How to Detect Impurities in Rhodochrosite Using Spectrography

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Spectrography Analysis Background and Objectives

Rhodochrosite, a manganese carbonate mineral (MnCO3), has gained significant attention in both industrial applications and gemstone markets due to its distinctive pink to red coloration and valuable mineral properties. The detection and quantification of impurities in rhodochrosite samples have become increasingly important for quality control, mineral processing optimization, and geological studies. Spectrographic analysis has emerged as a powerful analytical technique for this purpose, offering non-destructive, rapid, and highly sensitive detection capabilities.

The evolution of spectrographic techniques for mineral analysis dates back to the mid-20th century, with significant advancements occurring in the 1970s and 1980s with the development of more sophisticated instrumentation. In recent years, the integration of artificial intelligence and machine learning algorithms with spectrographic data processing has revolutionized impurity detection capabilities, allowing for more accurate identification of trace elements and contaminants in rhodochrosite samples.

Current spectrographic methods employed for rhodochrosite analysis include X-ray fluorescence (XRF), Raman spectroscopy, Fourier-transform infrared spectroscopy (FTIR), and laser-induced breakdown spectroscopy (LIBS). Each technique offers distinct advantages in terms of sensitivity, specificity, and practical application scenarios. The technological trajectory indicates a move toward portable, field-deployable spectrographic systems that can provide real-time analysis in mining operations and geological surveys.

The primary technical objective of this research is to develop and optimize spectrographic methodologies specifically tailored for rhodochrosite impurity detection. This includes establishing standardized protocols for sample preparation, data acquisition, and spectral interpretation that can reliably identify and quantify common impurities such as calcium, iron, zinc, and magnesium carbonates, as well as silicate minerals that frequently occur alongside rhodochrosite.

Additionally, this research aims to address the challenges associated with distinguishing between structural impurities (elements incorporated into the crystal lattice) and physical inclusions (separate mineral phases) within rhodochrosite samples. This distinction is crucial for understanding formation conditions and determining appropriate processing methods for different applications.

The long-term technical goal is to create a comprehensive spectral database of rhodochrosite samples with varying impurity profiles, coupled with advanced pattern recognition algorithms that can automatically identify impurity signatures with high accuracy and sensitivity. Such a system would significantly enhance quality control processes in mining operations, improve the efficiency of rhodochrosite beneficiation, and provide valuable insights into the geological conditions under which different rhodochrosite deposits formed.

The evolution of spectrographic techniques for mineral analysis dates back to the mid-20th century, with significant advancements occurring in the 1970s and 1980s with the development of more sophisticated instrumentation. In recent years, the integration of artificial intelligence and machine learning algorithms with spectrographic data processing has revolutionized impurity detection capabilities, allowing for more accurate identification of trace elements and contaminants in rhodochrosite samples.

Current spectrographic methods employed for rhodochrosite analysis include X-ray fluorescence (XRF), Raman spectroscopy, Fourier-transform infrared spectroscopy (FTIR), and laser-induced breakdown spectroscopy (LIBS). Each technique offers distinct advantages in terms of sensitivity, specificity, and practical application scenarios. The technological trajectory indicates a move toward portable, field-deployable spectrographic systems that can provide real-time analysis in mining operations and geological surveys.

The primary technical objective of this research is to develop and optimize spectrographic methodologies specifically tailored for rhodochrosite impurity detection. This includes establishing standardized protocols for sample preparation, data acquisition, and spectral interpretation that can reliably identify and quantify common impurities such as calcium, iron, zinc, and magnesium carbonates, as well as silicate minerals that frequently occur alongside rhodochrosite.

Additionally, this research aims to address the challenges associated with distinguishing between structural impurities (elements incorporated into the crystal lattice) and physical inclusions (separate mineral phases) within rhodochrosite samples. This distinction is crucial for understanding formation conditions and determining appropriate processing methods for different applications.

The long-term technical goal is to create a comprehensive spectral database of rhodochrosite samples with varying impurity profiles, coupled with advanced pattern recognition algorithms that can automatically identify impurity signatures with high accuracy and sensitivity. Such a system would significantly enhance quality control processes in mining operations, improve the efficiency of rhodochrosite beneficiation, and provide valuable insights into the geological conditions under which different rhodochrosite deposits formed.

Market Demand for Accurate Impurity Detection in Minerals

The mineral processing industry has witnessed a significant surge in demand for accurate impurity detection technologies, particularly for semi-precious stones like rhodochrosite. This demand is primarily driven by the growing applications of rhodochrosite in jewelry, industrial processes, and technological components where purity levels directly impact product quality and value.

The global mineral analysis market was valued at approximately $456 million in 2022 and is projected to reach $712 million by 2028, growing at a CAGR of 7.7%. Within this broader market, spectrographic analysis equipment for semi-precious stones represents a specialized but rapidly expanding segment, with rhodochrosite analysis showing particular growth due to its increasing commercial importance.

Jewelry manufacturers constitute a major market segment, requiring precise impurity detection to ensure aesthetic quality and appropriate pricing of rhodochrosite specimens. Even minor impurities can significantly alter the stone's characteristic pink coloration and translucency, directly affecting market value. Premium rhodochrosite specimens with minimal impurities command prices up to 300% higher than those with visible inclusions or color inconsistencies.

The industrial sector presents another substantial market for rhodochrosite impurity detection. As a manganese carbonate mineral, purified rhodochrosite serves as a valuable source of manganese for steel production, electronics manufacturing, and chemical processes. Impurities can compromise the effectiveness of rhodochrosite in these applications, creating strong economic incentives for accurate detection methods.

Environmental regulations have further intensified market demand for precise impurity analysis. Some rhodochrosite deposits contain trace amounts of toxic elements like lead, arsenic, and cadmium. Regulatory frameworks in North America, Europe, and increasingly in Asia require comprehensive impurity profiling before rhodochrosite can be processed or incorporated into consumer products.

Research institutions and geological survey organizations represent another significant market segment, requiring advanced spectrographic solutions for mineralogical research, deposit characterization, and mining feasibility studies. These organizations typically seek high-precision instruments capable of detecting impurities at parts-per-billion levels.

The market shows strong regional variations, with North America and Europe leading in adoption of advanced spectrographic technologies, while the Asia-Pacific region demonstrates the fastest growth rate, particularly in China where rhodochrosite has cultural significance and growing industrial applications. Market research indicates that customers are willing to pay premium prices for spectrographic solutions offering non-destructive testing capabilities, rapid analysis times, and integration with digital data management systems.

The global mineral analysis market was valued at approximately $456 million in 2022 and is projected to reach $712 million by 2028, growing at a CAGR of 7.7%. Within this broader market, spectrographic analysis equipment for semi-precious stones represents a specialized but rapidly expanding segment, with rhodochrosite analysis showing particular growth due to its increasing commercial importance.

Jewelry manufacturers constitute a major market segment, requiring precise impurity detection to ensure aesthetic quality and appropriate pricing of rhodochrosite specimens. Even minor impurities can significantly alter the stone's characteristic pink coloration and translucency, directly affecting market value. Premium rhodochrosite specimens with minimal impurities command prices up to 300% higher than those with visible inclusions or color inconsistencies.

The industrial sector presents another substantial market for rhodochrosite impurity detection. As a manganese carbonate mineral, purified rhodochrosite serves as a valuable source of manganese for steel production, electronics manufacturing, and chemical processes. Impurities can compromise the effectiveness of rhodochrosite in these applications, creating strong economic incentives for accurate detection methods.

Environmental regulations have further intensified market demand for precise impurity analysis. Some rhodochrosite deposits contain trace amounts of toxic elements like lead, arsenic, and cadmium. Regulatory frameworks in North America, Europe, and increasingly in Asia require comprehensive impurity profiling before rhodochrosite can be processed or incorporated into consumer products.

Research institutions and geological survey organizations represent another significant market segment, requiring advanced spectrographic solutions for mineralogical research, deposit characterization, and mining feasibility studies. These organizations typically seek high-precision instruments capable of detecting impurities at parts-per-billion levels.

The market shows strong regional variations, with North America and Europe leading in adoption of advanced spectrographic technologies, while the Asia-Pacific region demonstrates the fastest growth rate, particularly in China where rhodochrosite has cultural significance and growing industrial applications. Market research indicates that customers are willing to pay premium prices for spectrographic solutions offering non-destructive testing capabilities, rapid analysis times, and integration with digital data management systems.

Current Spectrographic Methods and Limitations for Rhodochrosite

Spectrographic analysis has emerged as a cornerstone technique for mineral identification and impurity detection in geological samples. For rhodochrosite (MnCO₃), a manganese carbonate mineral valued both industrially and as a gemstone, several spectrographic methods are currently employed with varying degrees of effectiveness.

X-ray fluorescence (XRF) spectroscopy represents one of the most widely utilized techniques for elemental analysis of rhodochrosite. This non-destructive method can detect impurities such as iron, calcium, magnesium, and zinc that commonly substitute for manganese in the crystal lattice. Modern XRF systems offer detection limits down to parts per million (ppm) levels, making them suitable for identifying major impurities. However, XRF struggles with light elements (atomic number <11) and cannot provide information about the chemical state of impurities.

Raman spectroscopy has gained significant traction for rhodochrosite analysis due to its ability to identify both crystalline structure and chemical composition. The technique can distinguish between rhodochrosite and similar carbonate minerals through characteristic vibrational modes at approximately 1086 cm⁻¹ (CO₃²⁻ symmetric stretching) and 291 cm⁻¹ (Mn-O lattice vibrations). While Raman offers excellent spatial resolution (down to 1 μm), it suffers from fluorescence interference when analyzing rhodochrosite samples with certain impurities, particularly rare earth elements.

Fourier-transform infrared (FTIR) spectroscopy complements Raman analysis by providing detailed information about molecular bonds in rhodochrosite. FTIR can identify carbonate substitutions and water-related impurities through characteristic absorption bands. The technique's primary limitation lies in its relatively poor spatial resolution compared to other methods, making it less effective for analyzing heterogeneous samples with microscopic impurity distributions.

Laser-induced breakdown spectroscopy (LIBS) offers rapid elemental analysis with minimal sample preparation. By creating a plasma from the sample surface using a focused laser pulse, LIBS can detect trace elements at concentrations as low as 1-10 ppm. However, the technique's accuracy is compromised by matrix effects, where the composition of the bulk material affects the emission intensity of impurity elements.

Inductively coupled plasma mass spectrometry (ICP-MS), while highly sensitive with detection limits in the parts per billion (ppb) range, requires dissolution of the sample, making it destructive and unsuitable for precious specimens. Additionally, sample preparation is time-consuming and introduces potential contamination risks.

The primary challenge across all current spectrographic methods is achieving simultaneous high sensitivity, spatial resolution, and non-destructive analysis. Most techniques excel in one or two of these aspects but fall short in others, necessitating a multi-analytical approach for comprehensive impurity characterization in rhodochrosite.

X-ray fluorescence (XRF) spectroscopy represents one of the most widely utilized techniques for elemental analysis of rhodochrosite. This non-destructive method can detect impurities such as iron, calcium, magnesium, and zinc that commonly substitute for manganese in the crystal lattice. Modern XRF systems offer detection limits down to parts per million (ppm) levels, making them suitable for identifying major impurities. However, XRF struggles with light elements (atomic number <11) and cannot provide information about the chemical state of impurities.

Raman spectroscopy has gained significant traction for rhodochrosite analysis due to its ability to identify both crystalline structure and chemical composition. The technique can distinguish between rhodochrosite and similar carbonate minerals through characteristic vibrational modes at approximately 1086 cm⁻¹ (CO₃²⁻ symmetric stretching) and 291 cm⁻¹ (Mn-O lattice vibrations). While Raman offers excellent spatial resolution (down to 1 μm), it suffers from fluorescence interference when analyzing rhodochrosite samples with certain impurities, particularly rare earth elements.

Fourier-transform infrared (FTIR) spectroscopy complements Raman analysis by providing detailed information about molecular bonds in rhodochrosite. FTIR can identify carbonate substitutions and water-related impurities through characteristic absorption bands. The technique's primary limitation lies in its relatively poor spatial resolution compared to other methods, making it less effective for analyzing heterogeneous samples with microscopic impurity distributions.

Laser-induced breakdown spectroscopy (LIBS) offers rapid elemental analysis with minimal sample preparation. By creating a plasma from the sample surface using a focused laser pulse, LIBS can detect trace elements at concentrations as low as 1-10 ppm. However, the technique's accuracy is compromised by matrix effects, where the composition of the bulk material affects the emission intensity of impurity elements.

Inductively coupled plasma mass spectrometry (ICP-MS), while highly sensitive with detection limits in the parts per billion (ppb) range, requires dissolution of the sample, making it destructive and unsuitable for precious specimens. Additionally, sample preparation is time-consuming and introduces potential contamination risks.

The primary challenge across all current spectrographic methods is achieving simultaneous high sensitivity, spatial resolution, and non-destructive analysis. Most techniques excel in one or two of these aspects but fall short in others, necessitating a multi-analytical approach for comprehensive impurity characterization in rhodochrosite.

Established Spectrographic Solutions for Rhodochrosite Analysis

01 Removal of impurities from rhodochrosite ore

Various methods are employed to remove impurities from rhodochrosite ore during processing. These techniques include physical separation, chemical leaching, and flotation processes to eliminate gangue minerals and other contaminants. The purification processes aim to increase the manganese content and reduce harmful elements that could affect the quality of the final product. Effective impurity removal is essential for producing high-grade rhodochrosite suitable for industrial applications.- Removal of impurities from rhodochrosite ore: Various methods are employed to remove impurities from rhodochrosite ore during processing. These techniques include acid leaching, flotation, magnetic separation, and chemical treatments to eliminate contaminants such as iron, silica, calcium, and other metal impurities. The purification processes aim to increase the manganese content and reduce harmful elements that affect the quality of the final product.

- Identification and analysis of rhodochrosite impurities: Analytical methods are used to identify and quantify impurities present in rhodochrosite minerals. These techniques include X-ray diffraction, spectroscopic analysis, chemical composition testing, and microscopic examination to determine the types and concentrations of impurities. Understanding the impurity profile is essential for developing effective purification strategies and assessing the quality of rhodochrosite samples.

- Beneficiation techniques for rhodochrosite processing: Beneficiation techniques are applied to upgrade rhodochrosite ore quality by separating valuable minerals from gangue materials. These processes include crushing, grinding, screening, gravity separation, and selective flotation to concentrate the rhodochrosite and reduce impurity content. Advanced beneficiation methods help improve the economic value of rhodochrosite by producing higher-grade concentrates with fewer impurities.

- Utilization of rhodochrosite with impurities: Methods for utilizing rhodochrosite that contains certain levels of impurities have been developed for various applications. These approaches involve adapting processing techniques to accommodate the presence of specific impurities or developing applications where certain impurities do not significantly impact performance. This enables the use of lower-grade rhodochrosite resources that would otherwise be economically unviable to purify completely.

- Environmental considerations in rhodochrosite impurity management: Environmental aspects of managing impurities from rhodochrosite processing are addressed through sustainable practices. These include waste treatment methods, recycling of processing chemicals, containment of harmful impurities, and remediation techniques for processing residues. Environmentally friendly approaches aim to minimize the ecological impact of rhodochrosite purification while complying with environmental regulations.

02 Identification and characterization of rhodochrosite impurities

Analytical techniques are used to identify and characterize impurities present in rhodochrosite minerals. These methods include X-ray diffraction, spectroscopic analysis, and chemical testing to determine the composition and concentration of various impurities. Common impurities found in rhodochrosite include iron compounds, silicates, carbonates of other metals, and trace elements. Understanding the impurity profile is crucial for developing effective purification strategies and assessing the quality of rhodochrosite samples.Expand Specific Solutions03 Beneficiation processes for rhodochrosite purification

Beneficiation processes are specifically designed to upgrade rhodochrosite ore by removing impurities and increasing manganese content. These processes may include crushing, grinding, gravity separation, magnetic separation, and selective flotation techniques. The selection of appropriate beneficiation methods depends on the nature and concentration of impurities present in the raw material. Advanced beneficiation technologies can significantly improve the purity and economic value of rhodochrosite products.Expand Specific Solutions04 Treatment of rhodochrosite for specific applications

Specialized treatment methods are developed to prepare rhodochrosite for specific industrial applications by addressing particular impurity concerns. These treatments may involve selective leaching, thermal processing, or chemical modifications to eliminate impurities that would interfere with the intended use. For applications in electronics, catalysts, or high-purity manganese compounds, additional purification steps may be required to meet stringent quality standards. The treatment processes are tailored based on the end-use requirements and the initial impurity profile of the rhodochrosite material.Expand Specific Solutions05 Environmental considerations in rhodochrosite impurity management

Environmental aspects of managing impurities from rhodochrosite processing are increasingly important. Technologies and methods are developed to minimize the environmental impact of waste materials containing impurities separated from rhodochrosite. These approaches include recycling of process water, treatment of acid mine drainage, safe disposal of tailings, and recovery of valuable by-products from impurity fractions. Sustainable practices in rhodochrosite processing aim to reduce pollution while maximizing resource utilization and economic benefits.Expand Specific Solutions

Leading Companies and Research Institutions in Mineral Analysis

The detection of impurities in rhodochrosite using spectrography represents an emerging technical field at the intersection of mineralogy and analytical chemistry. Currently in its growth phase, this market is expanding as mining operations and materials science applications demand higher purity standards. The technology is moderately mature, with academic institutions like Central South University, Guizhou University, and University of Science & Technology Beijing leading fundamental research. Industrial players including Changsha Research Institute of Mining & Metallurgy are developing practical applications, while pharmaceutical companies such as Teva Pharmaceutical and Alembic Ltd. are exploring spectrographic techniques for quality control in mineral-based formulations. The competitive landscape features collaboration between academic research centers and industrial partners, with increasing investment in advanced spectroscopic equipment and data analysis methodologies.

Guizhou University

Technical Solution: Guizhou University has developed a comprehensive spectrographic approach for detecting impurities in rhodochrosite using a combination of X-ray fluorescence (XRF) spectroscopy and Fourier Transform Infrared (FTIR) spectroscopy. Their method involves sample preparation through fine grinding and pressing into pellets, followed by XRF analysis to identify elemental impurities such as Fe, Ca, Mg, and heavy metals. The university's research team has optimized detection parameters to achieve sensitivity down to 0.01% for most common impurities. Additionally, they employ FTIR spectroscopy to identify molecular compounds and structural impurities that may not be detected by elemental analysis alone. Their system includes specialized software for spectral pattern recognition that can automatically flag samples with impurity levels exceeding predetermined thresholds.

Strengths: High sensitivity for detecting multiple types of impurities simultaneously; comprehensive analysis combining elemental and molecular detection; automated pattern recognition reduces human error. Weaknesses: Requires relatively complex sample preparation; expensive equipment setup; may require specialized training for operation and data interpretation.

University of Science & Technology Beijing

Technical Solution: University of Science & Technology Beijing has pioneered an advanced laser-induced breakdown spectroscopy (LIBS) technique specifically calibrated for rhodochrosite impurity detection. Their approach utilizes a high-energy pulsed laser that creates a micro-plasma on the sample surface, generating a spectral emission that is analyzed to determine elemental composition. The university has developed proprietary algorithms that can distinguish between matrix elements and impurities with high precision. Their system incorporates a dual-pulse LIBS configuration that enhances sensitivity by up to 10-fold compared to conventional single-pulse systems, allowing detection of trace impurities at concentrations below 10 ppm. The technology also features real-time mapping capabilities that can visualize the spatial distribution of impurities across the sample, providing insights into formation conditions and potential beneficiation strategies. The system has been validated through comparison with inductively coupled plasma mass spectrometry (ICP-MS) results, showing excellent correlation for most elements of interest.

Strengths: Minimal sample preparation requirements; capability for rapid in-situ analysis; high spatial resolution mapping of impurity distribution; non-destructive testing option for valuable specimens. Weaknesses: Potential matrix effects requiring careful calibration; less sensitive than some laboratory techniques for certain elements; higher initial equipment investment compared to conventional spectroscopy.

Key Spectral Signatures and Detection Algorithms for Impurities

Novel compounds

PatentInactiveIN508MUM2006A

Innovation

- Development of a relative retention time (RRT) methodology for accurate identification of impurities in spectroscopic analysis, which overcomes the limitations of absolute retention time measurements that vary due to instrumental conditions.

- Selection of an appropriate reference marker compound (other than the API itself) that is detectable but won't saturate the column, enabling more reproducible and reliable impurity identification.

- Establishment of specific purity standards for pharmaceutical compounds that balance theoretical purity ideals with practical safety requirements for clinical use, particularly focusing on impurity limits below 0.1 percent.

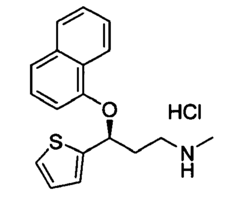

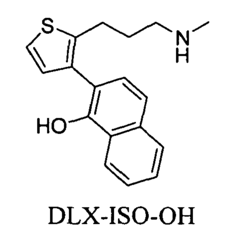

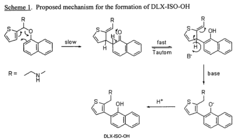

Process for the preparation of duloxetine hydrochloride

PatentInactiveEP2100888A2

Innovation

- A process involving heating a mixture of duloxetine with specific solvents and inorganic bases to isolate and remove 2-(N-methyl-propanamine)-3-(2-naphthol) thiophene, using it as a reference marker or standard for analysis and purification, and employing HPLC for quantification and impurity profiling.

Environmental Impact of Rhodochrosite Mining and Processing

The mining and processing of rhodochrosite present significant environmental challenges that must be addressed through comprehensive management strategies. Extraction activities typically involve open-pit or underground mining operations, which cause substantial landscape alteration and habitat disruption in the surrounding ecosystems. The removal of overburden and waste rock creates large volumes of material that must be properly managed to prevent acid mine drainage and heavy metal leaching.

Water resources are particularly vulnerable during rhodochrosite mining operations. The process requires substantial water usage, potentially depleting local supplies in arid regions where many manganese deposits are found. Additionally, without proper treatment systems, wastewater from processing facilities may contain elevated levels of manganese, lead, zinc, and other potentially harmful elements that can contaminate groundwater and surface water bodies.

Air quality degradation represents another environmental concern, primarily through dust emissions containing fine particulate matter. These emissions occur during blasting, crushing, and transportation activities. The dust may contain manganese particles which, when inhaled in high concentrations over extended periods, can lead to neurological issues in nearby communities.

Spectrographic analysis plays a crucial role in environmental monitoring around rhodochrosite mining operations. By implementing real-time spectrographic monitoring systems, mining companies can detect impurities released into the environment before they reach harmful levels. This technology enables the identification of specific contaminants in water discharges, dust emissions, and soil samples, allowing for targeted mitigation measures.

Sustainable mining practices are increasingly being adopted by responsible operators. These include closed-loop water systems that minimize freshwater consumption and wastewater discharge, dust suppression technologies, and progressive land reclamation. Advanced spectrographic techniques help optimize these processes by providing precise data on impurity concentrations, enabling more efficient separation of rhodochrosite from waste materials and reducing the overall environmental footprint.

Regulatory frameworks worldwide are becoming more stringent regarding the environmental impacts of mining operations. Companies must conduct thorough environmental impact assessments before commencing operations and implement continuous monitoring programs throughout the mine's lifecycle. Spectrographic analysis serves as a valuable tool for demonstrating compliance with these regulations and identifying potential issues before they develop into serious environmental problems.

Water resources are particularly vulnerable during rhodochrosite mining operations. The process requires substantial water usage, potentially depleting local supplies in arid regions where many manganese deposits are found. Additionally, without proper treatment systems, wastewater from processing facilities may contain elevated levels of manganese, lead, zinc, and other potentially harmful elements that can contaminate groundwater and surface water bodies.

Air quality degradation represents another environmental concern, primarily through dust emissions containing fine particulate matter. These emissions occur during blasting, crushing, and transportation activities. The dust may contain manganese particles which, when inhaled in high concentrations over extended periods, can lead to neurological issues in nearby communities.

Spectrographic analysis plays a crucial role in environmental monitoring around rhodochrosite mining operations. By implementing real-time spectrographic monitoring systems, mining companies can detect impurities released into the environment before they reach harmful levels. This technology enables the identification of specific contaminants in water discharges, dust emissions, and soil samples, allowing for targeted mitigation measures.

Sustainable mining practices are increasingly being adopted by responsible operators. These include closed-loop water systems that minimize freshwater consumption and wastewater discharge, dust suppression technologies, and progressive land reclamation. Advanced spectrographic techniques help optimize these processes by providing precise data on impurity concentrations, enabling more efficient separation of rhodochrosite from waste materials and reducing the overall environmental footprint.

Regulatory frameworks worldwide are becoming more stringent regarding the environmental impacts of mining operations. Companies must conduct thorough environmental impact assessments before commencing operations and implement continuous monitoring programs throughout the mine's lifecycle. Spectrographic analysis serves as a valuable tool for demonstrating compliance with these regulations and identifying potential issues before they develop into serious environmental problems.

Standardization and Quality Control Protocols for Analysis

Effective standardization and quality control protocols are essential for ensuring reliable and reproducible results when using spectrographic techniques to detect impurities in rhodochrosite. These protocols must address various aspects of the analytical process, from sample preparation to data interpretation, to minimize variability and enhance the accuracy of impurity detection.

Sample preparation standardization represents the foundation of quality control in rhodochrosite analysis. This includes establishing precise protocols for crushing, grinding, and sieving samples to achieve consistent particle sizes, typically between 45-75 μm. Standardized cleaning procedures using ultrasonic baths with specific solvents help eliminate surface contaminants that might interfere with spectroscopic readings.

Calibration procedures form another critical component of quality control. Regular calibration using certified reference materials (CRMs) with known impurity concentrations ensures measurement accuracy. For rhodochrosite analysis, manganese carbonate standards with controlled levels of common impurities such as iron, calcium, and magnesium are particularly valuable. Calibration curves should be established at least bi-weekly or whenever environmental conditions change significantly.

Instrument performance verification protocols must be implemented to maintain analytical integrity. This includes daily wavelength calibration checks, resolution tests, and signal-to-noise ratio assessments. For rhodochrosite analysis, particular attention should be paid to spectral regions associated with common impurities (Fe at 259.94 nm, Ca at 422.67 nm, and Mg at 285.21 nm).

Quality control during measurement involves the use of control samples analyzed at regular intervals throughout analytical runs. A recommended approach is to analyze one control sample per every 10 unknown samples, with acceptance criteria typically set at ±5% of established values. Duplicate analyses of approximately 10% of samples help assess precision, with relative standard deviation (RSD) values below 3% considered acceptable for most applications.

Data processing standardization is equally important, requiring consistent baseline correction methods, peak integration parameters, and spectral deconvolution techniques. For rhodochrosite, specialized algorithms may be necessary to address matrix effects caused by the high manganese content, which can interfere with certain impurity signals.

Documentation and traceability complete the quality control framework. All analytical procedures, calibration records, and maintenance logs must be thoroughly documented according to ISO/IEC 17025 guidelines. Each sample should be assigned a unique identifier, with complete records of its handling history from collection through analysis.

Proficiency testing through participation in interlaboratory comparison programs provides external validation of analytical methods. For rhodochrosite analysis, specialized programs focusing on manganese-rich minerals offer valuable benchmarking opportunities to assess laboratory performance against peer institutions.

Sample preparation standardization represents the foundation of quality control in rhodochrosite analysis. This includes establishing precise protocols for crushing, grinding, and sieving samples to achieve consistent particle sizes, typically between 45-75 μm. Standardized cleaning procedures using ultrasonic baths with specific solvents help eliminate surface contaminants that might interfere with spectroscopic readings.

Calibration procedures form another critical component of quality control. Regular calibration using certified reference materials (CRMs) with known impurity concentrations ensures measurement accuracy. For rhodochrosite analysis, manganese carbonate standards with controlled levels of common impurities such as iron, calcium, and magnesium are particularly valuable. Calibration curves should be established at least bi-weekly or whenever environmental conditions change significantly.

Instrument performance verification protocols must be implemented to maintain analytical integrity. This includes daily wavelength calibration checks, resolution tests, and signal-to-noise ratio assessments. For rhodochrosite analysis, particular attention should be paid to spectral regions associated with common impurities (Fe at 259.94 nm, Ca at 422.67 nm, and Mg at 285.21 nm).

Quality control during measurement involves the use of control samples analyzed at regular intervals throughout analytical runs. A recommended approach is to analyze one control sample per every 10 unknown samples, with acceptance criteria typically set at ±5% of established values. Duplicate analyses of approximately 10% of samples help assess precision, with relative standard deviation (RSD) values below 3% considered acceptable for most applications.

Data processing standardization is equally important, requiring consistent baseline correction methods, peak integration parameters, and spectral deconvolution techniques. For rhodochrosite, specialized algorithms may be necessary to address matrix effects caused by the high manganese content, which can interfere with certain impurity signals.

Documentation and traceability complete the quality control framework. All analytical procedures, calibration records, and maintenance logs must be thoroughly documented according to ISO/IEC 17025 guidelines. Each sample should be assigned a unique identifier, with complete records of its handling history from collection through analysis.

Proficiency testing through participation in interlaboratory comparison programs provides external validation of analytical methods. For rhodochrosite analysis, specialized programs focusing on manganese-rich minerals offer valuable benchmarking opportunities to assess laboratory performance against peer institutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!