How to Improve The Combustion Efficiency Of Internal Combustion Engines?

Technology Background And Goals

The analysis will cover the geographical distribution of relevant technologies, the competitive landscape of major players, and a detailed examination of current mainstream solutions, including their technical details and implementation considerations. Additionally, it will delve into core patents and technical literature to uncover innovative approaches and potential future research directions for enhancing combustion efficiency in internal combustion engines.

Market Demand Analysis

- Growing Demand for Fuel Efficiency

Rising fuel costs and environmental concerns have driven the demand for more fuel-efficient internal combustion engines across various sectors, including automotive, transportation, and power generation. - Stringent Emission Regulations

Governments worldwide have implemented stringent emission regulations to reduce greenhouse gas emissions and air pollution, compelling manufacturers to develop cleaner and more efficient combustion technologies. - Automotive Industry Shift

The automotive industry is transitioning towards electrification, but internal combustion engines will remain relevant, especially in commercial vehicles and specific market segments, necessitating continued improvements in combustion efficiency. - Emerging Markets Potential

Developing economies with rapidly growing transportation and industrial sectors present significant market opportunities for efficient internal combustion engine technologies. - Technological Advancements

Advancements in areas such as direct injection, turbocharging, and variable valve timing have enabled improved combustion efficiency, driving market demand for these technologies.

Technology Status And Challenges

- Combustion Fundamentals

Overview of the basic principles and processes involved in internal combustion engines, including air-fuel mixture preparation, ignition, and combustion reactions. - Efficiency Limitations

Identification of key factors that limit the efficiency of current internal combustion engines, such as heat losses, incomplete combustion, and emissions. - Advanced Combustion Concepts

Introduction to advanced combustion strategies aimed at improving efficiency, including lean burn, homogeneous charge compression ignition (HCCI), and low-temperature combustion (LTC). - Fuel Injection Systems

Analysis of modern fuel injection systems and their impact on combustion efficiency, including direct injection, common rail, and gasoline direct injection (GDI). - Ignition Systems

Evaluation of ignition systems and their role in optimizing combustion, such as spark ignition, compression ignition, and alternative ignition methods.

Current Technical Solutions

01 Fuel Injection Strategies

Optimizing injection timing, pressure, and spray patterns for better fuel atomization and air mixing, leading to more complete combustion and reduced emissions.- Fuel Injection Strategies: Optimizing injection timing, pressure, and spray patterns for better fuel atomization and air mixing, leading to more complete combustion and reduced emissions.

- Combustion Chamber Design: Optimizing chamber shape, piston bowl geometry, and valve configurations to promote better air-fuel mixing, turbulence, and combustion characteristics for higher thermal efficiency and lower emissions.

- Exhaust Gas Recirculation (EGR): Recirculating exhaust gases into the combustion chamber to dilute the air-fuel mixture, reducing peak combustion temperatures and NOx emissions while improving combustion efficiency.

- Variable Valve Timing: Adjusting intake and exhaust valve timing for better control over the air-fuel mixture and combustion process, leading to improved efficiency, reduced emissions, and enhanced performance.

- Advanced Ignition Systems: Utilizing multiple spark plugs or laser ignition to initiate and control combustion more effectively, promoting faster and more complete burning for reduced emissions and improved fuel economy.

02 Combustion Chamber Design

Optimizing chamber shape, piston bowl geometry, and valve configurations for better air-fuel mixing, turbulence, and combustion characteristics, resulting in higher thermal efficiency and lower emissions.Expand Specific Solutions03 Exhaust Gas Recirculation (EGR)

Recirculating exhaust gases into the combustion chamber to dilute the air-fuel mixture, reducing peak combustion temperatures and NOx emissions while improving combustion efficiency and fuel economy.Expand Specific Solutions04 Advanced Ignition Systems

Employing multiple spark plugs or laser ignition to promote faster and more complete burning of the air-fuel mixture, enhancing combustion efficiency and enabling leaner or diluted mixtures.Expand Specific Solutions05 Turbocharging and Supercharging

Increasing the density of the air-fuel mixture entering the combustion chamber, allowing for more efficient combustion, higher power output, and enabling downsizing and downspeeding strategies for improved fuel economy.Expand Specific Solutions

Main Player Analysis

Toyota Motor Corp.

Robert Bosch GmbH

Key Technology Interpretation

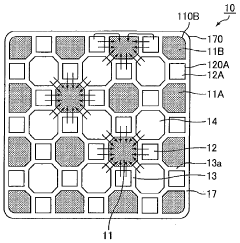

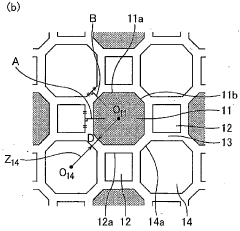

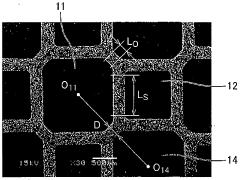

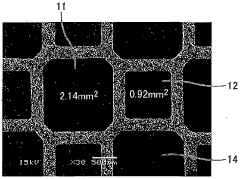

- The use of a honeycomb filter structure to increase the surface area for heat transfer and improve combustion efficiency.

- The honeycomb filter is positioned in the exhaust path to capture and burn unburned fuel particles, reducing emissions and improving combustion efficiency.

- The honeycomb filter can be integrated with other emission control systems, such as exhaust gas recirculation (EGR) or selective catalytic reduction (SCR), for a comprehensive approach to improving combustion efficiency and reducing emissions.

Internal Combustion Engines Efficiency Improvement Environmental Impact

Improving the combustion efficiency of internal combustion engines is a critical focus area for reducing environmental impact. Efficient combustion ensures that the engine extracts the maximum amount of energy from fuel, thus minimizing fuel consumption and reducing the emission of harmful exhaust gases such as carbon dioxide (CO2), nitrogen oxides (NOx), and unburned hydrocarbons. By enhancing combustion efficiency, we can significantly contribute to curbing global CO2 emissions, thereby aligning with international climate goals to mitigate climate change.

Higher combustion efficiency also helps in reducing the emission of particulate matter, which has detrimental effects on air quality and public health. Alongside direct environmental benefits, efficient engines require less fuel, which conserves natural resources and reduces the environmental impact associated with fuel extraction, processing, and transportation.

Advanced technologies such as turbocharging, direct fuel injection, and variable valve timing are among the promising solutions being explored to enhance combustion efficiency. Moreover, the adoption of alternative fuels, such as biofuels, paired with improved combustion techniques, can further decrease the carbon footprint of internal combustion engines. The incorporation of advanced control systems to optimize engine performance under various operating conditions also plays a crucial role in achieving sustainable and efficient combustion.

Internal Combustion Engines Efficiency Improvement Policy And Regulatory Impact

Policy and regulatory frameworks significantly impact the advancement and adoption of technologies aimed at improving the combustion efficiency of internal combustion engines (ICEs). These policies often seek to balance environmental concerns with technological innovation by setting stringent emissions standards and promoting fuel efficiency. Governments around the world have implemented regulations to reduce greenhouse gas emissions, which directly urge manufacturers to innovate in engine design and fuel composition.

Tax incentives and subsidies provide further motivation for companies to invest in research and development focused on enhancing ICE combustion efficiency. These financial instruments aim to lower the barrier for adopting cleaner technologies, accelerating innovation cycles and bringing more energy-efficient engines to market. Regulatory bodies also play a crucial role by establishing testing protocols that validate fuel efficiency improvements, thus ensuring compliance and encouraging ongoing enhancements.

Moreover, international agreements such as the Paris Accord necessitate the alignment of national regulations, fostering a global coherence in technological strategies to combat climate change. Such policies not only set future targets but also drive current industrial shifts toward cleaner combustion solutions. Therefore, staying abreast of these regulatory changes is essential for stakeholders aiming to maintain competitive advantage and contribute to sustainable development goals.