Optimized Camshaft Profiles for Maximum Engine Efficiency and Performance

Camshafts Technology Background And Goals

This report aims to explore and analyze the current state, challenges, and future development trends of optimized camshaft and valve train designs for enhancing engine performance and efficiency. This involves a comprehensive assessment of existing technologies, key players, and potential innovative solutions in this field.

The analysis will delve into the technical intricacies of camshaft profiles and valve train mechanisms, identifying the critical factors that influence engine power output, fuel efficiency, and emissions. It will also examine the geographical distribution of relevant research and development activities, as well as the competitive landscape among major industry players.

Camshafts Market Demand Analysis

- Market Size and Growth

The market for camshafts with optimized cam profiles and valve train designs is driven by the increasing demand for high-performance and fuel-efficient engines in the automotive industry. This market segment is expected to experience significant growth due to stricter emission regulations and consumer preferences for vehicles with improved performance and fuel economy. - Industry Trends

Key trends shaping the demand for optimized camshafts include the adoption of advanced engine technologies such as variable valve timing, cylinder deactivation, and turbocharging. Additionally, the trend towards downsizing engines while maintaining performance levels is driving the need for optimized valve train designs. - Application Segments

The primary application segments for optimized camshafts include passenger vehicles, commercial vehicles, and high-performance sports cars. Within these segments, the demand is particularly high for gasoline and diesel engines used in luxury and performance-oriented vehicles. - Regional Demand

The demand for optimized camshafts is highest in regions with stringent emission regulations and a strong automotive industry, such as North America, Europe, and Asia-Pacific. Emerging markets like China and India are also expected to contribute significantly to the market growth due to increasing vehicle production and consumer demand for fuel-efficient vehicles.

Camshafts Technology Status And Challenges

- Technological Landscape

Camshafts have evolved from simple cylindrical designs to complex profiles optimized for specific engine requirements. Advanced manufacturing techniques like precision casting and machining enable intricate cam profiles. - Key Challenges

Balancing conflicting demands for high performance, efficiency, and emissions reduction. Overcoming limitations of conventional valve train designs. Integrating camshafts with variable valve timing systems. - Geographical Distribution

Major automotive manufacturing hubs like the U.S., Europe, Japan, and China lead camshaft technology development. Emerging markets like India and Southeast Asia are catching up rapidly.

Camshafts Current Technical Solutions

01 Camshaft Profiles and Designs

Modifying cam lobe shapes, incorporating variable valve timing mechanisms, and utilizing multiple camshafts for different valve operations to optimize valve timing and lift.- Camshaft Profiles and Designs: Optimizing valve timing and lift through modified cam lobe shapes, variable valve timing mechanisms, and multiple camshafts for different operating conditions.

- Valve Train Components and Configurations: Reducing friction, improving durability, and enhancing valve control through optimized rocker arm designs, roller finger followers, hydraulic lash adjusters, and variable valve lift mechanisms.

- Variable Valve Timing Systems: Adjusting valve opening and closing timing based on engine conditions to improve fuel efficiency, reduce emissions, and enhance performance across a wide range of speeds and loads.

- Cam Phasing and Control Mechanisms: Adjusting camshaft timing relative to crankshaft position to optimize valve timing for different engine operating conditions, improving performance and efficiency.

- Valve Train Noise and Vibration Reduction: Improving engine refinement and durability through optimized valve spring designs, hydraulic lash adjusters, and damping mechanisms to reduce noise and vibration in valve train systems.

02 Valve Train Components and Configurations

Optimizing valve actuation and reducing friction losses through roller-based components, adjustable components, and lightweight materials in valve train components like rocker arms, pushrods, and valve lifters.Expand Specific Solutions03 Variable Valve Timing and Lift Systems

Dynamically adjusting valve timing and lift based on engine conditions using cam phasers, switchable cam lobes, or electro-hydraulic actuators to optimize performance and emissions.Expand Specific Solutions04 Camshaft and Valve Train Materials and Coatings

Improving durability, reducing friction, and enhancing wear resistance through lightweight alloys, ceramic coatings, and diamond-like carbon coatings for camshafts and valve train components.Expand Specific Solutions05 Camshaft and Valve Train Manufacturing Processes

Producing camshafts and valve train components with high precision and quality through advanced machining techniques, surface treatments, and assembly methods to ensure optimal performance and reliability.Expand Specific Solutions

Camshafts Main Player Analysis

GM Global Technology Operations LLC

Eaton Intelligent Power Ltd.

Camshafts Key Technology Interpretation

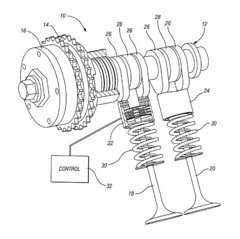

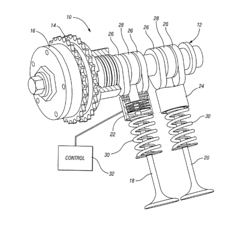

- The invention uses a two-step valve train with direct acting switching valve lifters and dual intake valves and cams for varying modes of operation, allowing selective high lift or low lift levels of intake and exhaust valve operation.

- The invention incorporates a camshaft phase changer that varies the phase of the intake valves to alter valve timing for different operating modes.

- The use of dual intake valves and cams allows for more precise control and optimization of the intake valve events.

Camshafts Engine Performance Improvement Analysis

The camshaft plays a crucial role in an engine's performance, and increasing its compression ratio can potentially enhance efficiency and power output. Understanding the need to improve camshaft-related technologies involves analyzing technical advancements that influence engine dynamics. This encompasses exploring materials science progress, like using lightweight, durable alloys that withstand higher stress without increasing mass. Moreover, precision engineering technologies such as advanced CNC machining enable more complex camshaft designs that optimize valve timing and lift profiles, leading to a higher compression ratio.

Key industry players in camshaft technology invest in proprietary techniques that bolster performance. Companies might explore variable valve timing systems that adjust the camshaft’s function dynamically based on engine load and speed, enhancing fuel efficiency and power. Efforts also focus on integrating computer-aided engineering tools to simulate and refine camshaft designs during the development phase, significantly reducing time-to-market for new solutions.

Camshafts Efficiency Enhancement Regulatory Impact

Improving the compression ratio of camshafts is a critical component in enhancing the efficiency of internal combustion engines. As regulatory standards increasingly demand reductions in emissions and improvements in fuel efficiency, automotive manufacturers are urged to explore advanced technologies. Compliance with regulations such as Euro 6 or the forthcoming Euro 7 standards necessitates innovation in camshaft design, owing to their impact on the combustion process. Enhanced compression ratios can lead to improved thermal efficiency, thereby reducing carbon emissions and aligning with stringent regulatory requirements. Legislations worldwide are increasingly focusing on reducing vehicular environmental footprints, making it imperative for automotive industries to adopt technologies that boost engine performance while meeting emission limits. This focus encourages the pursuit of innovations such as variable valve timing technologies and dual-mode camshaft systems to optimize compression and enhance overall engine efficacy. Therefore, improvements in camshaft compression ratios not only meet regulatory compliance but also provide significant competitive advantages by delivering superior performance and adhering to progressively stricter environmental standards. In conclusion, regulatory impacts serve as a catalyst for the continuous evolution of camshaft technologies, driving increased efficiency and sustainability in automotive engineering.