Improving The Waste Heat Recovery Efficiency Of Internal Combustion Engines

Technology Background and Goals

Internal combustion engines inherently generate a significant amount of waste heat during the combustion process, with a substantial portion being expelled through the exhaust system and cooling system. Recovering and utilizing this waste heat can lead to increased fuel efficiency, reduced emissions, and improved overall system performance. The key challenges lie in developing cost-effective and reliable waste heat recovery systems that can effectively capture and convert the waste heat into usable energy forms, such as electricity or mechanical work.

Market Demand Analysis

- Market Potential

Internal combustion engines are widely used in various industries, including automotive, marine, and power generation. The market for waste heat recovery systems in these sectors is substantial, driven by the need for improved energy efficiency and reduced emissions. - Regulatory Drivers

Stringent environmental regulations and emission standards are compelling manufacturers to adopt technologies that enhance fuel efficiency and reduce greenhouse gas emissions. Waste heat recovery systems offer a viable solution to meet these regulatory requirements. - Energy Savings

Recovering waste heat from internal combustion engines can significantly improve overall system efficiency, leading to substantial energy savings. This is particularly attractive in industries where fuel costs constitute a significant portion of operating expenses. - Industrial Applications

Beyond the automotive sector, waste heat recovery systems have potential applications in industrial processes that rely on internal combustion engines, such as combined heat and power (CHP) systems, and in the oil and gas industry for powering remote operations.

Technology Status and Challenges

- Historical Development

Tracing the evolution of waste heat recovery technologies for internal combustion engines, from early thermoelectric generators to modern organic Rankine cycles and turbocompounding systems. - Current Challenges

Identifying key technical hurdles, such as low thermal efficiency, material limitations, system complexity, and integration issues with existing engine designs. - Geographical Distribution

Highlighting regions with significant research activities and industrial implementations, including Europe, North America, and Asia.

Technology Evolution Path

Current Technical Solutions

01 Exhaust Gas Heat Recovery Systems

These systems recover waste heat from engine exhaust gases, using it for purposes like generating steam or preheating intake air to improve overall engine efficiency.- Exhaust Gas Heat Recovery Systems: These systems recover waste heat from engine exhaust gases, utilizing it for various purposes like generating steam or preheating intake air to enhance overall engine efficiency.

- Rankine Cycle Waste Heat Recovery Systems: Employing a Rankine cycle, these systems convert engine waste heat into mechanical or electrical power by vaporizing a working fluid to drive a turbine or expander.

- Thermoelectric Waste Heat Recovery Systems: These systems utilize thermoelectric generators (TEGs) to directly convert waste heat into electrical energy, exploiting the temperature difference between hot exhaust gases and a cooler heat sink to generate voltage.

- Organic Rankine Cycle Waste Heat Recovery Systems: Employing an organic Rankine cycle with an organic working fluid having a lower boiling point than water, these systems enable effective waste heat recovery at lower temperature ranges, suitable for various engine applications.

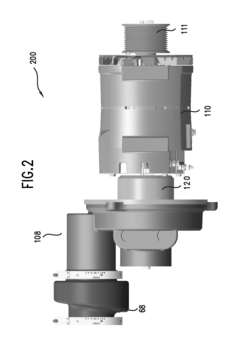

- Integrated Waste Heat Recovery Systems: These systems integrate waste heat recovery components directly into the engine design, enabling more efficient heat transfer and recovery, potentially including components like exhaust gas recirculation (EGR) coolers or integrated exhaust manifolds with heat exchangers.

02 Rankine Cycle Waste Heat Recovery Systems

Utilizing a Rankine cycle, these systems convert engine waste heat into mechanical or electrical power by vaporizing a working fluid to drive a turbine or expander.03 Thermoelectric Waste Heat Recovery Systems

These systems employ thermoelectric generators (TEGs) to directly convert waste heat into electrical energy using the Seebeck effect, exploiting the temperature difference between hot and cold sides.04 Organic Rankine Cycle Waste Heat Recovery Systems

Using an organic working fluid with a lower boiling point than water, these systems enable waste heat recovery from lower-temperature sources like engine coolant or exhaust gas recirculation systems.05 Waste Heat Recovery Systems for Hybrid Vehicles

In hybrid vehicles, these systems integrate with the internal combustion engine and electric motor/generator to improve overall efficiency, utilizing recovered heat for cabin heating, battery thermal management, or generating additional electrical power.

Main Player Analysis

Honda Motor Co., Ltd.

Robert Bosch GmbH

Key Technology Interpretation

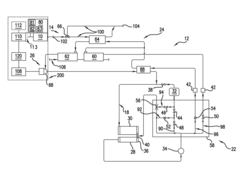

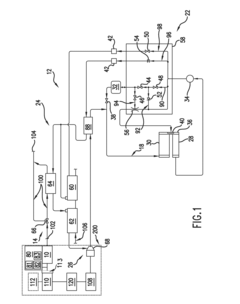

- The integration of a waste heat recovery system with a vehicle's internal combustion engine to extract and utilize waste heat energy. this allows for the generation of power to supplement the vehicle's efficiency, potentially reducing the need for external power sources.

- The provided electrical energy is derived from recovered waste heat energy, which further increases the relative efficiency of the vehicle.

Potential Innovation Direction

- Internal Combustion Engines with Thermoelectric Waste Heat Recovery Systems

- Internal Combustion Engines with Organic Rankine Cycle Waste Heat Recovery Systems

- Internal Combustion Engines with Turbocompound Waste Heat Recovery Systems

Environmental Impact Analysis of The Technology

Improving waste heat recovery efficiency in internal combustion engines holds significant potential for environmental impact reduction. The utilization of recovered heat reduces the necessity for additional fuel consumption, subsequently decreasing emissions of carbon dioxide and other greenhouse gases. This improvement contributes to lower air pollutants, including nitrogen oxides and particulate matter, which are harmful to human health and the environment.

Efficient heat recovery also promotes resource conservation, allowing engines to achieve optimal energy use. This process minimizes waste, aligns with sustainable practices, and supports compliance with increasingly stringent environmental regulations. By optimizing engine thermal efficiency, there is a direct positive impact on fuel economy, translating into fewer operational resources and reduced costs.

Furthermore, implementing advanced technologies for heat recovery can stimulate innovation and industry growth in clean technology sectors. These advancements offer opportunities to reduce environmental footprints through engineering solutions that align with global climate goals. Overall, enhancing waste heat recovery not only benefits engine performance but also aligns with sustainable development objectives, showcasing a commitment to reducing the automotive industry's environmental impact.

Policy and Regulatory Impact of The Technology

The improvement of waste heat recovery efficiency in internal combustion engines could be significantly influenced by policy and regulatory frameworks. As governments worldwide increasingly mandate stringent emissions standards, there is an escalated push for technologies that enhance energy efficiency and reduce carbon footprints, such as waste heat recovery systems in internal combustion engines. Regulatory policies that provide subsidies or tax incentives for adopting waste heat recovery technologies can stimulate market interest and accelerate adoption rates, especially in transportation and industrial sectors.

Moreover, international agreements on climate change, such as the Paris Agreement, put pressure on countries to improve energy efficiency across their industries, indirectly impacting the adoption of advanced waste recovery systems. Compliance requirements with regional emissions standards, like the Euro 7 for automotive engines in Europe, or equivalent regulations in other markets, further dictate technological innovations and investments in this domain.

Understanding these policy and regulatory impacts is crucial for aligning technological advancements with market needs and ensuring compliance and competitiveness. Stakeholders in the waste heat recovery sector must stay abreast of evolving regulations and strategically position their offerings to leverage the benefits of alignments with governmental policies, thus ensuring sustainable growth and market expansion.