Maximize Combustion Efficiency with Innovative Fuel and Air Management

Technology Background and Goals

Particular emphasis should be placed on elucidating the critical technological breakthroughs and innovations that have shaped the current state of the art, while also highlighting the remaining challenges and bottlenecks that need to be addressed. The analysis should provide a holistic perspective on the technological landscape, encompassing both the theoretical underpinnings and practical implementations of these advanced systems.

Market Demand Analysis

- Growing Demand for Fuel Efficiency

Rising fuel costs and environmental concerns have driven the demand for more fuel-efficient internal combustion engines. Stricter emissions regulations and consumer preferences for eco-friendly vehicles have accelerated this trend. - Automotive Industry Shift

The automotive industry is transitioning towards electrification, but internal combustion engines will remain relevant, especially in commercial vehicles and certain markets. Improving their efficiency is crucial for meeting emission targets. - Emerging Markets Potential

Developing economies with growing transportation needs present significant market opportunities for advanced internal combustion engine technologies. Cost-effective solutions are essential to cater to these price-sensitive markets. - Aftermarket Demand

The aftermarket segment for engine upgrades and retrofits is expected to grow, driven by the desire to extend the lifespan of existing vehicles and improve their performance and efficiency.

Technology Status and Challenges

- Technological Evolution

Internal combustion engines have undergone significant advancements, transitioning from carbureted systems to electronic fuel injection and advanced air management systems. - Current Challenges

Key challenges include improving fuel efficiency, reducing emissions, and enhancing power output while meeting stringent environmental regulations. - Geographical Distribution

Major automotive manufacturing hubs, such as the United States, Europe, Japan, and China, are at the forefront of internal combustion engine technology development.

Technology Evolution Path

Current Technical Solutions

01 Combustion Efficiency Improvement

Various techniques are employed to enhance combustion efficiency, leading to improved performance. These include optimizing air-fuel mixture, advanced ignition systems, and efficient combustion chamber designs.- Combustion Efficiency Improvement: Various techniques are employed to enhance combustion efficiency, leading to improved performance. These include optimizing air-fuel mixture, advanced ignition systems, and efficient combustion chamber designs.

- Emission Reduction Strategies: Strategies like exhaust gas recirculation systems, catalytic converters, and particulate filters are implemented to reduce harmful emissions like nitrogen oxides, carbon monoxide, and particulate matter.

- Fuel Efficiency Enhancement: Techniques like direct fuel injection systems, variable valve timing, and turbocharging/supercharging are employed to enhance fuel efficiency by extracting more energy from the fuel while reducing consumption.

- Engine Cooling Optimization: Effective cooling systems, including liquid cooling, air cooling, and advanced heat dissipation methods, are employed to ensure efficient heat transfer and temperature regulation for optimal engine performance.

- Engine Control and Monitoring Improvement: Advanced electronic control units and sensor systems are implemented to monitor and regulate various engine parameters, enabling precise control and optimization of engine performance.

02 Emission Reduction

Strategies like catalytic converters, exhaust gas recirculation systems, and advanced fuel injection technologies are implemented to reduce harmful emissions, improving environmental performance.03 Fuel Efficiency Enhancement

Techniques like optimized engine design, variable valve timing systems, and lightweight materials are employed to improve fuel efficiency.04 Engine Cooling System Advancement

Advancements in engine cooling systems, such as advanced coolants, optimized radiator designs, and improved heat transfer mechanisms, enhance performance and durability.05 Engine Control System Optimization

Advanced engine control systems, including electronic control units, sensors, and algorithms, are developed to optimize performance by monitoring and adjusting various engine parameters.

Main Player Analysis

Toyota Motor Corp.

GM Global Technology Operations LLC

Key Technology Interpretation

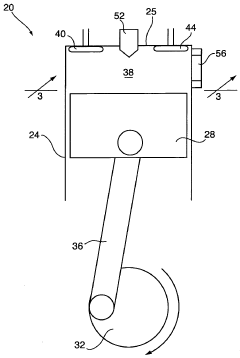

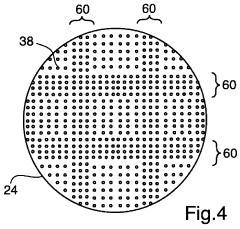

- Applying acoustic energy to the fuel-air mixture in the combustion chamber to alter the combustion characteristics, with the frequency and power level dependent on the volume and amount of the mixture.

- Determining the volume of the combustion chamber and the amount of fuel-air mixture, and using this information to control the applied acoustic energy.

- Introducing a novel method of controlling combustion by applying acoustic energy after the fuel-air mixture is introduced into the combustion chamber, rather than solely adjusting parameters during mixture formation or introduction.

Potential Innovation Direction

- Internal Combustion Engines with Advanced Fuel Injection Systems

- Internal Combustion Engines with Advanced Air Management Systems

- Internal Combustion Engines with Advanced Combustion Strategies

Economic Analysis of The Technology

Conducting an economic analysis of innovative fuel and air management systems aimed at maximizing combustion efficiency involves evaluating the financial impact on production costs and potential benefits. Implementing these advanced systems could lead to a significant reduction in fuel consumption, thus lowering operational expenses. With fuel costs constituting a major portion of operational budgets in industries like transportation and manufacturing, the economic advantages of increased efficiency are substantial.

Moreover, improving combustion efficiency can lead to a decrease in emissions, potentially reducing expenses related to environmental compliance and carbon credits. This not only enhances sustainability credentials but also positions companies to benefit from potential government incentives or subsidies aimed at promoting cleaner technologies.

The cost of integrating these innovative technologies must also be considered, including initial investment, installation, and maintenance expenses. However, the potential long-term savings on fuel and operational costs may offset these initial expenditures. Additionally, businesses may experience indirect economic benefits such as improved market competitiveness and customer perception.

In conclusion, thorough cost-benefit analysis and market-specific evaluation are crucial in determining the economic feasibility of adopting these advanced fuel and air management solutions.

Policy And Regulatory Impact of The Technology

The policy and regulatory impact on maximizing combustion efficiency with innovative fuel and air management is significant. Regulatory frameworks such as emissions standards and clean air guidelines drive the need for improved combustion processes to reduce pollutants. Agencies like the Environmental Protection Agency (EPA) in the U.S. and the European Union’s emission regulations set clear benchmarks for permissible emissions, prompting innovation in combustion technologies. Compliance with these regulations necessitates the adoption of advanced fuel management systems and air quality control mechanisms.

Government incentives and subsidies for research and development in clean energy technologies further stimulate advancements in this area. These support mechanisms can lower the financial barriers for companies investing in innovative combustion solutions, accelerating the development and adoption of new technologies. Additionally, policies promoting environmental sustainability and the transition to alternative fuels can lead to greater adoption of innovative combustion management systems, as these policies often encourage the use of technologies that enhance energy efficiency and reduce environmental impact.

Overall, regulatory pressures and policy incentives work hand in hand to shape the landscape for combustion efficiency innovations, guiding companies towards cleaner and more efficient combustion solutions in their operations.