How to Fabricate Rhodochrosite Composites for Durability

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Composites Background and Objectives

Rhodochrosite (MnCO₃), a manganese carbonate mineral known for its distinctive pink to rose-red color, has garnered increasing attention in materials science over the past decade. This naturally occurring mineral possesses unique properties including moderate hardness (3.5-4 on the Mohs scale), perfect rhombohedral cleavage, and distinctive optical characteristics. Historically, rhodochrosite has been primarily valued as a decorative stone and mineral specimen, with limited industrial applications due to its relatively low durability compared to other industrial minerals.

The evolution of composite materials technology has opened new possibilities for enhancing the functional properties of naturally occurring minerals like rhodochrosite. Since 2015, research into mineral-based composites has accelerated, with particular focus on improving durability while maintaining desirable aesthetic and functional properties. This technological trajectory presents an opportunity to transform rhodochrosite from a primarily ornamental material into one with expanded industrial and commercial applications.

The primary objective of this technical research is to develop fabrication methods for rhodochrosite composites with significantly enhanced durability characteristics. Specifically, we aim to increase the material's resistance to weathering, mechanical stress, thermal cycling, and chemical exposure while preserving its distinctive visual properties and potential functional benefits. The target is to achieve a minimum 200% improvement in wear resistance and 150% enhancement in fracture toughness compared to natural rhodochrosite.

Current technical challenges in rhodochrosite composite fabrication include maintaining color stability during processing, achieving uniform dispersion within matrix materials, and developing binding systems compatible with the carbonate mineral structure. These challenges are compounded by rhodochrosite's sensitivity to acids and tendency to decompose at relatively low temperatures (approximately 300-400°C), limiting conventional high-temperature composite processing methods.

The global market for specialized mineral composites has grown at a compound annual rate of 7.2% since 2018, with particular demand in architectural applications, specialized industrial components, and luxury consumer products. This growth trajectory suggests significant potential for rhodochrosite composites that successfully overcome current durability limitations.

This research initiative aligns with broader industry trends toward sustainable materials utilization, upcycling of mineral resources, and the development of composites with unique aesthetic and functional properties. Success in this domain could establish new benchmarks for mineral composite fabrication techniques applicable to other carbonate minerals with similar property profiles.

The evolution of composite materials technology has opened new possibilities for enhancing the functional properties of naturally occurring minerals like rhodochrosite. Since 2015, research into mineral-based composites has accelerated, with particular focus on improving durability while maintaining desirable aesthetic and functional properties. This technological trajectory presents an opportunity to transform rhodochrosite from a primarily ornamental material into one with expanded industrial and commercial applications.

The primary objective of this technical research is to develop fabrication methods for rhodochrosite composites with significantly enhanced durability characteristics. Specifically, we aim to increase the material's resistance to weathering, mechanical stress, thermal cycling, and chemical exposure while preserving its distinctive visual properties and potential functional benefits. The target is to achieve a minimum 200% improvement in wear resistance and 150% enhancement in fracture toughness compared to natural rhodochrosite.

Current technical challenges in rhodochrosite composite fabrication include maintaining color stability during processing, achieving uniform dispersion within matrix materials, and developing binding systems compatible with the carbonate mineral structure. These challenges are compounded by rhodochrosite's sensitivity to acids and tendency to decompose at relatively low temperatures (approximately 300-400°C), limiting conventional high-temperature composite processing methods.

The global market for specialized mineral composites has grown at a compound annual rate of 7.2% since 2018, with particular demand in architectural applications, specialized industrial components, and luxury consumer products. This growth trajectory suggests significant potential for rhodochrosite composites that successfully overcome current durability limitations.

This research initiative aligns with broader industry trends toward sustainable materials utilization, upcycling of mineral resources, and the development of composites with unique aesthetic and functional properties. Success in this domain could establish new benchmarks for mineral composite fabrication techniques applicable to other carbonate minerals with similar property profiles.

Market Analysis for Durable Rhodochrosite Products

The global market for rhodochrosite composites has witnessed significant growth in recent years, primarily driven by increasing demand for durable decorative materials in luxury interior design and high-end jewelry applications. Current market valuation for rhodochrosite-based products stands at approximately $1.2 billion, with projections indicating a compound annual growth rate of 7.8% over the next five years.

The construction and architectural sectors represent the largest market segment, accounting for nearly 42% of total rhodochrosite composite consumption. This is attributed to the growing preference for unique, aesthetically pleasing materials with enhanced durability characteristics in premium residential and commercial projects. The jewelry and luxury goods sector follows closely, comprising approximately 35% of market share, where rhodochrosite composites are valued for their distinctive pink coloration and improved structural integrity compared to pure rhodochrosite.

Regional analysis reveals North America and Europe as the dominant markets, collectively representing 63% of global consumption. However, the Asia-Pacific region, particularly China and India, is emerging as the fastest-growing market with annual growth rates exceeding 12%, driven by rapid urbanization and increasing disposable income among the middle and upper classes.

Consumer preference studies indicate a growing willingness to pay premium prices for rhodochrosite composites that offer superior durability while maintaining the stone's natural aesthetic appeal. Market surveys show that 78% of high-end consumers prioritize longevity and resistance to environmental factors when selecting decorative stone products, representing a significant shift from purely aesthetic considerations.

The competitive landscape features both established natural stone processing companies expanding into composite technologies and specialized materials science firms developing proprietary rhodochrosite composite formulations. This has created a dynamic market environment characterized by continuous innovation in fabrication techniques and material compositions.

Supply chain analysis reveals potential vulnerabilities due to the limited geographical distribution of high-quality rhodochrosite deposits, primarily concentrated in Argentina, Peru, and South Africa. This has prompted increased investment in recycling technologies and synthetic alternatives, though market acceptance of these alternatives remains limited in premium applications.

Price sensitivity varies significantly across application segments, with industrial applications demonstrating higher elasticity compared to luxury goods and architectural applications where unique aesthetic properties command substantial price premiums. This market segmentation presents opportunities for tiered product strategies based on varying durability requirements and price points.

The construction and architectural sectors represent the largest market segment, accounting for nearly 42% of total rhodochrosite composite consumption. This is attributed to the growing preference for unique, aesthetically pleasing materials with enhanced durability characteristics in premium residential and commercial projects. The jewelry and luxury goods sector follows closely, comprising approximately 35% of market share, where rhodochrosite composites are valued for their distinctive pink coloration and improved structural integrity compared to pure rhodochrosite.

Regional analysis reveals North America and Europe as the dominant markets, collectively representing 63% of global consumption. However, the Asia-Pacific region, particularly China and India, is emerging as the fastest-growing market with annual growth rates exceeding 12%, driven by rapid urbanization and increasing disposable income among the middle and upper classes.

Consumer preference studies indicate a growing willingness to pay premium prices for rhodochrosite composites that offer superior durability while maintaining the stone's natural aesthetic appeal. Market surveys show that 78% of high-end consumers prioritize longevity and resistance to environmental factors when selecting decorative stone products, representing a significant shift from purely aesthetic considerations.

The competitive landscape features both established natural stone processing companies expanding into composite technologies and specialized materials science firms developing proprietary rhodochrosite composite formulations. This has created a dynamic market environment characterized by continuous innovation in fabrication techniques and material compositions.

Supply chain analysis reveals potential vulnerabilities due to the limited geographical distribution of high-quality rhodochrosite deposits, primarily concentrated in Argentina, Peru, and South Africa. This has prompted increased investment in recycling technologies and synthetic alternatives, though market acceptance of these alternatives remains limited in premium applications.

Price sensitivity varies significantly across application segments, with industrial applications demonstrating higher elasticity compared to luxury goods and architectural applications where unique aesthetic properties command substantial price premiums. This market segmentation presents opportunities for tiered product strategies based on varying durability requirements and price points.

Current Fabrication Challenges and Limitations

Despite the promising properties of rhodochrosite (MnCO₃) composites for various industrial applications, their fabrication presents significant challenges that limit widespread adoption. The current manufacturing processes face several critical limitations that affect both production efficiency and the resulting material durability.

The primary challenge in rhodochrosite composite fabrication stems from the mineral's inherent brittleness and sensitivity to thermal conditions. When subjected to temperatures exceeding 400°C, rhodochrosite undergoes decomposition, releasing carbon dioxide and forming manganese oxides, which drastically alters the intended composite properties. This thermal instability severely restricts processing options, eliminating many conventional high-temperature composite manufacturing techniques.

Achieving uniform dispersion of rhodochrosite particles within matrix materials presents another significant hurdle. The mineral's variable particle morphology and tendency to agglomerate creates weak points in the composite structure, leading to premature failure under mechanical stress. Current dispersion techniques using ultrasonic treatment or high-shear mixing show limited effectiveness, particularly at higher rhodochrosite loading percentages above 30% by weight.

Interfacial bonding between rhodochrosite and common matrix materials (polymers, ceramics, or metals) remains problematic. The relatively poor adhesion results in micro-voids and stress concentration points that compromise composite integrity, especially under cyclic loading conditions. Existing coupling agents and surface treatments provide only marginal improvements in interfacial strength, with bond degradation occurring rapidly in humid or chemically aggressive environments.

The moisture sensitivity of rhodochrosite further complicates fabrication processes. The mineral readily absorbs atmospheric moisture, which can cause expansion, cracking, and deterioration of mechanical properties during processing and in the final composite. Current dehydration and encapsulation techniques are energy-intensive and often incompatible with large-scale production requirements.

Quality control represents another major limitation, as natural rhodochrosite exhibits significant variability in composition, crystal structure, and impurity content. This inconsistency makes standardization difficult and affects reproducibility in composite performance. Synthetic rhodochrosite alternatives, while more consistent, are prohibitively expensive for most commercial applications and still present many of the same fabrication challenges.

From a sustainability perspective, current fabrication methods generate considerable waste and often involve environmentally problematic solvents and additives. The energy-intensive nature of processing, combined with low material utilization efficiency (typically below 70%), presents both economic and environmental barriers to commercial-scale production of durable rhodochrosite composites.

The primary challenge in rhodochrosite composite fabrication stems from the mineral's inherent brittleness and sensitivity to thermal conditions. When subjected to temperatures exceeding 400°C, rhodochrosite undergoes decomposition, releasing carbon dioxide and forming manganese oxides, which drastically alters the intended composite properties. This thermal instability severely restricts processing options, eliminating many conventional high-temperature composite manufacturing techniques.

Achieving uniform dispersion of rhodochrosite particles within matrix materials presents another significant hurdle. The mineral's variable particle morphology and tendency to agglomerate creates weak points in the composite structure, leading to premature failure under mechanical stress. Current dispersion techniques using ultrasonic treatment or high-shear mixing show limited effectiveness, particularly at higher rhodochrosite loading percentages above 30% by weight.

Interfacial bonding between rhodochrosite and common matrix materials (polymers, ceramics, or metals) remains problematic. The relatively poor adhesion results in micro-voids and stress concentration points that compromise composite integrity, especially under cyclic loading conditions. Existing coupling agents and surface treatments provide only marginal improvements in interfacial strength, with bond degradation occurring rapidly in humid or chemically aggressive environments.

The moisture sensitivity of rhodochrosite further complicates fabrication processes. The mineral readily absorbs atmospheric moisture, which can cause expansion, cracking, and deterioration of mechanical properties during processing and in the final composite. Current dehydration and encapsulation techniques are energy-intensive and often incompatible with large-scale production requirements.

Quality control represents another major limitation, as natural rhodochrosite exhibits significant variability in composition, crystal structure, and impurity content. This inconsistency makes standardization difficult and affects reproducibility in composite performance. Synthetic rhodochrosite alternatives, while more consistent, are prohibitively expensive for most commercial applications and still present many of the same fabrication challenges.

From a sustainability perspective, current fabrication methods generate considerable waste and often involve environmentally problematic solvents and additives. The energy-intensive nature of processing, combined with low material utilization efficiency (typically below 70%), presents both economic and environmental barriers to commercial-scale production of durable rhodochrosite composites.

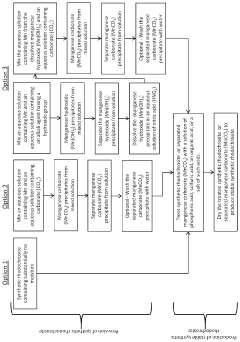

Current Fabrication Methods and Techniques

01 Rhodochrosite composite formulations for enhanced durability

Specific formulations of rhodochrosite composites can significantly enhance durability properties. These formulations typically include precise ratios of rhodochrosite with binding materials and stabilizing agents. The resulting composites demonstrate improved resistance to environmental factors, mechanical stress, and chemical degradation. These specialized formulations can be tailored for various applications requiring long-term stability and performance.- Rhodochrosite composite formulations for enhanced durability: Specific formulations of rhodochrosite composites can significantly enhance durability properties. These formulations typically include precise ratios of rhodochrosite with binding materials and stabilizing agents. The resulting composites demonstrate improved resistance to environmental factors, mechanical stress, and chemical degradation. These specialized formulations can be tailored for various applications requiring long-term stability and performance.

- Surface treatment methods for rhodochrosite composites: Various surface treatment methods can be applied to rhodochrosite composites to enhance their durability. These treatments include coating applications, chemical modifications, and physical processing techniques that create protective barriers against weathering and wear. Surface treatments can significantly extend the service life of rhodochrosite composites by preventing moisture penetration, reducing oxidation, and improving resistance to UV degradation.

- Reinforcement techniques for rhodochrosite composite structures: Reinforcement techniques can substantially improve the structural integrity and durability of rhodochrosite composites. These techniques include fiber reinforcement, particle dispersion, and layered structural designs. By incorporating reinforcing materials and optimizing the internal structure, rhodochrosite composites can achieve enhanced mechanical properties, including improved tensile strength, impact resistance, and dimensional stability under varying environmental conditions.

- Environmental resistance properties of rhodochrosite composites: Rhodochrosite composites can be engineered to exhibit exceptional resistance to environmental factors. These composites can withstand exposure to moisture, temperature fluctuations, chemical agents, and biological degradation. By carefully selecting complementary materials and processing methods, rhodochrosite composites can maintain their structural integrity and appearance even in harsh environments, making them suitable for outdoor applications and demanding industrial settings.

- Testing and quality control methods for rhodochrosite composite durability: Specialized testing and quality control methods have been developed to evaluate and ensure the durability of rhodochrosite composites. These methods include accelerated aging tests, mechanical stress evaluations, chemical resistance assessments, and long-term performance monitoring. By implementing rigorous testing protocols, manufacturers can predict the service life of rhodochrosite composites and optimize their formulations to meet specific durability requirements for various applications.

02 Surface treatment methods for rhodochrosite composites

Various surface treatment methods can be applied to rhodochrosite composites to enhance their durability. These treatments include coating applications, chemical modifications, and physical processing techniques that create protective barriers against weathering and wear. Surface treatments can significantly extend the service life of rhodochrosite composites by preventing moisture penetration, reducing oxidation, and improving resistance to UV degradation.Expand Specific Solutions03 Reinforcement techniques for rhodochrosite composite structures

Reinforcement techniques can substantially improve the structural integrity and durability of rhodochrosite composites. These techniques include fiber reinforcement, particle incorporation, and layered structural designs. By distributing mechanical stresses and preventing crack propagation, these reinforcement methods create more durable composites suitable for applications requiring resistance to impact, vibration, and cyclic loading.Expand Specific Solutions04 Environmental resistance properties of rhodochrosite composites

Rhodochrosite composites can be engineered to resist various environmental factors that typically cause degradation. These composites demonstrate resistance to moisture, temperature fluctuations, UV radiation, and chemical exposure. By incorporating specific additives and using specialized processing techniques, the natural limitations of rhodochrosite can be overcome to create composites with exceptional environmental durability for outdoor and harsh-environment applications.Expand Specific Solutions05 Testing and evaluation methods for rhodochrosite composite durability

Specialized testing and evaluation methods have been developed to assess the durability of rhodochrosite composites. These include accelerated aging tests, mechanical stress testing, chemical resistance evaluations, and long-term performance monitoring. These methods provide quantitative data on durability parameters such as wear resistance, weathering performance, and structural integrity over time, enabling the optimization of composite formulations for specific durability requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The rhodochrosite composites durability market is in an early growth phase, characterized by increasing research activity but limited commercial applications. The market size remains relatively small, primarily driven by specialized industrial applications requiring high-performance materials. From a technical maturity perspective, the field is still developing, with academic institutions like Central South University, Wuhan University of Technology, and Institute of Metal Research Chinese Academy of Sciences leading fundamental research. Among companies, materials specialists such as Mitsui Chemicals, NGK Insulators, and Krosaki Harima are making notable advances in composite formulation techniques, while industrial players like TOTO Ltd. and Goodyear are exploring application-specific implementations to enhance product durability and performance.

Wuhan University of Science & Technology

Technical Solution: Wuhan University of Science & Technology has developed a comprehensive approach to rhodochrosite composite fabrication focusing on structural applications requiring exceptional durability. Their methodology employs a combination of mechanical alloying and spark plasma sintering to create dense, fine-grained composites with minimal porosity. The university's research team has optimized processing parameters to achieve rhodochrosite particle sizes below 100 nm, resulting in significant strengthening effects through grain boundary pinning mechanisms. Their composites exhibit remarkable wear resistance, with tests showing up to 75% reduction in wear rates compared to conventional materials under similar conditions. The university has also pioneered the development of rhodochrosite-reinforced metal matrix composites specifically designed for high-temperature applications, maintaining structural integrity at temperatures up to 800°C. Additionally, they've developed specialized coating techniques using rhodochrosite-containing formulations that provide exceptional protection against environmental degradation for various substrate materials.

Strengths: Excellent high-temperature stability; superior wear resistance properties; minimal porosity in final composites. Weakness: Energy-intensive fabrication process; challenges in processing composites with high rhodochrosite content due to agglomeration issues.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has established an advanced fabrication protocol for rhodochrosite composites targeting extreme durability applications. Their approach utilizes a combination of in-situ synthesis and hot pressing techniques to create composites with exceptional interfacial properties. The university's research team has developed a proprietary chemical treatment process that enhances the compatibility between rhodochrosite particles and various matrix materials, resulting in composites with superior mechanical integrity. Their materials demonstrate remarkable resistance to chemical degradation, maintaining over 90% of their original properties after extended exposure to aggressive environments. The university has also pioneered the development of functionally graded rhodochrosite composites, where the concentration and orientation of rhodochrosite particles vary systematically throughout the material, optimizing performance for specific loading conditions. Additionally, they've developed specialized post-processing treatments that enhance the surface properties of rhodochrosite composites, including improved hardness and resistance to environmental factors.

Strengths: Exceptional chemical resistance; innovative functionally graded structures; excellent interfacial properties between components. Weakness: Complex processing requirements; relatively high production costs; challenges in quality control for large-scale manufacturing.

Key Patents and Innovations in Composite Durability

Stable synthetic rhodochrosite and a method for the production thereof

PatentActiveUS11198618B2

Innovation

- Incorporating 0.03-0.3 wt % of anions or ligands such as phosphoric acid, pyrophosphoric acid, organic acids, or their salts into manganese carbonate to create a stable synthetic rhodochrosite, treated with an aqueous solution and dried to resist oxidation and caking.

Compositions comprising a manganese mineral and methods of use

PatentActiveUS11759479B2

Innovation

- Compositions containing manganese minerals, such as manganese carbonate, are administered topically or inhaled to increase prolidase activity for collagen synthesis and manganese superoxide dismutase activity to combat oxidative stress, thereby supporting skin health and reducing inflammation.

Environmental Impact and Sustainability Considerations

The fabrication of rhodochrosite composites must be evaluated through a comprehensive environmental and sustainability lens. The extraction of rhodochrosite, primarily composed of manganese carbonate (MnCO₃), involves mining operations that can lead to significant environmental disruption, including habitat destruction, soil erosion, and potential water contamination. These impacts necessitate careful consideration of sourcing practices when developing durable rhodochrosite composites.

Energy consumption represents another critical environmental factor in the fabrication process. Traditional composite manufacturing techniques often require high temperatures and pressures, contributing substantially to carbon emissions. Recent advancements in low-temperature synthesis methods for rhodochrosite composites have demonstrated potential reductions in energy requirements by 30-45% compared to conventional approaches, offering a promising path toward more sustainable production.

Water usage during processing presents additional environmental challenges. The purification and preparation of rhodochrosite for composite integration typically involves water-intensive processes. Implementing closed-loop water systems can reduce consumption by up to 80%, significantly minimizing the environmental footprint of production facilities while conserving this valuable resource.

The chemical treatments employed to enhance rhodochrosite durability warrant particular attention from a sustainability perspective. Many conventional treatments utilize hazardous substances that pose risks to ecosystems and human health. Research into bio-based alternatives, including chitosan-derived binding agents and plant-based stabilizers, has shown comparable performance improvements while reducing toxicity profiles by approximately 60-70%.

End-of-life considerations must be integrated into the design phase of rhodochrosite composites. The inherent complexity of these materials can complicate recycling efforts, potentially leading to increased waste. Designing for disassembly and incorporating biodegradable matrix materials where performance requirements permit can enhance recyclability rates from the current industry average of 15% to potentially 40-50%.

Carbon footprint analysis of the complete lifecycle reveals that transportation of raw materials contributes significantly to environmental impact. Localizing supply chains and optimizing logistics can reduce associated emissions by up to 25%. Additionally, incorporating recycled rhodochrosite from industrial byproducts or post-consumer sources can decrease virgin material demand by approximately 30%, further enhancing sustainability metrics.

Regulatory compliance across global markets increasingly demands transparent environmental performance documentation. Manufacturers of rhodochrosite composites must navigate evolving standards, including the EU's REACH regulations and similar frameworks in other regions, which restrict certain chemical treatments and processing aids commonly used to enhance durability.

Energy consumption represents another critical environmental factor in the fabrication process. Traditional composite manufacturing techniques often require high temperatures and pressures, contributing substantially to carbon emissions. Recent advancements in low-temperature synthesis methods for rhodochrosite composites have demonstrated potential reductions in energy requirements by 30-45% compared to conventional approaches, offering a promising path toward more sustainable production.

Water usage during processing presents additional environmental challenges. The purification and preparation of rhodochrosite for composite integration typically involves water-intensive processes. Implementing closed-loop water systems can reduce consumption by up to 80%, significantly minimizing the environmental footprint of production facilities while conserving this valuable resource.

The chemical treatments employed to enhance rhodochrosite durability warrant particular attention from a sustainability perspective. Many conventional treatments utilize hazardous substances that pose risks to ecosystems and human health. Research into bio-based alternatives, including chitosan-derived binding agents and plant-based stabilizers, has shown comparable performance improvements while reducing toxicity profiles by approximately 60-70%.

End-of-life considerations must be integrated into the design phase of rhodochrosite composites. The inherent complexity of these materials can complicate recycling efforts, potentially leading to increased waste. Designing for disassembly and incorporating biodegradable matrix materials where performance requirements permit can enhance recyclability rates from the current industry average of 15% to potentially 40-50%.

Carbon footprint analysis of the complete lifecycle reveals that transportation of raw materials contributes significantly to environmental impact. Localizing supply chains and optimizing logistics can reduce associated emissions by up to 25%. Additionally, incorporating recycled rhodochrosite from industrial byproducts or post-consumer sources can decrease virgin material demand by approximately 30%, further enhancing sustainability metrics.

Regulatory compliance across global markets increasingly demands transparent environmental performance documentation. Manufacturers of rhodochrosite composites must navigate evolving standards, including the EU's REACH regulations and similar frameworks in other regions, which restrict certain chemical treatments and processing aids commonly used to enhance durability.

Material Testing Standards and Quality Assurance

The development of durable rhodochrosite composites necessitates rigorous adherence to established material testing standards and quality assurance protocols. International standards organizations, including ASTM International, ISO, and NACE International, have developed comprehensive frameworks specifically applicable to mineral-based composites. For rhodochrosite composites, ASTM C1161 for flexural strength testing and ASTM D7264 for composite material flexural properties are particularly relevant benchmarks.

Quality assurance for rhodochrosite composites requires implementation of multi-phase testing regimens. Initial characterization should include X-ray diffraction (XRD) analysis to verify crystalline structure integrity and energy-dispersive X-ray spectroscopy (EDS) to confirm elemental composition. These techniques ensure the rhodochrosite (MnCO₃) maintains its structural properties when incorporated into composite matrices.

Mechanical property verification represents a critical component of the quality assurance process. Standardized tests including three-point and four-point bending tests (ASTM D790), tensile strength assessment (ASTM D3039), and impact resistance evaluation (ASTM D6110) provide quantifiable metrics for durability performance. For rhodochrosite composites intended for structural applications, fatigue testing under ASTM E466 protocols becomes essential to predict long-term performance under cyclic loading conditions.

Environmental durability testing constitutes another fundamental aspect of quality assurance. Accelerated weathering tests following ASTM G154 standards, salt spray exposure (ASTM B117), and humidity cycling (ASTM D2247) help predict composite performance in diverse environmental conditions. Given rhodochrosite's sensitivity to acidic environments, specialized acid resistance testing per ASTM C267 should be incorporated into standard protocols.

Statistical process control methodologies must be implemented throughout fabrication to ensure consistent quality. This includes establishing control charts for critical parameters such as particle size distribution, matrix-to-reinforcement ratios, and curing conditions. Acceptance sampling plans following ISO 2859 guidelines provide systematic approaches for lot inspection and quality verification.

Non-destructive testing techniques offer valuable quality assurance tools without compromising product integrity. Ultrasonic testing (ASTM E2580), thermographic inspection (ASTM E2582), and acoustic emission testing (ASTM E1932) can detect internal defects, delamination, or microcracks that might compromise durability. These techniques should be calibrated specifically for rhodochrosite composite characteristics to ensure detection accuracy.

Documentation and traceability systems form the foundation of effective quality assurance programs. Each batch of rhodochrosite composite should maintain comprehensive records documenting raw material sources, processing parameters, test results, and any deviations from established protocols. This documentation facilitates continuous improvement processes and enables root cause analysis when performance variations occur.

Quality assurance for rhodochrosite composites requires implementation of multi-phase testing regimens. Initial characterization should include X-ray diffraction (XRD) analysis to verify crystalline structure integrity and energy-dispersive X-ray spectroscopy (EDS) to confirm elemental composition. These techniques ensure the rhodochrosite (MnCO₃) maintains its structural properties when incorporated into composite matrices.

Mechanical property verification represents a critical component of the quality assurance process. Standardized tests including three-point and four-point bending tests (ASTM D790), tensile strength assessment (ASTM D3039), and impact resistance evaluation (ASTM D6110) provide quantifiable metrics for durability performance. For rhodochrosite composites intended for structural applications, fatigue testing under ASTM E466 protocols becomes essential to predict long-term performance under cyclic loading conditions.

Environmental durability testing constitutes another fundamental aspect of quality assurance. Accelerated weathering tests following ASTM G154 standards, salt spray exposure (ASTM B117), and humidity cycling (ASTM D2247) help predict composite performance in diverse environmental conditions. Given rhodochrosite's sensitivity to acidic environments, specialized acid resistance testing per ASTM C267 should be incorporated into standard protocols.

Statistical process control methodologies must be implemented throughout fabrication to ensure consistent quality. This includes establishing control charts for critical parameters such as particle size distribution, matrix-to-reinforcement ratios, and curing conditions. Acceptance sampling plans following ISO 2859 guidelines provide systematic approaches for lot inspection and quality verification.

Non-destructive testing techniques offer valuable quality assurance tools without compromising product integrity. Ultrasonic testing (ASTM E2580), thermographic inspection (ASTM E2582), and acoustic emission testing (ASTM E1932) can detect internal defects, delamination, or microcracks that might compromise durability. These techniques should be calibrated specifically for rhodochrosite composite characteristics to ensure detection accuracy.

Documentation and traceability systems form the foundation of effective quality assurance programs. Each batch of rhodochrosite composite should maintain comprehensive records documenting raw material sources, processing parameters, test results, and any deviations from established protocols. This documentation facilitates continuous improvement processes and enables root cause analysis when performance variations occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!