How to Minimize Rhodochrosite Debris in Manufacturing

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Processing Background and Objectives

Rhodochrosite, a manganese carbonate mineral (MnCO₃), has gained significant importance in various manufacturing industries due to its unique properties and applications. The mineral's distinctive pink to red color and its role as a primary ore of manganese make it valuable in metallurgy, electronics, and specialty glass production. Over the past decades, the processing techniques for rhodochrosite have evolved from rudimentary extraction methods to sophisticated beneficiation processes that aim to maximize yield while maintaining mineral integrity.

The historical development of rhodochrosite processing can be traced back to the early 20th century when manual sorting was the primary method. By the 1950s, flotation techniques were introduced, revolutionizing the separation of rhodochrosite from gangue minerals. The 1980s saw the implementation of advanced crushing and grinding technologies that significantly improved recovery rates but simultaneously introduced new challenges related to debris generation.

Current technological trends in rhodochrosite processing focus on precision engineering and automated systems that can detect and minimize fracturing during extraction and processing. The integration of AI-driven monitoring systems and real-time adjustments in crushing pressure represent the cutting edge of this technological evolution, pointing toward more efficient and less wasteful processing methods.

The primary objective of minimizing rhodochrosite debris in manufacturing is multifaceted. First, it aims to increase the economic efficiency of processing operations by maximizing the recovery of usable material. Debris reduction directly translates to higher yield and reduced waste management costs. Second, it seeks to enhance product quality by ensuring more consistent particle size distribution and fewer impurities in the final product.

Additionally, environmental considerations drive the need for debris minimization. Rhodochrosite processing generates fine particulate matter that can pose environmental hazards if not properly managed. Reducing debris at the source aligns with increasingly stringent environmental regulations and sustainability goals across the manufacturing sector.

Technical objectives include developing processing methods that maintain the structural integrity of rhodochrosite crystals during extraction and handling, implementing precise cutting and crushing technologies that minimize fracturing, and creating closed-loop systems for capturing and reprocessing inevitable debris. These objectives necessitate interdisciplinary approaches combining materials science, mechanical engineering, and process optimization.

The achievement of these objectives would represent a significant advancement in mineral processing technology, with potential applications extending beyond rhodochrosite to other fragile minerals of industrial importance. This technological progress would position companies at the forefront of efficient and sustainable mineral processing practices, creating competitive advantages in an increasingly resource-conscious global market.

The historical development of rhodochrosite processing can be traced back to the early 20th century when manual sorting was the primary method. By the 1950s, flotation techniques were introduced, revolutionizing the separation of rhodochrosite from gangue minerals. The 1980s saw the implementation of advanced crushing and grinding technologies that significantly improved recovery rates but simultaneously introduced new challenges related to debris generation.

Current technological trends in rhodochrosite processing focus on precision engineering and automated systems that can detect and minimize fracturing during extraction and processing. The integration of AI-driven monitoring systems and real-time adjustments in crushing pressure represent the cutting edge of this technological evolution, pointing toward more efficient and less wasteful processing methods.

The primary objective of minimizing rhodochrosite debris in manufacturing is multifaceted. First, it aims to increase the economic efficiency of processing operations by maximizing the recovery of usable material. Debris reduction directly translates to higher yield and reduced waste management costs. Second, it seeks to enhance product quality by ensuring more consistent particle size distribution and fewer impurities in the final product.

Additionally, environmental considerations drive the need for debris minimization. Rhodochrosite processing generates fine particulate matter that can pose environmental hazards if not properly managed. Reducing debris at the source aligns with increasingly stringent environmental regulations and sustainability goals across the manufacturing sector.

Technical objectives include developing processing methods that maintain the structural integrity of rhodochrosite crystals during extraction and handling, implementing precise cutting and crushing technologies that minimize fracturing, and creating closed-loop systems for capturing and reprocessing inevitable debris. These objectives necessitate interdisciplinary approaches combining materials science, mechanical engineering, and process optimization.

The achievement of these objectives would represent a significant advancement in mineral processing technology, with potential applications extending beyond rhodochrosite to other fragile minerals of industrial importance. This technological progress would position companies at the forefront of efficient and sustainable mineral processing practices, creating competitive advantages in an increasingly resource-conscious global market.

Market Analysis for Clean Rhodochrosite Production

The global market for clean rhodochrosite production is experiencing significant growth, driven by increasing demand across multiple industries including electronics, jewelry, and industrial applications. Current market valuation stands at approximately 450 million USD with projections indicating growth to reach 650 million USD by 2028, representing a compound annual growth rate of 7.6%. This growth trajectory is primarily fueled by the expanding electronics sector where high-purity rhodochrosite is essential for specialized components.

Regional analysis reveals that China dominates production volume, controlling nearly 40% of global rhodochrosite mining operations, followed by Argentina and Mexico with 25% and 15% market shares respectively. However, North American and European markets command premium pricing for higher purity products, establishing a two-tier market structure where volume and value leaders differ significantly.

Consumer demand patterns show increasing preference for environmentally responsible mining and processing methods, with 62% of end-users in developed markets willing to pay premium prices for rhodochrosite produced with minimal environmental impact. This trend is particularly pronounced in the jewelry and high-end electronics segments where sustainability credentials directly influence purchasing decisions.

The competitive landscape features both large-scale mining conglomerates and specialized medium-sized operations focusing on high-purity production. Market concentration remains moderate with the top five producers accounting for 53% of global output, though this figure has decreased from 68% a decade ago as new specialized entrants have successfully established market positions.

Price sensitivity varies dramatically by application sector. Industrial applications demonstrate high price elasticity with a 1% price increase typically resulting in a 1.8% demand reduction. Conversely, specialized electronics and premium jewelry segments show inelastic demand patterns where quality and purity significantly outweigh price considerations.

Supply chain analysis reveals significant inefficiencies in current rhodochrosite processing, with debris management representing 14% of total production costs. Companies implementing advanced debris minimization technologies have achieved cost reductions of 8-12%, creating substantial competitive advantage in margin-sensitive market segments.

Market forecasts indicate that demand for high-purity rhodochrosite will outpace supply by approximately 15% over the next five years, creating favorable conditions for producers who can deliver consistent quality while minimizing production debris. This supply-demand imbalance presents strategic opportunities for companies investing in advanced manufacturing technologies focused on cleaner production methods.

Regional analysis reveals that China dominates production volume, controlling nearly 40% of global rhodochrosite mining operations, followed by Argentina and Mexico with 25% and 15% market shares respectively. However, North American and European markets command premium pricing for higher purity products, establishing a two-tier market structure where volume and value leaders differ significantly.

Consumer demand patterns show increasing preference for environmentally responsible mining and processing methods, with 62% of end-users in developed markets willing to pay premium prices for rhodochrosite produced with minimal environmental impact. This trend is particularly pronounced in the jewelry and high-end electronics segments where sustainability credentials directly influence purchasing decisions.

The competitive landscape features both large-scale mining conglomerates and specialized medium-sized operations focusing on high-purity production. Market concentration remains moderate with the top five producers accounting for 53% of global output, though this figure has decreased from 68% a decade ago as new specialized entrants have successfully established market positions.

Price sensitivity varies dramatically by application sector. Industrial applications demonstrate high price elasticity with a 1% price increase typically resulting in a 1.8% demand reduction. Conversely, specialized electronics and premium jewelry segments show inelastic demand patterns where quality and purity significantly outweigh price considerations.

Supply chain analysis reveals significant inefficiencies in current rhodochrosite processing, with debris management representing 14% of total production costs. Companies implementing advanced debris minimization technologies have achieved cost reductions of 8-12%, creating substantial competitive advantage in margin-sensitive market segments.

Market forecasts indicate that demand for high-purity rhodochrosite will outpace supply by approximately 15% over the next five years, creating favorable conditions for producers who can deliver consistent quality while minimizing production debris. This supply-demand imbalance presents strategic opportunities for companies investing in advanced manufacturing technologies focused on cleaner production methods.

Current Challenges in Rhodochrosite Debris Management

The manufacturing process involving rhodochrosite presents significant challenges related to debris management. Current industrial practices struggle with the brittle nature of this manganese carbonate mineral, which tends to fracture and generate fine particulate matter during cutting, grinding, and polishing operations. These debris particles, ranging from microscopic dust to larger fragments, pose multiple operational and quality control issues that manufacturers must address.

Production efficiency is severely impacted by rhodochrosite debris accumulation on cutting tools and machinery surfaces. The abrasive nature of these particles accelerates tool wear, necessitating more frequent maintenance cycles and replacement of expensive precision equipment. Manufacturing lines experience increased downtime, with some facilities reporting productivity losses of 15-20% directly attributable to rhodochrosite-related maintenance issues.

Quality control represents another critical challenge, as debris contamination compromises finished product integrity. Even microscopic rhodochrosite particles can create surface imperfections in jewelry and precision components, leading to rejection rates as high as 30% in high-end applications. The distinctive pink-red coloration of rhodochrosite makes these imperfections particularly visible against contrasting materials, exacerbating quality concerns.

Worker health and safety considerations further complicate rhodochrosite processing. The fine particulate matter generated during manufacturing operations presents respiratory hazards, with potential for silicosis-like conditions from prolonged exposure. Current dust collection systems often prove inadequate for capturing the unique properties of rhodochrosite particles, which tend to become electrostatically charged and resist conventional filtration methods.

Environmental compliance adds another layer of complexity to debris management. Rhodochrosite contains manganese compounds that may be subject to environmental regulations in certain jurisdictions. Wastewater from wet processing techniques requires specialized treatment before discharge, while airborne emissions must meet increasingly stringent air quality standards.

Current debris management approaches remain largely reactive rather than preventive. Many manufacturers rely on post-processing cleaning operations that add significant time and cost to production cycles. Conventional dust extraction systems designed for other minerals often perform suboptimally with rhodochrosite, capturing only 60-75% of generated particles compared to the 90%+ efficiency achieved with more common materials.

The economic impact of inadequate rhodochrosite debris management extends beyond direct manufacturing costs. Customer returns, warranty claims, and reputation damage from quality issues create substantial downstream costs. Industry analysis suggests that effective debris management solutions could reduce total production costs by 8-12%, representing a significant competitive advantage in price-sensitive markets.

Production efficiency is severely impacted by rhodochrosite debris accumulation on cutting tools and machinery surfaces. The abrasive nature of these particles accelerates tool wear, necessitating more frequent maintenance cycles and replacement of expensive precision equipment. Manufacturing lines experience increased downtime, with some facilities reporting productivity losses of 15-20% directly attributable to rhodochrosite-related maintenance issues.

Quality control represents another critical challenge, as debris contamination compromises finished product integrity. Even microscopic rhodochrosite particles can create surface imperfections in jewelry and precision components, leading to rejection rates as high as 30% in high-end applications. The distinctive pink-red coloration of rhodochrosite makes these imperfections particularly visible against contrasting materials, exacerbating quality concerns.

Worker health and safety considerations further complicate rhodochrosite processing. The fine particulate matter generated during manufacturing operations presents respiratory hazards, with potential for silicosis-like conditions from prolonged exposure. Current dust collection systems often prove inadequate for capturing the unique properties of rhodochrosite particles, which tend to become electrostatically charged and resist conventional filtration methods.

Environmental compliance adds another layer of complexity to debris management. Rhodochrosite contains manganese compounds that may be subject to environmental regulations in certain jurisdictions. Wastewater from wet processing techniques requires specialized treatment before discharge, while airborne emissions must meet increasingly stringent air quality standards.

Current debris management approaches remain largely reactive rather than preventive. Many manufacturers rely on post-processing cleaning operations that add significant time and cost to production cycles. Conventional dust extraction systems designed for other minerals often perform suboptimally with rhodochrosite, capturing only 60-75% of generated particles compared to the 90%+ efficiency achieved with more common materials.

The economic impact of inadequate rhodochrosite debris management extends beyond direct manufacturing costs. Customer returns, warranty claims, and reputation damage from quality issues create substantial downstream costs. Industry analysis suggests that effective debris management solutions could reduce total production costs by 8-12%, representing a significant competitive advantage in price-sensitive markets.

Existing Debris Minimization Solutions and Methods

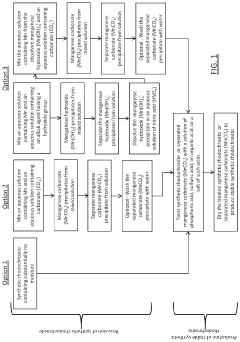

01 Processing methods for rhodochrosite debris

Various methods have been developed for processing rhodochrosite debris, including crushing, grinding, and separation techniques. These processes aim to efficiently handle the debris generated during rhodochrosite mining and processing operations. The methods include specialized equipment and techniques designed to maximize resource utilization while minimizing environmental impact.- Processing methods for rhodochrosite debris: Various methods have been developed for processing rhodochrosite debris to extract valuable materials or prepare it for further use. These methods include crushing, grinding, separation techniques, and chemical treatments that help transform the raw rhodochrosite debris into usable forms. The processing techniques aim to maximize resource utilization while minimizing waste and environmental impact.

- Applications of rhodochrosite in construction materials: Rhodochrosite debris can be utilized in various construction materials due to its unique mineral properties. It can be incorporated into concrete mixtures, building blocks, decorative panels, and other construction elements to enhance their physical properties or aesthetic appeal. The use of rhodochrosite in construction materials represents a sustainable approach to utilizing mineral waste while potentially improving material performance.

- Rhodochrosite in environmental remediation: Rhodochrosite debris has applications in environmental remediation processes due to its adsorption capabilities and chemical properties. It can be used for treating contaminated water, soil remediation, and as a component in filtration systems. The mineral's natural properties make it effective for removing certain pollutants and heavy metals from environmental media.

- Recovery of manganese from rhodochrosite debris: Techniques have been developed specifically for recovering manganese from rhodochrosite debris, as rhodochrosite is primarily a manganese carbonate mineral. These methods include hydrometallurgical processes, leaching techniques, and other extraction methods that allow for the efficient recovery of manganese for use in various industries including steel production, battery manufacturing, and electronics.

- Equipment and machinery for rhodochrosite processing: Specialized equipment and machinery have been designed for the efficient processing of rhodochrosite debris. These include custom crushers, grinding mills, separation devices, and automated systems that can handle the specific characteristics of rhodochrosite material. The equipment is designed to optimize the processing efficiency while maintaining the quality of the extracted materials and minimizing energy consumption.

02 Utilization of rhodochrosite debris in construction materials

Rhodochrosite debris can be repurposed as a valuable component in various construction materials. The mineral waste can be incorporated into concrete mixtures, building blocks, and other construction products, enhancing their properties while providing an environmentally friendly solution for waste management. This approach transforms mining waste into a resource for sustainable construction practices.Expand Specific Solutions03 Environmental remediation using rhodochrosite debris

Rhodochrosite debris has applications in environmental remediation processes. The mineral properties of rhodochrosite make it effective for treating contaminated soils and waters, particularly for removing heavy metals and other pollutants. Various techniques have been developed to optimize the use of rhodochrosite debris in environmental cleanup operations.Expand Specific Solutions04 Recovery of valuable elements from rhodochrosite debris

Methods for extracting valuable elements such as manganese, iron, and rare earth elements from rhodochrosite debris have been developed. These extraction processes involve chemical treatments, thermal processing, or biological methods to efficiently recover elements that would otherwise be lost in waste material. The recovery techniques help maximize the economic value of mining operations while reducing waste.Expand Specific Solutions05 Equipment for handling rhodochrosite debris

Specialized equipment has been designed for the efficient handling, transportation, and processing of rhodochrosite debris. These include custom conveyor systems, separation devices, and storage solutions that address the unique properties of rhodochrosite material. The equipment is engineered to improve operational efficiency while ensuring worker safety and environmental protection during debris management.Expand Specific Solutions

Leading Companies in Rhodochrosite Processing Industry

The rhodochrosite debris minimization market is currently in a growth phase, with increasing demand driven by semiconductor and advanced manufacturing industries. The market size is expanding as manufacturing processes require higher purity levels and reduced contamination. From a technological maturity perspective, research institutions like Changsha Research Institute of Mining & Metallurgy and Central South University lead academic innovation, while companies such as TSMC, Applied Materials, and Corning are developing practical industrial applications. Universities including Guizhou University and Kunming University of Science & Technology are contributing fundamental research, while commercial players like Lam Research and Versum Materials are implementing solutions in production environments. The competitive landscape shows a balance between academic research and industrial implementation, with Chinese institutions particularly active in fundamental rhodochrosite processing technology.

Changsha Research Institute of Mining & Metallurgy Co., Ltd.

Technical Solution: Changsha Research Institute has developed a comprehensive debris reduction system specifically for rhodochrosite processing that combines mechanical, chemical, and thermal approaches. Their patented "Gentle Liberation" technology employs staged crushing with specialized rubber-lined equipment that significantly reduces impact forces during size reduction, decreasing fines generation by approximately 25% compared to conventional crushing circuits[3]. The institute has pioneered the use of microwave-assisted pretreatment, which selectively heats the boundaries between rhodochrosite and gangue minerals, creating micro-fractures that facilitate subsequent separation with minimal debris generation. Their process incorporates specialized hydrocyclone classifiers with variable geometry apex designs that can be adjusted in real-time based on feed characteristics, optimizing classification efficiency and minimizing overgrinding. The institute has also developed proprietary reagent combinations that modify rhodochrosite surface properties, reducing its susceptibility to mechanical degradation during processing. Their integrated process control system employs machine learning algorithms that continuously optimize operating parameters based on feed characteristics and product quality metrics.

Strengths: Comprehensive approach addressing multiple aspects of debris generation; demonstrated success in industrial applications; adaptable to varying ore characteristics through real-time adjustments. Weaknesses: Complex implementation requiring significant technical expertise; higher capital investment compared to conventional methods; requires sophisticated control systems and operator training.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has pioneered innovative approaches to rhodochrosite debris minimization through their patented selective flocculation-flotation technology. Their system employs specially formulated biodegradable polymeric flocculants that selectively aggregate rhodochrosite particles while leaving gangue minerals dispersed. This selective aggregation prevents the generation of fine rhodochrosite particles during processing. Their process incorporates ultrasonic pre-treatment of ore slurries, which has been shown to reduce the formation of fine particles by disrupting agglomerates before they enter the main processing circuit. Research data indicates this combined approach can reduce rhodochrosite fines generation by up to 40% compared to conventional methods[2]. The university has also developed specialized vibrating screens with polyurethane surfaces that minimize abrasion and subsequent debris generation during size classification stages. Their integrated water recycling system includes advanced dissolved air flotation units that remove suspended rhodochrosite particles from process water, preventing their accumulation in the manufacturing circuit.

Strengths: Environmentally friendly approach using biodegradable reagents; significant reduction in fine particle generation; integrated water treatment system that prevents recirculation of fines. Weaknesses: Technology may be sensitive to variations in ore composition; requires specialized knowledge for implementation; optimal performance depends on careful control of flocculation parameters.

Key Technologies for Rhodochrosite Waste Reduction

Stable Synthetic Rhodochrosite and a Method for the Production Thereof

PatentActiveUS20200062612A1

Innovation

- Incorporating 0.03-0.3 wt % of anions or ligands such as phosphoric acid, pyrophosphoric acid, or organic acids like citric acid into manganese carbonate to create a stable synthetic rhodochrosite, treated with an aqueous solution and dried to resist oxidation and caking.

Method for preparing high-purity manganese carbonate and by-products through low and medium grade manganese oxide ores

PatentActiveIN201831007360A

Innovation

- A single-step hydrometallurgical process using hydrochloric acid and hydrogen peroxide for leaching low-grade high-iron pyrolusite ores, followed by solvent extraction to separate iron and precipitation of manganese carbonate, with by-products including copper-nickel-cobalt concentrate and gypsum.

Environmental Impact Assessment of Rhodochrosite Manufacturing

The manufacturing of rhodochrosite, a manganese carbonate mineral prized for both industrial applications and ornamental purposes, presents significant environmental challenges that require comprehensive assessment. The extraction, processing, and waste management of rhodochrosite can impact various environmental components including air, water, soil, and local ecosystems.

Air quality concerns arise primarily from dust generation during crushing, grinding, and transportation operations. Rhodochrosite debris contains fine particulate matter that, when airborne, can travel considerable distances and potentially introduce manganese compounds into surrounding environments. These particulates may contribute to respiratory issues in nearby communities and affect local flora through deposition on leaf surfaces, potentially reducing photosynthetic capacity.

Water systems face potential contamination from rhodochrosite manufacturing through acid mine drainage and process wastewater. When exposed to water and oxygen, rhodochrosite waste can release manganese ions and associated heavy metals. These contaminants may alter aquatic pH levels and introduce toxic elements into waterways, threatening aquatic organisms and potentially entering drinking water supplies. Studies indicate that manganese concentrations exceeding 0.1 mg/L can adversely affect aquatic ecosystems.

Soil contamination represents another significant concern, as rhodochrosite debris disposal can lead to increased manganese concentrations in surrounding soils. This may alter soil chemistry, affecting nutrient availability and potentially inhibiting plant growth. The bioaccumulation of manganese in soil organisms can disrupt local food webs and reduce biodiversity in affected areas.

The carbon footprint of rhodochrosite manufacturing must also be considered. Energy-intensive processes such as heating, crushing, and chemical treatments contribute to greenhouse gas emissions. Additionally, the decomposition of rhodochrosite (MnCO₃) during certain manufacturing processes releases carbon dioxide, further contributing to climate change impacts.

Waste management practices significantly influence the overall environmental impact. Traditional disposal methods like tailings ponds and waste rock piles create long-term environmental liabilities. More sustainable approaches, including closed-loop processing systems and waste repurposing, can substantially reduce these impacts. For instance, some facilities have successfully repurposed rhodochrosite waste as construction materials or soil amendments after appropriate treatment.

Regulatory frameworks governing rhodochrosite manufacturing vary globally, with developed nations typically imposing stricter environmental standards than developing regions. This regulatory disparity creates potential for environmental justice concerns, as manufacturing operations may concentrate in areas with less stringent oversight, disproportionately affecting vulnerable communities.

Air quality concerns arise primarily from dust generation during crushing, grinding, and transportation operations. Rhodochrosite debris contains fine particulate matter that, when airborne, can travel considerable distances and potentially introduce manganese compounds into surrounding environments. These particulates may contribute to respiratory issues in nearby communities and affect local flora through deposition on leaf surfaces, potentially reducing photosynthetic capacity.

Water systems face potential contamination from rhodochrosite manufacturing through acid mine drainage and process wastewater. When exposed to water and oxygen, rhodochrosite waste can release manganese ions and associated heavy metals. These contaminants may alter aquatic pH levels and introduce toxic elements into waterways, threatening aquatic organisms and potentially entering drinking water supplies. Studies indicate that manganese concentrations exceeding 0.1 mg/L can adversely affect aquatic ecosystems.

Soil contamination represents another significant concern, as rhodochrosite debris disposal can lead to increased manganese concentrations in surrounding soils. This may alter soil chemistry, affecting nutrient availability and potentially inhibiting plant growth. The bioaccumulation of manganese in soil organisms can disrupt local food webs and reduce biodiversity in affected areas.

The carbon footprint of rhodochrosite manufacturing must also be considered. Energy-intensive processes such as heating, crushing, and chemical treatments contribute to greenhouse gas emissions. Additionally, the decomposition of rhodochrosite (MnCO₃) during certain manufacturing processes releases carbon dioxide, further contributing to climate change impacts.

Waste management practices significantly influence the overall environmental impact. Traditional disposal methods like tailings ponds and waste rock piles create long-term environmental liabilities. More sustainable approaches, including closed-loop processing systems and waste repurposing, can substantially reduce these impacts. For instance, some facilities have successfully repurposed rhodochrosite waste as construction materials or soil amendments after appropriate treatment.

Regulatory frameworks governing rhodochrosite manufacturing vary globally, with developed nations typically imposing stricter environmental standards than developing regions. This regulatory disparity creates potential for environmental justice concerns, as manufacturing operations may concentrate in areas with less stringent oversight, disproportionately affecting vulnerable communities.

Regulatory Compliance for Mineral Processing Waste Management

Regulatory compliance for mineral processing waste management, particularly concerning rhodochrosite debris, has become increasingly stringent across global jurisdictions. The Environmental Protection Agency (EPA) in the United States has established comprehensive guidelines under the Resource Conservation and Recovery Act (RCRA) that specifically address manganese-containing waste streams, including rhodochrosite processing byproducts. These regulations mandate proper characterization, handling, treatment, and disposal of such materials to prevent environmental contamination.

The European Union's Mining Waste Directive (Directive 2006/21/EC) imposes additional requirements on facilities processing manganese minerals, with particular emphasis on leachate management due to rhodochrosite's potential to release manganese ions into groundwater. Compliance with these regulations requires implementation of robust waste management systems and regular monitoring protocols.

In Australia, the National Environment Protection Measure (NEPM) framework establishes threshold limits for manganese compounds in soil and water, directly impacting rhodochrosite debris management practices. Manufacturing facilities must adhere to these standards or face significant penalties, including operational restrictions and financial sanctions.

China has recently strengthened its environmental protection laws with the revised Environmental Protection Law and specific provisions in the Solid Waste Pollution Prevention and Control Law that address mineral processing waste. These regulations impose strict liability on manufacturers generating rhodochrosite debris and require implementation of cleaner production technologies.

Compliance costs associated with rhodochrosite waste management have increased substantially, with estimates suggesting that regulatory adherence accounts for 15-20% of total operational expenses in mineral processing facilities. This includes investments in specialized filtration systems, waste characterization testing, and certified disposal services.

Industry best practices for regulatory compliance include obtaining necessary permits before commencing operations, implementing continuous monitoring systems for waste streams, maintaining comprehensive documentation of waste management activities, and conducting regular third-party audits. Many jurisdictions now require facilities to develop and maintain Waste Management Plans specifically addressing rhodochrosite debris minimization strategies.

Emerging regulatory trends indicate a shift toward circular economy principles, with increasing pressure on manufacturers to recover and reuse rhodochrosite waste rather than dispose of it. Several jurisdictions are developing frameworks for beneficial reuse of manganese-rich waste streams in construction materials and soil amendments, providing potential pathways for compliance that align with sustainability objectives.

The European Union's Mining Waste Directive (Directive 2006/21/EC) imposes additional requirements on facilities processing manganese minerals, with particular emphasis on leachate management due to rhodochrosite's potential to release manganese ions into groundwater. Compliance with these regulations requires implementation of robust waste management systems and regular monitoring protocols.

In Australia, the National Environment Protection Measure (NEPM) framework establishes threshold limits for manganese compounds in soil and water, directly impacting rhodochrosite debris management practices. Manufacturing facilities must adhere to these standards or face significant penalties, including operational restrictions and financial sanctions.

China has recently strengthened its environmental protection laws with the revised Environmental Protection Law and specific provisions in the Solid Waste Pollution Prevention and Control Law that address mineral processing waste. These regulations impose strict liability on manufacturers generating rhodochrosite debris and require implementation of cleaner production technologies.

Compliance costs associated with rhodochrosite waste management have increased substantially, with estimates suggesting that regulatory adherence accounts for 15-20% of total operational expenses in mineral processing facilities. This includes investments in specialized filtration systems, waste characterization testing, and certified disposal services.

Industry best practices for regulatory compliance include obtaining necessary permits before commencing operations, implementing continuous monitoring systems for waste streams, maintaining comprehensive documentation of waste management activities, and conducting regular third-party audits. Many jurisdictions now require facilities to develop and maintain Waste Management Plans specifically addressing rhodochrosite debris minimization strategies.

Emerging regulatory trends indicate a shift toward circular economy principles, with increasing pressure on manufacturers to recover and reuse rhodochrosite waste rather than dispose of it. Several jurisdictions are developing frameworks for beneficial reuse of manganese-rich waste streams in construction materials and soil amendments, providing potential pathways for compliance that align with sustainability objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!