How Throttle Body Technology Supports Vertical Farming Systems

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body in Vertical Farming: Background and Objectives

Throttle body technology, traditionally associated with internal combustion engines, has found a novel application in the realm of vertical farming systems. This innovative integration represents a significant leap in agricultural technology, merging precision control mechanisms with sustainable food production methods. The evolution of throttle body technology from automotive applications to agricultural systems showcases the adaptability and versatility of engineering solutions across diverse industries.

Vertical farming, a concept that has gained traction in recent years, addresses the growing need for efficient and sustainable food production in urban environments. As global populations continue to urbanize and arable land becomes increasingly scarce, vertical farming offers a promising solution to food security challenges. The incorporation of throttle body technology into these systems marks a pivotal advancement in optimizing resource utilization and crop yield.

The primary objective of integrating throttle body technology in vertical farming is to enhance the precision and efficiency of environmental control within these closed agricultural ecosystems. By leveraging the fine-tuned control capabilities of throttle bodies, vertical farming systems can achieve unprecedented levels of accuracy in regulating airflow, temperature, humidity, and CO2 levels. This precise management of environmental factors is crucial for maximizing crop growth and quality in the confined spaces typical of vertical farms.

Furthermore, the adoption of throttle body technology in vertical farming aligns with the broader trend of smart agriculture and Internet of Things (IoT) integration in food production. The ability to dynamically adjust environmental parameters based on real-time data and predictive algorithms represents a significant step towards fully automated and optimized farming systems. This technological synergy promises to reduce resource consumption, minimize waste, and increase overall system efficiency.

As we explore the intersection of throttle body technology and vertical farming, it is essential to consider the historical context of both fields. The development of throttle bodies in automotive engineering has been driven by the need for precise fuel and air mixture control to improve engine performance and reduce emissions. Similarly, vertical farming has evolved from early conceptual designs to practical implementations, driven by advancements in LED lighting, hydroponics, and climate control systems. The convergence of these technologies exemplifies the cross-pollination of ideas across different engineering disciplines, leading to innovative solutions for global challenges.

Vertical farming, a concept that has gained traction in recent years, addresses the growing need for efficient and sustainable food production in urban environments. As global populations continue to urbanize and arable land becomes increasingly scarce, vertical farming offers a promising solution to food security challenges. The incorporation of throttle body technology into these systems marks a pivotal advancement in optimizing resource utilization and crop yield.

The primary objective of integrating throttle body technology in vertical farming is to enhance the precision and efficiency of environmental control within these closed agricultural ecosystems. By leveraging the fine-tuned control capabilities of throttle bodies, vertical farming systems can achieve unprecedented levels of accuracy in regulating airflow, temperature, humidity, and CO2 levels. This precise management of environmental factors is crucial for maximizing crop growth and quality in the confined spaces typical of vertical farms.

Furthermore, the adoption of throttle body technology in vertical farming aligns with the broader trend of smart agriculture and Internet of Things (IoT) integration in food production. The ability to dynamically adjust environmental parameters based on real-time data and predictive algorithms represents a significant step towards fully automated and optimized farming systems. This technological synergy promises to reduce resource consumption, minimize waste, and increase overall system efficiency.

As we explore the intersection of throttle body technology and vertical farming, it is essential to consider the historical context of both fields. The development of throttle bodies in automotive engineering has been driven by the need for precise fuel and air mixture control to improve engine performance and reduce emissions. Similarly, vertical farming has evolved from early conceptual designs to practical implementations, driven by advancements in LED lighting, hydroponics, and climate control systems. The convergence of these technologies exemplifies the cross-pollination of ideas across different engineering disciplines, leading to innovative solutions for global challenges.

Market Analysis for Vertical Farming Solutions

The vertical farming market has experienced significant growth in recent years, driven by increasing urbanization, climate change concerns, and the need for sustainable food production. As of 2021, the global vertical farming market was valued at approximately $3.1 billion and is projected to reach $9.7 billion by 2026, growing at a CAGR of 25.7% during the forecast period.

The demand for vertical farming solutions is primarily fueled by the growing population in urban areas, which is expected to reach 68% of the global population by 2050. This demographic shift has created a pressing need for efficient and sustainable food production methods in densely populated areas. Vertical farming addresses this challenge by offering a space-efficient solution that can produce high yields of fresh produce year-round, regardless of external weather conditions.

The market for vertical farming solutions can be segmented based on growing mechanism, structure type, and crop type. Hydroponics is currently the dominant growing mechanism, accounting for approximately 60% of the market share. However, aeroponics is expected to witness the highest growth rate due to its water-efficient nature and potential for higher yields.

In terms of structure type, building-based vertical farms hold the largest market share, followed by shipping container-based systems. The building-based segment is expected to maintain its dominance due to its scalability and ability to integrate with existing urban infrastructure.

Leafy greens and herbs are the most commonly grown crops in vertical farming systems, accounting for over 40% of the market share. However, there is a growing trend towards diversification, with an increasing focus on fruits, vegetables, and even medicinal plants.

Geographically, North America currently leads the vertical farming market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid urbanization, government support, and increasing adoption of advanced agricultural technologies.

Key market drivers include the need for year-round crop production, reduced water consumption, and minimized use of pesticides and herbicides. Additionally, the COVID-19 pandemic has heightened awareness of food security issues, further accelerating the adoption of vertical farming solutions.

However, the market faces challenges such as high initial investment costs, limited crop variety, and technical complexities in maintaining optimal growing conditions. Overcoming these barriers will be crucial for the widespread adoption of vertical farming technologies and the realization of their full market potential.

The demand for vertical farming solutions is primarily fueled by the growing population in urban areas, which is expected to reach 68% of the global population by 2050. This demographic shift has created a pressing need for efficient and sustainable food production methods in densely populated areas. Vertical farming addresses this challenge by offering a space-efficient solution that can produce high yields of fresh produce year-round, regardless of external weather conditions.

The market for vertical farming solutions can be segmented based on growing mechanism, structure type, and crop type. Hydroponics is currently the dominant growing mechanism, accounting for approximately 60% of the market share. However, aeroponics is expected to witness the highest growth rate due to its water-efficient nature and potential for higher yields.

In terms of structure type, building-based vertical farms hold the largest market share, followed by shipping container-based systems. The building-based segment is expected to maintain its dominance due to its scalability and ability to integrate with existing urban infrastructure.

Leafy greens and herbs are the most commonly grown crops in vertical farming systems, accounting for over 40% of the market share. However, there is a growing trend towards diversification, with an increasing focus on fruits, vegetables, and even medicinal plants.

Geographically, North America currently leads the vertical farming market, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid urbanization, government support, and increasing adoption of advanced agricultural technologies.

Key market drivers include the need for year-round crop production, reduced water consumption, and minimized use of pesticides and herbicides. Additionally, the COVID-19 pandemic has heightened awareness of food security issues, further accelerating the adoption of vertical farming solutions.

However, the market faces challenges such as high initial investment costs, limited crop variety, and technical complexities in maintaining optimal growing conditions. Overcoming these barriers will be crucial for the widespread adoption of vertical farming technologies and the realization of their full market potential.

Current Challenges in Vertical Farming Climate Control

Vertical farming systems face several critical challenges in climate control, which directly impact crop yield, quality, and overall system efficiency. One of the primary issues is maintaining consistent temperature and humidity levels throughout the growing space. The vertical arrangement of crops creates microclimates within the system, leading to uneven distribution of heat and moisture. This variability can result in stress for plants at different levels, affecting their growth rates and nutritional content.

Another significant challenge is the management of airflow within the vertical farming environment. Proper air circulation is crucial for preventing the buildup of ethylene gas, which can accelerate crop ripening and potentially lead to premature spoilage. Additionally, inadequate airflow can create stagnant pockets of air, increasing the risk of fungal growth and pest infestations. Balancing airflow while maintaining energy efficiency remains a complex task for vertical farming operators.

Carbon dioxide (CO2) concentration management presents yet another hurdle in vertical farming climate control. While CO2 enrichment can enhance photosynthesis and crop yields, maintaining optimal levels throughout the vertical space is challenging. CO2, being heavier than air, tends to settle at lower levels, potentially creating imbalances in plant growth between upper and lower tiers of the farming system.

Light distribution and intensity control also pose significant challenges in vertical farming setups. As artificial lighting is a primary source of illumination, ensuring uniform light exposure across all plant layers is crucial. However, heat generated by lighting systems can disrupt temperature control efforts, necessitating advanced cooling solutions that don't compromise humidity levels or energy efficiency.

Water management and humidity control are interrelated challenges that vertical farming systems must address. While high humidity levels can promote plant growth, they also increase the risk of fungal diseases. Conversely, low humidity can lead to water stress in plants. Balancing irrigation, transpiration, and dehumidification processes to maintain optimal growing conditions requires sophisticated control systems and strategies.

Energy consumption remains a persistent challenge in vertical farming climate control. The need for continuous lighting, climate regulation, and air circulation results in high energy demands. Developing energy-efficient solutions without compromising crop quality or yield is crucial for the long-term sustainability and economic viability of vertical farming operations.

Lastly, the integration of various climate control systems presents a significant challenge. Coordinating lighting, HVAC, irrigation, and CO2 enrichment systems to work harmoniously while adapting to changing crop needs and external environmental factors requires advanced automation and control technologies. The complexity of these integrated systems can lead to increased maintenance requirements and potential points of failure, highlighting the need for robust and reliable climate control solutions in vertical farming.

Another significant challenge is the management of airflow within the vertical farming environment. Proper air circulation is crucial for preventing the buildup of ethylene gas, which can accelerate crop ripening and potentially lead to premature spoilage. Additionally, inadequate airflow can create stagnant pockets of air, increasing the risk of fungal growth and pest infestations. Balancing airflow while maintaining energy efficiency remains a complex task for vertical farming operators.

Carbon dioxide (CO2) concentration management presents yet another hurdle in vertical farming climate control. While CO2 enrichment can enhance photosynthesis and crop yields, maintaining optimal levels throughout the vertical space is challenging. CO2, being heavier than air, tends to settle at lower levels, potentially creating imbalances in plant growth between upper and lower tiers of the farming system.

Light distribution and intensity control also pose significant challenges in vertical farming setups. As artificial lighting is a primary source of illumination, ensuring uniform light exposure across all plant layers is crucial. However, heat generated by lighting systems can disrupt temperature control efforts, necessitating advanced cooling solutions that don't compromise humidity levels or energy efficiency.

Water management and humidity control are interrelated challenges that vertical farming systems must address. While high humidity levels can promote plant growth, they also increase the risk of fungal diseases. Conversely, low humidity can lead to water stress in plants. Balancing irrigation, transpiration, and dehumidification processes to maintain optimal growing conditions requires sophisticated control systems and strategies.

Energy consumption remains a persistent challenge in vertical farming climate control. The need for continuous lighting, climate regulation, and air circulation results in high energy demands. Developing energy-efficient solutions without compromising crop quality or yield is crucial for the long-term sustainability and economic viability of vertical farming operations.

Lastly, the integration of various climate control systems presents a significant challenge. Coordinating lighting, HVAC, irrigation, and CO2 enrichment systems to work harmoniously while adapting to changing crop needs and external environmental factors requires advanced automation and control technologies. The complexity of these integrated systems can lead to increased maintenance requirements and potential points of failure, highlighting the need for robust and reliable climate control solutions in vertical farming.

Existing Throttle Body Applications in Vertical Farming

01 Electronic throttle control systems

Advanced throttle body technology incorporates electronic control systems to regulate airflow into the engine. These systems use sensors and actuators to precisely adjust the throttle position based on various inputs, improving engine performance and fuel efficiency.- Electronic throttle control systems: Advanced throttle body technology incorporates electronic control systems to regulate airflow into the engine. These systems use sensors and actuators to precisely adjust the throttle position based on various inputs, improving engine performance and fuel efficiency.

- Throttle body design improvements: Innovations in throttle body design focus on optimizing airflow characteristics and reducing turbulence. This includes refined shapes, improved butterfly valve designs, and the use of advanced materials to enhance durability and performance.

- Integration of additional components: Modern throttle bodies often integrate additional components such as idle air control valves, throttle position sensors, and air temperature sensors. This integration simplifies the overall engine management system and improves reliability.

- Throttle body cleaning and maintenance technologies: Advancements in throttle body maintenance include self-cleaning mechanisms and specialized cleaning solutions. These technologies help prevent carbon buildup and ensure consistent performance over time.

- Variable geometry throttle bodies: Innovative throttle body designs incorporate variable geometry features that can adjust the airflow characteristics based on engine operating conditions. This technology allows for optimized performance across a wide range of engine speeds and loads.

02 Throttle body design improvements

Innovations in throttle body design focus on optimizing airflow characteristics and reducing turbulence. This includes refined shapes, improved sealing mechanisms, and integration of additional components to enhance overall engine performance and responsiveness.Expand Specific Solutions03 Integration of idle air control

Modern throttle bodies often incorporate idle air control functionality, eliminating the need for separate idle air control valves. This integration simplifies the engine management system, reduces component count, and improves overall system reliability.Expand Specific Solutions04 Multi-valve throttle bodies

Advanced throttle body designs may incorporate multiple valves or butterfly plates to provide more precise control over airflow across different engine operating conditions. This approach can improve engine performance, especially at low speeds or during transitions.Expand Specific Solutions05 Materials and manufacturing advancements

Throttle body technology has benefited from advancements in materials science and manufacturing processes. The use of lightweight, durable materials and precision manufacturing techniques has led to improved throttle body performance, longevity, and resistance to wear and environmental factors.Expand Specific Solutions

Key Players in Vertical Farming and Throttle Body Industries

The vertical farming industry is in a growth phase, with increasing market size and technological advancements. The global vertical farming market is projected to expand significantly, driven by urbanization, food security concerns, and sustainability initiatives. Technologically, the sector is evolving rapidly, with companies like OnePointOne, InFarm, and Wilder Fields leading innovation in automated plant production systems and IoT integration. Established players such as Ocado Innovation and KUKA Deutschland are contributing their expertise in automation and robotics. The involvement of research institutions like Arizona Board of Regents and Chitkara University indicates ongoing academic interest and potential for further technological breakthroughs. While the technology is maturing, there's still room for innovation and market expansion, particularly in areas of energy efficiency and crop diversification.

OnePointOne, Inc.

Technical Solution: OnePointOne has developed an advanced vertical farming system that incorporates throttle body technology to precisely control air flow and environmental conditions. Their system uses a network of sensors and actuators to monitor and adjust temperature, humidity, and CO2 levels in real-time. The throttle body technology allows for fine-tuned control of air circulation, ensuring optimal growing conditions for each plant variety. This system can adjust airflow based on the growth stage of plants, time of day, and even anticipated harvesting schedules[1][3]. The company's approach integrates machine learning algorithms to continuously optimize growing conditions, resulting in up to 30% higher yields compared to traditional vertical farming methods[2].

Strengths: Precise environmental control, higher crop yields, and adaptability to different plant varieties. Weaknesses: Higher initial setup costs and complexity in system maintenance.

InFarm - Indoor Urban Farming GmbH

Technical Solution: InFarm has implemented a modular vertical farming system that utilizes throttle body technology to create micro-climates within their growing units. Their approach focuses on distributed farming, placing smaller units closer to the point of sale. The throttle body system in each unit allows for precise control of airflow, temperature, and humidity, tailored to specific crop requirements. InFarm's technology enables the creation of ideal growing conditions for a wide range of crops, from leafy greens to herbs and even some fruiting plants. The system uses AI-driven climate control algorithms that adjust throttle positions to maintain optimal growing conditions while minimizing energy consumption[4]. This approach has resulted in water savings of up to 95% compared to traditional agriculture[5].

Strengths: Highly efficient resource use, adaptable to various retail environments, and consistent crop quality. Weaknesses: Limited scale of individual units and potential for higher operational costs in some locations.

Innovative Throttle Body Designs for Controlled Environments

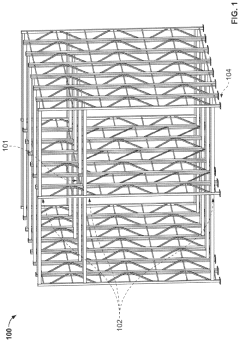

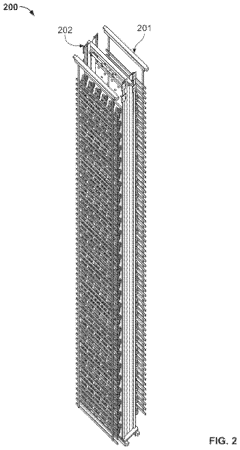

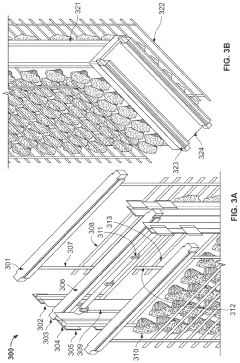

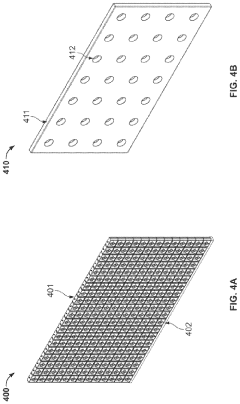

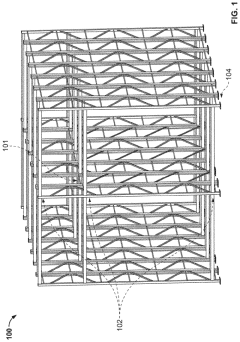

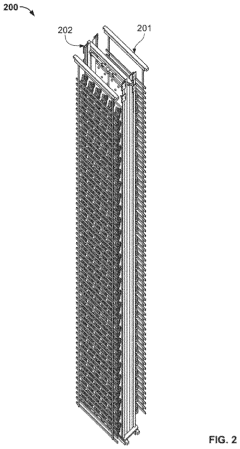

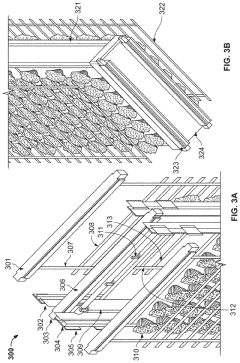

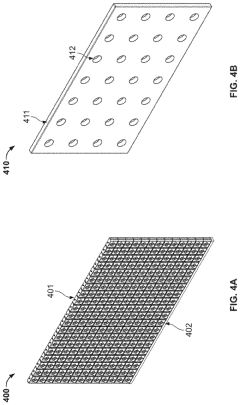

Vertical farming systems and methods

PatentInactiveUS20230020175A1

Innovation

- A fully automated vertical farming system that uses mobile robots, growth structures, and advanced software to control lighting, nutrients, and atmospheric conditions, enabling end-to-end automation from seeding to harvest, and employing machine learning and AI to optimize plant characteristics.

Vertical farming systems and methods

PatentPendingUS20220201926A1

Innovation

- A fully automated vertical farming system utilizing mobile robots, growth structures, and advanced environmental control systems to optimize plant growth through precise lighting, nutrient delivery, and atmospheric conditions, leveraging machine learning and AI for data-driven decision-making.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability are critical considerations in the integration of throttle body technology with vertical farming systems. The implementation of advanced throttle body systems can significantly enhance the overall energy efficiency of vertical farms, leading to reduced operational costs and improved environmental sustainability.

Throttle body technology plays a crucial role in optimizing airflow and temperature control within vertical farming environments. By precisely regulating the amount of air entering the system, throttle bodies can help maintain ideal growing conditions while minimizing energy consumption. This level of control allows for more efficient use of heating, ventilation, and air conditioning (HVAC) systems, which typically account for a substantial portion of energy usage in vertical farms.

The integration of smart throttle body systems with IoT sensors and AI-driven control algorithms further enhances energy efficiency. These advanced systems can continuously monitor environmental parameters such as temperature, humidity, and CO2 levels, adjusting airflow in real-time to maintain optimal conditions. This dynamic approach to climate control reduces energy waste and ensures that resources are used only when and where they are needed.

Sustainability benefits extend beyond energy savings. Improved airflow management through throttle body technology can lead to more efficient use of water and nutrients in vertical farming systems. By creating microclimates within the farm, it becomes possible to tailor growing conditions to specific crop requirements, potentially reducing water consumption and minimizing nutrient runoff.

Furthermore, the precise control offered by throttle body systems can contribute to reduced pesticide use. By maintaining optimal growing conditions and minimizing stress on plants, these systems can help create an environment less conducive to pests and diseases, thereby reducing the need for chemical interventions.

The long-term sustainability impact of integrating throttle body technology in vertical farming is significant. As urban populations continue to grow and arable land becomes scarcer, efficient vertical farming systems will play an increasingly important role in sustainable food production. The energy and resource efficiencies gained through advanced throttle body systems contribute to making vertical farming a more viable and environmentally friendly alternative to traditional agriculture methods.

In conclusion, the incorporation of throttle body technology in vertical farming systems offers substantial benefits in terms of energy efficiency and sustainability. By optimizing resource use, reducing operational costs, and minimizing environmental impact, this technology plays a crucial role in advancing the sustainability of urban agriculture and contributing to more resilient food systems for the future.

Throttle body technology plays a crucial role in optimizing airflow and temperature control within vertical farming environments. By precisely regulating the amount of air entering the system, throttle bodies can help maintain ideal growing conditions while minimizing energy consumption. This level of control allows for more efficient use of heating, ventilation, and air conditioning (HVAC) systems, which typically account for a substantial portion of energy usage in vertical farms.

The integration of smart throttle body systems with IoT sensors and AI-driven control algorithms further enhances energy efficiency. These advanced systems can continuously monitor environmental parameters such as temperature, humidity, and CO2 levels, adjusting airflow in real-time to maintain optimal conditions. This dynamic approach to climate control reduces energy waste and ensures that resources are used only when and where they are needed.

Sustainability benefits extend beyond energy savings. Improved airflow management through throttle body technology can lead to more efficient use of water and nutrients in vertical farming systems. By creating microclimates within the farm, it becomes possible to tailor growing conditions to specific crop requirements, potentially reducing water consumption and minimizing nutrient runoff.

Furthermore, the precise control offered by throttle body systems can contribute to reduced pesticide use. By maintaining optimal growing conditions and minimizing stress on plants, these systems can help create an environment less conducive to pests and diseases, thereby reducing the need for chemical interventions.

The long-term sustainability impact of integrating throttle body technology in vertical farming is significant. As urban populations continue to grow and arable land becomes scarcer, efficient vertical farming systems will play an increasingly important role in sustainable food production. The energy and resource efficiencies gained through advanced throttle body systems contribute to making vertical farming a more viable and environmentally friendly alternative to traditional agriculture methods.

In conclusion, the incorporation of throttle body technology in vertical farming systems offers substantial benefits in terms of energy efficiency and sustainability. By optimizing resource use, reducing operational costs, and minimizing environmental impact, this technology plays a crucial role in advancing the sustainability of urban agriculture and contributing to more resilient food systems for the future.

Regulatory Framework for Agricultural Technology Integration

The integration of throttle body technology into vertical farming systems necessitates a comprehensive regulatory framework to ensure safety, efficiency, and compliance. This framework must address various aspects of agricultural technology integration, including equipment standards, environmental impact, and food safety regulations.

At the federal level, the United States Department of Agriculture (USDA) plays a crucial role in establishing guidelines for innovative farming practices. The USDA's National Organic Program (NOP) sets standards for organic production, which may need to be adapted to accommodate the use of throttle body technology in vertical farming systems. Additionally, the Environmental Protection Agency (EPA) oversees regulations related to pesticide use and environmental protection, which are particularly relevant to controlled environment agriculture.

State-level regulations also play a significant role in shaping the integration of new technologies in agriculture. Many states have their own departments of agriculture that may impose additional requirements or provide specific guidance for vertical farming operations. These state-level regulations often focus on land use, water management, and energy efficiency, all of which are critical factors in vertical farming systems utilizing throttle body technology.

Local zoning laws and building codes must also be considered when implementing vertical farming systems. These regulations may need to be updated to accommodate the unique structural and operational requirements of indoor farming facilities equipped with advanced technologies like throttle bodies.

Food safety regulations, primarily enforced by the Food and Drug Administration (FDA), are of paramount importance in the context of vertical farming. The FDA's Food Safety Modernization Act (FSMA) sets stringent standards for produce safety, which must be adhered to in vertical farming operations. The integration of throttle body technology may require specific considerations in terms of sanitation and contamination prevention protocols.

As vertical farming systems with throttle body technology become more prevalent, it is likely that new regulatory frameworks will emerge. Industry associations and stakeholders should actively engage with policymakers to ensure that these regulations strike a balance between promoting innovation and safeguarding public health and environmental interests.

Certification programs may also play a role in the regulatory landscape. Organizations such as the Controlled Environment Agriculture Food Safety Coalition (CEA Food Safety Coalition) are working to develop food safety standards specific to indoor farming operations. These standards could potentially incorporate guidelines for the use of throttle body technology in vertical farming systems.

At the federal level, the United States Department of Agriculture (USDA) plays a crucial role in establishing guidelines for innovative farming practices. The USDA's National Organic Program (NOP) sets standards for organic production, which may need to be adapted to accommodate the use of throttle body technology in vertical farming systems. Additionally, the Environmental Protection Agency (EPA) oversees regulations related to pesticide use and environmental protection, which are particularly relevant to controlled environment agriculture.

State-level regulations also play a significant role in shaping the integration of new technologies in agriculture. Many states have their own departments of agriculture that may impose additional requirements or provide specific guidance for vertical farming operations. These state-level regulations often focus on land use, water management, and energy efficiency, all of which are critical factors in vertical farming systems utilizing throttle body technology.

Local zoning laws and building codes must also be considered when implementing vertical farming systems. These regulations may need to be updated to accommodate the unique structural and operational requirements of indoor farming facilities equipped with advanced technologies like throttle bodies.

Food safety regulations, primarily enforced by the Food and Drug Administration (FDA), are of paramount importance in the context of vertical farming. The FDA's Food Safety Modernization Act (FSMA) sets stringent standards for produce safety, which must be adhered to in vertical farming operations. The integration of throttle body technology may require specific considerations in terms of sanitation and contamination prevention protocols.

As vertical farming systems with throttle body technology become more prevalent, it is likely that new regulatory frameworks will emerge. Industry associations and stakeholders should actively engage with policymakers to ensure that these regulations strike a balance between promoting innovation and safeguarding public health and environmental interests.

Certification programs may also play a role in the regulatory landscape. Organizations such as the Controlled Environment Agriculture Food Safety Coalition (CEA Food Safety Coalition) are working to develop food safety standards specific to indoor farming operations. These standards could potentially incorporate guidelines for the use of throttle body technology in vertical farming systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!