrease, improving the overall cost-benefit ratio over time.

In conclusion, while the initial investment in throttle body design for solar panels is substantial, the long-term benefits in energy efficiency, reduced infrastructure needs, and potential maintenance savings present a compelling case for adoption. As the technology matures and production scales up, the cost-benefit analysis is likely to become increasingly favorable, positioning throttle body-enhanced solar panels as a valuable innovation in the renewable energy sector.

However, the long-term benefits of this innovation are substantial. Enhanced solar panel efficiency translates to increased energy output per unit area, potentially reducing the overall number of panels required for a given power generation target. This reduction in panel quantity can lead to savings in installation costs, land use, and associated infrastructure expenses. Moreover, the improved energy conversion rates result in higher electricity generation over the panel's lifetime, increasing the return on investment for solar farm operators and individual consumers alike.

Maintenance costs present a nuanced picture. While the introduction of moving parts in the form of throttle bodies may initially suggest higher maintenance requirements, advanced materials and precision engineering can mitigate these concerns. The potential for self-cleaning mechanisms within the throttle design could actually reduce long-term maintenance needs and associated costs compared to traditional static panel designs.

Energy storage considerations also factor into the cost-benefit equation. The ability of throttle body-equipped panels to more efficiently capture and convert solar energy during peak hours could reduce the reliance on expensive energy storage solutions, offering additional cost savings in large-scale solar installations.

From an environmental perspective, the increased efficiency of throttle body-enhanced panels contributes to a reduced carbon footprint per unit of energy produced. This aligns with global sustainability goals and may offer financial benefits through carbon credits or green energy incentives in certain markets.

The scalability of throttle body technology in solar panels presents opportunities for economies of scale. As production volumes increase and manufacturing processes are optimized, the per-unit cost of implementing this technology is expected to decrease, improving the overall cost-benefit ratio over time.

In conclusion, while the initial investment in throttle body design for solar panels is substantial, the long-term benefits in energy efficiency, reduced infrastructure needs, and potential maintenance savings present a compelling case for adoption. As the technology matures and production scales up, the cost-benefit analysis is likely to become increasingly favorable, positioning throttle body-enhanced solar panels as a valuable innovation in the renewable energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!