Turbine Engines With Lightweight And High-Temperature Materials For Improved Performance

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engines Lightweight Materials Background

The primary objective of this research is to explore the development of lightweight and high-temperature materials for turbine engines, aiming to enhance their performance and efficiency. Turbine engines are widely used in aviation, power generation, and various industrial applications, where weight reduction and high-temperature resistance are crucial factors for improved fuel efficiency, increased power output, and extended operational life.

Advancements in materials science have opened up new possibilities for developing innovative materials that can withstand extreme temperatures while maintaining a low density. This research aims to investigate the potential of these cutting-edge materials, such as ceramic matrix composites, intermetallic alloys, and advanced coatings, for application in turbine engine components like blades, combustion chambers, and nozzles. The ultimate goal is to identify and evaluate the most promising materials and manufacturing techniques that can enable the next generation of high-performance turbine engines.

Advancements in materials science have opened up new possibilities for developing innovative materials that can withstand extreme temperatures while maintaining a low density. This research aims to investigate the potential of these cutting-edge materials, such as ceramic matrix composites, intermetallic alloys, and advanced coatings, for application in turbine engine components like blades, combustion chambers, and nozzles. The ultimate goal is to identify and evaluate the most promising materials and manufacturing techniques that can enable the next generation of high-performance turbine engines.

High-Temperature Materials Market Demand Analysis

- Aerospace Industry Demand

The aerospace industry is a major consumer of high-temperature materials for turbine engines. Lightweight and heat-resistant materials enable higher operating temperatures, improving engine efficiency and reducing fuel consumption. - Power Generation Sector

High-temperature materials are crucial for gas turbines used in power plants. Increased operating temperatures lead to higher thermal efficiency and reduced emissions. - Automotive Industry

Automotive turbochargers and exhaust systems require high-temperature materials to withstand extreme conditions and improve engine performance. - Industrial Applications

Various industrial processes, such as metal processing and chemical manufacturing, rely on high-temperature materials for furnaces, reactors, and heat exchangers.

Lightweight High-Temperature Materials Technology Status

- Lightweight Materials

Exploring advanced lightweight materials like carbon fiber composites, aluminum alloys, and titanium alloys for turbine components to reduce overall weight. - High-Temperature Materials

Investigating high-temperature resistant materials such as ceramic matrix composites, nickel-based superalloys, and refractory metals for hot sections of turbines. - Material Processing

Developing advanced manufacturing techniques like additive manufacturing, hot isostatic pressing, and thermal barrier coatings for improved material properties. - Design Optimization

Utilizing computational modeling and simulation tools to optimize component designs for lightweight and high-temperature performance. - Testing and Validation

Conducting rigorous testing and validation of new materials and designs under simulated operating conditions to ensure reliability and performance.

Current Lightweight High-Temperature Material Solutions

01 Ceramic Matrix Composites (CMCs)

Lightweight, high-temperature materials for turbine components like blades, vanes, and combustors. Offer superior thermal and mechanical properties for higher operating temperatures and improved efficiency.- Ceramic Matrix Composites (CMCs): Lightweight, high-temperature materials for turbine components like blades, combustion chambers, and exhaust nozzles. Consist of ceramic matrix reinforced with ceramic fibers, providing high strength and thermal resistance.

- Intermetallic Compounds: Lightweight, high-temperature materials like nickel aluminides and titanium aluminides. Suitable for turbine components due to high strength-to-weight ratios and oxidation resistance.

- Thermal Barrier Coatings (TBCs): Ceramic topcoats like yttria-stabilized zirconia (YSZ) applied to turbine components for insulation and high-temperature protection, increasing operating temperature and lifespan.

- Refractory Metals and Alloys: High-melting-point materials like molybdenum, niobium, and their alloys. Lightweight, high-strength at high temperatures, suitable for turbine nozzles, combustion chambers, and afterburners.

- Superalloys: Nickel-based and cobalt-based alloys designed for high-temperature strength, creep resistance, and oxidation resistance. Used in turbine blades, disks, and combustors.

02 Intermetallic Compounds

Lightweight, high-temperature materials like nickel aluminides and titanium aluminides for turbine blades and vanes. Offer improved strength, oxidation resistance, and creep resistance.Expand Specific Solutions03 Thermal Barrier Coatings

Ceramic coatings like yttria-stabilized zirconia applied to turbine components for insulation and high-temperature protection, increasing operating temperature and lifespan.Expand Specific Solutions04 Refractory Metal Alloys

Nickel-based and cobalt-based superalloys designed for high-temperature strength, creep resistance, and oxidation resistance in turbine hot-section components like blades and vanes.Expand Specific Solutions05 Metal Matrix Composites (MMCs)

Lightweight materials combining metal matrix with reinforcing fibers or particles. Offer high strength-to-weight ratios and improved thermal and mechanical properties for turbine components.Expand Specific Solutions

Key Players in Lightweight High-Temperature Materials

The research on turbine engines with lightweight and high-temperature materials for improved performance is a highly competitive field, driven by the increasing demand for more efficient and environmentally friendly aircraft engines. The market is substantial, with major players like General Electric, Rolls-Royce, Honeywell, and United Technologies dominating the industry. However, the technology is still evolving, with companies like Siemens, Mitsubishi Heavy Industries, and Pratt & Whitney actively investing in research and development. Universities and research institutes, such as the University of Florida, Zhejiang University, and the German Aerospace Center (DLR), are also contributing to the advancement of this technology through their cutting-edge research.

General Electric Company

Technical Solution: GE has developed advanced lightweight and high-temperature materials like ceramic matrix composites (CMCs) and single-crystal superalloys for turbine engines, enabling higher operating temperatures and improved fuel efficiency.

Strengths: Extensive experience, strong R&D capabilities, broad portfolio. Weaknesses: High production costs, potential supply chain challenges.

United Technologies Corp.

Technical Solution: United Technologies, through Pratt & Whitney, has developed CMCs and thermal barrier coatings (TBCs) for high-temperature turbine engine applications, enabling improved performance and fuel efficiency.

Strengths: Extensive expertise, strong R&D capabilities, broad portfolio. Weaknesses: Scaling up production, managing supply chain complexities.

Core Patents and Research on Lightweight High-Temperature Materials

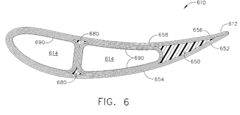

Ceramic matrix composite articles having small complex features

PatentInactiveEP1930548A3

Innovation

- 1. Developing new materials like ceramic matrix composites (CMCs) that can withstand higher operating temperatures and provide reduced weight compared to high temperature alloys.

- 2. Applying ceramic thermal barrier coatings (TBCs) on component surfaces to reduce heat transfer rate and provide thermal protection, allowing components to withstand higher temperatures.

- 3. Introducing cooling holes for film cooling to improve thermal capability and protection of components.

Environmental Impact of Lightweight High-Temperature Turbine Engines

The widespread adoption of lightweight and high-temperature materials in turbine engines presents both opportunities and challenges from an environmental perspective. On one hand, these advanced materials can significantly improve engine efficiency, leading to reduced fuel consumption and lower greenhouse gas emissions. However, the production processes and disposal methods for these materials may have adverse environmental impacts that need to be carefully evaluated and mitigated.

A comprehensive life cycle assessment is crucial to understand the environmental footprint of lightweight high-temperature turbine engines. This assessment should consider the extraction and processing of raw materials, manufacturing processes, energy consumption during operation, and end-of-life disposal or recycling strategies. Particular attention should be given to the potential release of hazardous substances, energy-intensive production methods, and the recyclability of these advanced materials.

Additionally, the development and implementation of sustainable manufacturing practices, as well as responsible waste management strategies, are essential to minimize the environmental impact of these engines. Collaboration between industry, academia, and regulatory bodies is vital to establish guidelines and standards that promote environmental stewardship while enabling technological advancements in this field.

A comprehensive life cycle assessment is crucial to understand the environmental footprint of lightweight high-temperature turbine engines. This assessment should consider the extraction and processing of raw materials, manufacturing processes, energy consumption during operation, and end-of-life disposal or recycling strategies. Particular attention should be given to the potential release of hazardous substances, energy-intensive production methods, and the recyclability of these advanced materials.

Additionally, the development and implementation of sustainable manufacturing practices, as well as responsible waste management strategies, are essential to minimize the environmental impact of these engines. Collaboration between industry, academia, and regulatory bodies is vital to establish guidelines and standards that promote environmental stewardship while enabling technological advancements in this field.

Regulatory Landscape for Lightweight High-Temperature Turbine Engines

The regulatory landscape for lightweight high-temperature turbine engines encompasses a complex web of standards, guidelines, and certification processes aimed at ensuring safety, reliability, and environmental compliance. These regulations are established by various national and international bodies, such as aviation authorities, environmental agencies, and industry organizations.

Key regulatory aspects include material selection and testing protocols for high-temperature alloys, design specifications for turbine components, emissions standards for aircraft engines, and certification requirements for airworthiness. Stringent safety regulations govern the manufacturing processes, quality control measures, and maintenance procedures for these advanced turbine engines. Environmental regulations also play a crucial role, addressing noise levels, greenhouse gas emissions, and the overall environmental impact throughout the engine's lifecycle.

Compliance with these regulations is a critical prerequisite for the commercial deployment of lightweight high-temperature turbine engines. Manufacturers must navigate this intricate regulatory landscape, ensuring their products meet the highest standards of safety, performance, and sustainability. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is essential to continuously refine and adapt these regulations to accommodate technological advancements and evolving environmental concerns.

Key regulatory aspects include material selection and testing protocols for high-temperature alloys, design specifications for turbine components, emissions standards for aircraft engines, and certification requirements for airworthiness. Stringent safety regulations govern the manufacturing processes, quality control measures, and maintenance procedures for these advanced turbine engines. Environmental regulations also play a crucial role, addressing noise levels, greenhouse gas emissions, and the overall environmental impact throughout the engine's lifecycle.

Compliance with these regulations is a critical prerequisite for the commercial deployment of lightweight high-temperature turbine engines. Manufacturers must navigate this intricate regulatory landscape, ensuring their products meet the highest standards of safety, performance, and sustainability. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions is essential to continuously refine and adapt these regulations to accommodate technological advancements and evolving environmental concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!