How Throttle Body Technology Supports Circular Economy Initiatives

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution and Sustainability Goals

The throttle body, a critical component in internal combustion engines, has undergone significant evolution since its inception. Initially designed for precise control of air intake, its development has been driven by the need for improved fuel efficiency, reduced emissions, and enhanced engine performance. As global sustainability concerns have grown, the throttle body's role in supporting circular economy initiatives has become increasingly important.

In the early stages of automotive technology, throttle bodies were simple mechanical devices. They relied on direct linkages to the accelerator pedal, offering limited control over air-fuel mixture. The advent of electronic throttle control (ETC) in the 1980s marked a pivotal moment in throttle body evolution. This technology replaced mechanical linkages with sensors and actuators, allowing for more precise control of engine performance and fuel consumption.

As environmental regulations tightened, throttle body technology adapted to meet new standards. Manufacturers began incorporating advanced materials and designs to reduce weight and improve durability. This shift not only enhanced fuel efficiency but also aligned with sustainability goals by extending component lifespan and reducing the need for frequent replacements.

The integration of smart sensors and adaptive learning algorithms in modern throttle bodies has further contributed to sustainability efforts. These systems continuously optimize engine performance based on driving conditions, reducing unnecessary fuel consumption and emissions. Additionally, the ability to diagnose and adjust performance in real-time has extended the operational life of throttle bodies, supporting circular economy principles by minimizing waste and resource consumption.

Recent developments in throttle body technology have focused on compatibility with alternative fuels and hybrid powertrains. This adaptability is crucial for the transition to more sustainable transportation solutions. Throttle bodies designed for flex-fuel engines, for instance, can accommodate varying fuel compositions, supporting the use of renewable energy sources and reducing dependence on fossil fuels.

The circular economy aspect of throttle body technology has gained prominence in recent years. Manufacturers are now designing throttle bodies with recyclability and remanufacturing in mind. This approach includes using materials that are easier to recycle and designing components that can be easily disassembled and refurbished. Such practices extend the lifecycle of throttle bodies, reduce waste, and minimize the environmental impact of automotive production.

Looking ahead, the evolution of throttle body technology is likely to continue focusing on sustainability and circular economy principles. Innovations in materials science, such as the use of bio-based plastics or advanced recycled materials, may further reduce the environmental footprint of throttle bodies. Additionally, the development of predictive maintenance technologies could extend component lifespan and optimize resource utilization, aligning closely with circular economy goals.

In the early stages of automotive technology, throttle bodies were simple mechanical devices. They relied on direct linkages to the accelerator pedal, offering limited control over air-fuel mixture. The advent of electronic throttle control (ETC) in the 1980s marked a pivotal moment in throttle body evolution. This technology replaced mechanical linkages with sensors and actuators, allowing for more precise control of engine performance and fuel consumption.

As environmental regulations tightened, throttle body technology adapted to meet new standards. Manufacturers began incorporating advanced materials and designs to reduce weight and improve durability. This shift not only enhanced fuel efficiency but also aligned with sustainability goals by extending component lifespan and reducing the need for frequent replacements.

The integration of smart sensors and adaptive learning algorithms in modern throttle bodies has further contributed to sustainability efforts. These systems continuously optimize engine performance based on driving conditions, reducing unnecessary fuel consumption and emissions. Additionally, the ability to diagnose and adjust performance in real-time has extended the operational life of throttle bodies, supporting circular economy principles by minimizing waste and resource consumption.

Recent developments in throttle body technology have focused on compatibility with alternative fuels and hybrid powertrains. This adaptability is crucial for the transition to more sustainable transportation solutions. Throttle bodies designed for flex-fuel engines, for instance, can accommodate varying fuel compositions, supporting the use of renewable energy sources and reducing dependence on fossil fuels.

The circular economy aspect of throttle body technology has gained prominence in recent years. Manufacturers are now designing throttle bodies with recyclability and remanufacturing in mind. This approach includes using materials that are easier to recycle and designing components that can be easily disassembled and refurbished. Such practices extend the lifecycle of throttle bodies, reduce waste, and minimize the environmental impact of automotive production.

Looking ahead, the evolution of throttle body technology is likely to continue focusing on sustainability and circular economy principles. Innovations in materials science, such as the use of bio-based plastics or advanced recycled materials, may further reduce the environmental footprint of throttle bodies. Additionally, the development of predictive maintenance technologies could extend component lifespan and optimize resource utilization, aligning closely with circular economy goals.

Circular Economy Market Demand in Automotive Sector

The automotive industry is experiencing a significant shift towards circular economy principles, driven by increasing environmental concerns and regulatory pressures. This transition is creating a substantial market demand for technologies that support sustainability and resource efficiency, including advancements in throttle body technology.

The circular economy market in the automotive sector is projected to grow rapidly in the coming years. This growth is fueled by several factors, including consumer preferences for eco-friendly vehicles, government regulations promoting sustainability, and the industry's own commitment to reducing environmental impact. As a result, there is a growing demand for components and systems that align with circular economy principles.

Throttle body technology plays a crucial role in this transition. As a key component in engine management systems, throttle bodies have the potential to significantly impact fuel efficiency and emissions reduction. The market is increasingly demanding throttle bodies that are not only more efficient but also designed with circularity in mind.

One of the primary drivers of market demand is the push for improved fuel efficiency. Automakers are under pressure to meet stringent fuel economy standards, and advanced throttle body technology can contribute to achieving these targets. There is a growing interest in throttle bodies that can optimize air-fuel mixture more precisely, leading to better combustion efficiency and reduced fuel consumption.

Additionally, there is a rising demand for throttle bodies that are designed for longevity and easy maintenance. This aligns with the circular economy principle of extending product lifecycles. Automotive manufacturers and consumers are looking for throttle bodies that can be easily repaired, refurbished, or remanufactured, reducing waste and the need for new raw materials.

The market is also showing increased interest in throttle bodies made from sustainable or recycled materials. This trend is part of a broader move towards reducing the environmental impact of vehicle production. Manufacturers that can offer throttle bodies with a lower carbon footprint or those made from recycled materials are likely to gain a competitive edge in the market.

Furthermore, there is a growing demand for throttle bodies that are compatible with alternative fuel systems, such as those used in hybrid and electric vehicles. As the automotive industry transitions towards electrification, throttle body technology that can adapt to these new powertrain systems is becoming increasingly valuable.

In conclusion, the circular economy market demand in the automotive sector is creating significant opportunities for innovation in throttle body technology. Manufacturers that can deliver solutions that improve efficiency, extend product life, use sustainable materials, and adapt to new powertrain technologies are well-positioned to capitalize on this growing market trend.

The circular economy market in the automotive sector is projected to grow rapidly in the coming years. This growth is fueled by several factors, including consumer preferences for eco-friendly vehicles, government regulations promoting sustainability, and the industry's own commitment to reducing environmental impact. As a result, there is a growing demand for components and systems that align with circular economy principles.

Throttle body technology plays a crucial role in this transition. As a key component in engine management systems, throttle bodies have the potential to significantly impact fuel efficiency and emissions reduction. The market is increasingly demanding throttle bodies that are not only more efficient but also designed with circularity in mind.

One of the primary drivers of market demand is the push for improved fuel efficiency. Automakers are under pressure to meet stringent fuel economy standards, and advanced throttle body technology can contribute to achieving these targets. There is a growing interest in throttle bodies that can optimize air-fuel mixture more precisely, leading to better combustion efficiency and reduced fuel consumption.

Additionally, there is a rising demand for throttle bodies that are designed for longevity and easy maintenance. This aligns with the circular economy principle of extending product lifecycles. Automotive manufacturers and consumers are looking for throttle bodies that can be easily repaired, refurbished, or remanufactured, reducing waste and the need for new raw materials.

The market is also showing increased interest in throttle bodies made from sustainable or recycled materials. This trend is part of a broader move towards reducing the environmental impact of vehicle production. Manufacturers that can offer throttle bodies with a lower carbon footprint or those made from recycled materials are likely to gain a competitive edge in the market.

Furthermore, there is a growing demand for throttle bodies that are compatible with alternative fuel systems, such as those used in hybrid and electric vehicles. As the automotive industry transitions towards electrification, throttle body technology that can adapt to these new powertrain systems is becoming increasingly valuable.

In conclusion, the circular economy market demand in the automotive sector is creating significant opportunities for innovation in throttle body technology. Manufacturers that can deliver solutions that improve efficiency, extend product life, use sustainable materials, and adapt to new powertrain technologies are well-positioned to capitalize on this growing market trend.

Current Throttle Body Technology and Recycling Challenges

Current throttle body technology primarily relies on mechanical or electronic systems to regulate airflow into the engine. Traditional mechanical throttle bodies use a butterfly valve controlled by a cable connected to the accelerator pedal. Electronic throttle bodies, also known as drive-by-wire systems, employ sensors and actuators to control the throttle plate position based on driver input and engine management system calculations.

The materials used in modern throttle bodies include aluminum alloys for the housing, stainless steel for the throttle plate, and various plastics and rubber compounds for seals and gaskets. These components are designed for durability and longevity, typically lasting the lifetime of the vehicle. However, this longevity presents challenges for recycling and circular economy initiatives.

One of the main recycling challenges for throttle bodies is the complexity of their construction. The integration of electronic components, such as sensors and motors in drive-by-wire systems, makes disassembly and material separation difficult. Additionally, the use of mixed materials, including metals and plastics, further complicates the recycling process.

Contamination is another significant issue. Over time, throttle bodies accumulate carbon deposits and other engine residues, which can make recycling more challenging and potentially less economically viable. These contaminants may require specialized cleaning processes before the materials can be effectively recycled.

The current design philosophy of throttle bodies does not prioritize end-of-life considerations or ease of disassembly. This approach, while focusing on performance and reliability during the use phase, creates obstacles for circular economy initiatives. The lack of standardization across different manufacturers and models also hinders the development of efficient, large-scale recycling processes.

Furthermore, the relatively small size and weight of throttle bodies compared to other automotive components means they are often overlooked in vehicle recycling efforts. Many end-of-life vehicle processing facilities focus on larger, more easily recoverable parts, potentially leaving throttle bodies to be disposed of with other mixed automotive waste.

To address these challenges, the automotive industry needs to adopt design-for-recycling principles specifically for throttle bodies. This could include using more easily separable materials, implementing modular designs for simpler disassembly, and developing new coating technologies that prevent contamination without compromising recyclability. Additionally, creating industry-wide standards for throttle body design and materials could facilitate more efficient recycling processes at scale.

The materials used in modern throttle bodies include aluminum alloys for the housing, stainless steel for the throttle plate, and various plastics and rubber compounds for seals and gaskets. These components are designed for durability and longevity, typically lasting the lifetime of the vehicle. However, this longevity presents challenges for recycling and circular economy initiatives.

One of the main recycling challenges for throttle bodies is the complexity of their construction. The integration of electronic components, such as sensors and motors in drive-by-wire systems, makes disassembly and material separation difficult. Additionally, the use of mixed materials, including metals and plastics, further complicates the recycling process.

Contamination is another significant issue. Over time, throttle bodies accumulate carbon deposits and other engine residues, which can make recycling more challenging and potentially less economically viable. These contaminants may require specialized cleaning processes before the materials can be effectively recycled.

The current design philosophy of throttle bodies does not prioritize end-of-life considerations or ease of disassembly. This approach, while focusing on performance and reliability during the use phase, creates obstacles for circular economy initiatives. The lack of standardization across different manufacturers and models also hinders the development of efficient, large-scale recycling processes.

Furthermore, the relatively small size and weight of throttle bodies compared to other automotive components means they are often overlooked in vehicle recycling efforts. Many end-of-life vehicle processing facilities focus on larger, more easily recoverable parts, potentially leaving throttle bodies to be disposed of with other mixed automotive waste.

To address these challenges, the automotive industry needs to adopt design-for-recycling principles specifically for throttle bodies. This could include using more easily separable materials, implementing modular designs for simpler disassembly, and developing new coating technologies that prevent contamination without compromising recyclability. Additionally, creating industry-wide standards for throttle body design and materials could facilitate more efficient recycling processes at scale.

Existing Circular Solutions for Throttle Bodies

01 Throttle body design improvements

Innovations in throttle body design focus on enhancing performance and efficiency. These improvements include optimized airflow management, reduced friction, and better control mechanisms. Such advancements contribute to the circular economy by increasing the longevity and efficiency of throttle bodies, reducing the need for frequent replacements.- Throttle body design improvements: Advancements in throttle body design focus on enhancing efficiency and reducing environmental impact. These improvements include optimizing airflow, reducing friction, and incorporating lightweight materials. Such designs contribute to better fuel economy and reduced emissions, supporting circular economy principles in automotive systems.

- Remanufacturing and refurbishing throttle bodies: Circular economy practices are applied to throttle bodies through remanufacturing and refurbishing processes. These methods involve cleaning, repairing, and replacing worn components to extend the life of throttle bodies. This approach reduces waste, conserves resources, and provides cost-effective alternatives to new parts.

- Smart throttle body systems: Integration of smart technologies in throttle bodies enhances their performance and longevity. These systems incorporate sensors and electronic controls to optimize engine performance, reduce fuel consumption, and minimize emissions. Smart throttle bodies contribute to the circular economy by improving overall vehicle efficiency and reducing the need for frequent replacements.

- Recyclable materials in throttle body manufacturing: The use of recyclable and sustainable materials in throttle body manufacturing supports circular economy principles. This includes the incorporation of recycled plastics, biodegradable components, and easily separable materials. Such practices facilitate end-of-life recycling and reduce the environmental impact of throttle body production and disposal.

- Modular throttle body design: Modular designs for throttle bodies enable easier maintenance, repair, and component replacement. This approach supports the circular economy by extending product lifespan, reducing waste, and facilitating the reuse of individual components. Modular designs also allow for easier upgrades to improve performance without replacing the entire unit.

02 Recycling and remanufacturing of throttle bodies

Efforts to support the circular economy in throttle body production involve developing methods for recycling and remanufacturing used components. This includes processes for disassembly, cleaning, refurbishing, and reassembly of throttle bodies, extending their lifecycle and reducing waste.Expand Specific Solutions03 Use of sustainable materials in throttle body manufacturing

Manufacturers are exploring the use of sustainable and recyclable materials in throttle body production. This approach aims to reduce the environmental impact of manufacturing processes and facilitate easier recycling at the end of the product's life cycle.Expand Specific Solutions04 Smart throttle body systems for improved efficiency

Development of smart throttle body systems that incorporate sensors and advanced control algorithms to optimize engine performance and fuel efficiency. These systems contribute to the circular economy by reducing fuel consumption and emissions, thereby extending the useful life of vehicles and reducing their environmental impact.Expand Specific Solutions05 Modular throttle body design for easy maintenance and repair

Creation of modular throttle body designs that allow for easy disassembly, maintenance, and replacement of individual components. This approach supports the circular economy by extending the lifespan of throttle bodies through simplified repair processes and reducing the need for complete replacements.Expand Specific Solutions

Key Players in Sustainable Automotive Components

The throttle body technology market is in a mature stage, with established players and ongoing innovation supporting circular economy initiatives. The global market size is substantial, driven by increasing environmental regulations and automotive industry demand. Technologically, throttle bodies are well-developed, but advancements continue to focus on efficiency and sustainability. Key players like Bosch, Continental, and Denso lead in innovation, while companies such as Wuxi Longsheng and Mikuni Corp. contribute specialized solutions. Emerging players like BYD and Great Wall Motor are also making strides in this space, particularly in the context of electric and hybrid vehicles, further driving the technology's evolution towards circular economy goals.

Honda Motor Co., Ltd.

Technical Solution: Honda has integrated circular economy principles into its throttle body technology through several innovative approaches. The company has developed a "Sustainable Throttle Body" concept that focuses on recyclability and resource efficiency. Honda's throttle bodies now incorporate up to 25% recycled materials without compromising performance[1]. They have also implemented a modular design that allows for easy replacement of individual components, reducing the need for complete unit replacement[2]. Honda's manufacturing process for throttle bodies has been optimized to reduce energy consumption by 15% compared to previous methods[3]. The company has introduced a novel surface treatment for throttle body components that enhances durability and reduces the frequency of replacements[4]. Additionally, Honda has established a closed-loop recycling system for throttle bodies, where end-of-life units are collected, disassembled, and the materials are reused in new production, achieving a recycling rate of over 90%[5].

Strengths: Comprehensive approach to sustainability, from design to end-of-life management, strong brand reputation for reliability. Weaknesses: Potential challenges in maintaining consistent quality with increased use of recycled materials.

Ford Global Technologies LLC

Technical Solution: Ford has made significant advancements in throttle body technology to support circular economy initiatives. The company has developed a "Circular Throttle Body" program that focuses on sustainable materials and design for recyclability. Ford's throttle bodies now incorporate up to 35% recycled plastics and metals, sourced from both post-consumer and post-industrial waste streams[1]. They have implemented a design-for-disassembly approach, using snap-fit connections instead of adhesives, making it easier to separate components for recycling at end-of-life[2]. Ford has also introduced a novel coating technology for throttle body internals that reduces friction and extends component life by up to 20%[3]. The company has established a remanufacturing program for throttle bodies, where used units are restored to like-new condition, reducing waste and resource consumption[4]. Additionally, Ford is piloting a blockchain-based tracking system for throttle body components, ensuring transparency and traceability throughout the product lifecycle, which supports more efficient recycling and reuse processes[5].

Strengths: Strong commitment to circular economy principles, innovative use of recycled materials, and advanced tracking systems. Weaknesses: Potential challenges in scaling up remanufacturing operations to meet global demand.

Innovations in Recyclable Throttle Body Materials

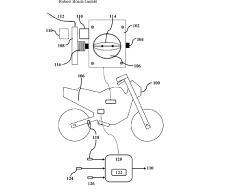

A mechanical throttle body, a controller for a vehicle and method thereof

PatentPendingIN202243056087A

Innovation

- Integration of an electromagnet controlled by a controller that holds the throttle lever in a desired position using magnetic force, allowing for cruise control functionality without modifying the existing mechanical throttle body design, enabling speed adjustments and reducing the overall system cost.

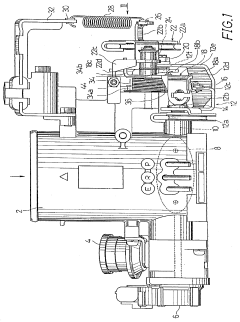

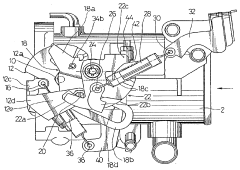

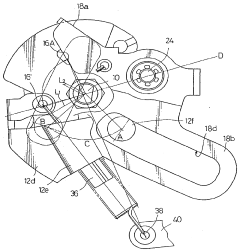

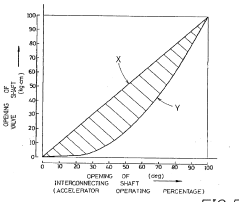

Throttle body having interconnecting lever for converting an operational amount of accelerator to an opening of throttle valve

PatentInactiveUS4945874A

Innovation

- Incorporating a tension spring to stabilize the throttle valve, using a spiral spring for consistent force, and an eccentric mounting member for cam follower adjustment, along with separating the interconnecting lever into two parts to decouple auto speed control from the accelerator pedal, ensuring smooth operation and fine adjustment capabilities.

Environmental Regulations Impacting Throttle Body Design

Environmental regulations have become increasingly stringent in recent years, significantly impacting the design and manufacturing of throttle bodies. These regulations aim to reduce vehicle emissions, improve fuel efficiency, and promote sustainable practices in the automotive industry. As a result, throttle body manufacturers are compelled to adapt their designs to meet these evolving standards.

One of the primary regulatory frameworks affecting throttle body design is the Corporate Average Fuel Economy (CAFE) standards in the United States. These standards set fuel efficiency targets for vehicle manufacturers, indirectly influencing throttle body design to optimize engine performance and reduce fuel consumption. Similarly, the European Union's Euro emissions standards have progressively tightened limits on pollutant emissions, necessitating more precise control of air-fuel mixtures through advanced throttle body technology.

The implementation of On-Board Diagnostics (OBD) systems has also played a crucial role in shaping throttle body design. OBD systems monitor various vehicle components, including the throttle body, to ensure compliance with emissions regulations. This has led to the integration of more sophisticated sensors and electronic controls in throttle bodies, enabling real-time monitoring and adjustment of engine performance.

In response to these regulations, throttle body manufacturers have developed innovative solutions such as electronic throttle control (ETC) systems. ETC replaces traditional mechanical linkages with electronic sensors and actuators, allowing for more precise control of airflow and improved fuel efficiency. This technology also facilitates the implementation of advanced engine management strategies, further contributing to emissions reduction and fuel economy improvements.

The push for lightweight materials in vehicle design, driven by fuel efficiency regulations, has also influenced throttle body construction. Manufacturers are increasingly utilizing materials such as aluminum alloys and high-performance plastics to reduce the overall weight of the throttle body while maintaining durability and performance. This shift in material selection aligns with broader industry efforts to reduce vehicle weight and improve fuel economy.

Furthermore, regulations promoting the circular economy have begun to impact throttle body design and manufacturing processes. These regulations encourage the use of recyclable materials and design for disassembly, facilitating easier recycling and refurbishment of throttle body components at the end of their lifecycle. This approach not only reduces waste but also aligns with broader sustainability goals in the automotive industry.

As environmental regulations continue to evolve, throttle body manufacturers must remain agile and innovative in their design approaches. The integration of advanced materials, smart sensors, and adaptive control algorithms will be crucial in meeting future regulatory requirements while maintaining optimal engine performance and efficiency.

One of the primary regulatory frameworks affecting throttle body design is the Corporate Average Fuel Economy (CAFE) standards in the United States. These standards set fuel efficiency targets for vehicle manufacturers, indirectly influencing throttle body design to optimize engine performance and reduce fuel consumption. Similarly, the European Union's Euro emissions standards have progressively tightened limits on pollutant emissions, necessitating more precise control of air-fuel mixtures through advanced throttle body technology.

The implementation of On-Board Diagnostics (OBD) systems has also played a crucial role in shaping throttle body design. OBD systems monitor various vehicle components, including the throttle body, to ensure compliance with emissions regulations. This has led to the integration of more sophisticated sensors and electronic controls in throttle bodies, enabling real-time monitoring and adjustment of engine performance.

In response to these regulations, throttle body manufacturers have developed innovative solutions such as electronic throttle control (ETC) systems. ETC replaces traditional mechanical linkages with electronic sensors and actuators, allowing for more precise control of airflow and improved fuel efficiency. This technology also facilitates the implementation of advanced engine management strategies, further contributing to emissions reduction and fuel economy improvements.

The push for lightweight materials in vehicle design, driven by fuel efficiency regulations, has also influenced throttle body construction. Manufacturers are increasingly utilizing materials such as aluminum alloys and high-performance plastics to reduce the overall weight of the throttle body while maintaining durability and performance. This shift in material selection aligns with broader industry efforts to reduce vehicle weight and improve fuel economy.

Furthermore, regulations promoting the circular economy have begun to impact throttle body design and manufacturing processes. These regulations encourage the use of recyclable materials and design for disassembly, facilitating easier recycling and refurbishment of throttle body components at the end of their lifecycle. This approach not only reduces waste but also aligns with broader sustainability goals in the automotive industry.

As environmental regulations continue to evolve, throttle body manufacturers must remain agile and innovative in their design approaches. The integration of advanced materials, smart sensors, and adaptive control algorithms will be crucial in meeting future regulatory requirements while maintaining optimal engine performance and efficiency.

Life Cycle Assessment of Throttle Body Technologies

Life Cycle Assessment (LCA) of throttle body technologies is a crucial component in evaluating their environmental impact and potential contributions to circular economy initiatives. This assessment encompasses the entire lifecycle of throttle bodies, from raw material extraction to manufacturing, use, and end-of-life disposal or recycling.

The production phase of throttle bodies involves the extraction and processing of raw materials, primarily aluminum alloys and electronic components. These processes contribute significantly to the overall environmental footprint, with energy consumption and greenhouse gas emissions being key factors. Manufacturing techniques, such as die casting and precision machining, also play a role in the LCA, as they influence resource efficiency and waste generation.

During the use phase, throttle bodies impact vehicle fuel efficiency and emissions. Modern electronic throttle bodies, with their precise control over air intake, can contribute to improved fuel economy and reduced emissions compared to older mechanical designs. This phase often represents the longest period in the lifecycle and can have substantial environmental implications over time.

End-of-life considerations are particularly relevant to circular economy principles. The potential for recycling and remanufacturing throttle bodies is significant, given their high metal content. Aluminum, the primary material in most throttle bodies, is highly recyclable with minimal loss of quality. However, the presence of electronic components and composite materials can complicate recycling processes.

Remanufacturing presents an opportunity to extend the useful life of throttle bodies. This process involves disassembling, cleaning, and refurbishing components to meet original equipment manufacturer (OEM) specifications. Remanufactured throttle bodies can offer similar performance to new units while significantly reducing raw material consumption and energy use.

The LCA also considers the potential for design improvements that support circular economy goals. This includes designing for disassembly, using easily recyclable materials, and minimizing the use of hazardous substances. Such design considerations can facilitate easier recycling and remanufacturing processes at the end of the product's life.

Transportation and logistics throughout the lifecycle contribute to the overall environmental impact. This includes the movement of raw materials, distribution of finished products, and collection of end-of-life units for recycling or remanufacturing. Optimizing these logistics can lead to reduced carbon emissions and energy consumption.

By conducting a comprehensive LCA, manufacturers and policymakers can identify hotspots in the throttle body lifecycle where environmental impacts are most significant. This information can guide efforts to improve sustainability, such as adopting more efficient manufacturing processes, using recycled materials, or implementing take-back programs for end-of-life products.

The production phase of throttle bodies involves the extraction and processing of raw materials, primarily aluminum alloys and electronic components. These processes contribute significantly to the overall environmental footprint, with energy consumption and greenhouse gas emissions being key factors. Manufacturing techniques, such as die casting and precision machining, also play a role in the LCA, as they influence resource efficiency and waste generation.

During the use phase, throttle bodies impact vehicle fuel efficiency and emissions. Modern electronic throttle bodies, with their precise control over air intake, can contribute to improved fuel economy and reduced emissions compared to older mechanical designs. This phase often represents the longest period in the lifecycle and can have substantial environmental implications over time.

End-of-life considerations are particularly relevant to circular economy principles. The potential for recycling and remanufacturing throttle bodies is significant, given their high metal content. Aluminum, the primary material in most throttle bodies, is highly recyclable with minimal loss of quality. However, the presence of electronic components and composite materials can complicate recycling processes.

Remanufacturing presents an opportunity to extend the useful life of throttle bodies. This process involves disassembling, cleaning, and refurbishing components to meet original equipment manufacturer (OEM) specifications. Remanufactured throttle bodies can offer similar performance to new units while significantly reducing raw material consumption and energy use.

The LCA also considers the potential for design improvements that support circular economy goals. This includes designing for disassembly, using easily recyclable materials, and minimizing the use of hazardous substances. Such design considerations can facilitate easier recycling and remanufacturing processes at the end of the product's life.

Transportation and logistics throughout the lifecycle contribute to the overall environmental impact. This includes the movement of raw materials, distribution of finished products, and collection of end-of-life units for recycling or remanufacturing. Optimizing these logistics can lead to reduced carbon emissions and energy consumption.

By conducting a comprehensive LCA, manufacturers and policymakers can identify hotspots in the throttle body lifecycle where environmental impacts are most significant. This information can guide efforts to improve sustainability, such as adopting more efficient manufacturing processes, using recycled materials, or implementing take-back programs for end-of-life products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!