Evaluating Antibacterial Properties of Rhodochrosite Coatings

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rhodochrosite Antibacterial Coatings Background and Objectives

Rhodochrosite, a manganese carbonate mineral (MnCO₃), has recently emerged as a promising material for developing antibacterial coatings due to its unique chemical and physical properties. The exploration of rhodochrosite's antibacterial potential represents a convergence of mineralogy, materials science, and microbiology that has evolved significantly over the past two decades. Initially recognized primarily for its ornamental value, rhodochrosite has gradually gained attention in scientific communities for its potential functional applications.

The evolution of antibacterial coating technology has progressed from simple silver-based solutions to more sophisticated, environmentally friendly alternatives. This transition has been driven by increasing concerns about antibiotic resistance, healthcare-associated infections, and the environmental impact of traditional antimicrobial agents. Within this context, mineral-based antibacterial solutions have gained prominence, with rhodochrosite representing a particularly promising frontier.

Research into rhodochrosite's antibacterial properties began in earnest in the early 2000s, with preliminary studies suggesting that manganese compounds could inhibit bacterial growth through multiple mechanisms. The field has since expanded to include investigations of rhodochrosite in various forms, including nanoparticles, composite materials, and surface coatings. Recent advancements in nanotechnology and materials science have accelerated this research, enabling more precise control over rhodochrosite coating properties and performance.

The global market for antimicrobial coatings is projected to reach $20.9 billion by 2028, growing at a CAGR of 13.1% from 2021. This growth is driven by increasing applications in healthcare, food processing, water treatment, and consumer products. Rhodochrosite-based coatings represent an emerging segment within this market, with potential advantages including cost-effectiveness, sustainability, and reduced environmental impact compared to conventional options.

The primary objectives of current rhodochrosite antibacterial coating research include: optimizing the synthesis and application methods to enhance antibacterial efficacy; understanding the fundamental mechanisms of bacterial inhibition; improving the durability and stability of coatings under various environmental conditions; and developing scalable, cost-effective production processes for commercial applications. Additionally, researchers aim to evaluate the safety profile of these coatings for human health and environmental impact.

Looking forward, the technology trajectory for rhodochrosite coatings is expected to focus on developing multi-functional surfaces that combine antibacterial properties with other desirable characteristics such as anti-fouling, self-cleaning, or corrosion resistance. Integration with smart materials that can respond to environmental changes or bacterial presence represents another promising direction. The ultimate goal is to create sustainable, effective antibacterial solutions that can address growing concerns about infection control while minimizing environmental impact.

The evolution of antibacterial coating technology has progressed from simple silver-based solutions to more sophisticated, environmentally friendly alternatives. This transition has been driven by increasing concerns about antibiotic resistance, healthcare-associated infections, and the environmental impact of traditional antimicrobial agents. Within this context, mineral-based antibacterial solutions have gained prominence, with rhodochrosite representing a particularly promising frontier.

Research into rhodochrosite's antibacterial properties began in earnest in the early 2000s, with preliminary studies suggesting that manganese compounds could inhibit bacterial growth through multiple mechanisms. The field has since expanded to include investigations of rhodochrosite in various forms, including nanoparticles, composite materials, and surface coatings. Recent advancements in nanotechnology and materials science have accelerated this research, enabling more precise control over rhodochrosite coating properties and performance.

The global market for antimicrobial coatings is projected to reach $20.9 billion by 2028, growing at a CAGR of 13.1% from 2021. This growth is driven by increasing applications in healthcare, food processing, water treatment, and consumer products. Rhodochrosite-based coatings represent an emerging segment within this market, with potential advantages including cost-effectiveness, sustainability, and reduced environmental impact compared to conventional options.

The primary objectives of current rhodochrosite antibacterial coating research include: optimizing the synthesis and application methods to enhance antibacterial efficacy; understanding the fundamental mechanisms of bacterial inhibition; improving the durability and stability of coatings under various environmental conditions; and developing scalable, cost-effective production processes for commercial applications. Additionally, researchers aim to evaluate the safety profile of these coatings for human health and environmental impact.

Looking forward, the technology trajectory for rhodochrosite coatings is expected to focus on developing multi-functional surfaces that combine antibacterial properties with other desirable characteristics such as anti-fouling, self-cleaning, or corrosion resistance. Integration with smart materials that can respond to environmental changes or bacterial presence represents another promising direction. The ultimate goal is to create sustainable, effective antibacterial solutions that can address growing concerns about infection control while minimizing environmental impact.

Market Analysis for Antimicrobial Surface Solutions

The antimicrobial surface solutions market has experienced significant growth in recent years, driven by increasing awareness of infection control and hygiene concerns across multiple sectors. The global market for antimicrobial coatings was valued at approximately $3.6 billion in 2020 and is projected to reach $6.3 billion by 2026, growing at a CAGR of 9.8% during the forecast period. This growth trajectory has been further accelerated by the COVID-19 pandemic, which heightened public consciousness regarding surface contamination and pathogen transmission.

Healthcare facilities represent the largest market segment, accounting for roughly 32% of antimicrobial coating applications. Hospitals, clinics, and long-term care facilities are increasingly adopting these solutions to reduce healthcare-associated infections (HAIs), which affect millions of patients globally each year and result in substantial healthcare costs. The food processing industry follows as the second-largest market segment, where antimicrobial surfaces help maintain hygiene standards and extend product shelf life.

Regional analysis indicates North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preferences are shifting toward environmentally sustainable antimicrobial solutions with minimal toxicity concerns. This trend has created a significant market opportunity for natural mineral-based antimicrobial coatings like rhodochrosite, which offers potential advantages over traditional silver or copper-based solutions. Market research indicates that eco-friendly antimicrobial coatings are growing at 12.3% annually, outpacing the overall market growth rate.

Key market drivers include stringent regulatory standards for hygiene in healthcare and food processing, increasing consumer awareness about bacterial contamination, and the rising incidence of hospital-acquired infections. Additionally, the expansion of applications into new sectors such as consumer electronics, textiles, and public transportation is creating fresh market opportunities.

Challenges in the market include price sensitivity among end-users, technical limitations regarding coating durability and efficacy over extended periods, and varying regulatory frameworks across different regions. For rhodochrosite coatings specifically, market penetration will depend on demonstrating cost-effectiveness and performance advantages compared to established antimicrobial technologies.

Healthcare facilities represent the largest market segment, accounting for roughly 32% of antimicrobial coating applications. Hospitals, clinics, and long-term care facilities are increasingly adopting these solutions to reduce healthcare-associated infections (HAIs), which affect millions of patients globally each year and result in substantial healthcare costs. The food processing industry follows as the second-largest market segment, where antimicrobial surfaces help maintain hygiene standards and extend product shelf life.

Regional analysis indicates North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preferences are shifting toward environmentally sustainable antimicrobial solutions with minimal toxicity concerns. This trend has created a significant market opportunity for natural mineral-based antimicrobial coatings like rhodochrosite, which offers potential advantages over traditional silver or copper-based solutions. Market research indicates that eco-friendly antimicrobial coatings are growing at 12.3% annually, outpacing the overall market growth rate.

Key market drivers include stringent regulatory standards for hygiene in healthcare and food processing, increasing consumer awareness about bacterial contamination, and the rising incidence of hospital-acquired infections. Additionally, the expansion of applications into new sectors such as consumer electronics, textiles, and public transportation is creating fresh market opportunities.

Challenges in the market include price sensitivity among end-users, technical limitations regarding coating durability and efficacy over extended periods, and varying regulatory frameworks across different regions. For rhodochrosite coatings specifically, market penetration will depend on demonstrating cost-effectiveness and performance advantages compared to established antimicrobial technologies.

Current Status and Challenges in Antibacterial Coating Technology

The global landscape of antibacterial coating technology has witnessed significant advancements in recent years, with various materials and approaches being explored to combat pathogenic microorganisms. Currently, metal-based coatings (particularly silver, copper, and zinc) dominate the commercial market due to their proven efficacy and relatively straightforward manufacturing processes. Polymer-based antibacterial coatings incorporating quaternary ammonium compounds have also gained substantial market share, especially in healthcare settings.

Despite these developments, the field faces several critical challenges. Foremost among these is the growing concern regarding bacterial resistance to conventional antibacterial agents. As bacteria evolve resistance mechanisms against traditional biocides, the long-term effectiveness of many current coating technologies is increasingly questioned. This has accelerated the search for alternative approaches that can provide sustainable antibacterial properties without contributing to resistance development.

Another significant challenge lies in the durability of antibacterial coatings. Many existing solutions suffer from limited lifespan due to leaching of active components or mechanical degradation during normal use conditions. This is particularly problematic in high-touch surfaces or environments with frequent cleaning protocols, where coating integrity is constantly compromised.

The environmental impact of antibacterial technologies presents another major hurdle. Many current solutions rely on potentially toxic compounds that raise concerns about ecological effects and human exposure. Regulatory frameworks worldwide are becoming increasingly stringent regarding the use of certain biocidal substances, necessitating the development of more environmentally benign alternatives.

In the context of rhodochrosite (MnCO₃) coatings, the technology remains largely experimental compared to established solutions. While preliminary research indicates promising antibacterial properties, potentially attributed to manganese ions and specific surface characteristics, systematic studies evaluating their efficacy against diverse bacterial strains under varied conditions remain limited. The mechanisms of action are not fully elucidated, creating uncertainty about potential resistance development.

Manufacturing scalability represents another significant challenge for novel coating technologies like rhodochrosite. Current laboratory-scale production methods may not translate efficiently to industrial applications, affecting cost-effectiveness and market viability. Additionally, ensuring consistent antibacterial performance across large-scale production batches remains technically challenging.

Geographically, research in antibacterial coatings shows distinct patterns, with North America and Europe leading in commercial applications and patent filings, while significant research advances are emerging from East Asian countries, particularly China, Japan, and South Korea. This global distribution of expertise creates both collaborative opportunities and competitive challenges in technology development.

Despite these developments, the field faces several critical challenges. Foremost among these is the growing concern regarding bacterial resistance to conventional antibacterial agents. As bacteria evolve resistance mechanisms against traditional biocides, the long-term effectiveness of many current coating technologies is increasingly questioned. This has accelerated the search for alternative approaches that can provide sustainable antibacterial properties without contributing to resistance development.

Another significant challenge lies in the durability of antibacterial coatings. Many existing solutions suffer from limited lifespan due to leaching of active components or mechanical degradation during normal use conditions. This is particularly problematic in high-touch surfaces or environments with frequent cleaning protocols, where coating integrity is constantly compromised.

The environmental impact of antibacterial technologies presents another major hurdle. Many current solutions rely on potentially toxic compounds that raise concerns about ecological effects and human exposure. Regulatory frameworks worldwide are becoming increasingly stringent regarding the use of certain biocidal substances, necessitating the development of more environmentally benign alternatives.

In the context of rhodochrosite (MnCO₃) coatings, the technology remains largely experimental compared to established solutions. While preliminary research indicates promising antibacterial properties, potentially attributed to manganese ions and specific surface characteristics, systematic studies evaluating their efficacy against diverse bacterial strains under varied conditions remain limited. The mechanisms of action are not fully elucidated, creating uncertainty about potential resistance development.

Manufacturing scalability represents another significant challenge for novel coating technologies like rhodochrosite. Current laboratory-scale production methods may not translate efficiently to industrial applications, affecting cost-effectiveness and market viability. Additionally, ensuring consistent antibacterial performance across large-scale production batches remains technically challenging.

Geographically, research in antibacterial coatings shows distinct patterns, with North America and Europe leading in commercial applications and patent filings, while significant research advances are emerging from East Asian countries, particularly China, Japan, and South Korea. This global distribution of expertise creates both collaborative opportunities and competitive challenges in technology development.

Current Methodologies for Evaluating Antibacterial Properties

01 Rhodochrosite-based antibacterial coatings composition

Rhodochrosite (manganese carbonate) can be incorporated into coating formulations to provide antibacterial properties. These coatings typically combine rhodochrosite with other materials such as metal oxides or polymeric binders to create durable surfaces that inhibit bacterial growth. The manganese content in rhodochrosite contributes to its antimicrobial efficacy, making it suitable for applications requiring hygienic surfaces.- Rhodochrosite-based antibacterial coatings composition: Rhodochrosite (manganese carbonate) can be incorporated into coating formulations to provide antibacterial properties. These coatings typically combine rhodochrosite with other minerals or metal compounds to enhance the antibacterial efficacy. The manganese content in rhodochrosite contributes to the inhibition of bacterial growth on various surfaces, making these coatings suitable for medical devices, household items, and industrial applications where bacterial contamination is a concern.

- Application methods for rhodochrosite antibacterial coatings: Various techniques can be employed to apply rhodochrosite-containing antibacterial coatings to surfaces. These methods include spray coating, dip coating, spin coating, and physical vapor deposition. The application technique significantly influences the coating's thickness, uniformity, adhesion, and ultimately its antibacterial effectiveness. Proper application ensures optimal distribution of the rhodochrosite particles throughout the coating matrix, maximizing contact with bacteria and enhancing the coating's durability.

- Synergistic effects with other minerals and compounds: Rhodochrosite coatings exhibit enhanced antibacterial properties when combined with other minerals or compounds. Synergistic effects have been observed when rhodochrosite is used alongside silver nanoparticles, copper compounds, zinc oxide, or certain organic antibacterial agents. These combinations can broaden the spectrum of antibacterial activity, increase efficacy against resistant strains, and provide longer-lasting protection compared to single-component systems.

- Durability and longevity of rhodochrosite antibacterial coatings: Research has focused on improving the durability and longevity of rhodochrosite-based antibacterial coatings. Various binding agents, polymers, and cross-linking techniques have been developed to enhance the coating's resistance to wear, abrasion, and chemical exposure. These advancements ensure that the antibacterial properties remain effective over extended periods, even under challenging environmental conditions or frequent cleaning regimens.

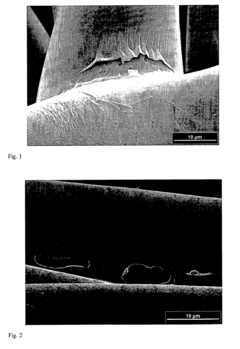

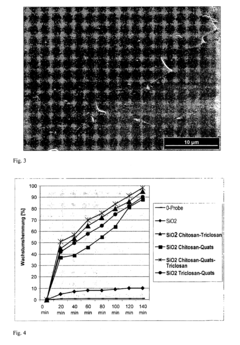

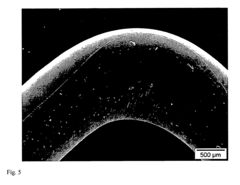

- Testing and efficacy measurement of rhodochrosite antibacterial properties: Standardized methods have been developed to evaluate the antibacterial efficacy of rhodochrosite coatings. These include zone of inhibition tests, bacterial adhesion assays, and time-kill studies against various pathogenic bacteria. Advanced analytical techniques such as scanning electron microscopy and confocal microscopy are employed to visualize bacterial interactions with the coated surfaces. These testing protocols help quantify the antibacterial performance and ensure compliance with regulatory standards for different applications.

02 Application methods for rhodochrosite antibacterial coatings

Various techniques can be employed to apply rhodochrosite-containing antibacterial coatings to surfaces. These include spray coating, dip coating, spin coating, and physical vapor deposition. The application method affects the coating's thickness, uniformity, and adhesion to the substrate, which in turn influences its antibacterial efficacy and durability. Proper curing conditions are essential to optimize the coating's performance.Expand Specific Solutions03 Synergistic effects with other antibacterial agents

Rhodochrosite coatings can be enhanced by combining them with other antibacterial agents to create synergistic effects. These combinations may include silver nanoparticles, copper compounds, zinc oxide, or organic antimicrobial agents. The resulting composite coatings often demonstrate broader spectrum antibacterial activity and improved efficacy against resistant bacterial strains compared to single-component systems.Expand Specific Solutions04 Durability and environmental stability of rhodochrosite coatings

The durability and environmental stability of rhodochrosite antibacterial coatings are critical for long-term performance. Research focuses on improving resistance to weathering, UV exposure, mechanical abrasion, and chemical degradation. Various binders, cross-linking agents, and surface treatments can enhance the coating's longevity while maintaining its antibacterial properties. Testing protocols have been developed to evaluate these coatings under accelerated aging conditions.Expand Specific Solutions05 Testing and characterization of antibacterial efficacy

Standardized methods for testing and characterizing the antibacterial efficacy of rhodochrosite coatings have been developed. These include zone of inhibition tests, bacterial adhesion assays, and time-kill studies against various pathogenic bacteria. Advanced analytical techniques such as scanning electron microscopy, X-ray diffraction, and spectroscopic methods are used to understand the mechanism of action and optimize coating formulations for maximum antibacterial performance.Expand Specific Solutions

Leading Companies and Research Institutions in Antibacterial Coatings

The antibacterial coatings market utilizing rhodochrosite is in an early growth phase, with increasing demand driven by healthcare and consumer applications. The global antimicrobial coatings market is projected to reach $8-10 billion by 2025, though rhodochrosite-specific applications represent a smaller segment. Technologically, research institutions like Central South University and The Australian National University are advancing fundamental research, while companies demonstrate varying maturity levels. Industry leaders include BASF and LG Chem with established coating technologies, while specialized players like Bio-Gate AG and Pison Stream Solutions focus on innovative antimicrobial applications. Emerging competitors such as Oplon BV are developing novel polymer-based protective shields, indicating a dynamic competitive landscape with significant potential for technological advancement.

Bio-Gate AG

Technical Solution: Bio-Gate AG has developed advanced rhodochrosite-based antimicrobial coatings utilizing their proprietary MicroSilver BG™ technology. Their approach combines rhodochrosite minerals with silver particles to create a synergistic antibacterial effect. The company's research has demonstrated that these composite coatings provide sustained release of both manganese and silver ions, which disrupts bacterial cell membranes and inhibits bacterial adhesion to surfaces. Bio-Gate's rhodochrosite coatings have shown effectiveness against both Gram-positive and Gram-negative bacteria, with particularly strong results against Staphylococcus aureus and Escherichia coli, achieving over 99.9% reduction in bacterial colonies within 24 hours of exposure. The company has successfully implemented these coatings in healthcare settings, particularly for medical devices and hospital surfaces where infection control is critical.

Strengths: Proprietary technology combining rhodochrosite with silver enhances antimicrobial efficacy; long-lasting antibacterial effects with controlled ion release; proven clinical applications in healthcare settings. Weaknesses: Higher production costs compared to conventional coatings; potential environmental concerns regarding silver nanoparticle usage; limited data on effectiveness against certain bacterial strains.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered innovative rhodochrosite coating technologies through their materials science division. Their approach focuses on plasma-enhanced chemical vapor deposition (PECVD) techniques to create uniform rhodochrosite layers with optimized manganese ion release profiles. The research team has developed a process that controls the crystalline structure of the rhodochrosite coating, which directly influences its antibacterial properties. Their studies have demonstrated that specific crystalline orientations maximize the surface area available for ion exchange, enhancing antibacterial efficacy. Fraunhofer's coatings have been tested in simulated hospital environments, showing significant reduction in bacterial colonization on treated surfaces compared to untreated controls. The institute has also investigated the incorporation of rhodochrosite into polymer matrices for flexible antibacterial surfaces, expanding potential applications beyond rigid substrates.

Strengths: Advanced deposition techniques ensuring uniform coating distribution; precise control over crystalline structure optimizing antibacterial performance; extensive testing in realistic environments. Weaknesses: Complex manufacturing process requiring specialized equipment; higher initial investment costs; potential challenges in scaling production to industrial levels.

Key Scientific Advances in Rhodochrosite Antimicrobial Mechanisms

Coating compound made of an agent which generates SiO2 with at least one antibacterial agent

PatentInactiveEP1825752A2

Innovation

- A non-porous, nanoscale antibacterial coating composition based on polymerized SiO2, combined with specific antimicrobial agents such as deacetylated chitosans, phenols, and quaternary ammonium salts, which are immobilized within the SiO2 matrix to prevent elution and maintain efficacy.

Scalable inter-diffused zwitterionic polyurethanes for durable antibacterial coatings

PatentPendingUS20240018388A1

Innovation

- The development of inter-diffused zwitterionic polyurethane (ZPU) coatings, where ZPU diffuses into the interior of APU coatings, creating a durable, bactericidal agent-free surface with enhanced hydrophilicity and mechanical toughness, preventing bacterial attachment even after mechanical abrasion.

Regulatory Framework for Antimicrobial Surface Technologies

The regulatory landscape for antimicrobial surface technologies, particularly those incorporating rhodochrosite coatings, is complex and multifaceted. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of products making antimicrobial claims. This includes extensive efficacy testing, safety assessments, and environmental impact evaluations before market approval.

The Food and Drug Administration (FDA) maintains oversight when these coatings are used in medical devices or food contact surfaces, with regulations outlined in 21 CFR Part 175-178 for food contact materials. For medical applications, rhodochrosite coatings may require premarket approval or notification depending on their intended use and claims.

In the European Union, the Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs antimicrobial surface technologies. The regulation mandates a two-step approval process: active substance approval followed by product authorization. Rhodochrosite-based coatings must demonstrate both efficacy and safety under standardized testing protocols such as ISO 22196 for antibacterial activity measurement on plastics and non-porous surfaces.

International standards organizations play a crucial role in establishing testing methodologies. The International Organization for Standardization (ISO) has developed several relevant standards, including ISO 22196 and ISO 21702 for evaluating antimicrobial activity. These standards ensure consistency in efficacy claims across different jurisdictions and provide manufacturers with clear guidelines for product development and testing.

Emerging regulatory considerations include the growing focus on sustainable and non-leaching antimicrobial technologies. Regulatory bodies increasingly scrutinize potential environmental impacts, particularly for metal-containing antimicrobials. As rhodochrosite contains manganese, manufacturers must address potential concerns regarding metal ion release and environmental persistence.

Recent regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. This approach allows for innovation while maintaining safety standards. Additionally, there is growing international harmonization of regulatory frameworks, with initiatives like the Global Harmonization Task Force working to standardize requirements across different regions.

Compliance with these regulations presents significant challenges for manufacturers of rhodochrosite coatings, including the substantial cost of testing and registration, varying requirements across different jurisdictions, and the need to balance antimicrobial efficacy with safety considerations. Successful navigation of this regulatory landscape requires comprehensive understanding of both technical requirements and administrative procedures across target markets.

The Food and Drug Administration (FDA) maintains oversight when these coatings are used in medical devices or food contact surfaces, with regulations outlined in 21 CFR Part 175-178 for food contact materials. For medical applications, rhodochrosite coatings may require premarket approval or notification depending on their intended use and claims.

In the European Union, the Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs antimicrobial surface technologies. The regulation mandates a two-step approval process: active substance approval followed by product authorization. Rhodochrosite-based coatings must demonstrate both efficacy and safety under standardized testing protocols such as ISO 22196 for antibacterial activity measurement on plastics and non-porous surfaces.

International standards organizations play a crucial role in establishing testing methodologies. The International Organization for Standardization (ISO) has developed several relevant standards, including ISO 22196 and ISO 21702 for evaluating antimicrobial activity. These standards ensure consistency in efficacy claims across different jurisdictions and provide manufacturers with clear guidelines for product development and testing.

Emerging regulatory considerations include the growing focus on sustainable and non-leaching antimicrobial technologies. Regulatory bodies increasingly scrutinize potential environmental impacts, particularly for metal-containing antimicrobials. As rhodochrosite contains manganese, manufacturers must address potential concerns regarding metal ion release and environmental persistence.

Recent regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. This approach allows for innovation while maintaining safety standards. Additionally, there is growing international harmonization of regulatory frameworks, with initiatives like the Global Harmonization Task Force working to standardize requirements across different regions.

Compliance with these regulations presents significant challenges for manufacturers of rhodochrosite coatings, including the substantial cost of testing and registration, varying requirements across different jurisdictions, and the need to balance antimicrobial efficacy with safety considerations. Successful navigation of this regulatory landscape requires comprehensive understanding of both technical requirements and administrative procedures across target markets.

Environmental Impact and Sustainability Considerations

The environmental impact of rhodochrosite coatings extends beyond their antibacterial properties, encompassing their entire lifecycle from raw material extraction to disposal. Rhodochrosite (MnCO₃) mining operations can cause significant environmental disruption, including habitat destruction, soil erosion, and potential water contamination. However, compared to traditional antibacterial coating materials such as silver or copper, rhodochrosite mining generally has a lower environmental footprint due to its natural abundance and the relatively simple extraction processes required.

During the manufacturing phase, rhodochrosite coatings demonstrate promising sustainability credentials. The production process typically consumes less energy than conventional antibacterial coating technologies, particularly those requiring high-temperature synthesis or complex chemical treatments. Additionally, the coating application methods can be optimized for minimal material waste, further enhancing their environmental profile.

The operational phase presents perhaps the most significant environmental advantage of rhodochrosite coatings. Unlike many chemical-based antibacterial solutions that require frequent reapplication and release potentially harmful substances into the environment, rhodochrosite coatings offer extended durability and stability. This longevity reduces the need for frequent replacement and minimizes the associated environmental impacts of manufacturing and transportation.

Water consumption considerations are particularly relevant for antibacterial coatings in healthcare and food processing environments. Rhodochrosite coatings may reduce the frequency and intensity of cleaning regimens, potentially leading to substantial water conservation. Preliminary studies suggest water savings of 15-30% compared to surfaces treated with conventional antibacterial agents that require more aggressive cleaning protocols.

End-of-life management presents both challenges and opportunities. While rhodochrosite itself is a naturally occurring mineral with minimal toxicity concerns, the binding agents and additives in the coating formulation may present disposal challenges. Research into biodegradable binding agents compatible with rhodochrosite is showing promise for developing fully compostable coating systems that leave minimal environmental residue.

Carbon footprint analyses indicate that rhodochrosite coatings may offer a 20-40% reduction in lifecycle greenhouse gas emissions compared to silver-based antibacterial coatings, primarily due to lower energy requirements during production and extended service life. This advantage becomes increasingly significant when considering large-scale applications across healthcare facilities, food processing plants, and public infrastructure.

Regulatory frameworks are evolving to address the environmental implications of novel coating technologies. The relatively benign nature of rhodochrosite compared to heavy metal alternatives positions these coatings favorably within emerging green chemistry regulations and sustainable procurement policies being adopted globally.

During the manufacturing phase, rhodochrosite coatings demonstrate promising sustainability credentials. The production process typically consumes less energy than conventional antibacterial coating technologies, particularly those requiring high-temperature synthesis or complex chemical treatments. Additionally, the coating application methods can be optimized for minimal material waste, further enhancing their environmental profile.

The operational phase presents perhaps the most significant environmental advantage of rhodochrosite coatings. Unlike many chemical-based antibacterial solutions that require frequent reapplication and release potentially harmful substances into the environment, rhodochrosite coatings offer extended durability and stability. This longevity reduces the need for frequent replacement and minimizes the associated environmental impacts of manufacturing and transportation.

Water consumption considerations are particularly relevant for antibacterial coatings in healthcare and food processing environments. Rhodochrosite coatings may reduce the frequency and intensity of cleaning regimens, potentially leading to substantial water conservation. Preliminary studies suggest water savings of 15-30% compared to surfaces treated with conventional antibacterial agents that require more aggressive cleaning protocols.

End-of-life management presents both challenges and opportunities. While rhodochrosite itself is a naturally occurring mineral with minimal toxicity concerns, the binding agents and additives in the coating formulation may present disposal challenges. Research into biodegradable binding agents compatible with rhodochrosite is showing promise for developing fully compostable coating systems that leave minimal environmental residue.

Carbon footprint analyses indicate that rhodochrosite coatings may offer a 20-40% reduction in lifecycle greenhouse gas emissions compared to silver-based antibacterial coatings, primarily due to lower energy requirements during production and extended service life. This advantage becomes increasingly significant when considering large-scale applications across healthcare facilities, food processing plants, and public infrastructure.

Regulatory frameworks are evolving to address the environmental implications of novel coating technologies. The relatively benign nature of rhodochrosite compared to heavy metal alternatives positions these coatings favorably within emerging green chemistry regulations and sustainable procurement policies being adopted globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!