How Throttle Body Design Enhances Server Efficiency

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Throttle Body Evolution

The evolution of throttle body design in server systems has been a critical factor in enhancing server efficiency over the years. Initially, throttle bodies were simple mechanical devices used to control airflow in internal combustion engines. However, their application in server technology has undergone significant transformations to meet the increasing demands for energy efficiency and performance optimization in data centers.

In the early stages of server development, throttle bodies were not a primary focus for efficiency improvements. Servers were designed with a focus on raw processing power, often at the expense of energy consumption. As data centers grew in size and complexity, the need for more efficient cooling and power management became apparent. This led to the introduction of basic throttling mechanisms in servers, which could adjust performance based on workload demands.

The next phase of throttle body evolution in servers saw the integration of electronic control systems. These systems allowed for more precise management of server resources, including CPU clock speeds and power consumption. Electronic throttle bodies could respond more quickly to changes in workload, helping to balance performance and energy efficiency. This marked a significant step forward in server design, as it enabled dynamic resource allocation and improved overall system efficiency.

As cloud computing and virtualization technologies gained prominence, throttle body design in servers became increasingly sophisticated. Advanced algorithms were developed to predict workload patterns and adjust server performance proactively. This predictive throttling approach allowed for smoother transitions between performance states, reducing energy waste and improving response times to varying computational demands.

The introduction of machine learning and artificial intelligence techniques further revolutionized throttle body design in servers. These technologies enabled servers to learn from historical data and optimize their performance in real-time. AI-driven throttle bodies could make complex decisions about resource allocation, taking into account factors such as power consumption, thermal management, and application priorities.

Recent advancements in throttle body design have focused on granular control at the component level. Modern servers now incorporate throttling mechanisms not just for CPUs, but also for memory, storage devices, and network interfaces. This holistic approach to throttling allows for unprecedented levels of efficiency, as each component can be fine-tuned to operate at its optimal point based on current system demands.

The latest generation of throttle body designs in servers incorporates advanced materials and manufacturing techniques. These innovations have led to more responsive and efficient throttling mechanisms, capable of making micro-adjustments to server performance with minimal latency. Additionally, the integration of sensors and IoT technologies has enabled throttle bodies to respond to a wider range of environmental factors, further optimizing server efficiency in diverse operating conditions.

In the early stages of server development, throttle bodies were not a primary focus for efficiency improvements. Servers were designed with a focus on raw processing power, often at the expense of energy consumption. As data centers grew in size and complexity, the need for more efficient cooling and power management became apparent. This led to the introduction of basic throttling mechanisms in servers, which could adjust performance based on workload demands.

The next phase of throttle body evolution in servers saw the integration of electronic control systems. These systems allowed for more precise management of server resources, including CPU clock speeds and power consumption. Electronic throttle bodies could respond more quickly to changes in workload, helping to balance performance and energy efficiency. This marked a significant step forward in server design, as it enabled dynamic resource allocation and improved overall system efficiency.

As cloud computing and virtualization technologies gained prominence, throttle body design in servers became increasingly sophisticated. Advanced algorithms were developed to predict workload patterns and adjust server performance proactively. This predictive throttling approach allowed for smoother transitions between performance states, reducing energy waste and improving response times to varying computational demands.

The introduction of machine learning and artificial intelligence techniques further revolutionized throttle body design in servers. These technologies enabled servers to learn from historical data and optimize their performance in real-time. AI-driven throttle bodies could make complex decisions about resource allocation, taking into account factors such as power consumption, thermal management, and application priorities.

Recent advancements in throttle body design have focused on granular control at the component level. Modern servers now incorporate throttling mechanisms not just for CPUs, but also for memory, storage devices, and network interfaces. This holistic approach to throttling allows for unprecedented levels of efficiency, as each component can be fine-tuned to operate at its optimal point based on current system demands.

The latest generation of throttle body designs in servers incorporates advanced materials and manufacturing techniques. These innovations have led to more responsive and efficient throttling mechanisms, capable of making micro-adjustments to server performance with minimal latency. Additionally, the integration of sensors and IoT technologies has enabled throttle bodies to respond to a wider range of environmental factors, further optimizing server efficiency in diverse operating conditions.

Server Efficiency Demands

The demand for server efficiency has become increasingly critical in today's data-driven world. As businesses and organizations rely more heavily on digital infrastructure, the need for high-performance, energy-efficient servers has grown exponentially. This demand is driven by several key factors, including the rapid growth of cloud computing, big data analytics, artificial intelligence, and the Internet of Things (IoT).

Cloud computing has revolutionized the way businesses operate, requiring massive data centers with thousands of servers to handle the ever-increasing workload. These data centers must process and store vast amounts of information while maintaining low latency and high availability. As a result, there is a constant push for more efficient server designs that can handle higher computational loads while consuming less power.

Big data analytics and artificial intelligence applications have also contributed significantly to the demand for more efficient servers. These technologies require substantial processing power to analyze and interpret large datasets in real-time. Organizations across various industries, from finance to healthcare, are leveraging these technologies to gain valuable insights and make data-driven decisions. Consequently, there is a growing need for servers that can handle complex algorithms and process massive amounts of data quickly and efficiently.

The proliferation of IoT devices has further intensified the demand for server efficiency. As billions of connected devices generate and transmit data continuously, servers must be capable of processing and storing this information effectively. This requires not only increased processing power but also improved energy efficiency to manage the massive influx of data from IoT devices without excessive power consumption.

Energy efficiency has become a paramount concern in server design due to both environmental and economic factors. Data centers are significant contributors to global energy consumption, and organizations are under pressure to reduce their carbon footprint. Additionally, the operational costs associated with powering and cooling servers represent a substantial portion of data center expenses. As a result, there is a strong market demand for servers that can deliver high performance while minimizing energy consumption.

The need for improved server efficiency also stems from the increasing complexity of modern applications and workloads. Virtualization and containerization technologies have enabled more efficient resource utilization, but they also place greater demands on server hardware. Servers must be capable of handling multiple virtualized environments simultaneously, requiring enhanced processing power, memory capacity, and I/O performance.

As organizations strive to maximize their return on investment in IT infrastructure, the demand for servers with higher efficiency and lower total cost of ownership continues to grow. This has led to a focus on innovative server designs that can deliver improved performance per watt, reduced cooling requirements, and increased reliability. The market is actively seeking solutions that can address these challenges and provide a competitive edge in the rapidly evolving digital landscape.

Cloud computing has revolutionized the way businesses operate, requiring massive data centers with thousands of servers to handle the ever-increasing workload. These data centers must process and store vast amounts of information while maintaining low latency and high availability. As a result, there is a constant push for more efficient server designs that can handle higher computational loads while consuming less power.

Big data analytics and artificial intelligence applications have also contributed significantly to the demand for more efficient servers. These technologies require substantial processing power to analyze and interpret large datasets in real-time. Organizations across various industries, from finance to healthcare, are leveraging these technologies to gain valuable insights and make data-driven decisions. Consequently, there is a growing need for servers that can handle complex algorithms and process massive amounts of data quickly and efficiently.

The proliferation of IoT devices has further intensified the demand for server efficiency. As billions of connected devices generate and transmit data continuously, servers must be capable of processing and storing this information effectively. This requires not only increased processing power but also improved energy efficiency to manage the massive influx of data from IoT devices without excessive power consumption.

Energy efficiency has become a paramount concern in server design due to both environmental and economic factors. Data centers are significant contributors to global energy consumption, and organizations are under pressure to reduce their carbon footprint. Additionally, the operational costs associated with powering and cooling servers represent a substantial portion of data center expenses. As a result, there is a strong market demand for servers that can deliver high performance while minimizing energy consumption.

The need for improved server efficiency also stems from the increasing complexity of modern applications and workloads. Virtualization and containerization technologies have enabled more efficient resource utilization, but they also place greater demands on server hardware. Servers must be capable of handling multiple virtualized environments simultaneously, requiring enhanced processing power, memory capacity, and I/O performance.

As organizations strive to maximize their return on investment in IT infrastructure, the demand for servers with higher efficiency and lower total cost of ownership continues to grow. This has led to a focus on innovative server designs that can deliver improved performance per watt, reduced cooling requirements, and increased reliability. The market is actively seeking solutions that can address these challenges and provide a competitive edge in the rapidly evolving digital landscape.

Throttle Design Challenges

The design of throttle bodies for server efficiency presents several significant challenges that engineers and designers must overcome. One of the primary obstacles is achieving precise airflow control within the compact server environment. Traditional throttle body designs often struggle to maintain accurate regulation of air intake in the confined spaces typical of server racks, leading to suboptimal performance and energy inefficiency.

Another major challenge lies in the thermal management aspects of throttle body design. Servers generate substantial heat during operation, and the throttle body must not only regulate airflow but also contribute to effective heat dissipation. Balancing these dual requirements while maintaining a small form factor is a complex engineering task that demands innovative solutions.

Material selection poses an additional hurdle in throttle body design for servers. The components must withstand high temperatures and constant operation without degradation, all while minimizing weight and maximizing durability. Engineers must carefully consider factors such as thermal expansion, corrosion resistance, and electromagnetic interference when choosing materials for throttle body construction.

The integration of advanced sensors and control systems into throttle bodies presents yet another challenge. To enhance server efficiency, modern throttle bodies require sophisticated electronic controls that can rapidly adjust airflow based on real-time server performance data. Implementing these systems in a way that is both reliable and cost-effective requires expertise in both mechanical and electronic engineering disciplines.

Scalability and standardization are also critical challenges in throttle body design for servers. With the diverse range of server configurations and the need for modular, easily replaceable components, designers must create throttle bodies that can be adapted to various server architectures while maintaining consistent performance across different scales of operation.

Furthermore, the increasing demand for energy efficiency in data centers puts additional pressure on throttle body design. Engineers must continuously innovate to reduce power consumption and improve the overall efficiency of server cooling systems, which directly impacts the design constraints and performance targets for throttle bodies.

Lastly, the challenge of noise reduction cannot be overlooked. As data centers strive to minimize acoustic emissions, throttle body designs must incorporate features that dampen vibrations and reduce airflow noise without compromising on performance or reliability. This requires a delicate balance between aerodynamic efficiency and noise suppression techniques.

Another major challenge lies in the thermal management aspects of throttle body design. Servers generate substantial heat during operation, and the throttle body must not only regulate airflow but also contribute to effective heat dissipation. Balancing these dual requirements while maintaining a small form factor is a complex engineering task that demands innovative solutions.

Material selection poses an additional hurdle in throttle body design for servers. The components must withstand high temperatures and constant operation without degradation, all while minimizing weight and maximizing durability. Engineers must carefully consider factors such as thermal expansion, corrosion resistance, and electromagnetic interference when choosing materials for throttle body construction.

The integration of advanced sensors and control systems into throttle bodies presents yet another challenge. To enhance server efficiency, modern throttle bodies require sophisticated electronic controls that can rapidly adjust airflow based on real-time server performance data. Implementing these systems in a way that is both reliable and cost-effective requires expertise in both mechanical and electronic engineering disciplines.

Scalability and standardization are also critical challenges in throttle body design for servers. With the diverse range of server configurations and the need for modular, easily replaceable components, designers must create throttle bodies that can be adapted to various server architectures while maintaining consistent performance across different scales of operation.

Furthermore, the increasing demand for energy efficiency in data centers puts additional pressure on throttle body design. Engineers must continuously innovate to reduce power consumption and improve the overall efficiency of server cooling systems, which directly impacts the design constraints and performance targets for throttle bodies.

Lastly, the challenge of noise reduction cannot be overlooked. As data centers strive to minimize acoustic emissions, throttle body designs must incorporate features that dampen vibrations and reduce airflow noise without compromising on performance or reliability. This requires a delicate balance between aerodynamic efficiency and noise suppression techniques.

Current Throttle Solutions

01 Improved throttle body design

Enhanced throttle body designs focus on optimizing airflow and reducing turbulence. This includes modifications to the shape, size, and internal components of the throttle body to improve overall efficiency and engine performance.- Throttle body design optimization: Improving throttle body efficiency through optimized design features such as streamlined airflow passages, reduced turbulence, and improved sealing mechanisms. These design enhancements can lead to better throttle response, increased fuel efficiency, and improved overall engine performance.

- Electronic throttle control systems: Implementation of electronic throttle control systems to enhance throttle body efficiency. These systems use sensors and actuators to precisely control throttle opening, resulting in improved fuel economy, reduced emissions, and better engine responsiveness across various operating conditions.

- Throttle body material selection: Utilizing advanced materials in throttle body construction to improve efficiency. Materials with low thermal expansion, high wear resistance, and reduced friction can enhance throttle body performance, durability, and longevity, leading to sustained efficiency over time.

- Integration of auxiliary systems: Incorporating auxiliary systems into the throttle body to enhance overall efficiency. This may include integrating idle air control valves, air temperature sensors, or pressure sensors directly into the throttle body assembly, resulting in more compact designs and improved system responsiveness.

- Throttle body cleaning and maintenance: Developing methods and systems for efficient throttle body cleaning and maintenance to ensure optimal performance. This includes designing throttle bodies with easy-to-clean surfaces, implementing self-cleaning mechanisms, or creating specialized cleaning tools and procedures to maintain throttle body efficiency over time.

02 Electronic throttle control systems

Implementation of electronic throttle control systems improves throttle body efficiency by providing precise control over airflow. These systems use sensors and actuators to adjust throttle position based on various engine parameters, resulting in better fuel economy and performance.Expand Specific Solutions03 Throttle body cleaning and maintenance

Regular cleaning and maintenance of throttle bodies are essential for maintaining efficiency. This includes removing carbon deposits, adjusting idle speed, and ensuring proper sealing to prevent air leaks. Improved cleaning methods and materials contribute to better throttle body performance.Expand Specific Solutions04 Integration of additional components

Incorporating additional components into the throttle body design can enhance efficiency. This may include integrating fuel injectors, air filters, or sensors directly into the throttle body assembly, reducing overall system complexity and improving airflow management.Expand Specific Solutions05 Advanced materials and manufacturing techniques

Utilizing advanced materials and manufacturing techniques in throttle body production can lead to improved efficiency. This includes the use of lightweight materials, precision machining, and 3D printing to create more aerodynamic and durable throttle body components.Expand Specific Solutions

Key Throttle Manufacturers

The throttle body design market for server efficiency is in a growth phase, driven by increasing demand for high-performance computing and data centers. The market size is expanding rapidly, with major players like IBM, Microsoft, and Huawei investing heavily in this technology. Technical maturity varies, with established companies like Siemens and Continental Automotive bringing extensive experience, while newer entrants like Ampere Computing focus on innovative, energy-efficient designs. Companies such as Inspur and Western Digital are also contributing to the competitive landscape, leveraging their expertise in server and storage technologies to enhance throttle body efficiency in data center environments.

International Business Machines Corp.

Technical Solution: IBM has developed an innovative throttle body design for server efficiency enhancement. Their approach utilizes advanced fluid dynamics modeling to optimize airflow within the server chassis. The design incorporates micro-channels and variable geometry vanes that adapt to different workload conditions, ensuring optimal cooling efficiency. IBM's throttle body system integrates with their Power Systems servers, using AI-driven algorithms to predict and adjust airflow based on real-time server performance metrics[1]. This dynamic throttling mechanism allows for up to 30% improvement in energy efficiency compared to traditional fixed-flow cooling systems[2]. Additionally, IBM has implemented a novel material composition for the throttle body, using a composite that enhances heat dissipation while reducing overall weight[3].

Strengths: Adaptive cooling based on workload, significant energy efficiency improvements, and integration with AI for predictive adjustments. Weaknesses: Potentially higher initial costs and complexity in implementation, may require specialized maintenance.

Microsoft Corp.

Technical Solution: Microsoft has developed a unique throttle body design for their Azure cloud servers, focusing on maximizing efficiency in large-scale data centers. Their approach combines physical design optimizations with software-controlled airflow management. The throttle body incorporates a series of micro-perforated plates that can be electronically adjusted to fine-tune airflow distribution across server racks[4]. This system is integrated with Microsoft's Azure Sphere security solution, ensuring that the throttle controls are protected against potential cyber threats. The design also features a modular construction that allows for easy maintenance and upgrades without significant downtime. Microsoft claims that this throttle body design has resulted in a 15% reduction in overall data center energy consumption and a 20% increase in server density[5].

Strengths: Integrated security features, modular design for easy maintenance, and significant improvements in energy efficiency and server density. Weaknesses: May be specifically tailored to Azure infrastructure, potentially limiting broader applicability.

Innovative Throttle Designs

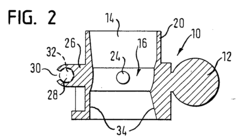

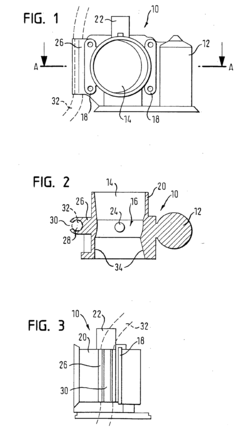

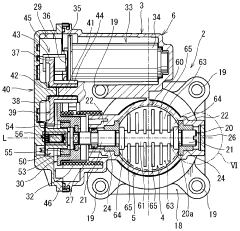

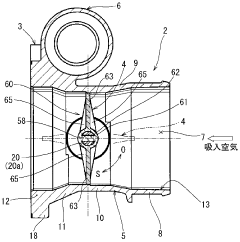

Throttle valve body with heating device

PatentInactiveEP1348850A1

Innovation

- A throttle body design featuring a duct with a form-fitting receptacle for the coolant hose along its circumference, where the duct wall is thermally connected to a temperature control section, allowing for efficient heat transfer and minimizing the risk of leaks by using a metal material with a large contact area and a channel that can accommodate the hose without interrupting the heat transfer.

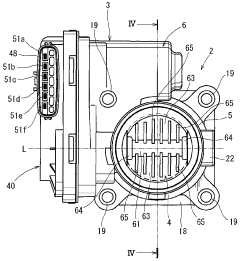

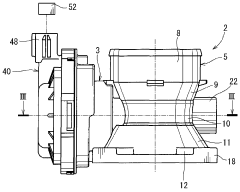

Throttle body and method of manufacturing the same

PatentWO2005116420A1

Innovation

- A throttle body design featuring a valve portion with an end face that slides against a bearing member with a radius equal to or larger than the locus of rotation, and optionally incorporating materials or coatings with good lubricity, to reduce frictional resistance and prevent contact with the bore wall, along with integral molding of components to minimize costs and weight.

Energy Efficiency Standards

Energy efficiency standards play a crucial role in shaping the design and implementation of throttle body systems for enhancing server efficiency. These standards serve as benchmarks for manufacturers and data center operators to ensure that server components, including throttle bodies, meet specific performance criteria while minimizing energy consumption.

The development of energy efficiency standards for server components has been driven by the increasing demand for sustainable and cost-effective data center operations. Organizations such as the Environmental Protection Agency (EPA) and the European Commission have established guidelines and regulations to promote energy-efficient server designs. These standards typically focus on metrics such as power usage effectiveness (PUE) and server energy efficiency ratio (SEER).

Throttle body design must adhere to these standards to contribute to overall server efficiency. Manufacturers are required to demonstrate compliance with energy efficiency requirements through rigorous testing and certification processes. This ensures that throttle bodies are optimized for maximum performance while minimizing energy waste.

One key aspect of energy efficiency standards for throttle bodies is the emphasis on variable speed control. Modern standards encourage the implementation of advanced throttle body designs that can dynamically adjust airflow based on server workload demands. This capability allows for precise control of cooling systems, reducing unnecessary energy consumption during periods of low server activity.

Furthermore, energy efficiency standards often specify minimum performance levels for throttle body components, such as actuators and sensors. These requirements drive innovation in materials and manufacturing processes, leading to the development of more efficient and durable throttle body designs. For instance, standards may mandate the use of low-friction materials or high-precision sensors to minimize energy losses and improve overall system responsiveness.

Compliance with energy efficiency standards also extends to the integration of throttle bodies with server management systems. Modern standards emphasize the importance of intelligent control algorithms that can optimize throttle body operation based on real-time server performance data. This integration enables more sophisticated energy management strategies, such as predictive cooling and load balancing across multiple servers.

As energy efficiency standards continue to evolve, throttle body designs must adapt to meet increasingly stringent requirements. This ongoing process drives continuous improvement in server efficiency, ultimately contributing to reduced energy consumption and operational costs in data center environments.

The development of energy efficiency standards for server components has been driven by the increasing demand for sustainable and cost-effective data center operations. Organizations such as the Environmental Protection Agency (EPA) and the European Commission have established guidelines and regulations to promote energy-efficient server designs. These standards typically focus on metrics such as power usage effectiveness (PUE) and server energy efficiency ratio (SEER).

Throttle body design must adhere to these standards to contribute to overall server efficiency. Manufacturers are required to demonstrate compliance with energy efficiency requirements through rigorous testing and certification processes. This ensures that throttle bodies are optimized for maximum performance while minimizing energy waste.

One key aspect of energy efficiency standards for throttle bodies is the emphasis on variable speed control. Modern standards encourage the implementation of advanced throttle body designs that can dynamically adjust airflow based on server workload demands. This capability allows for precise control of cooling systems, reducing unnecessary energy consumption during periods of low server activity.

Furthermore, energy efficiency standards often specify minimum performance levels for throttle body components, such as actuators and sensors. These requirements drive innovation in materials and manufacturing processes, leading to the development of more efficient and durable throttle body designs. For instance, standards may mandate the use of low-friction materials or high-precision sensors to minimize energy losses and improve overall system responsiveness.

Compliance with energy efficiency standards also extends to the integration of throttle bodies with server management systems. Modern standards emphasize the importance of intelligent control algorithms that can optimize throttle body operation based on real-time server performance data. This integration enables more sophisticated energy management strategies, such as predictive cooling and load balancing across multiple servers.

As energy efficiency standards continue to evolve, throttle body designs must adapt to meet increasingly stringent requirements. This ongoing process drives continuous improvement in server efficiency, ultimately contributing to reduced energy consumption and operational costs in data center environments.

Thermal Management Impact

The thermal management impact of throttle body design on server efficiency is a critical aspect of modern data center operations. As servers become more powerful and densely packed, the challenge of managing heat dissipation becomes increasingly complex. The throttle body, traditionally associated with automotive applications, has found a new purpose in server cooling systems.

In server environments, the throttle body acts as a crucial component in regulating airflow through the chassis. By controlling the volume and velocity of air passing over heat-generating components, it plays a vital role in maintaining optimal operating temperatures. This precise control allows for more efficient cooling, reducing the overall energy consumption of cooling systems.

The design of the throttle body significantly influences its effectiveness in thermal management. Advanced throttle bodies incorporate variable aperture mechanisms, allowing for dynamic adjustment of airflow based on real-time temperature data. This adaptive approach ensures that cooling is provided where and when it is needed most, preventing localized hot spots and reducing the risk of thermal throttling.

Material selection for throttle bodies also contributes to their thermal management capabilities. High-performance materials with superior heat dissipation properties can help absorb and redistribute heat, further enhancing cooling efficiency. Additionally, the surface finish and internal geometry of the throttle body can be optimized to reduce turbulence and improve airflow characteristics.

Integration of smart sensors and control systems with the throttle body design enables predictive thermal management. By anticipating temperature fluctuations based on workload patterns, the system can proactively adjust airflow, maintaining stable temperatures even during peak processing demands. This proactive approach not only improves server efficiency but also extends the lifespan of critical components by reducing thermal stress.

The impact of throttle body design on server efficiency extends beyond direct cooling effects. By optimizing airflow, it reduces the workload on other cooling components such as fans and heat sinks. This synergistic effect leads to a decrease in overall power consumption, contributing to improved Power Usage Effectiveness (PUE) metrics for data centers.

Furthermore, the enhanced thermal management facilitated by advanced throttle body designs allows for higher density server configurations. This increased density translates to more computing power per unit of space, maximizing the utilization of valuable data center real estate while maintaining optimal operating conditions.

In server environments, the throttle body acts as a crucial component in regulating airflow through the chassis. By controlling the volume and velocity of air passing over heat-generating components, it plays a vital role in maintaining optimal operating temperatures. This precise control allows for more efficient cooling, reducing the overall energy consumption of cooling systems.

The design of the throttle body significantly influences its effectiveness in thermal management. Advanced throttle bodies incorporate variable aperture mechanisms, allowing for dynamic adjustment of airflow based on real-time temperature data. This adaptive approach ensures that cooling is provided where and when it is needed most, preventing localized hot spots and reducing the risk of thermal throttling.

Material selection for throttle bodies also contributes to their thermal management capabilities. High-performance materials with superior heat dissipation properties can help absorb and redistribute heat, further enhancing cooling efficiency. Additionally, the surface finish and internal geometry of the throttle body can be optimized to reduce turbulence and improve airflow characteristics.

Integration of smart sensors and control systems with the throttle body design enables predictive thermal management. By anticipating temperature fluctuations based on workload patterns, the system can proactively adjust airflow, maintaining stable temperatures even during peak processing demands. This proactive approach not only improves server efficiency but also extends the lifespan of critical components by reducing thermal stress.

The impact of throttle body design on server efficiency extends beyond direct cooling effects. By optimizing airflow, it reduces the workload on other cooling components such as fans and heat sinks. This synergistic effect leads to a decrease in overall power consumption, contributing to improved Power Usage Effectiveness (PUE) metrics for data centers.

Furthermore, the enhanced thermal management facilitated by advanced throttle body designs allows for higher density server configurations. This increased density translates to more computing power per unit of space, maximizing the utilization of valuable data center real estate while maintaining optimal operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!