How Throttle Body Technology Supports Space Habitat Sustainability

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution in Space Habitats

The evolution of throttle body technology in space habitats represents a critical aspect of life support systems and resource management in extraterrestrial environments. Initially developed for automotive applications, throttle bodies have undergone significant adaptations to meet the unique challenges of space habitation.

In the early stages of space habitat development, throttle bodies were primarily used for controlling air flow in environmental control and life support systems (ECLSS). These early designs focused on maintaining proper oxygen levels and air circulation within confined spaces. As space missions extended in duration, the role of throttle bodies expanded to include more sophisticated functions.

The next phase of evolution saw the integration of throttle bodies into water reclamation and purification systems. Engineers adapted the technology to precisely control the flow of water through filtration and treatment processes, ensuring efficient use of this precious resource in closed-loop systems. This adaptation significantly improved the sustainability of long-term space habitats by reducing water waste and enhancing recycling capabilities.

As space habitats grew in complexity, throttle body technology found applications in waste management systems. Modified throttle bodies were used to regulate the flow of gases produced during waste processing, contributing to odor control and the prevention of harmful gas buildup within the habitat. This application further demonstrated the versatility of throttle body technology in addressing multiple aspects of habitat sustainability.

The most recent advancements in throttle body technology for space habitats have focused on energy efficiency and miniaturization. Modern designs incorporate lightweight materials and advanced sensors, allowing for more precise control of various flows while consuming less power. These improvements have directly contributed to the overall energy efficiency of space habitats, a critical factor in long-term sustainability.

Looking towards future developments, researchers are exploring the potential of smart throttle bodies that can autonomously adjust to changing environmental conditions within the habitat. These systems would use artificial intelligence to optimize resource usage, further enhancing the sustainability of space habitats. Additionally, there is ongoing research into using throttle body principles in 3D printing applications within space, potentially allowing for on-demand manufacturing of replacement parts and tools.

The evolution of throttle body technology in space habitats exemplifies the innovative adaptation of terrestrial technologies to meet the unique challenges of space exploration. As we continue to push the boundaries of human presence in space, the role of throttle bodies in supporting habitat sustainability is likely to expand, driving further innovations in this critical technology.

In the early stages of space habitat development, throttle bodies were primarily used for controlling air flow in environmental control and life support systems (ECLSS). These early designs focused on maintaining proper oxygen levels and air circulation within confined spaces. As space missions extended in duration, the role of throttle bodies expanded to include more sophisticated functions.

The next phase of evolution saw the integration of throttle bodies into water reclamation and purification systems. Engineers adapted the technology to precisely control the flow of water through filtration and treatment processes, ensuring efficient use of this precious resource in closed-loop systems. This adaptation significantly improved the sustainability of long-term space habitats by reducing water waste and enhancing recycling capabilities.

As space habitats grew in complexity, throttle body technology found applications in waste management systems. Modified throttle bodies were used to regulate the flow of gases produced during waste processing, contributing to odor control and the prevention of harmful gas buildup within the habitat. This application further demonstrated the versatility of throttle body technology in addressing multiple aspects of habitat sustainability.

The most recent advancements in throttle body technology for space habitats have focused on energy efficiency and miniaturization. Modern designs incorporate lightweight materials and advanced sensors, allowing for more precise control of various flows while consuming less power. These improvements have directly contributed to the overall energy efficiency of space habitats, a critical factor in long-term sustainability.

Looking towards future developments, researchers are exploring the potential of smart throttle bodies that can autonomously adjust to changing environmental conditions within the habitat. These systems would use artificial intelligence to optimize resource usage, further enhancing the sustainability of space habitats. Additionally, there is ongoing research into using throttle body principles in 3D printing applications within space, potentially allowing for on-demand manufacturing of replacement parts and tools.

The evolution of throttle body technology in space habitats exemplifies the innovative adaptation of terrestrial technologies to meet the unique challenges of space exploration. As we continue to push the boundaries of human presence in space, the role of throttle bodies in supporting habitat sustainability is likely to expand, driving further innovations in this critical technology.

Space Habitat Sustainability Demands

Space habitat sustainability is a critical concern for long-term human presence in extraterrestrial environments. As we venture further into space exploration and consider establishing permanent settlements beyond Earth, the demand for sustainable systems and technologies becomes paramount. Space habitats must operate in closed-loop environments, where resources are limited and waste management is crucial. This necessitates the development of highly efficient life support systems that can recycle air, water, and other essential resources.

The primary challenge in space habitat sustainability lies in maintaining a stable and habitable environment for extended periods. This includes regulating atmospheric composition, temperature, and pressure, as well as managing waste and producing food. Advanced air revitalization systems are required to remove carbon dioxide and other contaminants while replenishing oxygen levels. Water recycling and purification technologies are essential to ensure a continuous supply of clean water for drinking, hygiene, and other uses.

Energy management is another critical aspect of space habitat sustainability. Solar power is often the primary energy source for space habitats, but efficient energy storage and distribution systems are necessary to maintain operations during periods of darkness or reduced solar exposure. Additionally, thermal management systems must be designed to regulate internal temperatures and protect inhabitants from extreme external conditions.

Food production in space habitats presents unique challenges and opportunities. Sustainable agriculture techniques, such as hydroponics and aeroponics, are being developed to grow crops in controlled environments with minimal resource consumption. These systems must be optimized for space constraints and designed to operate in microgravity or low-gravity conditions.

Waste management and recycling are crucial components of space habitat sustainability. Advanced waste processing systems are needed to convert organic waste into usable resources, such as fertilizer for plant growth or fuel for energy production. Inorganic waste must be efficiently recycled or repurposed to minimize the need for resupply missions and reduce the overall environmental impact of the habitat.

The psychological well-being of inhabitants is an often-overlooked aspect of space habitat sustainability. Designing living spaces that promote mental health and social interaction is essential for long-term missions. This includes considerations for privacy, communal areas, and recreational facilities that can help mitigate the effects of isolation and confinement.

As we continue to advance space exploration and habitat technologies, the integration of artificial intelligence and automation will play an increasingly important role in maintaining sustainable environments. These systems can optimize resource usage, predict and prevent potential failures, and adapt to changing conditions, thereby enhancing the overall sustainability and resilience of space habitats.

The primary challenge in space habitat sustainability lies in maintaining a stable and habitable environment for extended periods. This includes regulating atmospheric composition, temperature, and pressure, as well as managing waste and producing food. Advanced air revitalization systems are required to remove carbon dioxide and other contaminants while replenishing oxygen levels. Water recycling and purification technologies are essential to ensure a continuous supply of clean water for drinking, hygiene, and other uses.

Energy management is another critical aspect of space habitat sustainability. Solar power is often the primary energy source for space habitats, but efficient energy storage and distribution systems are necessary to maintain operations during periods of darkness or reduced solar exposure. Additionally, thermal management systems must be designed to regulate internal temperatures and protect inhabitants from extreme external conditions.

Food production in space habitats presents unique challenges and opportunities. Sustainable agriculture techniques, such as hydroponics and aeroponics, are being developed to grow crops in controlled environments with minimal resource consumption. These systems must be optimized for space constraints and designed to operate in microgravity or low-gravity conditions.

Waste management and recycling are crucial components of space habitat sustainability. Advanced waste processing systems are needed to convert organic waste into usable resources, such as fertilizer for plant growth or fuel for energy production. Inorganic waste must be efficiently recycled or repurposed to minimize the need for resupply missions and reduce the overall environmental impact of the habitat.

The psychological well-being of inhabitants is an often-overlooked aspect of space habitat sustainability. Designing living spaces that promote mental health and social interaction is essential for long-term missions. This includes considerations for privacy, communal areas, and recreational facilities that can help mitigate the effects of isolation and confinement.

As we continue to advance space exploration and habitat technologies, the integration of artificial intelligence and automation will play an increasingly important role in maintaining sustainable environments. These systems can optimize resource usage, predict and prevent potential failures, and adapt to changing conditions, thereby enhancing the overall sustainability and resilience of space habitats.

Throttle Body Challenges in Space

The implementation of throttle body technology in space habitats presents unique challenges due to the extreme conditions and critical nature of life support systems. One of the primary obstacles is the microgravity environment, which significantly alters fluid dynamics and affects the performance of traditional throttle body designs. The absence of gravity-driven flow necessitates the development of specialized mechanisms to ensure precise control over fluid and gas mixtures in life support and propulsion systems.

Material selection becomes crucial in space applications, as throttle bodies must withstand extreme temperature fluctuations, radiation exposure, and the corrosive effects of certain gases and fluids used in space habitats. The need for lightweight yet durable materials that can maintain structural integrity and functionality over extended periods adds another layer of complexity to the design process.

The vacuum of space introduces additional challenges, particularly in sealing and preventing leaks. Throttle bodies must be engineered to operate flawlessly in a near-zero pressure environment, requiring innovative sealing technologies and fail-safe mechanisms to prevent catastrophic failures that could compromise the habitat's integrity.

Maintenance and repair of throttle bodies in space present significant logistical hurdles. The limited resources and tools available on a space habitat necessitate designs that are not only reliable but also easily serviceable by astronauts with minimal specialized equipment. This requirement often conflicts with the need for complex, high-performance systems, creating a delicate balance between functionality and maintainability.

Power consumption is another critical factor, as energy resources in space habitats are finite and carefully managed. Throttle body systems must be designed for maximum efficiency, minimizing power draw while maintaining precise control over fluid and gas flows. This challenge is compounded by the need for redundancy in critical systems, which can increase overall power requirements.

The integration of throttle bodies with other life support and propulsion systems in a space habitat requires a holistic approach to design and engineering. Compatibility with various gases, liquids, and control systems is essential, as is the ability to operate seamlessly within the broader ecosystem of the habitat's environmental control and life support systems (ECLSS).

Lastly, the long-term reliability of throttle body technology in space is a paramount concern. With missions and habitats designed for extended durations, these components must function flawlessly for years without the possibility of easy replacement or major overhaul. This necessitates extensive testing, simulation, and the development of predictive maintenance strategies to ensure the longevity and reliability of throttle body systems in the unforgiving environment of space.

Material selection becomes crucial in space applications, as throttle bodies must withstand extreme temperature fluctuations, radiation exposure, and the corrosive effects of certain gases and fluids used in space habitats. The need for lightweight yet durable materials that can maintain structural integrity and functionality over extended periods adds another layer of complexity to the design process.

The vacuum of space introduces additional challenges, particularly in sealing and preventing leaks. Throttle bodies must be engineered to operate flawlessly in a near-zero pressure environment, requiring innovative sealing technologies and fail-safe mechanisms to prevent catastrophic failures that could compromise the habitat's integrity.

Maintenance and repair of throttle bodies in space present significant logistical hurdles. The limited resources and tools available on a space habitat necessitate designs that are not only reliable but also easily serviceable by astronauts with minimal specialized equipment. This requirement often conflicts with the need for complex, high-performance systems, creating a delicate balance between functionality and maintainability.

Power consumption is another critical factor, as energy resources in space habitats are finite and carefully managed. Throttle body systems must be designed for maximum efficiency, minimizing power draw while maintaining precise control over fluid and gas flows. This challenge is compounded by the need for redundancy in critical systems, which can increase overall power requirements.

The integration of throttle bodies with other life support and propulsion systems in a space habitat requires a holistic approach to design and engineering. Compatibility with various gases, liquids, and control systems is essential, as is the ability to operate seamlessly within the broader ecosystem of the habitat's environmental control and life support systems (ECLSS).

Lastly, the long-term reliability of throttle body technology in space is a paramount concern. With missions and habitats designed for extended durations, these components must function flawlessly for years without the possibility of easy replacement or major overhaul. This necessitates extensive testing, simulation, and the development of predictive maintenance strategies to ensure the longevity and reliability of throttle body systems in the unforgiving environment of space.

Current Space Throttle Solutions

01 Electronic throttle control systems

Advanced throttle body technology incorporates electronic control systems to regulate airflow into the engine. These systems use sensors and actuators to precisely adjust the throttle position based on various inputs, improving engine performance and fuel efficiency.- Electronic throttle control systems: Advanced throttle body technology incorporates electronic control systems to regulate airflow into the engine. These systems use sensors and actuators to precisely adjust the throttle position based on various engine parameters and driver input, improving fuel efficiency and engine performance.

- Throttle body design improvements: Innovations in throttle body design focus on optimizing airflow characteristics and reducing turbulence. This includes refined shapes, improved butterfly valve designs, and the use of advanced materials to enhance durability and performance while minimizing weight.

- Integration of additional components: Modern throttle bodies often integrate additional components such as idle air control valves, throttle position sensors, and air temperature sensors. This integration simplifies the overall engine management system and improves reliability by reducing the number of separate components.

- Throttle body manufacturing techniques: Advanced manufacturing techniques are employed to produce high-precision throttle bodies. These may include 3D printing, CNC machining, and innovative casting methods to achieve tighter tolerances and more consistent performance across production runs.

- Throttle body cleaning and maintenance systems: Technologies have been developed to address the issue of carbon buildup in throttle bodies. These include self-cleaning mechanisms, specialized coatings to prevent deposit formation, and improved designs that facilitate easier maintenance and cleaning procedures.

02 Throttle body design improvements

Innovations in throttle body design focus on optimizing airflow characteristics and reducing turbulence. This includes refined shapes, improved sealing mechanisms, and integration of additional components to enhance overall engine performance and responsiveness.Expand Specific Solutions03 Integration of idle air control

Modern throttle bodies often incorporate idle air control mechanisms directly into their design. This integration allows for better management of engine idle speed and smoother transitions between idle and acceleration, improving overall engine stability and efficiency.Expand Specific Solutions04 Multi-valve throttle bodies

Advanced throttle body designs may include multiple valves or butterflies to provide more precise control over airflow. This configuration allows for better management of air intake across different engine operating conditions, potentially improving performance and fuel economy.Expand Specific Solutions05 Throttle body materials and manufacturing

Advancements in materials science and manufacturing techniques have led to the development of lighter, more durable throttle bodies. These improvements can include the use of composite materials, advanced coatings, and precision manufacturing methods to enhance performance and longevity.Expand Specific Solutions

Key Space Throttle Manufacturers

The throttle body technology market for space habitat sustainability is in its early development stage, with significant potential for growth as space exploration and colonization efforts intensify. The market size is currently limited but expected to expand rapidly as more countries and private companies invest in space habitation projects. Technologically, the field is still evolving, with companies like The Boeing Co. and ILC Dover LP leading the way in aerospace innovations. Other players such as Robert Bosch GmbH and DENSO Corp. are leveraging their automotive expertise to contribute to space-grade throttle body systems. The involvement of research institutions like Chandigarh University and Southeast University indicates ongoing R&D efforts to advance this technology for space applications.

The Boeing Co.

Technical Solution: Boeing's approach to throttle body technology for space habitat sustainability focuses on advanced Environmental Control and Life Support Systems (ECLSS). Their system incorporates a sophisticated throttle body mechanism that precisely regulates air and fluid flow within the habitat. This technology enables fine-tuned control of atmospheric composition, pressure, and temperature, crucial for long-term space missions[1]. Boeing's throttle body design integrates with their cutting-edge air revitalization system, which removes carbon dioxide and other contaminants while replenishing oxygen. The system also manages humidity levels and filters particulates, ensuring a stable and healthy environment for astronauts[3]. Additionally, Boeing's throttle body technology plays a key role in their water recovery and management system, optimizing the use of limited water resources in space habitats[5].

Strengths: Highly integrated system design, proven reliability in space applications, and advanced control algorithms for optimal resource management. Weaknesses: High complexity may lead to increased maintenance requirements and potential single points of failure.

ILC Dover LP

Technical Solution: ILC Dover's approach to throttle body technology in space habitat sustainability centers on their expertise in flexible containment solutions. Their innovative design incorporates expandable habitats with integrated throttle body systems for atmosphere control. The throttle bodies are engineered to work within the unique constraints of inflatable structures, allowing for precise regulation of air pressure and composition as the habitat expands or contracts[2]. ILC Dover's system includes multi-layered, puncture-resistant materials that house miniaturized throttle bodies at key junctions, enabling localized control of air flow and pressure throughout the habitat[4]. This distributed approach enhances overall system resilience and allows for more efficient use of resources. The company has also developed smart fabrics with embedded sensors that work in conjunction with the throttle bodies to continuously monitor and adjust the internal environment[6].

Strengths: Lightweight and compact design, adaptability to various habitat configurations, and integration with advanced materials. Weaknesses: Potential challenges in scaling up for larger habitats and long-term durability in harsh space environments.

Innovative Space Throttle Designs

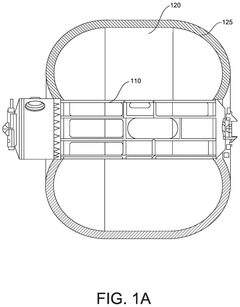

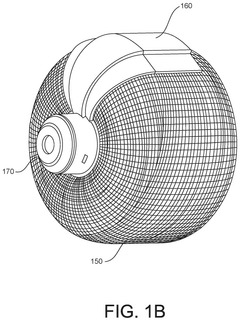

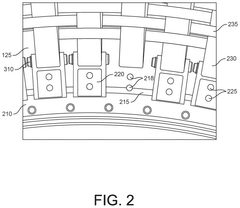

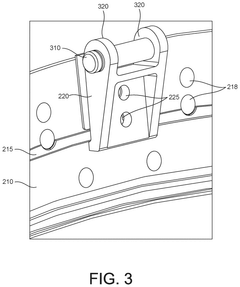

Mounting flange and bracket for a space habitat

PatentPendingUS20250137578A1

Innovation

- A mounting flange and bracket system is designed to securely couple the bladder of a space habitat to a cylindrical core, featuring a lip on the mounting flange, a bracket with a pin and protrusion for secure attachment, and a clamping ring to maintain an airtight seal.

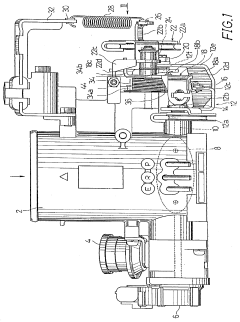

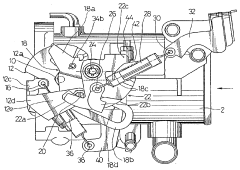

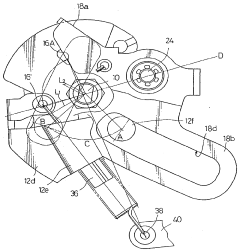

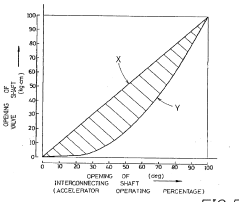

Throttle body having interconnecting lever for converting an operational amount of accelerator to an opening of throttle valve

PatentInactiveUS4945874A

Innovation

- Incorporating a tension spring to stabilize the throttle valve, using a spiral spring for consistent force, and an eccentric mounting member for cam follower adjustment, along with separating the interconnecting lever into two parts to decouple auto speed control from the accelerator pedal, ensuring smooth operation and fine adjustment capabilities.

Space Habitat Resource Management

Space habitat resource management is a critical aspect of ensuring long-term sustainability in extraterrestrial environments. Throttle body technology plays a significant role in optimizing resource utilization and maintaining life support systems within these habitats. By precisely controlling the flow of gases and liquids, throttle bodies contribute to efficient air circulation, water distribution, and waste management processes.

In space habitats, air quality management is paramount. Throttle bodies are integrated into ventilation systems to regulate the flow of air between different compartments, ensuring proper oxygen levels and removing carbon dioxide. This technology allows for dynamic adjustments based on occupancy and activity levels, minimizing energy consumption while maintaining a healthy atmosphere.

Water management in space habitats benefits greatly from throttle body technology. These devices control the flow of water through filtration and recycling systems, optimizing the use of this precious resource. By precisely metering water distribution, throttle bodies help prevent waste and ensure equitable access to clean water for all habitat occupants.

Waste management systems in space habitats also rely on throttle body technology. These devices regulate the flow of liquid and gaseous waste through treatment processes, ensuring efficient recycling and safe disposal. The precise control offered by throttle bodies helps maintain sanitary conditions and prevents contamination of living spaces.

Energy distribution within space habitats is another area where throttle body technology proves invaluable. By regulating the flow of coolants in power generation systems and controlling the distribution of electricity, these devices help optimize energy usage and prevent overloads. This contributes to the overall stability and longevity of the habitat's power infrastructure.

Throttle bodies also play a crucial role in maintaining optimal pressure levels within different sections of the space habitat. By controlling the flow of gases between compartments, these devices help create a stable and comfortable living environment for inhabitants. This is particularly important in multi-level habitats or those with varying atmospheric requirements.

In food production systems, throttle body technology aids in the precise delivery of nutrients and water to hydroponic or aeroponic gardens. This level of control ensures efficient use of resources and maximizes crop yields, contributing to the habitat's food security and sustainability.

As space habitats evolve and expand, the role of throttle body technology in resource management will likely grow. Future developments may include more advanced, AI-driven throttle systems that can anticipate and respond to changing environmental conditions, further enhancing the efficiency and sustainability of extraterrestrial living spaces.

In space habitats, air quality management is paramount. Throttle bodies are integrated into ventilation systems to regulate the flow of air between different compartments, ensuring proper oxygen levels and removing carbon dioxide. This technology allows for dynamic adjustments based on occupancy and activity levels, minimizing energy consumption while maintaining a healthy atmosphere.

Water management in space habitats benefits greatly from throttle body technology. These devices control the flow of water through filtration and recycling systems, optimizing the use of this precious resource. By precisely metering water distribution, throttle bodies help prevent waste and ensure equitable access to clean water for all habitat occupants.

Waste management systems in space habitats also rely on throttle body technology. These devices regulate the flow of liquid and gaseous waste through treatment processes, ensuring efficient recycling and safe disposal. The precise control offered by throttle bodies helps maintain sanitary conditions and prevents contamination of living spaces.

Energy distribution within space habitats is another area where throttle body technology proves invaluable. By regulating the flow of coolants in power generation systems and controlling the distribution of electricity, these devices help optimize energy usage and prevent overloads. This contributes to the overall stability and longevity of the habitat's power infrastructure.

Throttle bodies also play a crucial role in maintaining optimal pressure levels within different sections of the space habitat. By controlling the flow of gases between compartments, these devices help create a stable and comfortable living environment for inhabitants. This is particularly important in multi-level habitats or those with varying atmospheric requirements.

In food production systems, throttle body technology aids in the precise delivery of nutrients and water to hydroponic or aeroponic gardens. This level of control ensures efficient use of resources and maximizes crop yields, contributing to the habitat's food security and sustainability.

As space habitats evolve and expand, the role of throttle body technology in resource management will likely grow. Future developments may include more advanced, AI-driven throttle systems that can anticipate and respond to changing environmental conditions, further enhancing the efficiency and sustainability of extraterrestrial living spaces.

Throttle Body Reliability in Space

Throttle body reliability is a critical factor in ensuring the sustainability of space habitats. In the harsh and unforgiving environment of space, every component must perform flawlessly to maintain life support systems and overall habitat functionality. The throttle body, a key component in regulating air flow and fuel mixture in propulsion and environmental control systems, faces unique challenges in space applications.

The extreme temperature fluctuations, radiation exposure, and microgravity conditions in space can significantly impact the performance and longevity of throttle bodies. These factors necessitate the development of specialized materials and designs that can withstand the rigors of space environments while maintaining precise control over fluid dynamics. Advanced alloys and composite materials are being explored to enhance durability and reduce wear, ensuring consistent performance over extended periods.

Reliability in space throttle bodies is further improved through redundancy and fail-safe mechanisms. Multiple throttle bodies may be incorporated into critical systems, allowing for continued operation even if one unit fails. Additionally, advanced sensor technologies are integrated to monitor throttle body performance in real-time, enabling predictive maintenance and early detection of potential issues.

The use of electronic throttle control (ETC) systems in space applications has significantly enhanced reliability by eliminating mechanical linkages prone to failure. These systems offer more precise control and adaptability to changing environmental conditions, crucial for maintaining optimal habitat conditions. Furthermore, ETC systems can be easily integrated with spacecraft computer systems for comprehensive monitoring and adjustment.

To address the challenge of lubricant degradation in space, researchers are developing self-lubricating materials and dry lubricant coatings for throttle body components. These innovations aim to reduce friction and wear without relying on traditional liquid lubricants that may break down or evaporate in the vacuum of space.

Reliability testing for space-grade throttle bodies involves rigorous protocols that simulate the extreme conditions of space environments. These tests include thermal cycling, radiation exposure, vibration testing, and long-duration performance evaluations. Such comprehensive testing ensures that throttle bodies can maintain their functionality throughout extended space missions, contributing to the overall sustainability of space habitats.

The extreme temperature fluctuations, radiation exposure, and microgravity conditions in space can significantly impact the performance and longevity of throttle bodies. These factors necessitate the development of specialized materials and designs that can withstand the rigors of space environments while maintaining precise control over fluid dynamics. Advanced alloys and composite materials are being explored to enhance durability and reduce wear, ensuring consistent performance over extended periods.

Reliability in space throttle bodies is further improved through redundancy and fail-safe mechanisms. Multiple throttle bodies may be incorporated into critical systems, allowing for continued operation even if one unit fails. Additionally, advanced sensor technologies are integrated to monitor throttle body performance in real-time, enabling predictive maintenance and early detection of potential issues.

The use of electronic throttle control (ETC) systems in space applications has significantly enhanced reliability by eliminating mechanical linkages prone to failure. These systems offer more precise control and adaptability to changing environmental conditions, crucial for maintaining optimal habitat conditions. Furthermore, ETC systems can be easily integrated with spacecraft computer systems for comprehensive monitoring and adjustment.

To address the challenge of lubricant degradation in space, researchers are developing self-lubricating materials and dry lubricant coatings for throttle body components. These innovations aim to reduce friction and wear without relying on traditional liquid lubricants that may break down or evaporate in the vacuum of space.

Reliability testing for space-grade throttle bodies involves rigorous protocols that simulate the extreme conditions of space environments. These tests include thermal cycling, radiation exposure, vibration testing, and long-duration performance evaluations. Such comprehensive testing ensures that throttle bodies can maintain their functionality throughout extended space missions, contributing to the overall sustainability of space habitats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!