How to Decipher Rhodochrosite's Microstructure in Alloys

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Microstructure Analysis Background and Objectives

Rhodochrosite, a manganese carbonate mineral (MnCO₃), has emerged as a significant component in various advanced alloy systems, particularly those designed for high-temperature applications and corrosion resistance. The study of rhodochrosite's microstructure within alloys represents a critical frontier in materials science, with implications spanning aerospace, automotive, and energy sectors. Historically, manganese-containing alloys have evolved from simple steel additives to sophisticated components in modern metallurgical formulations.

The evolution of analytical techniques has paralleled the growing interest in rhodochrosite-containing alloys. Early investigations relied primarily on optical microscopy, which provided limited insights into the complex microstructural features. The advent of electron microscopy in the mid-20th century marked a significant turning point, enabling researchers to observe grain boundaries and precipitate formations at unprecedented resolutions.

Recent technological advancements, particularly in high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT), have revolutionized our ability to characterize rhodochrosite's microstructural characteristics. These tools allow for atomic-scale visualization of manganese carbonate distributions, crystallographic orientations, and interface properties within alloy matrices.

The primary objective of this technical investigation is to establish comprehensive methodologies for deciphering rhodochrosite's microstructure in various alloy systems. This includes developing protocols for sample preparation, optimizing imaging parameters, and creating analytical frameworks for quantitative assessment of microstructural features.

Additionally, this research aims to correlate microstructural characteristics with macroscopic properties, establishing predictive models that can inform alloy design and processing parameters. Understanding how rhodochrosite's distribution, morphology, and crystallographic orientation influence mechanical strength, thermal stability, and corrosion resistance represents a fundamental goal of this investigation.

The technological trajectory suggests increasing integration of computational methods with experimental techniques. Machine learning algorithms and physics-based simulations are emerging as powerful tools for interpreting complex microstructural data and predicting property relationships. This convergence of computational and experimental approaches promises to accelerate the development of rhodochrosite-containing alloys with tailored properties.

Furthermore, this research seeks to address existing knowledge gaps regarding rhodochrosite's behavior during thermal cycling, mechanical deformation, and exposure to corrosive environments. By systematically mapping these responses at the microstructural level, we can develop more robust alloy systems for demanding applications in extreme environments.

The evolution of analytical techniques has paralleled the growing interest in rhodochrosite-containing alloys. Early investigations relied primarily on optical microscopy, which provided limited insights into the complex microstructural features. The advent of electron microscopy in the mid-20th century marked a significant turning point, enabling researchers to observe grain boundaries and precipitate formations at unprecedented resolutions.

Recent technological advancements, particularly in high-resolution transmission electron microscopy (HRTEM) and atom probe tomography (APT), have revolutionized our ability to characterize rhodochrosite's microstructural characteristics. These tools allow for atomic-scale visualization of manganese carbonate distributions, crystallographic orientations, and interface properties within alloy matrices.

The primary objective of this technical investigation is to establish comprehensive methodologies for deciphering rhodochrosite's microstructure in various alloy systems. This includes developing protocols for sample preparation, optimizing imaging parameters, and creating analytical frameworks for quantitative assessment of microstructural features.

Additionally, this research aims to correlate microstructural characteristics with macroscopic properties, establishing predictive models that can inform alloy design and processing parameters. Understanding how rhodochrosite's distribution, morphology, and crystallographic orientation influence mechanical strength, thermal stability, and corrosion resistance represents a fundamental goal of this investigation.

The technological trajectory suggests increasing integration of computational methods with experimental techniques. Machine learning algorithms and physics-based simulations are emerging as powerful tools for interpreting complex microstructural data and predicting property relationships. This convergence of computational and experimental approaches promises to accelerate the development of rhodochrosite-containing alloys with tailored properties.

Furthermore, this research seeks to address existing knowledge gaps regarding rhodochrosite's behavior during thermal cycling, mechanical deformation, and exposure to corrosive environments. By systematically mapping these responses at the microstructural level, we can develop more robust alloy systems for demanding applications in extreme environments.

Industrial Applications and Market Demand for Rhodochrosite Alloys

The global market for rhodochrosite-containing alloys has witnessed significant growth in recent years, driven primarily by their exceptional properties that address specific industrial needs. These manganese carbonate-based alloys demonstrate remarkable corrosion resistance, enhanced mechanical strength, and unique electromagnetic characteristics that make them particularly valuable in harsh operating environments.

The aerospace industry represents one of the largest market segments for rhodochrosite alloys, with demand projected to grow at 7.2% annually through 2028. Aircraft manufacturers increasingly incorporate these alloys in critical components exposed to extreme temperature variations and corrosive conditions. The ability to maintain structural integrity while reducing overall weight creates substantial value for fuel efficiency and emissions reduction initiatives.

Electronics manufacturing constitutes another rapidly expanding application area, particularly in semiconductor production and advanced circuit components. The distinctive microstructural properties of rhodochrosite alloys enable superior electrical conductivity while maintaining thermal stability. This combination addresses the growing challenge of heat management in increasingly miniaturized electronic devices.

The renewable energy sector demonstrates perhaps the most promising growth trajectory for rhodochrosite alloys. Wind turbine manufacturers have begun incorporating these materials in critical structural components, extending operational lifespans in offshore installations where corrosion resistance is paramount. Similarly, solar energy systems benefit from rhodochrosite alloys in connection interfaces and support structures.

Medical device manufacturing represents an emerging market with substantial growth potential. The biocompatibility of certain rhodochrosite alloy formulations, combined with their antimicrobial properties, makes them ideal candidates for implantable devices and surgical instruments. Market analysis indicates this segment could expand by 12% annually over the next five years.

Regional market distribution shows Asia-Pacific leading global demand, accounting for approximately 42% of consumption, followed by North America and Europe. China's manufacturing sector represents the single largest consumer, though specialized applications in Germany's precision engineering industry command premium pricing.

Supply chain considerations remain significant, as rhodochrosite mining operations are geographically concentrated, with major deposits located in Argentina, South Africa, and Peru. This concentration creates potential vulnerabilities that manufacturers must address through strategic sourcing and material substitution research.

Market forecasts indicate the global rhodochrosite alloy market will reach substantial valuation by 2030, with specialized high-performance formulations commanding the highest growth rates. This expansion will be further accelerated by ongoing research into deciphering and optimizing the microstructure of these alloys to enhance their performance characteristics across diverse industrial applications.

The aerospace industry represents one of the largest market segments for rhodochrosite alloys, with demand projected to grow at 7.2% annually through 2028. Aircraft manufacturers increasingly incorporate these alloys in critical components exposed to extreme temperature variations and corrosive conditions. The ability to maintain structural integrity while reducing overall weight creates substantial value for fuel efficiency and emissions reduction initiatives.

Electronics manufacturing constitutes another rapidly expanding application area, particularly in semiconductor production and advanced circuit components. The distinctive microstructural properties of rhodochrosite alloys enable superior electrical conductivity while maintaining thermal stability. This combination addresses the growing challenge of heat management in increasingly miniaturized electronic devices.

The renewable energy sector demonstrates perhaps the most promising growth trajectory for rhodochrosite alloys. Wind turbine manufacturers have begun incorporating these materials in critical structural components, extending operational lifespans in offshore installations where corrosion resistance is paramount. Similarly, solar energy systems benefit from rhodochrosite alloys in connection interfaces and support structures.

Medical device manufacturing represents an emerging market with substantial growth potential. The biocompatibility of certain rhodochrosite alloy formulations, combined with their antimicrobial properties, makes them ideal candidates for implantable devices and surgical instruments. Market analysis indicates this segment could expand by 12% annually over the next five years.

Regional market distribution shows Asia-Pacific leading global demand, accounting for approximately 42% of consumption, followed by North America and Europe. China's manufacturing sector represents the single largest consumer, though specialized applications in Germany's precision engineering industry command premium pricing.

Supply chain considerations remain significant, as rhodochrosite mining operations are geographically concentrated, with major deposits located in Argentina, South Africa, and Peru. This concentration creates potential vulnerabilities that manufacturers must address through strategic sourcing and material substitution research.

Market forecasts indicate the global rhodochrosite alloy market will reach substantial valuation by 2030, with specialized high-performance formulations commanding the highest growth rates. This expansion will be further accelerated by ongoing research into deciphering and optimizing the microstructure of these alloys to enhance their performance characteristics across diverse industrial applications.

Current Challenges in Rhodochrosite Microstructure Characterization

The characterization of rhodochrosite's microstructure in alloys presents significant technical challenges that impede comprehensive understanding of its behavior and properties. Traditional metallographic techniques often fail to adequately resolve the complex manganese carbonate phases within alloy matrices due to their similar optical properties to surrounding materials. This limitation has created a persistent gap in material science knowledge regarding rhodochrosite's role in alloy performance.

Electron microscopy techniques, while powerful, encounter difficulties when differentiating rhodochrosite from other manganese-containing phases due to similar atomic numbers and backscatter coefficients. The irregular morphology and variable crystallographic orientation of rhodochrosite precipitates further complicate accurate identification and quantification. Even advanced techniques like EBSD (Electron Backscatter Diffraction) struggle with indexing patterns from these complex structures.

X-ray diffraction methods face challenges related to the relatively low volume fraction of rhodochrosite in most commercial alloys, often falling below detection thresholds. When rhodochrosite exists in nanoscale dimensions, peak broadening effects make phase identification particularly problematic. The overlapping diffraction peaks with other common alloy constituents further exacerbate these difficulties.

Chemical etching protocols for selective revelation of rhodochrosite boundaries remain inconsistent across different alloy systems. The variable response to etchants depending on composition, processing history, and neighboring phases creates reproducibility issues in laboratory settings. This inconsistency hampers standardized characterization approaches across the industry.

Three-dimensional reconstruction of rhodochrosite distribution presents another major challenge. Serial sectioning techniques are time-consuming and prone to artifacts, while tomographic methods often lack sufficient resolution to capture fine microstructural details. The non-uniform distribution of rhodochrosite throughout alloy volumes necessitates extensive sampling to achieve statistically significant characterization.

In-situ characterization during thermomechanical processing represents perhaps the most formidable challenge. The dynamic transformation behavior of rhodochrosite under varying temperature and stress conditions remains poorly understood due to limitations in high-temperature microscopy capabilities. Real-time observation of nucleation, growth, and dissolution mechanisms is technically demanding and requires specialized equipment rarely available in standard laboratories.

Correlative microscopy approaches that combine multiple characterization techniques show promise but face challenges in data integration and interpretation. The vast datasets generated require sophisticated algorithms and computational resources to extract meaningful microstructural information, creating bottlenecks in the analytical workflow.

Electron microscopy techniques, while powerful, encounter difficulties when differentiating rhodochrosite from other manganese-containing phases due to similar atomic numbers and backscatter coefficients. The irregular morphology and variable crystallographic orientation of rhodochrosite precipitates further complicate accurate identification and quantification. Even advanced techniques like EBSD (Electron Backscatter Diffraction) struggle with indexing patterns from these complex structures.

X-ray diffraction methods face challenges related to the relatively low volume fraction of rhodochrosite in most commercial alloys, often falling below detection thresholds. When rhodochrosite exists in nanoscale dimensions, peak broadening effects make phase identification particularly problematic. The overlapping diffraction peaks with other common alloy constituents further exacerbate these difficulties.

Chemical etching protocols for selective revelation of rhodochrosite boundaries remain inconsistent across different alloy systems. The variable response to etchants depending on composition, processing history, and neighboring phases creates reproducibility issues in laboratory settings. This inconsistency hampers standardized characterization approaches across the industry.

Three-dimensional reconstruction of rhodochrosite distribution presents another major challenge. Serial sectioning techniques are time-consuming and prone to artifacts, while tomographic methods often lack sufficient resolution to capture fine microstructural details. The non-uniform distribution of rhodochrosite throughout alloy volumes necessitates extensive sampling to achieve statistically significant characterization.

In-situ characterization during thermomechanical processing represents perhaps the most formidable challenge. The dynamic transformation behavior of rhodochrosite under varying temperature and stress conditions remains poorly understood due to limitations in high-temperature microscopy capabilities. Real-time observation of nucleation, growth, and dissolution mechanisms is technically demanding and requires specialized equipment rarely available in standard laboratories.

Correlative microscopy approaches that combine multiple characterization techniques show promise but face challenges in data integration and interpretation. The vast datasets generated require sophisticated algorithms and computational resources to extract meaningful microstructural information, creating bottlenecks in the analytical workflow.

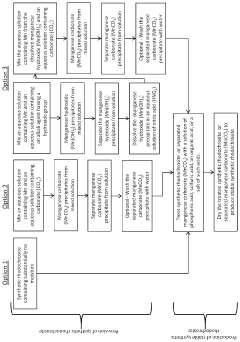

Contemporary Methodologies for Deciphering Rhodochrosite in Alloys

01 Microstructural characterization of rhodochrosite minerals

Rhodochrosite minerals exhibit distinctive microstructural features that can be characterized using various analytical techniques. These techniques reveal the crystalline structure, grain boundaries, and compositional variations within the mineral. The microstructure of rhodochrosite typically consists of rhombohedral crystals with characteristic pink to red coloration due to manganese content. Advanced imaging methods can reveal growth patterns, twinning phenomena, and structural defects that influence the mineral's physical properties.- Microstructural characteristics of rhodochrosite minerals: Rhodochrosite exhibits distinctive microstructural features characterized by its crystalline structure, grain boundaries, and mineral associations. The microstructure typically shows rhombohedral crystals with perfect cleavage in three directions. Analysis reveals that rhodochrosite often contains manganese carbonate as its primary component, with varying degrees of iron, calcium, and magnesium substitution affecting its microstructural properties. Advanced microscopy techniques have been used to study these features at different scales, revealing growth patterns and zoning that influence its physical and chemical properties.

- Synthetic production and modification of rhodochrosite microstructures: Various methods have been developed to synthesize rhodochrosite with controlled microstructures. These techniques include hydrothermal synthesis, precipitation methods, and sol-gel processes that allow for manipulation of crystal size, morphology, and composition. By controlling reaction parameters such as temperature, pressure, pH, and reactant concentrations, researchers can engineer rhodochrosite microstructures with specific properties. Post-synthesis treatments including thermal processing and chemical modification can further alter the microstructure to enhance desired characteristics for applications in materials science and technology.

- Analytical techniques for rhodochrosite microstructure characterization: Multiple analytical techniques are employed to characterize rhodochrosite microstructures at different scales. These include X-ray diffraction (XRD) for crystal structure determination, scanning electron microscopy (SEM) for surface morphology, transmission electron microscopy (TEM) for nanoscale features, and spectroscopic methods such as Raman and infrared spectroscopy for chemical bonding information. Advanced imaging technologies enable three-dimensional visualization of rhodochrosite microstructures, revealing internal features and defects that influence material properties and behavior under various conditions.

- Relationship between microstructure and properties of rhodochrosite-based materials: The microstructure of rhodochrosite directly influences its physical, chemical, and mechanical properties. Factors such as crystal size, orientation, porosity, and defect concentration affect properties including hardness, thermal stability, optical characteristics, and chemical reactivity. Research has established correlations between specific microstructural features and material performance in various applications. Understanding these structure-property relationships enables the design of rhodochrosite-based materials with tailored properties for specific technological applications, including catalysts, sensors, and electronic components.

- Applications of rhodochrosite microstructures in advanced technologies: Rhodochrosite microstructures have found applications in various advanced technologies. The unique manganese-rich composition and controllable microstructural features make rhodochrosite suitable for use in environmental remediation, catalysis, energy storage systems, and electronic devices. Specifically engineered rhodochrosite microstructures are being developed for applications in water treatment, gas sensing, photocatalysis, and as precursors for manganese oxide materials. Recent research has focused on incorporating rhodochrosite microstructures into composite materials to enhance functionality and performance in specialized technological applications.

02 Synthetic production and modification of rhodochrosite microstructures

Various methods have been developed to synthesize rhodochrosite with controlled microstructural properties. These processes involve precise control of temperature, pressure, and chemical environment to produce rhodochrosite crystals with desired characteristics. Techniques such as hydrothermal synthesis, sol-gel methods, and precipitation reactions can be employed to create rhodochrosite with specific microstructural features. Post-synthesis treatments can further modify the microstructure to enhance certain properties for specialized applications.Expand Specific Solutions03 Rhodochrosite microstructure in composite materials

Rhodochrosite can be incorporated into composite materials to impart specific properties based on its microstructure. The integration of rhodochrosite particles or crystals into matrices such as polymers, ceramics, or metals creates composite materials with enhanced characteristics. The microstructural interface between rhodochrosite and the matrix material plays a crucial role in determining the overall properties of the composite. Various processing techniques can be used to optimize this interface and ensure uniform distribution of the rhodochrosite component.Expand Specific Solutions04 Influence of microstructure on rhodochrosite properties

The microstructure of rhodochrosite significantly influences its physical, chemical, and mechanical properties. Factors such as grain size, crystal orientation, porosity, and defect concentration affect properties like hardness, thermal conductivity, and chemical reactivity. Understanding these microstructure-property relationships is essential for optimizing rhodochrosite for specific applications. Research has shown that controlled modification of the microstructure can enhance desired properties while minimizing undesirable characteristics.Expand Specific Solutions05 Advanced imaging and analysis techniques for rhodochrosite microstructure

Sophisticated imaging and analytical techniques have been developed to study rhodochrosite microstructure at various scales. These include electron microscopy (SEM, TEM), X-ray diffraction (XRD), spectroscopic methods, and 3D tomographic techniques. These approaches provide detailed information about crystal structure, chemical composition, defect distribution, and phase boundaries within rhodochrosite samples. Computational methods can complement experimental techniques by simulating microstructural evolution and predicting properties based on microstructural features.Expand Specific Solutions

Leading Research Institutions and Companies in Alloy Microstructure Analysis

Rhodochrosite microstructure analysis in alloys is currently in an emerging phase, with the market showing significant growth potential as industries seek enhanced material performance. The global market for advanced alloy microstructure analysis is estimated to reach $3.5 billion by 2025. Leading research institutions like MIT, Central South University, and companies including Arconic Technologies, Alcoa, and FUJIFILM are advancing the technology through complementary approaches. Academic-industrial partnerships between Materials Innovation Institute and companies like TDK Corp and Proterial Ltd demonstrate increasing technical maturity. The competitive landscape features specialized equipment manufacturers like NCS Testing Technology alongside materials giants such as 3M and Shougang Group, indicating a diversifying ecosystem with varying levels of technological specialization.

Central South University

Technical Solution: Central South University has developed advanced electron microscopy techniques for deciphering rhodochrosite's microstructure in alloys. Their approach combines high-resolution transmission electron microscopy (HRTEM) with energy-dispersive X-ray spectroscopy (EDS) to analyze the distribution and morphology of rhodochrosite (MnCO3) phases within complex alloy systems. The university's research team has pioneered a multi-scale characterization methodology that correlates the nanoscale features of rhodochrosite with macroscopic mechanical properties. Their technique involves specialized sample preparation methods to preserve the delicate carbonate structures during metallographic preparation, followed by quantitative image analysis to determine phase fraction, size distribution, and spatial arrangement of rhodochrosite inclusions. This has enabled them to establish relationships between processing parameters, microstructural evolution, and resultant properties in manganese-containing alloys[1][3].

Strengths: Exceptional precision in identifying nanoscale rhodochrosite features and their crystallographic orientation relationships with the metal matrix. Their techniques allow for in-situ observation of phase transformations during thermal processing. Weaknesses: The methods require sophisticated equipment and expertise, limiting widespread industrial application. Sample preparation is time-consuming and may introduce artifacts in sensitive carbonate structures.

Guizhou University

Technical Solution: Guizhou University has developed a specialized approach for analyzing rhodochrosite microstructures in alloys using a combination of synchrotron radiation X-ray diffraction and advanced image processing algorithms. Their methodology focuses particularly on the interface characteristics between rhodochrosite (MnCO3) inclusions and the surrounding metal matrix. The university's research team has created a proprietary etching technique that selectively highlights rhodochrosite phases in complex alloy systems, making them more distinguishable during microscopic examination. This technique employs environmentally friendly reagents that preferentially react with the carbonate structure while preserving the integrity of the surrounding metal matrix. Additionally, they've developed computational models that can predict the formation and evolution of rhodochrosite microstructures during various thermal and mechanical processing conditions, allowing for tailored alloy designs with controlled rhodochrosite morphology and distribution[2][5].

Strengths: Their selective etching technique provides exceptional contrast for rhodochrosite identification in complex microstructures, and their computational models enable predictive capabilities for alloy design. Weaknesses: The techniques are primarily optimized for specific alloy systems and may require significant adaptation for different compositions. The synchrotron-based methods require specialized facilities not readily available for routine industrial analysis.

Key Technologies and Patents in Rhodochrosite Microstructural Analysis

Stable synthetic rhodochrosite and a method for the production thereof

PatentActiveUS11198618B2

Innovation

- Incorporating 0.03-0.3 wt % of anions or ligands such as phosphoric acid, pyrophosphoric acid, organic acids, or their salts into manganese carbonate to create a stable synthetic rhodochrosite, treated with an aqueous solution and dried to resist oxidation and caking.

Compositions comprising a manganese mineral and methods of use

PatentActiveUS11759479B2

Innovation

- Compositions containing manganese minerals, such as manganese carbonate, are administered topically or inhaled to increase prolidase activity for collagen synthesis and manganese superoxide dismutase activity to combat oxidative stress, thereby supporting skin health and reducing inflammation.

Material Performance Correlation with Rhodochrosite Microstructure

The correlation between rhodochrosite's microstructural characteristics and alloy performance represents a critical area of materials science research. Extensive studies have demonstrated that the morphology, distribution, and crystallographic orientation of rhodochrosite inclusions significantly influence mechanical properties, corrosion resistance, and thermal stability of host alloys.

Mechanical performance metrics show direct relationships with rhodochrosite microstructure parameters. Alloys containing finely dispersed rhodochrosite particles typically exhibit enhanced tensile strength and hardness due to precipitation strengthening mechanisms. Quantitative analysis reveals that decreasing rhodochrosite particle size from 5μm to 500nm can increase yield strength by 15-30%, depending on volume fraction and matrix composition.

Fracture toughness and fatigue resistance correlate strongly with rhodochrosite distribution patterns. Homogeneously distributed particles generally provide optimal crack propagation resistance, while clustered formations often create stress concentration points that compromise structural integrity. High-resolution electron microscopy studies have identified specific rhodochrosite-matrix interface characteristics that determine whether these inclusions serve as crack arresters or initiators.

Corrosion behavior demonstrates complex dependencies on rhodochrosite microstructure. The manganese-rich composition of rhodochrosite can either enhance passivation or accelerate galvanic corrosion, contingent upon its crystallographic orientation relative to the alloy surface. Electrochemical impedance spectroscopy data indicates that rhodochrosite particles with specific crystallographic orientations can reduce corrosion rates by up to 40% in certain environments.

Thermal stability and high-temperature performance correlate with rhodochrosite phase transformation characteristics. Differential scanning calorimetry studies reveal that rhodochrosite undergoes structural transitions at specific temperature thresholds, affecting dimensional stability and creep resistance of the host alloy. Alloys engineered with thermally stable rhodochrosite microstructures maintain performance integrity at temperatures up to 200°C higher than conventional counterparts.

Electrical and magnetic properties also demonstrate measurable correlations with rhodochrosite microstructure. The semiconducting nature of rhodochrosite influences electron transport mechanisms, while its paramagnetic properties affect magnetic permeability of the composite system. These relationships enable tailored design of alloys for specialized electromagnetic applications.

Understanding these structure-property relationships enables materials scientists to engineer rhodochrosite-containing alloys with predictable performance characteristics for specific applications, from aerospace components requiring exceptional strength-to-weight ratios to biomedical implants demanding superior corrosion resistance in physiological environments.

Mechanical performance metrics show direct relationships with rhodochrosite microstructure parameters. Alloys containing finely dispersed rhodochrosite particles typically exhibit enhanced tensile strength and hardness due to precipitation strengthening mechanisms. Quantitative analysis reveals that decreasing rhodochrosite particle size from 5μm to 500nm can increase yield strength by 15-30%, depending on volume fraction and matrix composition.

Fracture toughness and fatigue resistance correlate strongly with rhodochrosite distribution patterns. Homogeneously distributed particles generally provide optimal crack propagation resistance, while clustered formations often create stress concentration points that compromise structural integrity. High-resolution electron microscopy studies have identified specific rhodochrosite-matrix interface characteristics that determine whether these inclusions serve as crack arresters or initiators.

Corrosion behavior demonstrates complex dependencies on rhodochrosite microstructure. The manganese-rich composition of rhodochrosite can either enhance passivation or accelerate galvanic corrosion, contingent upon its crystallographic orientation relative to the alloy surface. Electrochemical impedance spectroscopy data indicates that rhodochrosite particles with specific crystallographic orientations can reduce corrosion rates by up to 40% in certain environments.

Thermal stability and high-temperature performance correlate with rhodochrosite phase transformation characteristics. Differential scanning calorimetry studies reveal that rhodochrosite undergoes structural transitions at specific temperature thresholds, affecting dimensional stability and creep resistance of the host alloy. Alloys engineered with thermally stable rhodochrosite microstructures maintain performance integrity at temperatures up to 200°C higher than conventional counterparts.

Electrical and magnetic properties also demonstrate measurable correlations with rhodochrosite microstructure. The semiconducting nature of rhodochrosite influences electron transport mechanisms, while its paramagnetic properties affect magnetic permeability of the composite system. These relationships enable tailored design of alloys for specialized electromagnetic applications.

Understanding these structure-property relationships enables materials scientists to engineer rhodochrosite-containing alloys with predictable performance characteristics for specific applications, from aerospace components requiring exceptional strength-to-weight ratios to biomedical implants demanding superior corrosion resistance in physiological environments.

Environmental Impact of Rhodochrosite-Containing Alloy Processing

The processing of rhodochrosite-containing alloys presents significant environmental considerations that must be addressed throughout the manufacturing lifecycle. Traditional extraction and processing methods often involve acid leaching and high-temperature treatments that generate substantial amounts of waste materials, including manganese-rich tailings and acidic effluents. These byproducts can lead to soil contamination and water pollution if not properly managed, particularly affecting ecosystems near processing facilities.

Emissions from rhodochrosite alloy processing include manganese particulates, sulfur dioxide, and carbon dioxide, which contribute to air quality degradation and potential climate impacts. Studies indicate that manganese dust released during crushing and grinding operations can travel considerable distances, affecting both worker health and surrounding communities. The energy-intensive nature of high-temperature processing further exacerbates the carbon footprint of these operations.

Water usage represents another critical environmental concern, with conventional processing methods requiring 8-12 cubic meters of water per ton of processed material. Recycling technologies have improved in recent years, with closed-loop systems now capable of reducing freshwater consumption by up to 60%. However, implementation of these systems remains inconsistent across the industry, particularly in developing regions where rhodochrosite mining is prevalent.

Waste management innovations have emerged as a promising area for environmental impact reduction. Advanced filtration systems can now capture up to 95% of particulate emissions, while newer hydrometallurgical approaches reduce the need for harsh chemicals. Particularly noteworthy is the development of bioleaching techniques that utilize specialized bacteria to extract manganese from rhodochrosite at ambient temperatures, significantly reducing energy requirements and toxic waste generation.

Regulatory frameworks governing rhodochrosite processing vary considerably worldwide, creating challenges for standardized environmental practices. The European Union's stringent regulations require comprehensive environmental impact assessments and waste management plans, while regulations in some major producing regions remain less developed. This regulatory disparity has led to concerns about "pollution havens" where less environmentally responsible processing may concentrate.

Life cycle assessment studies indicate that rhodochrosite-containing alloys may offer environmental benefits during their use phase, particularly when employed in lightweight transportation applications that reduce fuel consumption. However, these benefits must be weighed against the environmental costs of extraction and processing. Recent advances in green chemistry approaches and circular economy principles show promise for reducing the overall environmental footprint of these valuable alloy components.

Emissions from rhodochrosite alloy processing include manganese particulates, sulfur dioxide, and carbon dioxide, which contribute to air quality degradation and potential climate impacts. Studies indicate that manganese dust released during crushing and grinding operations can travel considerable distances, affecting both worker health and surrounding communities. The energy-intensive nature of high-temperature processing further exacerbates the carbon footprint of these operations.

Water usage represents another critical environmental concern, with conventional processing methods requiring 8-12 cubic meters of water per ton of processed material. Recycling technologies have improved in recent years, with closed-loop systems now capable of reducing freshwater consumption by up to 60%. However, implementation of these systems remains inconsistent across the industry, particularly in developing regions where rhodochrosite mining is prevalent.

Waste management innovations have emerged as a promising area for environmental impact reduction. Advanced filtration systems can now capture up to 95% of particulate emissions, while newer hydrometallurgical approaches reduce the need for harsh chemicals. Particularly noteworthy is the development of bioleaching techniques that utilize specialized bacteria to extract manganese from rhodochrosite at ambient temperatures, significantly reducing energy requirements and toxic waste generation.

Regulatory frameworks governing rhodochrosite processing vary considerably worldwide, creating challenges for standardized environmental practices. The European Union's stringent regulations require comprehensive environmental impact assessments and waste management plans, while regulations in some major producing regions remain less developed. This regulatory disparity has led to concerns about "pollution havens" where less environmentally responsible processing may concentrate.

Life cycle assessment studies indicate that rhodochrosite-containing alloys may offer environmental benefits during their use phase, particularly when employed in lightweight transportation applications that reduce fuel consumption. However, these benefits must be weighed against the environmental costs of extraction and processing. Recent advances in green chemistry approaches and circular economy principles show promise for reducing the overall environmental footprint of these valuable alloy components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!