Enhancing Engine Power: The Role of Camshaft Compression Ratios

NOV 25, 20243 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Technology Background And Goals

The primary objective is to explore innovative approaches to increase the compression ratio of camshafts, thereby enhancing engine efficiency and reducing emissions. This involves analyzing current technological limitations and identifying potential breakthroughs. Key areas of focus include optimizing cam lobe profiles, investigating advanced materials and coatings, and exploring novel manufacturing techniques.

Potential innovations may encompass redesigning cam geometries, implementing variable valve timing systems, or integrating lightweight yet durable materials. Computational simulations and experimental testing will play a crucial role in evaluating the feasibility and performance gains of proposed solutions. The ultimate goal is to develop camshaft designs that push the boundaries of compression ratios while ensuring reliability and cost-effectiveness.

Potential innovations may encompass redesigning cam geometries, implementing variable valve timing systems, or integrating lightweight yet durable materials. Computational simulations and experimental testing will play a crucial role in evaluating the feasibility and performance gains of proposed solutions. The ultimate goal is to develop camshaft designs that push the boundaries of compression ratios while ensuring reliability and cost-effectiveness.

Market Demand Analysis

- Automotive Industry Demand

The automotive industry is a major consumer of camshafts, as they are a critical component in internal combustion engines. Increasing fuel efficiency and emission standards drive the demand for more advanced camshaft designs that enable higher compression ratios and optimized valve timing. - Industrial Machinery

Camshafts are widely used in various industrial machinery, such as compressors, pumps, and generators. The demand for more efficient and compact industrial equipment drives the need for camshafts with higher compression ratios. - Aerospace Applications

The aerospace industry requires lightweight and high-performance components, including camshafts. Increasing the compression ratio of camshafts can contribute to improved engine efficiency and reduced fuel consumption in aircraft and spacecraft. - Emerging Markets

Developing economies with growing manufacturing sectors and increasing vehicle ownership are expected to drive the demand for camshafts, including those with higher compression ratios, to meet emission regulations and fuel efficiency requirements.

Technology Status And Challenges

- Current Technological Landscape

Camshafts are a critical component in internal combustion engines, responsible for controlling the opening and closing of valves. The current state of camshaft technology is characterized by incremental improvements in materials, manufacturing processes, and design optimization. - Key Challenges

One of the primary challenges is achieving higher compression ratios while maintaining durability and performance. Higher compression ratios can improve engine efficiency but also increase mechanical stresses on components like camshafts. - Geographical Distribution

The development of camshaft technology is concentrated in regions with a strong automotive industry presence, such as North America, Europe, and Asia, particularly in countries like the United States, Germany, Japan, and China.

Current Technical Solutions

01 Camshaft Design for Improved Compression Ratio

The camshaft design can be optimized to increase the engine's compression ratio by adjusting the cam profile, cam timing, and valve lift, leading to improved efficiency and performance.- Camshaft Design for Improved Compression Ratio: The camshaft design can be optimized to increase the compression ratio, leading to improved engine efficiency and performance, by adjusting the cam profile, cam timing, and valve lift.

- Variable Compression Ratio Mechanisms: Some engines incorporate mechanisms that allow for variable compression ratios, adjusting the ratio based on operating conditions to optimize performance and efficiency.

- Piston and Cylinder Design for Higher Compression Ratio: The design of pistons and cylinders can be optimized for higher compression ratios by modifying the piston crown shape, cylinder head design, and combustion chamber geometry.

- Valve Train Design for Improved Compression Ratio: The valve train components, such as valves, valve springs, and rocker arms, can be designed to accommodate higher compression ratios by using stronger materials and optimizing the valve train geometry.

- Combustion Chamber Design for Higher Compression Ratio: The design of the combustion chamber can be optimized for higher compression ratios by modifying the chamber shape, surface area, and volume to improve combustion efficiency and reduce knocking.

02 Variable Compression Ratio Mechanisms

Some engines incorporate mechanisms that dynamically vary the compression ratio based on operating conditions, involving adjustable components like variable valve timing, variable cam phasing, or movable piston assemblies.Expand Specific Solutions03 Piston and Cylinder Design for High Compression Ratio

The piston and cylinder design can be optimized for higher compression ratios, involving features like compact combustion chambers, reduced crevice volumes, and optimized piston crown and bowl shapes.Expand Specific Solutions04 Camshaft Materials and Coatings

Specialized alloys, surface treatments, or coatings can be used for the camshaft to withstand higher pressures and temperatures associated with higher compression ratios.Expand Specific Solutions05 Camshaft and Valve Train Design for High Compression Ratio

The camshaft and valve train components can be optimized for higher compression ratios, involving features like reinforced cam lobes, stronger valve springs, and improved lubrication systems.Expand Specific Solutions

Main Player Analysis

The competitive landscape for increasing the compression ratio of camshafts is characterized by a mix of established automotive giants and specialized engineering firms. The industry is in a mature stage with significant advancements in materials and manufacturing processes. The market size is substantial, driven by the demand for more efficient and powerful engines.

Toyota Motor Corp.

Technical Solution: Toyota's VVT-i system optimizes camshaft timing, improving engine efficiency and performance for better fuel economy and reduced emissions.

Strength: Proven technology with wide application. Weakness: High development and implementation cost.

Ford Global Technologies LLC

Technical Solution: Ford's EcoBoost technology, including optimized camshaft profiles, enhances engine performance and fuel efficiency through turbocharging and direct injection.

Strength: High performance and efficiency. Weakness: Complexity in maintenance and repair.

Key Technology Interpretation

Variable compression ratio mechanism

PatentInactiveEP1505276B1

Innovation

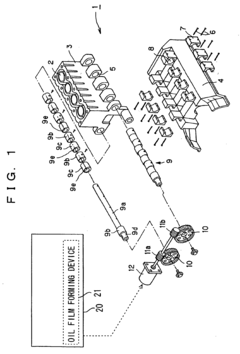

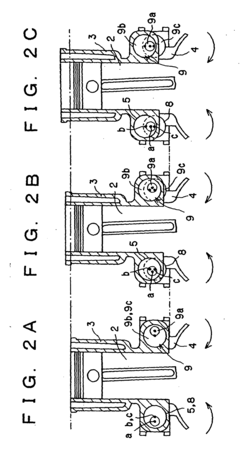

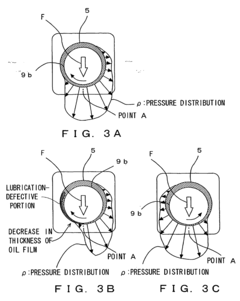

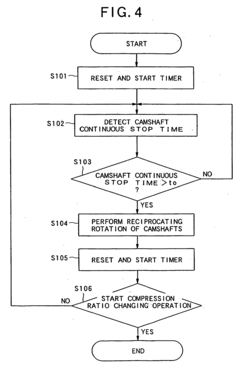

- An oil film forming device is provided to form oil films between the camshafts and bearing portions, preventing oil film shortages and reducing rotational resistance of the camshafts.

- The camshafts are rotatably mounted between the cylinder block and crankcase, and their rotation causes relative movement between the cylinder block and crankcase to change the compression ratio.

- The oil film forming device can be implemented in various ways, such as between the cam portions and cam receiving holes, between the shaft portions and shaft receiving holes, and between the movable bearing portions and bearing receiving holes.

Camshafts Compression Ratio Improvement Economic Analysis

Improving the compression ratio of camshafts can lead to significant economic benefits. Higher compression ratios result in increased thermal efficiency, reducing fuel consumption and operating costs. Additionally, it enables the use of smaller and lighter engines, lowering manufacturing expenses. However, achieving higher compression ratios requires advanced materials and precise engineering to withstand increased cylinder pressures. Thorough cost-benefit analysis is necessary to evaluate the economic viability of implementing such improvements, considering factors like research and development costs, production expenses, and potential fuel savings over the product lifecycle.

Camshafts Compression Ratio Improvement Policy And Regulatory Impact

The regulatory landscape surrounding camshaft compression ratio improvement is complex and evolving. Stringent emission standards and fuel efficiency targets are driving the need for higher compression ratios. However, concerns over increased NOx emissions and engine knock pose challenges. Policymakers aim to strike a balance between environmental protection and technological advancement. Comprehensive impact assessments are necessary to evaluate the effects on air quality, vehicle performance, and manufacturing costs. Collaborative efforts between industry, regulators, and research institutions are crucial for developing effective policies that foster innovation while mitigating potential drawbacks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!