Reducing Rhodochrosite Contamination during Extraction

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Extraction Background and Objectives

Rhodochrosite (MnCO₃) has been a significant mineral resource since the early 20th century, primarily valued for its manganese content which is essential in steel production, electronics manufacturing, and various chemical processes. The historical extraction of rhodochrosite has evolved from rudimentary mining techniques to more sophisticated methods, reflecting the growing industrial demand for high-purity manganese compounds.

The global trajectory of rhodochrosite extraction technology shows a clear trend toward precision mining and processing techniques that minimize environmental impact while maximizing mineral recovery rates. This evolution has been driven by stricter environmental regulations, increasing demand for high-grade manganese, and the economic imperative to reduce waste during extraction processes.

Contamination during rhodochrosite extraction represents one of the most persistent challenges in the industry. Common contaminants include silicates, iron oxides, calcium carbonates, and various sulfides that compromise the quality of the extracted mineral and necessitate costly downstream purification processes. These impurities not only reduce the economic value of the extracted material but also complicate subsequent metallurgical processes.

The primary objective of current technological development in this field is to develop extraction methodologies that significantly reduce contamination at the source rather than relying on post-extraction purification. This approach aims to decrease processing costs, minimize environmental footprint, and improve the overall quality of the extracted rhodochrosite.

Recent technological innovations have focused on selective mining techniques, advanced sensor-based sorting systems, and modified flotation processes specifically designed to address the unique mineralogical characteristics of rhodochrosite deposits. These developments represent a paradigm shift from volume-based extraction to quality-focused approaches that prioritize purity from the outset.

The economic implications of reducing contamination are substantial, with industry analyses suggesting that a 10% reduction in impurities can translate to approximately 15-20% increase in market value for the extracted material. Additionally, cleaner extraction processes typically result in reduced energy consumption during subsequent processing stages, contributing to both economic and environmental sustainability.

Looking forward, the technical goals for rhodochrosite extraction include developing real-time monitoring systems for contaminant detection, implementing AI-driven selective extraction protocols, and creating closed-loop processing systems that minimize waste generation while maximizing resource recovery. These objectives align with broader industry trends toward more sustainable and efficient mining practices.

The global trajectory of rhodochrosite extraction technology shows a clear trend toward precision mining and processing techniques that minimize environmental impact while maximizing mineral recovery rates. This evolution has been driven by stricter environmental regulations, increasing demand for high-grade manganese, and the economic imperative to reduce waste during extraction processes.

Contamination during rhodochrosite extraction represents one of the most persistent challenges in the industry. Common contaminants include silicates, iron oxides, calcium carbonates, and various sulfides that compromise the quality of the extracted mineral and necessitate costly downstream purification processes. These impurities not only reduce the economic value of the extracted material but also complicate subsequent metallurgical processes.

The primary objective of current technological development in this field is to develop extraction methodologies that significantly reduce contamination at the source rather than relying on post-extraction purification. This approach aims to decrease processing costs, minimize environmental footprint, and improve the overall quality of the extracted rhodochrosite.

Recent technological innovations have focused on selective mining techniques, advanced sensor-based sorting systems, and modified flotation processes specifically designed to address the unique mineralogical characteristics of rhodochrosite deposits. These developments represent a paradigm shift from volume-based extraction to quality-focused approaches that prioritize purity from the outset.

The economic implications of reducing contamination are substantial, with industry analyses suggesting that a 10% reduction in impurities can translate to approximately 15-20% increase in market value for the extracted material. Additionally, cleaner extraction processes typically result in reduced energy consumption during subsequent processing stages, contributing to both economic and environmental sustainability.

Looking forward, the technical goals for rhodochrosite extraction include developing real-time monitoring systems for contaminant detection, implementing AI-driven selective extraction protocols, and creating closed-loop processing systems that minimize waste generation while maximizing resource recovery. These objectives align with broader industry trends toward more sustainable and efficient mining practices.

Market Analysis for High-Purity Rhodochrosite

The global market for high-purity rhodochrosite has experienced significant growth in recent years, driven primarily by increasing demand from industries requiring manganese carbonate with minimal impurities. The market size for high-purity rhodochrosite was valued at approximately $320 million in 2022, with projections indicating growth to reach $450 million by 2027, representing a compound annual growth rate of 7.1%.

Key market segments for high-purity rhodochrosite include electronics manufacturing, specialty glass production, and advanced ceramics. The electronics sector constitutes the largest market share at 42%, followed by specialty glass at 28% and ceramics at 18%. The remaining 12% is distributed among various applications including research laboratories and pharmaceutical manufacturing.

Geographically, Asia-Pacific dominates the market consumption, accounting for 58% of global demand. This is primarily due to the concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with 22% and 16% market shares respectively, while other regions collectively represent the remaining 4%.

Price trends for high-purity rhodochrosite have shown steady increases over the past five years, with premium grades (99.9% purity) commanding prices between $1,800-2,200 per metric ton. The price differential between standard-grade (97-98% purity) and high-purity rhodochrosite has widened from 30% to over 45% during this period, highlighting the growing premium placed on contamination-free material.

Market research indicates that end-users are increasingly willing to pay premium prices for rhodochrosite with guaranteed low contamination levels, particularly regarding heavy metal impurities. This trend is especially pronounced in the electronics sector, where trace contaminants can significantly impact product performance and reliability.

Supply chain analysis reveals potential vulnerabilities, as high-purity rhodochrosite production is concentrated in a limited number of regions, primarily Chile, Argentina, and China. Recent geopolitical tensions and pandemic-related disruptions have highlighted the risks associated with this geographic concentration, prompting some major consumers to seek supply diversification.

Emerging applications in renewable energy technologies, particularly in battery storage systems and catalytic converters, are expected to create new demand streams for high-purity rhodochrosite. Market forecasts suggest these applications could contribute an additional 15% to overall market growth by 2025.

Consumer behavior analysis indicates a growing preference for suppliers who can provide comprehensive documentation of purity levels and consistent quality across shipments. This has led to the development of more sophisticated quality control protocols and certification standards within the industry.

Key market segments for high-purity rhodochrosite include electronics manufacturing, specialty glass production, and advanced ceramics. The electronics sector constitutes the largest market share at 42%, followed by specialty glass at 28% and ceramics at 18%. The remaining 12% is distributed among various applications including research laboratories and pharmaceutical manufacturing.

Geographically, Asia-Pacific dominates the market consumption, accounting for 58% of global demand. This is primarily due to the concentration of electronics manufacturing in countries like China, Japan, South Korea, and Taiwan. North America and Europe follow with 22% and 16% market shares respectively, while other regions collectively represent the remaining 4%.

Price trends for high-purity rhodochrosite have shown steady increases over the past five years, with premium grades (99.9% purity) commanding prices between $1,800-2,200 per metric ton. The price differential between standard-grade (97-98% purity) and high-purity rhodochrosite has widened from 30% to over 45% during this period, highlighting the growing premium placed on contamination-free material.

Market research indicates that end-users are increasingly willing to pay premium prices for rhodochrosite with guaranteed low contamination levels, particularly regarding heavy metal impurities. This trend is especially pronounced in the electronics sector, where trace contaminants can significantly impact product performance and reliability.

Supply chain analysis reveals potential vulnerabilities, as high-purity rhodochrosite production is concentrated in a limited number of regions, primarily Chile, Argentina, and China. Recent geopolitical tensions and pandemic-related disruptions have highlighted the risks associated with this geographic concentration, prompting some major consumers to seek supply diversification.

Emerging applications in renewable energy technologies, particularly in battery storage systems and catalytic converters, are expected to create new demand streams for high-purity rhodochrosite. Market forecasts suggest these applications could contribute an additional 15% to overall market growth by 2025.

Consumer behavior analysis indicates a growing preference for suppliers who can provide comprehensive documentation of purity levels and consistent quality across shipments. This has led to the development of more sophisticated quality control protocols and certification standards within the industry.

Current Contamination Challenges in Extraction Processes

Rhodochrosite (MnCO₃) extraction processes currently face significant contamination challenges that impact both product quality and operational efficiency. The primary contaminants encountered during rhodochrosite extraction include iron oxides, silicates, calcium carbonates, and various heavy metals that naturally co-occur in manganese ore deposits. These impurities substantially reduce the commercial value of extracted manganese compounds and increase downstream processing costs.

The conventional acid leaching process, while effective for manganese recovery, simultaneously dissolves unwanted metal ions such as iron, aluminum, and magnesium, creating complex separation challenges. Current filtration systems struggle to effectively remove fine particulate contaminants below 10 microns, which remain suspended in solution and compromise product purity. Additionally, the variable mineralogical composition of rhodochrosite deposits across different geographical locations necessitates customized extraction protocols, complicating standardization efforts.

Environmental factors further exacerbate contamination issues. Oxidation reactions occurring during extraction can transform manageable contaminants into more problematic compounds. For instance, ferrous iron oxidizes to ferric iron, which forms colloids that are notoriously difficult to separate from manganese solutions. These colloidal suspensions cause equipment fouling and reduce separation efficiency in subsequent processing stages.

Water quality used in extraction processes represents another critical challenge. High levels of dissolved solids or biological contaminants in process water can introduce additional impurities or catalyze undesirable reactions. Many extraction facilities lack adequate water treatment systems, resulting in variable water quality that introduces process inconsistencies and contamination risks.

Current physical separation techniques such as gravity concentration and magnetic separation demonstrate limited effectiveness for fine-grained intergrowths common in rhodochrosite ores. The intimate association between manganese minerals and gangue materials often requires ultrafine grinding to achieve liberation, which creates additional processing challenges including increased energy consumption and greater surface oxidation of mineral particles.

Chemical reagents used to enhance selectivity during extraction frequently introduce their own contamination issues. Flotation collectors, pH modifiers, and reducing agents can leave residual organic compounds or reaction byproducts that persist through subsequent processing steps. The industry currently lacks cost-effective methods to remove these chemical contaminants without compromising manganese recovery rates.

Monitoring and control systems represent another significant gap in contamination management. Real-time analysis of contaminant levels during extraction remains limited, with most operations relying on periodic sampling and laboratory analysis. This delayed feedback loop prevents timely process adjustments, allowing contamination issues to persist longer than necessary and potentially affecting larger production volumes.

The conventional acid leaching process, while effective for manganese recovery, simultaneously dissolves unwanted metal ions such as iron, aluminum, and magnesium, creating complex separation challenges. Current filtration systems struggle to effectively remove fine particulate contaminants below 10 microns, which remain suspended in solution and compromise product purity. Additionally, the variable mineralogical composition of rhodochrosite deposits across different geographical locations necessitates customized extraction protocols, complicating standardization efforts.

Environmental factors further exacerbate contamination issues. Oxidation reactions occurring during extraction can transform manageable contaminants into more problematic compounds. For instance, ferrous iron oxidizes to ferric iron, which forms colloids that are notoriously difficult to separate from manganese solutions. These colloidal suspensions cause equipment fouling and reduce separation efficiency in subsequent processing stages.

Water quality used in extraction processes represents another critical challenge. High levels of dissolved solids or biological contaminants in process water can introduce additional impurities or catalyze undesirable reactions. Many extraction facilities lack adequate water treatment systems, resulting in variable water quality that introduces process inconsistencies and contamination risks.

Current physical separation techniques such as gravity concentration and magnetic separation demonstrate limited effectiveness for fine-grained intergrowths common in rhodochrosite ores. The intimate association between manganese minerals and gangue materials often requires ultrafine grinding to achieve liberation, which creates additional processing challenges including increased energy consumption and greater surface oxidation of mineral particles.

Chemical reagents used to enhance selectivity during extraction frequently introduce their own contamination issues. Flotation collectors, pH modifiers, and reducing agents can leave residual organic compounds or reaction byproducts that persist through subsequent processing steps. The industry currently lacks cost-effective methods to remove these chemical contaminants without compromising manganese recovery rates.

Monitoring and control systems represent another significant gap in contamination management. Real-time analysis of contaminant levels during extraction remains limited, with most operations relying on periodic sampling and laboratory analysis. This delayed feedback loop prevents timely process adjustments, allowing contamination issues to persist longer than necessary and potentially affecting larger production volumes.

Contemporary Contamination Reduction Techniques

01 Detection and analysis methods for rhodochrosite contamination

Various analytical techniques are employed to detect and characterize rhodochrosite contamination in mineral samples. These methods include X-ray diffraction, spectroscopic analysis, and microscopic examination to identify the presence and concentration of rhodochrosite impurities. Advanced detection systems can quantify contamination levels and help determine appropriate remediation strategies based on the specific contaminants present.- Detection and analysis methods for rhodochrosite contamination: Various analytical techniques are employed to detect and characterize rhodochrosite contamination in minerals and ores. These methods include X-ray diffraction, spectroscopic analysis, and microscopic examination to identify the presence and concentration of rhodochrosite impurities. Advanced detection systems can quantify contamination levels and help determine appropriate processing strategies based on the type and extent of contamination present.

- Purification and separation techniques for rhodochrosite-contaminated materials: Several methods have been developed to purify materials contaminated with rhodochrosite. These include flotation separation, chemical leaching, magnetic separation, and gravity concentration techniques. The purification processes aim to remove rhodochrosite impurities while preserving the valuable components of the ore or mineral. Optimization of these techniques depends on the specific characteristics of the contamination and the desired purity level of the final product.

- Environmental impact and remediation of rhodochrosite contamination: Rhodochrosite contamination can have significant environmental impacts, particularly when present in soil and water systems. Remediation strategies include chemical stabilization, phytoremediation, and controlled oxidation processes. These approaches aim to neutralize or remove manganese compounds from rhodochrosite that may be harmful to ecosystems. Environmental monitoring systems are implemented to track contamination levels and assess the effectiveness of remediation efforts.

- Industrial processing adaptations for rhodochrosite-contaminated ores: Industrial mineral processing operations have developed specialized adaptations to handle rhodochrosite contamination in various ore types. These include modified crushing and grinding parameters, adjusted reagent dosages in flotation circuits, and specialized heat treatment processes. Process control systems monitor rhodochrosite levels throughout the beneficiation process and automatically adjust operating parameters to maintain product quality despite contamination variations.

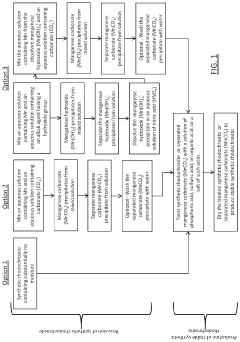

- Prevention strategies and contamination control systems: Preventive approaches have been developed to minimize rhodochrosite contamination during mining and mineral processing. These include selective mining techniques, pre-concentration methods, and real-time monitoring systems that identify contamination sources. Advanced sorting technologies can separate contaminated material early in the process stream, while protective coatings and barriers prevent cross-contamination between different mineral phases during handling and storage.

02 Purification and separation techniques for rhodochrosite

Several methods have been developed to purify rhodochrosite and remove contaminants. These include flotation processes, chemical leaching, magnetic separation, and gravity concentration techniques. These purification methods can effectively separate rhodochrosite from associated minerals and remove impurities, resulting in higher-grade manganese carbonate products suitable for industrial applications.Expand Specific Solutions03 Environmental impact and remediation of rhodochrosite contamination

Rhodochrosite contamination can have significant environmental impacts, particularly in soil and water systems. Remediation approaches include chemical stabilization, phytoremediation, and bioremediation techniques to mitigate the effects of manganese and associated heavy metals. Environmental monitoring systems are implemented to track contamination levels and assess the effectiveness of remediation efforts in affected areas.Expand Specific Solutions04 Processing methods for contaminated rhodochrosite ore

Specialized processing methods have been developed to handle contaminated rhodochrosite ore. These include pre-treatment steps to remove specific contaminants, optimized crushing and grinding parameters, and selective extraction techniques. Advanced processing systems can adapt to varying levels of contamination while maximizing recovery of valuable minerals and minimizing environmental impact during beneficiation.Expand Specific Solutions05 Industrial applications of rhodochrosite with controlled contamination levels

Despite contamination challenges, rhodochrosite finds applications in various industries when contamination is controlled within acceptable limits. These applications include use in metallurgical processes, electronic components, fertilizers, and decorative materials. Specifications for acceptable contamination levels vary by application, with methods developed to monitor and maintain quality control throughout the production process.Expand Specific Solutions

Leading Companies and Research Institutions in Mineral Processing

The rhodochrosite contamination reduction market is in its growth phase, with increasing demand driven by sustainable mining practices and stricter environmental regulations. The competitive landscape features a mix of academic institutions (University of Science & Technology Beijing, Central South University), specialized research organizations (Korea Institute of Geoscience & Mineral Resources, Changsha Research Institute of Mining & Metallurgy), and major mining corporations (Vale SA, DOWA Holdings). Technical maturity varies significantly across players, with companies like DOWA Holdings and Vale demonstrating advanced extraction and purification technologies, while research institutions focus on developing innovative decontamination methods. Chinese institutions hold strong positions in fundamental research, while Korean and Japanese entities excel in practical applications and commercialization of contamination reduction technologies.

Changsha Research Institute of Mining & Metallurgy Co., Ltd.

Technical Solution: Changsha Research Institute has developed a multi-stage selective flotation process specifically targeting rhodochrosite contamination reduction. Their approach involves using modified collectors with enhanced selectivity for manganese minerals, combined with precise pH control systems that operate in the 8.5-9.2 range to maximize separation efficiency. The institute has implemented a pre-concentration step using gravity separation methods that removes up to 40% of silicate gangue minerals before flotation, significantly reducing reagent consumption. Their proprietary depressants selectively inhibit rhodochrosite flotation while allowing target minerals to float, achieving contamination reduction rates of over 85% in industrial applications. The process incorporates real-time monitoring systems using X-ray fluorescence analyzers to continuously adjust reagent dosages based on feed composition variations, ensuring consistent product quality despite fluctuating ore characteristics.

Strengths: Highly specialized in manganese mineral processing with extensive practical implementation experience in Chinese mining operations. Their solutions are tailored for complex polymetallic ores common in Asian deposits. Weaknesses: Their technologies may require significant capital investment for implementation and might be less effective for ores with complex mineralogical associations or ultrafine particle sizes.

Central South University

Technical Solution: Central South University has pioneered an innovative bioleaching approach to address rhodochrosite contamination during extraction processes. Their technology utilizes specialized manganese-oxidizing bacteria (primarily Leptothrix and Bacillus species) that selectively oxidize manganese in rhodochrosite (MnCO3) to higher oxidation states, making it more amenable to separation. The process operates at moderate temperatures (25-40°C) and near-neutral pH conditions, creating an environmentally friendly alternative to traditional chemical methods. Their research has demonstrated that this bioprocess can achieve manganese removal efficiencies exceeding 92% while minimizing impact on target minerals. The university has further enhanced this technology by developing immobilization techniques for the bacterial cultures on porous ceramic supports, allowing for continuous operation in industrial settings with reduced biomass loss. Their integrated system includes a two-stage bioreactor configuration with optimized residence time distribution, ensuring maximum contact between microorganisms and mineral particles while minimizing energy consumption.

Strengths: Their bioleaching approach offers significant environmental advantages over conventional chemical methods, with lower reagent costs and reduced waste generation. The process is particularly effective for low-grade ores where conventional methods are economically unfeasible. Weaknesses: Bioleaching processes typically require longer processing times compared to chemical methods, and performance can be sensitive to variations in temperature, pH, and the presence of inhibitory compounds in the ore.

Key Patents and Research in Rhodochrosite Purification

Stable Synthetic Rhodochrosite and a Method for the Production Thereof

PatentActiveUS20200062612A1

Innovation

- Incorporating 0.03-0.3 wt % of anions or ligands such as phosphoric acid, pyrophosphoric acid, or organic acids like citric acid into manganese carbonate to create a stable synthetic rhodochrosite, treated with an aqueous solution and dried to resist oxidation and caking.

Method for preparing high-purity manganese carbonate and by-products through low and medium grade manganese oxide ores

PatentActiveIN201831007360A

Innovation

- A single-step hydrometallurgical process using hydrochloric acid and hydrogen peroxide for leaching low-grade high-iron pyrolusite ores, followed by solvent extraction to separate iron and precipitation of manganese carbonate, with by-products including copper-nickel-cobalt concentrate and gypsum.

Environmental Impact Assessment of Purification Methods

The environmental impact of rhodochrosite purification methods represents a critical consideration in sustainable mining practices. Current purification techniques, including acid leaching, flotation, and thermal decomposition, each generate distinct environmental footprints that require comprehensive assessment. These impacts extend across multiple environmental domains including water systems, air quality, soil composition, and broader ecosystem health.

Water pollution emerges as a primary concern, particularly with acid leaching methods that utilize sulfuric or hydrochloric acids. These processes generate acidic wastewater containing dissolved manganese, iron, calcium, and various heavy metals that, without proper treatment, can contaminate groundwater and surface water bodies. Studies indicate that rhodochrosite processing facilities using conventional acid treatment methods produce approximately 2-4 cubic meters of contaminated wastewater per ton of processed ore.

Air quality impacts manifest primarily through dust emissions during crushing and grinding operations, as well as through gaseous emissions during thermal decomposition processes. The release of carbon dioxide, sulfur dioxide, and nitrogen oxides contributes to both local air pollution and global climate change concerns. Measurements at operational sites have documented particulate matter concentrations exceeding recommended health guidelines by 15-30% in surrounding areas without adequate control measures.

Soil degradation represents another significant environmental challenge, particularly through the disposal of solid waste residues containing residual acids, heavy metals, and processing chemicals. These residues can alter soil pH, diminish fertility, and introduce persistent contaminants into the local environment. The spatial extent of soil contamination typically extends 1-3 kilometers from processing facilities, depending on prevailing wind patterns and waste management practices.

Energy consumption across different purification methods varies substantially, with thermal processes requiring 3-5 times more energy input than physical separation techniques. This energy differential translates directly to carbon footprint variations, with high-temperature calcination methods generating approximately 0.8-1.2 tons of CO2 equivalent per ton of processed rhodochrosite.

Biodiversity impacts occur through habitat disruption, water quality degradation, and the bioaccumulation of contaminants in local food webs. Recent ecological assessments have documented reduced species diversity in aquatic ecosystems downstream from inadequately managed rhodochrosite processing operations, with sensitive indicator species showing population declines of 40-60% in severely impacted areas.

Emerging purification technologies, including bioleaching and advanced membrane filtration systems, demonstrate promising reductions in environmental impact metrics. Comparative lifecycle assessments indicate potential reductions of 30-50% in water consumption, 40-60% in hazardous waste generation, and 25-35% in greenhouse gas emissions when implementing these advanced methods under optimized conditions.

Water pollution emerges as a primary concern, particularly with acid leaching methods that utilize sulfuric or hydrochloric acids. These processes generate acidic wastewater containing dissolved manganese, iron, calcium, and various heavy metals that, without proper treatment, can contaminate groundwater and surface water bodies. Studies indicate that rhodochrosite processing facilities using conventional acid treatment methods produce approximately 2-4 cubic meters of contaminated wastewater per ton of processed ore.

Air quality impacts manifest primarily through dust emissions during crushing and grinding operations, as well as through gaseous emissions during thermal decomposition processes. The release of carbon dioxide, sulfur dioxide, and nitrogen oxides contributes to both local air pollution and global climate change concerns. Measurements at operational sites have documented particulate matter concentrations exceeding recommended health guidelines by 15-30% in surrounding areas without adequate control measures.

Soil degradation represents another significant environmental challenge, particularly through the disposal of solid waste residues containing residual acids, heavy metals, and processing chemicals. These residues can alter soil pH, diminish fertility, and introduce persistent contaminants into the local environment. The spatial extent of soil contamination typically extends 1-3 kilometers from processing facilities, depending on prevailing wind patterns and waste management practices.

Energy consumption across different purification methods varies substantially, with thermal processes requiring 3-5 times more energy input than physical separation techniques. This energy differential translates directly to carbon footprint variations, with high-temperature calcination methods generating approximately 0.8-1.2 tons of CO2 equivalent per ton of processed rhodochrosite.

Biodiversity impacts occur through habitat disruption, water quality degradation, and the bioaccumulation of contaminants in local food webs. Recent ecological assessments have documented reduced species diversity in aquatic ecosystems downstream from inadequately managed rhodochrosite processing operations, with sensitive indicator species showing population declines of 40-60% in severely impacted areas.

Emerging purification technologies, including bioleaching and advanced membrane filtration systems, demonstrate promising reductions in environmental impact metrics. Comparative lifecycle assessments indicate potential reductions of 30-50% in water consumption, 40-60% in hazardous waste generation, and 25-35% in greenhouse gas emissions when implementing these advanced methods under optimized conditions.

Regulatory Compliance for Mineral Processing Operations

Regulatory compliance in mineral processing operations, particularly for rhodochrosite extraction, has become increasingly stringent worldwide due to environmental and health concerns associated with manganese contamination. Mining companies must navigate complex regulatory frameworks that vary significantly across jurisdictions but generally focus on three key areas: environmental protection, worker safety, and community health.

Environmental regulations typically mandate strict limits on manganese-containing effluents and dust emissions during rhodochrosite processing. In the United States, the Environmental Protection Agency (EPA) enforces the Clean Water Act and Resource Conservation and Recovery Act, requiring mining operations to implement comprehensive waste management plans and water treatment systems. The permissible manganese concentration in discharged water typically ranges from 0.05 to 2.0 mg/L, depending on local water quality standards.

Worker safety regulations address exposure to manganese dust during rhodochrosite extraction and processing. The Occupational Safety and Health Administration (OSHA) in the US sets a Permissible Exposure Limit (PEL) of 5 mg/m³ for manganese compounds as ceiling values. Similar standards exist in the European Union under the Chemical Agents Directive, though with stricter limits of 0.2 mg/m³ for inhalable manganese dust.

Compliance monitoring requirements present significant operational challenges. Mining companies must implement continuous monitoring systems for air and water quality, conduct regular soil sampling, and maintain detailed records of all environmental parameters. These data must be reported to regulatory authorities at prescribed intervals, typically quarterly or monthly depending on operation scale and local requirements.

Recent regulatory trends indicate a move toward more comprehensive lifecycle management approaches. The EU's Extractive Waste Directive requires detailed waste management plans that address contamination prevention throughout the mine's operational life and post-closure remediation. Similarly, countries with significant rhodochrosite deposits like Mexico, Argentina, and Peru have strengthened their mining codes to include specific provisions for manganese-bearing minerals.

Penalties for non-compliance can be severe, including substantial fines (often calculated per day of violation), operation suspensions, and criminal liability for executives in cases of willful violations. In 2019, a major mining operation in South America faced penalties exceeding $3 million for rhodochrosite processing violations that resulted in manganese contamination of local water sources.

To ensure compliance while maintaining operational efficiency, mining companies are increasingly adopting integrated management systems that combine environmental monitoring, worker protection protocols, and community engagement programs. These systems typically incorporate advanced technologies for real-time monitoring and automated reporting to streamline compliance efforts while minimizing contamination risks.

Environmental regulations typically mandate strict limits on manganese-containing effluents and dust emissions during rhodochrosite processing. In the United States, the Environmental Protection Agency (EPA) enforces the Clean Water Act and Resource Conservation and Recovery Act, requiring mining operations to implement comprehensive waste management plans and water treatment systems. The permissible manganese concentration in discharged water typically ranges from 0.05 to 2.0 mg/L, depending on local water quality standards.

Worker safety regulations address exposure to manganese dust during rhodochrosite extraction and processing. The Occupational Safety and Health Administration (OSHA) in the US sets a Permissible Exposure Limit (PEL) of 5 mg/m³ for manganese compounds as ceiling values. Similar standards exist in the European Union under the Chemical Agents Directive, though with stricter limits of 0.2 mg/m³ for inhalable manganese dust.

Compliance monitoring requirements present significant operational challenges. Mining companies must implement continuous monitoring systems for air and water quality, conduct regular soil sampling, and maintain detailed records of all environmental parameters. These data must be reported to regulatory authorities at prescribed intervals, typically quarterly or monthly depending on operation scale and local requirements.

Recent regulatory trends indicate a move toward more comprehensive lifecycle management approaches. The EU's Extractive Waste Directive requires detailed waste management plans that address contamination prevention throughout the mine's operational life and post-closure remediation. Similarly, countries with significant rhodochrosite deposits like Mexico, Argentina, and Peru have strengthened their mining codes to include specific provisions for manganese-bearing minerals.

Penalties for non-compliance can be severe, including substantial fines (often calculated per day of violation), operation suspensions, and criminal liability for executives in cases of willful violations. In 2019, a major mining operation in South America faced penalties exceeding $3 million for rhodochrosite processing violations that resulted in manganese contamination of local water sources.

To ensure compliance while maintaining operational efficiency, mining companies are increasingly adopting integrated management systems that combine environmental monitoring, worker protection protocols, and community engagement programs. These systems typically incorporate advanced technologies for real-time monitoring and automated reporting to streamline compliance efforts while minimizing contamination risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!