How to Achieve Higher Thermal Efficiency in Combustion Engines?

Internal Combustion Engines Technology Background And Goals

The primary objective is to comprehensively analyze the historical development and evolutionary trends of internal combustion engine technology, with a focus on identifying key milestones and breakthroughs that have contributed to improving thermal efficiency. This section provides a thorough understanding of the technological advancements and the driving forces behind the pursuit of higher thermal efficiency in internal combustion engines.

It is crucial to highlight the motivations and goals that have fueled research efforts in this field, such as the need for improved fuel economy, reduced emissions, and enhanced engine performance. Additionally, this section should outline the specific technical challenges and limitations that have hindered progress in achieving higher thermal efficiency, setting the stage for subsequent discussions on potential solutions and future research directions.

Market Demand Analysis

- Demand for Fuel Efficiency

Rising fuel costs and environmental concerns have driven the need for more fuel-efficient internal combustion engines (ICEs) in the automotive industry. - Regulatory Pressures

Stringent emission regulations and corporate average fuel economy (CAFE) standards have compelled automakers to improve ICE thermal efficiency. - Electrification Trend

The growing adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs) has increased the demand for more efficient ICEs in hybrid powertrains. - Commercial Vehicle Segment

The commercial vehicle segment, including trucks and buses, has a significant demand for highly efficient ICEs due to their high fuel consumption and operating costs. - Emerging Markets

Developing economies with rapidly growing automotive markets, such as China and India, have a strong demand for fuel-efficient and cost-effective ICE solutions.

Technology Status And Challenges

- Thermal Efficiency Limitations

Internal combustion engines face inherent limitations in thermal efficiency due to factors like combustion inefficiencies, heat transfer losses, and thermodynamic constraints. - Combustion Optimization Challenges

Achieving complete and efficient combustion is challenging, as it involves complex interactions between fuel-air mixing, ignition timing, and combustion chamber design. - Heat Transfer Losses

Significant heat is lost through the engine block, exhaust system, and cooling system, reducing overall thermal efficiency. - Thermodynamic Cycle Constraints

The theoretical limits of the Otto and Diesel cycles, along with practical constraints like peak pressures and temperatures, restrict the maximum achievable thermal efficiency.

Technology Evolution Path

Current Technical Solutions

01 Combustion Efficiency Enhancement

Various techniques optimize air-fuel mixture, fuel injection systems, and ignition systems to maximize chemical-to-mechanical energy conversion, increasing thermal efficiency.- Combustion Efficiency Enhancement: Various techniques optimize air-fuel mixture, fuel injection systems, and ignition systems to maximize chemical-to-mechanical energy conversion, increasing thermal efficiency.

- Heat Loss Minimization: Insulating the combustion chamber, using advanced cooling systems, and employing low thermal conductivity materials reduce heat losses, retaining more energy for useful work conversion.

- Engine Design Optimization: Factors like cylinder geometry, valve timing, and piston design are optimized through advanced simulations to improve combustion characteristics and reduce energy losses, enhancing thermal efficiency.

- Waste Heat Recovery: Waste heat recovery systems capture and utilize heat energy from exhaust or cooling systems, improving overall thermal efficiency by generating additional power or heating.

- Advanced Combustion Strategies: Novel strategies like HCCI and LTC offer improved thermal efficiency through reduced heat losses and more complete combustion, involving precise control of air-fuel mixtures and combustion timing.

02 Heat Loss Reduction

Insulation, advanced cooling systems, and low thermal conductivity materials minimize heat losses from the combustion chamber and exhaust, ensuring more energy conversion into useful work.03 Waste Heat Recovery

Waste heat recovery systems capture and utilize thermal energy from exhaust gases or cooling systems, improving overall thermal efficiency by generating additional power or heating.04 Advanced Engine Designs

Novel engine designs like variable compression ratio, opposed-piston, and split-cycle engines enhance thermal efficiency through optimized thermodynamic cycles, innovative combustion strategies, and improved heat transfer management.05 Turbocharging and Supercharging

Turbocharging and supercharging increase air-fuel mixture density, allowing more fuel combustion and higher power output, leading to improved thermal efficiency when combined with other efficiency-enhancing measures.

Main Player Analysis

Toyota Motor Corp.

Robert Bosch GmbH

Key Technology Interpretation

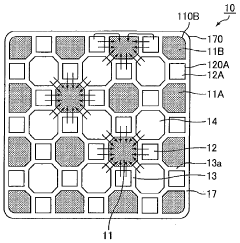

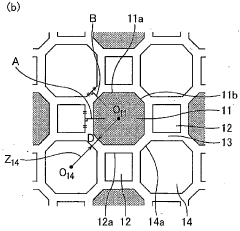

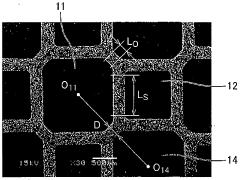

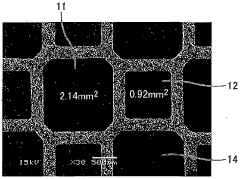

- The use of a honeycomb filter structure to increase the surface area for heat transfer and improve thermal efficiency.

- The honeycomb filter is positioned in the exhaust system to recover waste heat from the exhaust gases.

- The honeycomb filter can be coated with catalytic materials to promote chemical reactions and reduce emissions.

Potential Innovation Direction

Internal Combustion Engines Thermal Efficiency Improvement Economic Analysis

In the pursuit of higher thermal efficiency in combustion engines, an economic analysis offers essential insights into the financial feasibility and potential market implications of implementing advanced technologies. Increasing thermal efficiency in engines not only holds the promise of reducing fuel consumption and greenhouse gas emissions but also involves various costs, including research and development, new materials, and potential re-engineering of existing systems. The balance between these implementation costs and the projected savings on fuel and emission penalties is crucial.

Furthermore, an economic evaluation would consider the price elasticity of demand for vehicles equipped with high-efficiency combustion engines, as well as the potential market penetration rate. Increased efficiency could lead to cost savings over the engine's lifecycle, making it attractive for both consumers and manufacturers who seek to differentiate their products in a competitive market.

Finally, government incentives for reduced emissions and advancements in fuel efficiency also play a significant role. These incentives can mitigate some upfront costs, providing a smoother pathway for adopting new technologies within the combustion engine domain. Ultimately, a comprehensive economic analysis ensures that investments in improving thermal efficiency align with both market demands and regulatory requirements, securing a competitive edge.

Internal Combustion Engines Thermal Efficiency Improvement Policy And Regulatory Impact

Governments worldwide are imposing stringent emissions regulations aimed at reducing greenhouse gases and other pollutants, which directly affect the design and operation of combustion engines. These policies drive manufacturers to explore advanced technologies, such as turbocharging, direct fuel injection, and variable valve timing, to improve engine efficiency and comply with regulations.

Additionally, incentives for adopting clean and efficient technologies, such as tax credits and subsidies, further encourage research and development in this area. Regulatory frameworks also promote the integration of alternative fuels, such as biofuels and synthetic fuels, which can enhance thermal efficiency while reducing environmental impact.

These regulations not only create challenges but also provide opportunities for innovation. Companies are motivated to invest in research and development, leading to advancements in engine design, materials, and control systems that aim for higher thermal efficiency. As global regulations become increasingly stringent, continuous adaptation and innovation are essential for maintaining competitiveness and achieving compliance in the automotive industry.