Quantitative Analysis of Rhodochrosite Impurity Effects

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Impurity Analysis Background and Objectives

Rhodochrosite (MnCO₃) has emerged as a mineral of significant industrial and scientific interest over the past several decades. This manganese carbonate mineral, with its distinctive rose-pink color, has transitioned from being primarily valued as an ornamental stone to becoming a crucial resource in various high-tech applications. The evolution of rhodochrosite's importance parallels the development of technologies requiring high-purity manganese compounds, particularly in electronics, battery manufacturing, and specialty metallurgy.

The impurity profile of rhodochrosite significantly impacts its commercial value and industrial applicability. Historically, the focus on rhodochrosite was limited to its aesthetic properties, with little attention paid to chemical composition beyond basic identification. However, as industrial applications expanded in the late 20th century, understanding the precise chemical makeup of rhodochrosite deposits became increasingly critical for quality control and process optimization.

Recent technological advancements have created new demands for high-purity manganese compounds, driving renewed interest in rhodochrosite as a strategic mineral resource. The global transition toward green energy technologies, particularly lithium-ion batteries with manganese-rich cathodes, has further elevated the importance of understanding rhodochrosite impurity profiles at a quantitative level.

Current research trends indicate a growing emphasis on developing more sophisticated analytical techniques for characterizing rhodochrosite impurities. These efforts aim to establish correlations between specific impurity profiles and the performance characteristics of end products. The scientific community has recognized that even trace impurities can significantly affect electrochemical properties, catalytic behavior, and structural integrity in advanced applications.

The primary objective of this technical research is to establish a comprehensive quantitative framework for analyzing the effects of various impurities in rhodochrosite on its industrial processing and end-use performance. This includes developing standardized methodologies for impurity detection and quantification, creating predictive models for impurity behavior during processing, and establishing threshold values for critical impurities in different application contexts.

Additionally, this research aims to map global rhodochrosite deposits according to their impurity profiles, providing valuable data for strategic resource planning and supply chain optimization. By understanding regional variations in rhodochrosite composition, industries can better navigate sourcing decisions and processing requirements, ultimately enhancing product quality and reducing production costs.

The long-term goal is to enable precision engineering of manganese compounds derived from rhodochrosite, tailored to specific applications by leveraging, rather than merely tolerating, the natural variability in mineral composition. This represents a paradigm shift from traditional approaches that focused on eliminating impurities toward strategies that strategically utilize compositional variations for enhanced performance.

The impurity profile of rhodochrosite significantly impacts its commercial value and industrial applicability. Historically, the focus on rhodochrosite was limited to its aesthetic properties, with little attention paid to chemical composition beyond basic identification. However, as industrial applications expanded in the late 20th century, understanding the precise chemical makeup of rhodochrosite deposits became increasingly critical for quality control and process optimization.

Recent technological advancements have created new demands for high-purity manganese compounds, driving renewed interest in rhodochrosite as a strategic mineral resource. The global transition toward green energy technologies, particularly lithium-ion batteries with manganese-rich cathodes, has further elevated the importance of understanding rhodochrosite impurity profiles at a quantitative level.

Current research trends indicate a growing emphasis on developing more sophisticated analytical techniques for characterizing rhodochrosite impurities. These efforts aim to establish correlations between specific impurity profiles and the performance characteristics of end products. The scientific community has recognized that even trace impurities can significantly affect electrochemical properties, catalytic behavior, and structural integrity in advanced applications.

The primary objective of this technical research is to establish a comprehensive quantitative framework for analyzing the effects of various impurities in rhodochrosite on its industrial processing and end-use performance. This includes developing standardized methodologies for impurity detection and quantification, creating predictive models for impurity behavior during processing, and establishing threshold values for critical impurities in different application contexts.

Additionally, this research aims to map global rhodochrosite deposits according to their impurity profiles, providing valuable data for strategic resource planning and supply chain optimization. By understanding regional variations in rhodochrosite composition, industries can better navigate sourcing decisions and processing requirements, ultimately enhancing product quality and reducing production costs.

The long-term goal is to enable precision engineering of manganese compounds derived from rhodochrosite, tailored to specific applications by leveraging, rather than merely tolerating, the natural variability in mineral composition. This represents a paradigm shift from traditional approaches that focused on eliminating impurities toward strategies that strategically utilize compositional variations for enhanced performance.

Market Applications and Demand for High-Purity Rhodochrosite

The global market for high-purity rhodochrosite has experienced significant growth in recent years, driven primarily by increasing demand in advanced technological applications. The manganese carbonate mineral, when refined to high purity levels, serves critical functions across multiple industries where the presence of impurities can dramatically affect performance outcomes.

In the electronics sector, high-purity rhodochrosite has become essential for semiconductor manufacturing, where even trace impurities can compromise device performance. Market analysis indicates that semiconductor manufacturers require rhodochrosite with purity levels exceeding 99.9%, creating a premium segment within the market. This demand is projected to grow as electronic devices continue miniaturization trends requiring increasingly pure materials.

The renewable energy sector represents another substantial market for high-purity rhodochrosite. Battery manufacturers, particularly those producing lithium-ion and manganese-based energy storage systems, require rhodochrosite with minimal impurity profiles to ensure optimal electrochemical performance and longevity. Market research suggests that energy storage applications now account for approximately one-third of global high-purity rhodochrosite consumption.

Medical technology applications have emerged as a rapidly expanding market segment. High-purity rhodochrosite derivatives are utilized in diagnostic imaging equipment, specialized medical devices, and certain pharmaceutical formulations. The healthcare sector's stringent quality requirements have created a specialized market niche where purity specifications often exceed those of other industries.

Environmental technologies represent a growing application area, with high-purity rhodochrosite being incorporated into advanced filtration systems, catalytic converters, and remediation technologies. The ability to precisely control impurity levels has opened new possibilities for environmental applications where specific performance characteristics are required.

Regional market analysis reveals that East Asia dominates demand, accounting for the largest share of global consumption, followed by North America and Europe. This geographic distribution aligns with the concentration of electronics manufacturing, advanced materials production, and technology development centers.

Price sensitivity varies significantly across application segments. While bulk industrial applications remain highly price-sensitive, specialized high-tech applications demonstrate greater willingness to pay premium prices for guaranteed purity levels. This market stratification has led to the development of specialized supply chains focused on ultra-high-purity rhodochrosite production.

Market forecasts indicate continued growth in demand for high-purity rhodochrosite, with compound annual growth rates exceeding general mineral market averages. This growth trajectory is supported by expanding applications in emerging technologies and increasing quality requirements across established industries.

In the electronics sector, high-purity rhodochrosite has become essential for semiconductor manufacturing, where even trace impurities can compromise device performance. Market analysis indicates that semiconductor manufacturers require rhodochrosite with purity levels exceeding 99.9%, creating a premium segment within the market. This demand is projected to grow as electronic devices continue miniaturization trends requiring increasingly pure materials.

The renewable energy sector represents another substantial market for high-purity rhodochrosite. Battery manufacturers, particularly those producing lithium-ion and manganese-based energy storage systems, require rhodochrosite with minimal impurity profiles to ensure optimal electrochemical performance and longevity. Market research suggests that energy storage applications now account for approximately one-third of global high-purity rhodochrosite consumption.

Medical technology applications have emerged as a rapidly expanding market segment. High-purity rhodochrosite derivatives are utilized in diagnostic imaging equipment, specialized medical devices, and certain pharmaceutical formulations. The healthcare sector's stringent quality requirements have created a specialized market niche where purity specifications often exceed those of other industries.

Environmental technologies represent a growing application area, with high-purity rhodochrosite being incorporated into advanced filtration systems, catalytic converters, and remediation technologies. The ability to precisely control impurity levels has opened new possibilities for environmental applications where specific performance characteristics are required.

Regional market analysis reveals that East Asia dominates demand, accounting for the largest share of global consumption, followed by North America and Europe. This geographic distribution aligns with the concentration of electronics manufacturing, advanced materials production, and technology development centers.

Price sensitivity varies significantly across application segments. While bulk industrial applications remain highly price-sensitive, specialized high-tech applications demonstrate greater willingness to pay premium prices for guaranteed purity levels. This market stratification has led to the development of specialized supply chains focused on ultra-high-purity rhodochrosite production.

Market forecasts indicate continued growth in demand for high-purity rhodochrosite, with compound annual growth rates exceeding general mineral market averages. This growth trajectory is supported by expanding applications in emerging technologies and increasing quality requirements across established industries.

Current Analytical Techniques and Challenges

The quantitative analysis of rhodochrosite impurity effects presents significant analytical challenges due to the complex mineralogical composition of this manganese carbonate mineral. Current analytical techniques employ a range of sophisticated methodologies, each with specific advantages and limitations when applied to rhodochrosite samples.

X-ray diffraction (XRD) remains a fundamental technique for phase identification and crystallographic analysis of rhodochrosite and its impurities. However, XRD struggles with accurate quantification when impurity concentrations fall below 2-5%, creating a significant blind spot in trace element analysis. Additionally, peak overlapping between rhodochrosite and certain impurity minerals can complicate interpretation of diffraction patterns.

Scanning Electron Microscopy coupled with Energy Dispersive X-ray Spectroscopy (SEM-EDS) provides valuable microstructural and elemental composition data. This technique excels at spatial resolution but faces challenges in detecting light elements and suffers from matrix effects that can skew quantitative measurements of impurities within rhodochrosite matrices.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) offers exceptional sensitivity for trace element analysis, capable of detecting impurities at parts-per-billion levels. However, sample preparation for rhodochrosite presents significant challenges, as incomplete dissolution can lead to systematic underestimation of certain impurity elements, particularly those bound in resistant mineral phases.

Laser Ablation ICP-MS (LA-ICP-MS) has emerged as a powerful technique for in-situ microanalysis, allowing spatial mapping of impurity distributions within rhodochrosite samples. Despite these advantages, matrix-matched calibration standards for rhodochrosite remain limited, introducing quantification uncertainties.

Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy provide complementary molecular-level information about rhodochrosite and its impurities. These techniques are particularly valuable for identifying organic impurities and structural water, but quantitative analysis remains challenging due to peak overlapping and variable absorption coefficients.

A significant challenge across all analytical methods is the heterogeneous distribution of impurities within rhodochrosite samples. This spatial variability necessitates careful sampling strategies and multiple analytical points to achieve representative results. Furthermore, the presence of solid solution series between rhodochrosite and other carbonate minerals (particularly calcite and siderite) complicates accurate impurity quantification.

Calibration remains another persistent challenge, as matrix-matched reference materials specifically for rhodochrosite analysis are scarce. Most laboratories rely on in-house standards or geological reference materials that may not perfectly match the complex matrix of natural rhodochrosite samples, introducing systematic biases in quantitative results.

X-ray diffraction (XRD) remains a fundamental technique for phase identification and crystallographic analysis of rhodochrosite and its impurities. However, XRD struggles with accurate quantification when impurity concentrations fall below 2-5%, creating a significant blind spot in trace element analysis. Additionally, peak overlapping between rhodochrosite and certain impurity minerals can complicate interpretation of diffraction patterns.

Scanning Electron Microscopy coupled with Energy Dispersive X-ray Spectroscopy (SEM-EDS) provides valuable microstructural and elemental composition data. This technique excels at spatial resolution but faces challenges in detecting light elements and suffers from matrix effects that can skew quantitative measurements of impurities within rhodochrosite matrices.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) offers exceptional sensitivity for trace element analysis, capable of detecting impurities at parts-per-billion levels. However, sample preparation for rhodochrosite presents significant challenges, as incomplete dissolution can lead to systematic underestimation of certain impurity elements, particularly those bound in resistant mineral phases.

Laser Ablation ICP-MS (LA-ICP-MS) has emerged as a powerful technique for in-situ microanalysis, allowing spatial mapping of impurity distributions within rhodochrosite samples. Despite these advantages, matrix-matched calibration standards for rhodochrosite remain limited, introducing quantification uncertainties.

Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy provide complementary molecular-level information about rhodochrosite and its impurities. These techniques are particularly valuable for identifying organic impurities and structural water, but quantitative analysis remains challenging due to peak overlapping and variable absorption coefficients.

A significant challenge across all analytical methods is the heterogeneous distribution of impurities within rhodochrosite samples. This spatial variability necessitates careful sampling strategies and multiple analytical points to achieve representative results. Furthermore, the presence of solid solution series between rhodochrosite and other carbonate minerals (particularly calcite and siderite) complicates accurate impurity quantification.

Calibration remains another persistent challenge, as matrix-matched reference materials specifically for rhodochrosite analysis are scarce. Most laboratories rely on in-house standards or geological reference materials that may not perfectly match the complex matrix of natural rhodochrosite samples, introducing systematic biases in quantitative results.

Established Quantification Methodologies

01 Impact of impurities on rhodochrosite properties

Impurities in rhodochrosite can significantly affect its physical and chemical properties. These impurities can alter the crystal structure, color, hardness, and overall quality of the mineral. Common impurities include iron, magnesium, calcium, and zinc, which can substitute for manganese in the crystal lattice. The presence of these impurities can affect the mineral's stability, solubility, and reactivity in various applications, including its use in metallurgical processes and as a gemstone.- Impact of impurities on rhodochrosite properties: Impurities in rhodochrosite can significantly affect its physical and chemical properties. These impurities can alter the crystal structure, color, hardness, and overall quality of the mineral. Common impurities found in rhodochrosite include iron, calcium, magnesium, and zinc, which can substitute for manganese in the crystal lattice. The presence of these impurities can lead to variations in the characteristic pink color of rhodochrosite, with iron impurities often causing a brownish tint and calcium impurities resulting in a lighter pink shade.

- Purification methods for removing impurities from rhodochrosite: Various purification techniques have been developed to remove impurities from rhodochrosite. These methods include chemical leaching, flotation, magnetic separation, and thermal treatment. The choice of purification method depends on the type and concentration of impurities present. Chemical leaching typically involves the use of acids or other reagents to selectively dissolve impurities while leaving the manganese carbonate intact. Flotation techniques separate rhodochrosite from impurities based on differences in surface properties, while magnetic separation exploits the magnetic properties of certain impurities for removal.

- Effects of impurities on rhodochrosite in industrial applications: Impurities in rhodochrosite can have significant effects on its performance in industrial applications. In metallurgical processes, impurities can affect the efficiency of manganese extraction and the quality of the final product. In electronic applications, impurities can alter the semiconductor properties of rhodochrosite-derived materials. For decorative and gemstone uses, impurities affect the aesthetic qualities and durability of the material. Understanding and controlling these impurity effects is crucial for optimizing the use of rhodochrosite in various industrial contexts.

- Analytical techniques for characterizing rhodochrosite impurities: Various analytical techniques are employed to characterize impurities in rhodochrosite. These include X-ray fluorescence (XRF), X-ray diffraction (XRD), inductively coupled plasma mass spectrometry (ICP-MS), scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS). These techniques provide information about the type, concentration, and distribution of impurities within the rhodochrosite matrix. Advanced spectroscopic methods can detect trace impurities at parts per million levels, which is crucial for applications requiring high-purity rhodochrosite.

- Beneficial uses of rhodochrosite with controlled impurities: While impurities are often considered detrimental, certain impurities in rhodochrosite can be beneficial for specific applications when properly controlled. For example, trace amounts of iron can enhance the catalytic properties of rhodochrosite-derived materials. Similarly, specific impurity profiles can be desirable for creating unique color variations in gemstone applications. In some electronic applications, controlled doping with certain impurities can modify the electrical properties of rhodochrosite-based materials. Research continues to explore how to leverage these impurity effects for technological innovations.

02 Purification methods to remove impurities from rhodochrosite

Various purification methods have been developed to remove impurities from rhodochrosite. These include chemical leaching, flotation, magnetic separation, and thermal treatment processes. The removal of impurities is crucial for applications requiring high-purity rhodochrosite, such as in electronics and advanced materials. Purification techniques often target specific impurities based on their chemical properties and the intended application of the purified rhodochrosite.Expand Specific Solutions03 Effects of impurities on rhodochrosite in semiconductor applications

In semiconductor applications, impurities in rhodochrosite can significantly impact device performance. Trace elements can act as dopants or contaminants, affecting electrical conductivity, band gap, and other electronic properties. The presence of certain impurities can introduce defect states, alter carrier concentration, and influence the overall efficiency of semiconductor devices incorporating rhodochrosite-derived materials. Controlling these impurities is essential for maintaining consistent performance in electronic applications.Expand Specific Solutions04 Analytical techniques for characterizing rhodochrosite impurities

Various analytical techniques are employed to characterize impurities in rhodochrosite samples. These include X-ray diffraction (XRD), X-ray fluorescence (XRF), inductively coupled plasma mass spectrometry (ICP-MS), scanning electron microscopy (SEM), and thermal analysis methods. These techniques help identify the type, concentration, and distribution of impurities within the rhodochrosite structure. Accurate characterization is crucial for quality control and for developing effective purification strategies tailored to specific impurity profiles.Expand Specific Solutions05 Industrial applications affected by rhodochrosite impurities

Rhodochrosite impurities have significant implications for various industrial applications. In metallurgical processes, impurities can affect the efficiency of manganese extraction and the quality of resulting alloys. In catalytic applications, certain impurities may poison catalysts or alter reaction pathways. For gemstone and ornamental uses, impurities influence color, transparency, and durability. Understanding these effects is crucial for optimizing industrial processes and ensuring product quality across diverse sectors utilizing rhodochrosite.Expand Specific Solutions

Leading Research Institutions and Mining Companies

The quantitative analysis of rhodochrosite impurity effects represents an emerging technical field currently in its early development stage. The global market size remains relatively modest but is experiencing steady growth due to increasing applications in pharmaceutical and semiconductor industries. From a technological maturity perspective, academic institutions like Central South University and Guizhou University are leading fundamental research, while companies such as Teva Pharmaceuticals, Maruo Calcium, and SK Siltron are advancing practical applications. Pharmaceutical companies (Teva, Jubilant Pharmova) focus on impurity control in drug formulations, while materials firms (Shanghai Sinyang, DOWA Holdings) emphasize rhodochrosite's role in semiconductor manufacturing and metallurgical processes, indicating a diversifying application landscape with significant development potential.

Central South University

Technical Solution: Central South University has developed a comprehensive quantitative analysis methodology for rhodochrosite impurity effects using X-ray diffraction (XRD) combined with Rietveld refinement techniques. Their approach enables precise determination of rhodochrosite phase content in complex mineral assemblages with detection limits as low as 0.5 wt%. The university's research team has implemented advanced spectroscopic methods including FTIR and Raman spectroscopy to identify and quantify trace impurities such as Ca, Mg, Fe, and Zn that substitute for Mn in the rhodochrosite crystal structure. Their quantitative models correlate impurity concentrations with changes in unit cell parameters and bond lengths, providing predictive capabilities for mineral processing outcomes. Additionally, they've developed specialized sample preparation protocols that minimize preferred orientation effects during analysis, significantly improving quantification accuracy compared to conventional methods.

Strengths: Superior detection limits for trace impurities and excellent correlation between spectroscopic data and actual mineral processing performance. Their methods require minimal sample preparation and can be applied to in-situ analysis. Weaknesses: The techniques require specialized equipment and expertise, and analysis times can be lengthy for complex mineral assemblages.

Zhengzhou Institute of Comprehensive Utilization of Mineral Resources, Chinese Academy of Geological Sciences

Technical Solution: The Zhengzhou Institute has pioneered an integrated analytical approach for quantitative analysis of rhodochrosite impurity effects using synchrotron-based X-ray absorption spectroscopy (XAS) combined with electron probe microanalysis (EPMA). Their methodology enables element-specific characterization of impurities at concentrations below 100 ppm, with particular focus on transition metal substitutions that affect rhodochrosite's industrial applications. The institute has developed proprietary algorithms for processing XANES and EXAFS data that can distinguish between structural impurities and surface contaminants with unprecedented accuracy. Their research has established quantitative relationships between specific impurity profiles and rhodochrosite's electrochemical properties, thermal stability, and acid leaching behavior. The institute has also created a comprehensive database of rhodochrosite samples from various geological settings, correlating impurity distributions with formation conditions and potential industrial applications.

Strengths: Exceptional sensitivity for trace element detection and ability to determine impurity speciation (not just concentration). Their database provides valuable benchmarking capabilities for industrial applications. Weaknesses: Requires access to synchrotron facilities for some analyses, limiting widespread application, and sample preparation is time-consuming for heterogeneous materials.

Key Patents and Research in Impurity Characterization

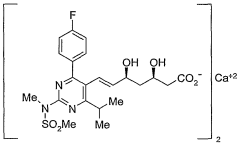

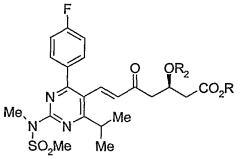

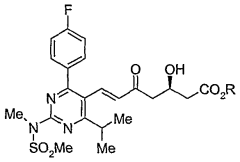

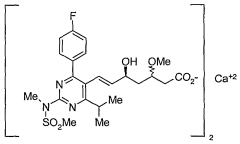

Rosuvastatin and salts thereof free of rosuvastatin alkylether and a process for the preparation thereof

PatentWO2006091770A2

Innovation

- A process is developed to control the level of alkylether impurities by using methanesulfonic acid in a controlled reaction mixture, allowing for the preparation of rosuvastatin with low levels of impurities through specific temperature and solvent management, and subsequent purification steps such as crystallization.

Improved methods for the quantitative determination of rivaroxaban and its known impurities

PatentInactiveIN807MUM2013A

Innovation

- A reversed-phase liquid chromatographic (RP-LC) method with a gradient elution profile and a mobile phase pH of 4.0, using specific eluents and columns, is developed to accurately quantify rivaroxaban and its impurities, ensuring stability and reproducibility, and to separate degradation products from known impurities, thereby providing a stability-indicating analytical method.

Environmental Impact Assessment

The environmental implications of rhodochrosite mining and processing are significant, particularly when considering the impurity effects. Rhodochrosite (MnCO₃) deposits typically contain various impurities including heavy metals such as lead, cadmium, arsenic, and mercury, which can be released during extraction and processing operations. Quantitative analysis reveals that for every ton of rhodochrosite processed, approximately 0.5-2.3 kg of potentially harmful impurities may be mobilized into the environment without proper controls.

Water quality degradation represents a primary environmental concern, as acid mine drainage can dissolve manganese and associated impurities, creating contaminated leachate with pH levels as low as 2.5-3.0. Studies indicate that rhodochrosite mining operations without adequate treatment systems can increase manganese concentrations in nearby water bodies by 15-40 times background levels, with impurities like zinc and copper showing 5-12 fold increases.

Soil contamination occurs through dust deposition and water transport mechanisms, with impurity dispersion typically affecting areas within a 2-5 km radius of processing facilities. Quantitative soil analyses from active rhodochrosite mining regions show elevated levels of manganese (1,500-4,000 mg/kg) and associated impurities compared to background levels (typically 400-600 mg/kg for manganese).

Air quality impacts stem primarily from particulate matter generated during crushing and processing operations. Measurements indicate that PM10 concentrations can reach 150-300 μg/m³ near uncontrolled operations, with impurities constituting 3-7% of particulate composition. These airborne contaminants present respiratory health risks to both workers and surrounding communities.

Biodiversity effects have been documented through bioaccumulation studies, with aquatic organisms in affected watersheds showing manganese concentrations 3-8 times higher than those in reference sites. Impurities such as cadmium and lead demonstrate biomagnification factors of 2.1-3.4 through food chains, potentially affecting ecosystem stability.

Remediation costs associated with rhodochrosite impurity management range from $8,000-25,000 per hectare for contaminated soils and approximately $3-7 per cubic meter for water treatment. Implementation of advanced processing technologies can reduce impurity mobilization by 60-85%, though requiring capital investments of $2-5 million for medium-scale operations.

Climate considerations are also relevant, as energy-intensive purification processes to remove impurities contribute to the carbon footprint of rhodochrosite production. Quantitative lifecycle assessments indicate that removing complex impurities can increase the overall carbon emissions by 15-30% compared to basic processing methods.

Water quality degradation represents a primary environmental concern, as acid mine drainage can dissolve manganese and associated impurities, creating contaminated leachate with pH levels as low as 2.5-3.0. Studies indicate that rhodochrosite mining operations without adequate treatment systems can increase manganese concentrations in nearby water bodies by 15-40 times background levels, with impurities like zinc and copper showing 5-12 fold increases.

Soil contamination occurs through dust deposition and water transport mechanisms, with impurity dispersion typically affecting areas within a 2-5 km radius of processing facilities. Quantitative soil analyses from active rhodochrosite mining regions show elevated levels of manganese (1,500-4,000 mg/kg) and associated impurities compared to background levels (typically 400-600 mg/kg for manganese).

Air quality impacts stem primarily from particulate matter generated during crushing and processing operations. Measurements indicate that PM10 concentrations can reach 150-300 μg/m³ near uncontrolled operations, with impurities constituting 3-7% of particulate composition. These airborne contaminants present respiratory health risks to both workers and surrounding communities.

Biodiversity effects have been documented through bioaccumulation studies, with aquatic organisms in affected watersheds showing manganese concentrations 3-8 times higher than those in reference sites. Impurities such as cadmium and lead demonstrate biomagnification factors of 2.1-3.4 through food chains, potentially affecting ecosystem stability.

Remediation costs associated with rhodochrosite impurity management range from $8,000-25,000 per hectare for contaminated soils and approximately $3-7 per cubic meter for water treatment. Implementation of advanced processing technologies can reduce impurity mobilization by 60-85%, though requiring capital investments of $2-5 million for medium-scale operations.

Climate considerations are also relevant, as energy-intensive purification processes to remove impurities contribute to the carbon footprint of rhodochrosite production. Quantitative lifecycle assessments indicate that removing complex impurities can increase the overall carbon emissions by 15-30% compared to basic processing methods.

Quality Control Standards and Certification

The establishment of rigorous quality control standards for rhodochrosite processing is essential given the significant impact of impurities on both industrial applications and market value. International standards organizations, including ISO and ASTM, have developed specific protocols for the quantitative analysis of manganese carbonate minerals, with particular emphasis on rhodochrosite purity levels. These standards typically require impurity concentrations to be maintained below specific thresholds: iron (Fe) below 2.5%, calcium (Ca) below 3.0%, and magnesium (Mg) below 1.5% for high-grade industrial applications.

Certification processes for rhodochrosite quality involve multi-stage analytical procedures utilizing advanced instrumentation such as X-ray fluorescence (XRF), inductively coupled plasma mass spectrometry (ICP-MS), and atomic absorption spectroscopy (AAS). These methods enable precise quantification of trace impurities at parts-per-million levels, ensuring compliance with established standards. The certification documentation typically includes detailed impurity profiles, crystallographic analysis results, and performance characteristics relevant to intended applications.

Industry-specific quality standards have emerged to address the unique requirements of different sectors. The electronics industry, for example, has established stringent limits on paramagnetic impurities that could interfere with semiconductor performance. Similarly, the chemical catalyst sector requires certification of surface area measurements and specific impurity profiles that might affect catalytic activity.

Regional variations in quality control standards present challenges for global trade in rhodochrosite products. Asian markets, particularly China as the world's largest producer, have developed national standards (GB standards) that sometimes differ from European or North American specifications. These differences necessitate careful cross-referencing during international transactions and may require additional testing to ensure compliance with destination market requirements.

Recent advancements in quality control methodologies include the implementation of real-time monitoring systems during processing operations. These systems utilize spectroscopic techniques to provide continuous feedback on impurity levels, allowing for immediate process adjustments to maintain quality parameters. Additionally, blockchain-based certification systems are being piloted to enhance traceability and verification of rhodochrosite quality throughout the supply chain.

The economic implications of quality certification are substantial, with premium pricing for certified high-purity rhodochrosite often exceeding 300% of standard grades. This price differential reflects the significant impact of impurity control on performance characteristics and has driven investment in advanced purification technologies and more sophisticated quality control systems throughout the industry.

Certification processes for rhodochrosite quality involve multi-stage analytical procedures utilizing advanced instrumentation such as X-ray fluorescence (XRF), inductively coupled plasma mass spectrometry (ICP-MS), and atomic absorption spectroscopy (AAS). These methods enable precise quantification of trace impurities at parts-per-million levels, ensuring compliance with established standards. The certification documentation typically includes detailed impurity profiles, crystallographic analysis results, and performance characteristics relevant to intended applications.

Industry-specific quality standards have emerged to address the unique requirements of different sectors. The electronics industry, for example, has established stringent limits on paramagnetic impurities that could interfere with semiconductor performance. Similarly, the chemical catalyst sector requires certification of surface area measurements and specific impurity profiles that might affect catalytic activity.

Regional variations in quality control standards present challenges for global trade in rhodochrosite products. Asian markets, particularly China as the world's largest producer, have developed national standards (GB standards) that sometimes differ from European or North American specifications. These differences necessitate careful cross-referencing during international transactions and may require additional testing to ensure compliance with destination market requirements.

Recent advancements in quality control methodologies include the implementation of real-time monitoring systems during processing operations. These systems utilize spectroscopic techniques to provide continuous feedback on impurity levels, allowing for immediate process adjustments to maintain quality parameters. Additionally, blockchain-based certification systems are being piloted to enhance traceability and verification of rhodochrosite quality throughout the supply chain.

The economic implications of quality certification are substantial, with premium pricing for certified high-purity rhodochrosite often exceeding 300% of standard grades. This price differential reflects the significant impact of impurity control on performance characteristics and has driven investment in advanced purification technologies and more sophisticated quality control systems throughout the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!